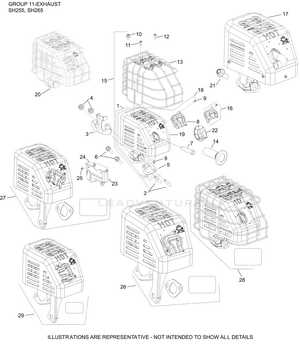

Kohler SH265 Parts Diagram for Easy Reference

Exploring the intricate arrangements of engine components is essential for anyone involved in maintenance or repair tasks. A clear visual representation helps enthusiasts and professionals alike grasp the relationships and functions of various elements within the machinery. This understanding not only streamlines the repair process but also enhances overall performance and longevity.

Having access to a detailed schematic allows individuals to easily identify parts, facilitating efficient troubleshooting. With a well-organized guide, users can delve into the specifics of each segment, ensuring that every component is in optimal condition. This knowledge serves as the ultimate tool in achieving effective repairs and replacements.

Furthermore, recognizing the role of each piece in the system contributes to informed decision-making when it comes to upgrades or modifications. A comprehensive overview empowers users to enhance their engines, paving the way for improved functionality and reliability. With such insights, anyone can navigate the complexities of their machinery with confidence.

Kohler SH265 Overview

This section provides a comprehensive examination of a specific engine model known for its reliability and efficiency in various applications. Understanding its components and functionality is essential for effective maintenance and operation.

Engine Features

The engine is designed with advanced technology to deliver optimal performance. Key characteristics include durability, fuel efficiency, and ease of use, making it suitable for a wide range of tasks.

Specifications

| Feature | Detail |

|---|---|

| Displacement | 265cc |

| Power Output | 7.5 HP |

| Fuel Type | Gasoline |

| Cooling System | Air-Cooled |

Importance of Parts Diagrams

Understanding the intricacies of machinery and equipment is essential for effective maintenance and repair. Visual representations that detail the various components and their relationships play a crucial role in simplifying complex systems. They provide a clear roadmap, enabling technicians and enthusiasts alike to navigate the assembly and disassembly processes with confidence.

Enhanced Clarity

Such visual aids eliminate ambiguity by illustrating how different elements fit together. This clarity is particularly beneficial when troubleshooting issues or replacing worn-out components, as it allows for quick identification of necessary items and their correct placement.

Efficient Repair Processes

With well-structured visuals, repair times can be significantly reduced. Technicians can quickly reference the layout, ensuring they have all required elements before starting the work. This leads to fewer interruptions and a more streamlined approach to fixing or upgrading machinery.

| Benefit | Description |

|---|---|

| Improved Understanding | Clarifies component relationships and functions. |

| Time Savings | Reduces downtime by streamlining repair processes. |

| Effective Troubleshooting | Aids in quickly identifying and resolving issues. |

| Increased Confidence | Provides reassurance during complex repairs. |

Common Applications of SH265 Engine

The engine in question is widely utilized across various sectors due to its reliability and efficiency. Its robust design makes it suitable for numerous tasks, ranging from outdoor power equipment to industrial applications.

Landscaping Equipment

This engine is often found in lawn mowers, hedge trimmers, and other gardening tools, providing the necessary power for effective performance in landscaping and maintenance tasks.

Construction Machinery

Its durability also makes it a popular choice for compact equipment such as generators and small excavators, ensuring consistent operation in demanding environments.

Key Components of Kohler SH265

Understanding the essential elements of this engine is crucial for maintenance and performance optimization. Each part plays a significant role in ensuring efficient operation and longevity.

Main Elements

- Crankshaft

- Piston Assembly

- Cylinder Head

- Fuel System

- Ignition System

Supporting Features

- Cooling System

- Lubrication System

- Air Filter

- Exhaust System

Familiarity with these components can help in troubleshooting and enhancing the overall efficiency of the engine.

How to Interpret the Diagram

Understanding a visual representation of mechanical components is crucial for effective maintenance and repair. It provides insight into how various elements interact and assists in identifying each part’s function within the system.

Key Elements to Note

- Labels: Each item is usually marked with specific identifiers that clarify its name or function.

- Connections: Arrows or lines indicate how parts are linked, showing the flow of operation.

- Grouping: Related components may be clustered, which helps in understanding assemblies.

Steps for Analysis

- Start by familiarizing yourself with the overall layout.

- Identify and read the labels to understand each component’s role.

- Trace the connections to visualize how the elements interact.

- Consult accompanying documentation for additional context and specifications.

Maintenance Tips for SH265 Parts

Proper upkeep of machinery components is essential for optimal performance and longevity. Regular maintenance not only enhances efficiency but also prevents unexpected breakdowns. This section outlines crucial practices that can extend the life of your engine components.

Regular Inspections

Frequent examinations of essential components can help identify wear and tear early. Look for signs of damage, such as cracks or corrosion, and address them promptly. Establish a schedule for routine checks to ensure no issues go unnoticed.

Cleaning and Lubrication

Keep all moving parts clean to prevent dirt and debris buildup. Regularly lubricate components according to the manufacturer’s guidelines. Using the appropriate oil not only reduces friction but also helps in dissipating heat, thereby improving overall performance.

Remember: Consistent maintenance practices will lead to a more reliable and efficient machine. Make these tips a part of your routine to ensure long-lasting functionality.

Identifying Genuine Kohler Parts

Understanding the importance of authentic components is essential for maintaining the longevity and performance of any machinery. Counterfeit items may seem appealing due to their lower cost, but they can lead to significant issues over time. Knowing how to distinguish original from imitation is crucial for any user.

Key Features of Authentic Components

Genuine items typically exhibit superior craftsmanship and attention to detail. Look for high-quality materials and precise manufacturing that meet industry standards. Authentic components often carry specific markings or logos, which serve as a guarantee of their legitimacy.

Where to Purchase

Acquiring items from reputable dealers is vital. Authorized retailers provide a guarantee of authenticity and offer support for installation and maintenance. Always verify the seller’s credentials and check for customer reviews to ensure a trustworthy purchase.

Common Issues and Solutions

Understanding the frequent challenges encountered with small engines can significantly enhance their performance and longevity. By addressing these common problems effectively, users can ensure smoother operation and reduced downtime.

Problem: Engine Won’t Start

This issue often arises from fuel blockage or spark plug failure. Solution: Check the fuel supply and replace the spark plug if necessary.

Problem: Overheating

Engines may overheat due to insufficient lubrication or debris in the cooling system. Solution: Ensure proper oil levels and clean any obstructions in the cooling fins.

Problem: Uneven Performance

Irregular operation can result from dirty filters or carburetor issues. Solution: Clean or replace air and fuel filters and inspect the carburetor for blockages.

Problem: Excessive Vibration

Vibration can be caused by unbalanced components or loose fittings. Solution: Tighten any loose parts and check for damaged or worn-out components.

Replacing Components: Step-by-Step Guide

Maintaining machinery often requires the careful replacement of various elements to ensure optimal performance. This process not only extends the life of the equipment but also enhances its efficiency. This guide will walk you through the necessary steps to effectively replace key components, making your task more manageable and straightforward.

Before starting, gather all required tools and replacement parts. Familiarize yourself with the specific components you plan to change, as well as any safety precautions needed. Having everything at hand will streamline the process and minimize disruptions.

Begin by disconnecting any power sources to prevent accidents. Once the equipment is safely powered down, remove any covers or panels that obstruct access to the parts you need to replace. Take care to keep track of screws and small components during this step.

Next, identify the components that require replacement. Inspect them for wear or damage and compare them with your new parts to ensure compatibility. Carefully remove the faulty elements, noting their orientation and attachment methods for proper reinstallation.

Install the new components in the reverse order of removal. Make sure they are securely fastened and aligned correctly to avoid future issues. After installation, double-check all connections and fittings to ensure everything is in place.

Finally, reassemble any covers or panels you previously removed. Once the equipment is fully reassembled, reconnect the power source and conduct a test run to confirm that everything functions as expected. Regular maintenance, including timely replacements, will help keep your machinery running smoothly.

Tools Needed for Repairs

Effective maintenance and restoration tasks require a well-selected set of instruments. Having the right equipment not only streamlines the process but also enhances safety and efficiency. Familiarity with essential tools can make troubleshooting significantly easier and help ensure that repairs are carried out correctly.

Basic Hand Tools

Standard hand tools such as wrenches, screwdrivers, and pliers are fundamental for most repair tasks. These instruments allow for adjustments, disassembly, and assembly of components, making them indispensable for any repair endeavor.

Specialized Equipment

In addition to basic tools, certain specialized equipment may be necessary depending on the complexity of the job. Items like torque wrenches, multimeters, and diagnostic testers provide precision and help in identifying specific issues, ensuring that repairs meet the highest standards.

Where to Find Replacement Parts

Locating suitable components for your equipment can significantly enhance its performance and longevity. Understanding where to source these items is crucial for maintaining functionality and efficiency.

Several avenues exist for acquiring necessary items:

| Source | Description |

|---|---|

| Authorized Dealers | Official retailers often provide high-quality components with manufacturer warranties. |

| Online Marketplaces | Websites offer a wide selection, often at competitive prices, enabling easy comparisons. |

| Local Hardware Stores | Convenient for quick purchases; staff can assist in finding specific items. |

| Salvage Yards | Great for finding used components at lower prices, but quality may vary. |

Benefits of Regular Maintenance

Consistent upkeep of machinery plays a crucial role in ensuring optimal performance and longevity. By adhering to a routine maintenance schedule, users can significantly enhance the efficiency of their equipment and reduce the likelihood of unexpected failures.

One of the primary advantages of regular servicing is the early detection of potential issues. Identifying problems before they escalate can save time and costs associated with major repairs. Furthermore, maintaining equipment in good working condition often results in improved fuel efficiency, which can lead to substantial savings over time.

Additionally, a well-maintained machine operates more reliably, ensuring that tasks are completed without interruption. This reliability is essential for businesses that depend on consistent operation for productivity and profitability. Lastly, regular maintenance contributes to safety, as it helps prevent accidents caused by equipment malfunction, thereby protecting both operators and bystanders.