Kohler Command 17.5 Parts Diagram Overview

In the world of small machinery, a clear comprehension of the various elements that make up an engine is crucial. Every piece plays a vital role in ensuring optimal performance and reliability. By examining these components, users can enhance their maintenance skills and troubleshoot issues more effectively.

This guide aims to provide a detailed overview of the essential elements found within a specific engine model. Each segment will highlight its functionality, contributing to a deeper understanding of how everything works together.

Furthermore, recognizing these parts not only aids in repairs but also assists in making informed decisions when purchasing replacements. Diving into the intricacies of engine design reveals the ultimate synergy of mechanics at play, fostering an appreciation for the craftsmanship involved.

Overview of Kohler Command 17.5 Engine

This section provides a comprehensive look at a small engine renowned for its reliability and efficiency. Designed for various applications, this power unit is favored by many for its robust performance and durability. With an emphasis on functionality, it features a well-engineered design that supports a wide range of equipment, making it a versatile choice in the industry.

The unit is equipped with advanced technologies that enhance fuel efficiency and minimize emissions. Its user-friendly features ensure ease of maintenance and operation, appealing to both professionals and hobbyists alike. Understanding its components and functionality is crucial for maximizing its potential and longevity.

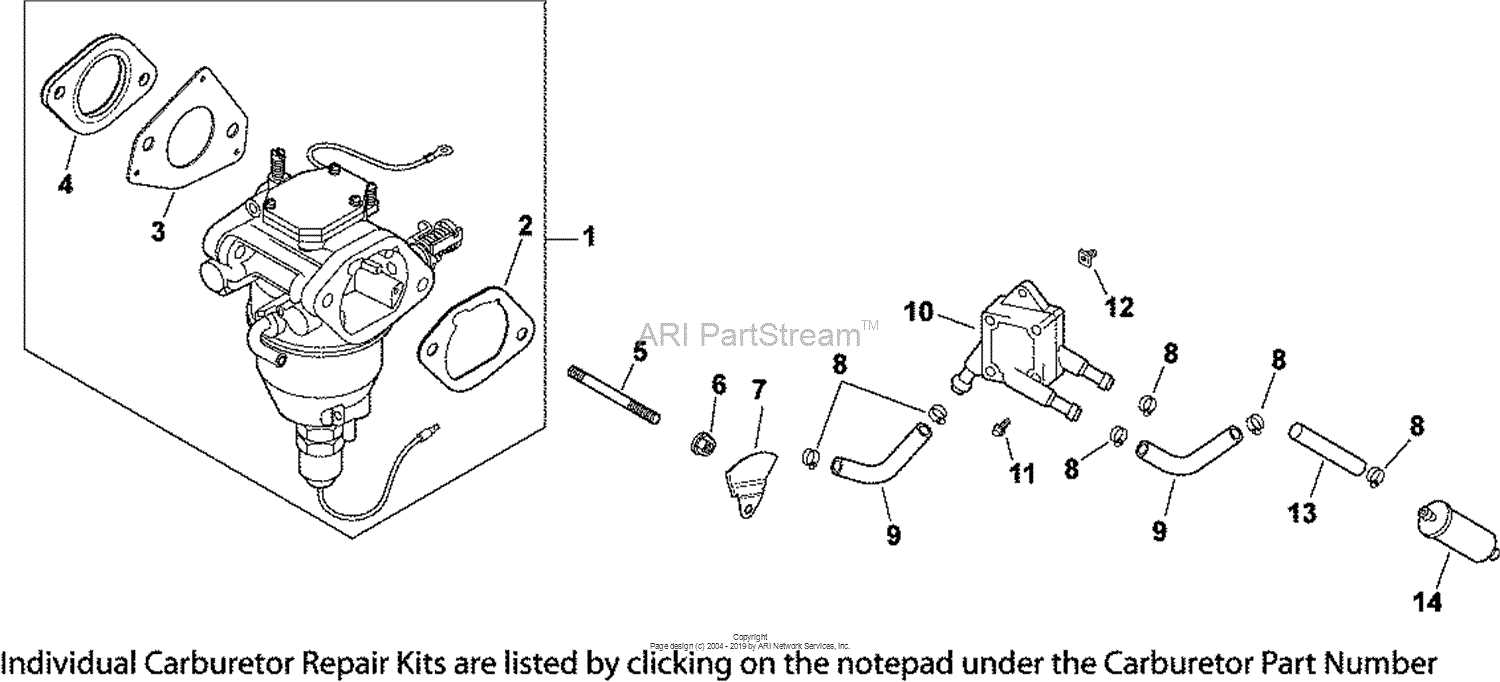

Importance of Parts Diagrams

Visual representations of components play a crucial role in understanding the structure and functionality of machinery. They serve as essential tools for both troubleshooting and maintenance, providing clarity on how various elements interact within a system. By breaking down complex assemblies into understandable segments, these illustrations enable users to identify issues more effectively and streamline repairs.

Moreover, such visual aids enhance communication among technicians, ensuring everyone involved shares a common understanding of the equipment. They facilitate efficient training for new personnel, allowing for quicker adaptation and skill development. Ultimately, the use of these representations leads to improved operational efficiency and reduced downtime.

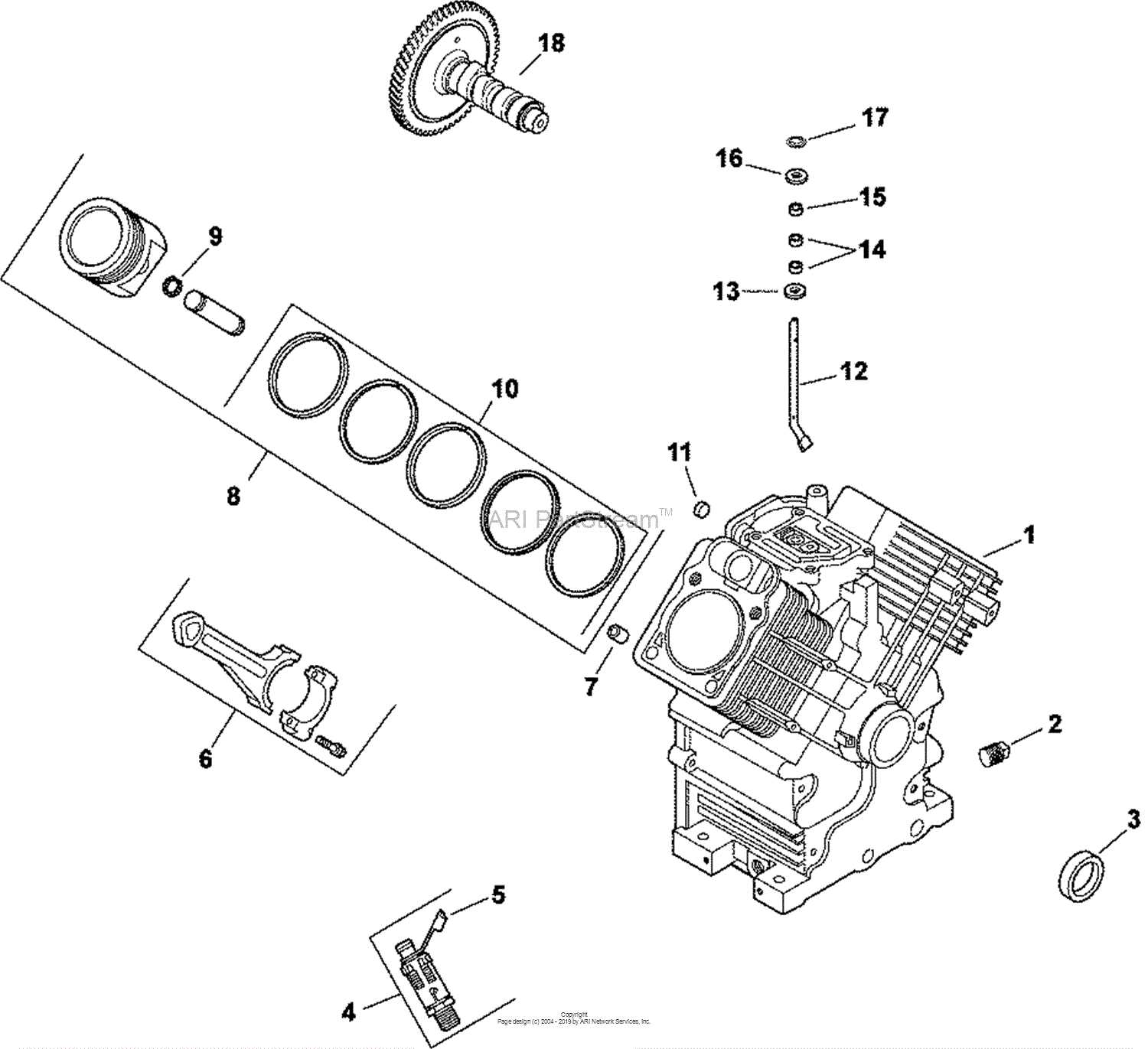

Key Components of the Engine

The functionality and efficiency of a motor rely heavily on its essential elements. Understanding these crucial parts helps in both maintenance and performance enhancement. Each component plays a specific role, contributing to the overall operation of the machine.

Primary Elements

- Crankshaft: Transforms linear motion into rotational motion, providing power to the system.

- Piston: Moves up and down within the cylinder, compressing the air-fuel mixture for combustion.

- Cylinder: Houses the piston and is integral to the combustion process.

- Valves: Control the intake of air and fuel and the exhaust of gases, ensuring efficient operation.

Supporting Systems

- Fuel System: Delivers the necessary fuel to the combustion chamber.

- Ignition System: Initiates combustion by creating a spark at the right moment.

- Cooling System: Maintains optimal operating temperatures to prevent overheating.

- Lubrication System: Reduces friction between moving parts, enhancing performance and longevity.

By familiarizing oneself with these vital components, one can ensure proper upkeep and potentially enhance the efficiency of the engine in various applications.

Understanding Engine Specifications

Engine specifications provide critical insights into the performance and efficiency of a power unit. By comprehending these details, users can make informed decisions regarding maintenance, compatibility, and overall functionality. This section aims to explore essential aspects of engine characteristics, enhancing the user’s knowledge and engagement.

Key Specifications

Several key specifications define the capabilities of an engine. These include horsepower, torque, displacement, and fuel type. Each parameter contributes to the engine’s overall performance and suitability for various applications.

| Specification | Description |

|---|---|

| Horsepower | Indicates the engine’s power output and efficiency. |

| Torque | Reflects the engine’s rotational force, crucial for acceleration. |

| Displacement | Measures the total volume of the engine’s cylinders, influencing power and efficiency. |

| Fuel Type | Specifies the type of fuel required, affecting performance and emissions. |

Importance of Specifications

Understanding these specifications allows users to optimize engine performance, ensuring the right choice for specific tasks. By analyzing each aspect, one can achieve the ultimate balance between power and efficiency, enhancing operational effectiveness.

Common Issues and Solutions

In the realm of small engines, various challenges may arise during operation and maintenance. Understanding these common problems can help users troubleshoot effectively and ensure optimal performance.

One frequent issue is difficulty starting the engine. This can often be attributed to a drained battery, clogged fuel lines, or stale fuel. To resolve this, check the battery charge, inspect the fuel system for blockages, and replace old fuel with fresh gasoline.

Another common concern is overheating. This may occur due to inadequate cooling or a dirty air filter. Users should regularly clean or replace the air filter and ensure that the cooling fins are free of debris to maintain proper airflow.

Additionally, unusual noises or vibrations can indicate mechanical problems. Inspecting for loose components or damaged parts is crucial. Tightening bolts and replacing worn elements can often rectify these issues.

Finally, inconsistent power output may stem from fuel quality or carburetor malfunctions. Using high-quality fuel and cleaning or adjusting the carburetor can help restore stable performance.

Maintenance Tips for Longevity

To ensure optimal performance and extend the lifespan of your equipment, regular upkeep is essential. Implementing a consistent maintenance routine can prevent potential issues and enhance overall efficiency.

1. Regular Inspection: Frequently examine components for wear and tear. Identifying problems early can save time and money.

2. Cleanliness: Keep all parts free from dirt and debris. This simple step helps maintain functionality and reduces the risk of malfunctions.

3. Fluid Checks: Regularly monitor oil and fuel levels. Proper lubrication minimizes friction and enhances engine performance.

4. Follow the Manual: Adhere to the manufacturer’s guidelines for maintenance intervals. This ensures you’re performing necessary tasks at the right times.

5. Seasonal Preparation: Before changing seasons, conduct thorough checks. Addressing any issues ahead of time can prevent more significant problems later.

By integrating these practices into your routine, you can significantly enhance the durability and reliability of your machinery.

Finding Genuine Replacement Parts

When it comes to maintaining and repairing outdoor power equipment, sourcing authentic components is essential for ensuring optimal performance and longevity. The right parts can make all the difference in keeping machinery running smoothly and efficiently. Utilizing original components not only helps maintain quality but also provides peace of mind for the operator.

Why Choose Authentic Components?

Opting for genuine components ensures compatibility and reliability, reducing the risk of malfunctions that can arise from inferior substitutes. These parts are specifically designed to meet the manufacturer’s specifications, which can lead to better overall performance and efficiency. Furthermore, authentic items often come with warranties, providing additional security for the buyer.

Where to Find Genuine Parts

To locate reliable components, start by visiting authorized retailers or the manufacturer’s official website. Online marketplaces can also offer genuine options, but it’s crucial to verify the seller’s reputation and read customer reviews. Additionally, reaching out to local repair shops or service centers can provide guidance and access to quality parts.

How to Read a Parts Diagram

Understanding a visual representation of components is essential for effective maintenance and repairs. These illustrations provide a clear overview of each element’s placement and function, enabling users to identify what they need quickly.

Start by Familiarizing Yourself with the layout. Typically, these visuals are divided into sections, each corresponding to specific groups of elements. Take note of any labels or numbers that indicate part names or identification codes.

Next, Pay Attention to the legend or key, which explains the symbols used. This can include shapes, lines, or shading that denote various types of components or connections. Understanding this can prevent confusion when locating parts.

Lastly, Reference the Index if available. An index can guide you to specific sections or components, helping you delve deeper into the assembly without wasting time. By mastering these techniques, you’ll enhance your ability to interpret these vital illustrations efficiently.

Tools Needed for Repairs

Having the right instruments at your disposal is crucial for efficient maintenance and repairs. A well-equipped toolbox not only streamlines the process but also ensures that tasks are completed accurately and safely. Below is a comprehensive list of essential tools that can aid in various repair projects.

Essential Hand Tools

- Wrenches: A variety of sizes, including adjustable and socket types.

- Screwdrivers: Flathead and Phillips types in multiple sizes.

- Pliers: Needle-nose and standard pliers for gripping and bending.

- Hammer: A standard claw hammer for driving nails and minor adjustments.

- Measuring Tape: For accurate measurements during repairs.

Power Tools

- Drill: A cordless drill for drilling holes and driving screws.

- Impact Wrench: For loosening and tightening bolts quickly.

- Saw: A hand or power saw for cutting materials as needed.

- Grinder: For smoothing out rough edges and surfaces.

- Sandpaper: Various grits for finishing touches.

Equipping yourself with these tools will significantly enhance your ability to tackle repair projects effectively. Regular maintenance not only prolongs the life of equipment but also ensures optimal performance.

Comparing Aftermarket vs. OEM Parts

When it comes to maintenance and repairs, the choice between different component sources can significantly impact performance and longevity. Understanding the distinctions between various options helps in making informed decisions that suit both budget and reliability needs.

Original equipment manufacturer (OEM) components are produced by the same company that manufactured the original items used in the equipment. In contrast, aftermarket components are made by third-party companies and can vary widely in quality and performance.

- Quality Assurance: OEM parts typically adhere to strict manufacturing standards, ensuring consistency and reliability.

- Cost: Aftermarket options often come at a lower price point, which can be appealing for budget-conscious consumers.

- Availability: Aftermarket parts may be more readily available, offering a wider selection for specific needs.

- Compatibility: OEM items are guaranteed to fit seamlessly with the original system, while aftermarket components may require adjustments.

Ultimately, the choice between these two types hinges on the specific requirements of the user, including performance expectations and financial considerations. Careful evaluation of each option can lead to a more satisfying outcome in the long run.

Repairing Common Component Failures

Understanding how to address frequent issues with engine parts is essential for maintaining optimal performance. Identifying the signs of malfunction and knowing the right steps for repair can save time and resources.

Here are some common components that often require attention:

- Fuel System: Clogs in the fuel filter or issues with the fuel pump can lead to inadequate performance.

- Ignition System: Worn spark plugs or faulty ignition coils can cause starting problems.

- Cooling System: Leaks in hoses or a malfunctioning radiator can lead to overheating.

- Oil System: Low oil levels or a dirty oil filter may cause engine wear.

To effectively tackle these issues, follow these general steps:

- Identify the symptoms of the failure.

- Refer to a repair manual for detailed instructions.

- Gather necessary tools and replacement parts.

- Carefully execute the repair process, ensuring all connections are secure.

- Test the system after repairs to confirm functionality.

Regular maintenance and prompt repairs are the ultimate keys to prolonging the life of your machinery.