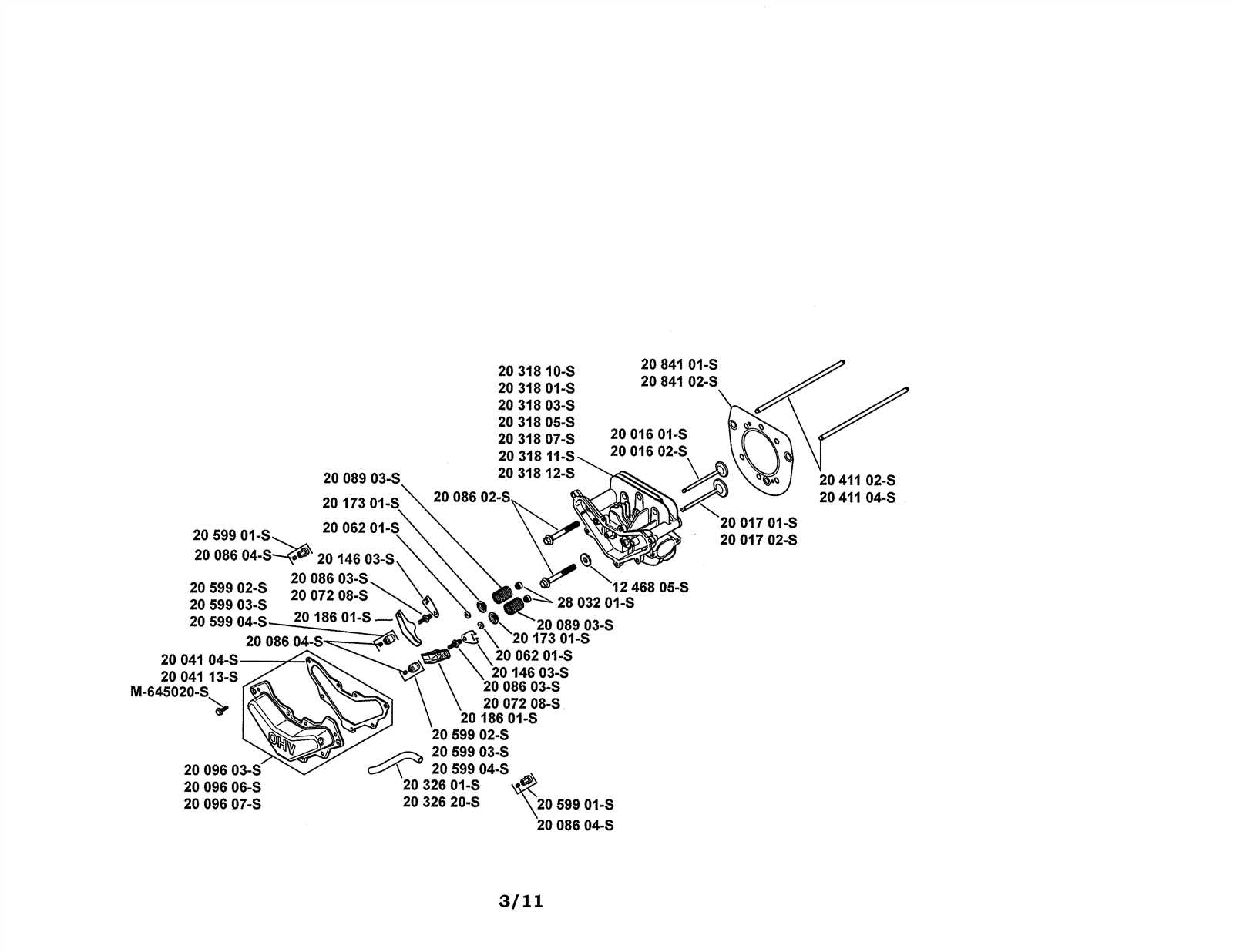

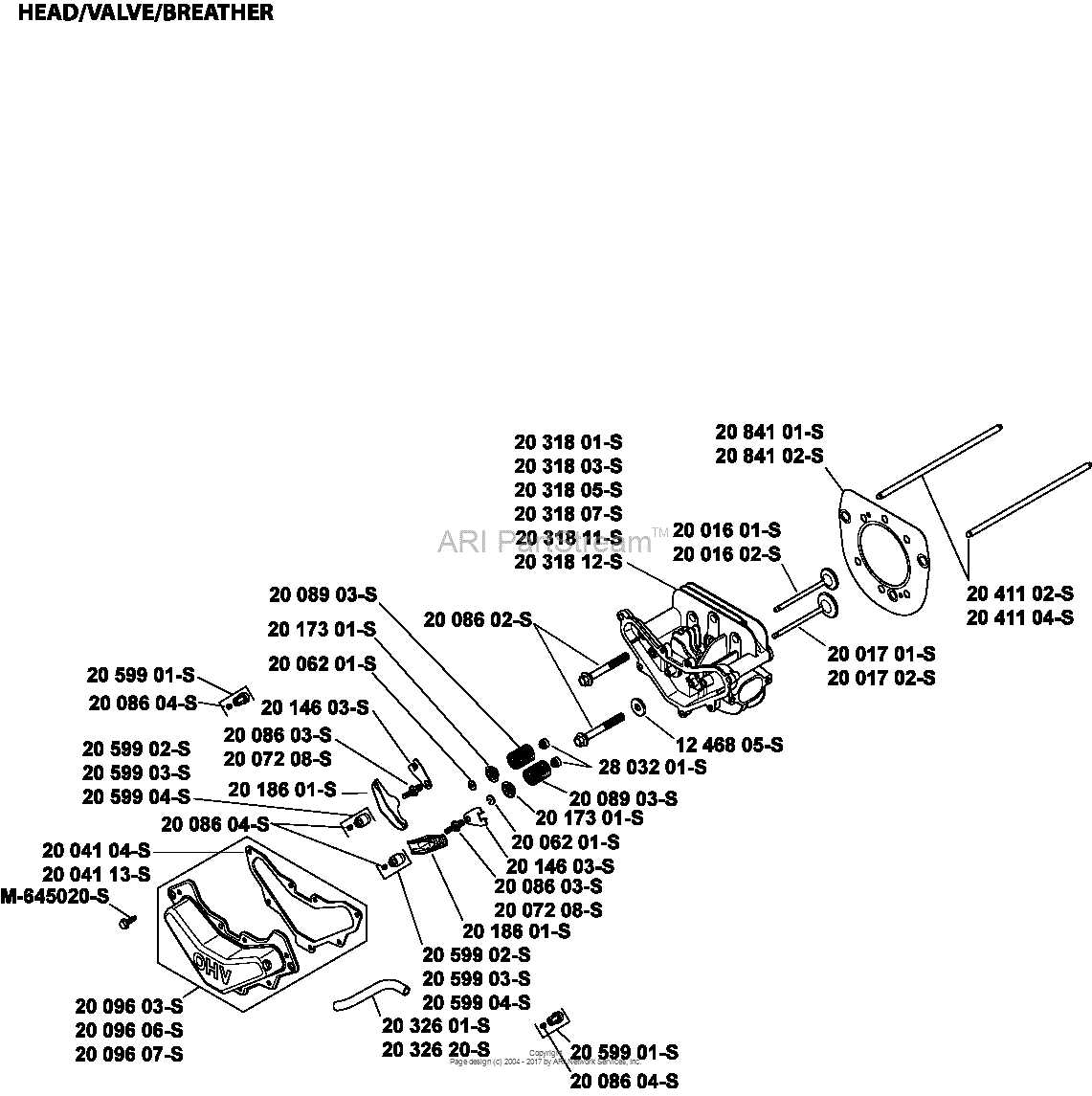

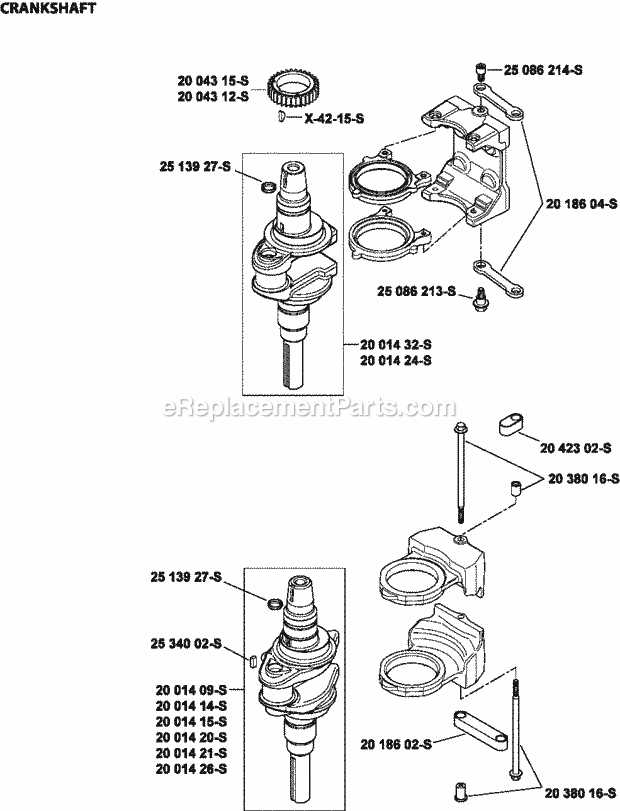

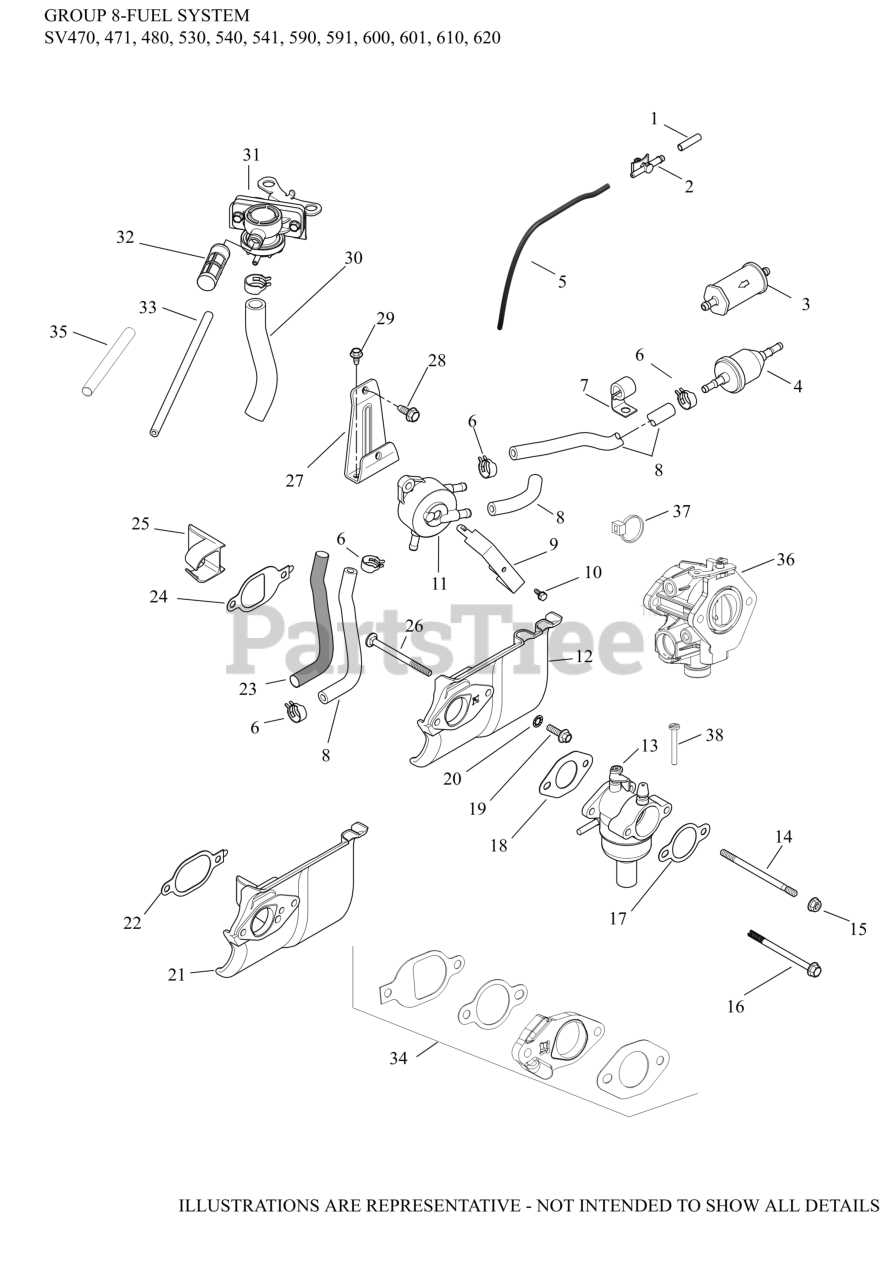

Kohler SV600 Parts Diagram for Easy Reference

When maintaining and repairing machinery, having a clear visual reference of the components is essential. This knowledge not only aids in identifying individual parts but also enhances the efficiency of any maintenance task. A detailed representation can guide enthusiasts and professionals alike through the intricate workings of their engines.

By exploring these layouts, one can gain insight into the functionality and arrangement of various elements within the engine. This understanding is crucial for diagnosing issues and ensuring optimal performance. Comprehensive illustrations serve as the ultimate resource for anyone looking to delve into the mechanics of their equipment.

Whether you are a seasoned mechanic or a novice, familiarity with the structure of your machine can make a significant difference. These guides empower users to approach repairs with confidence and precision, ultimately prolonging the lifespan of their machinery.

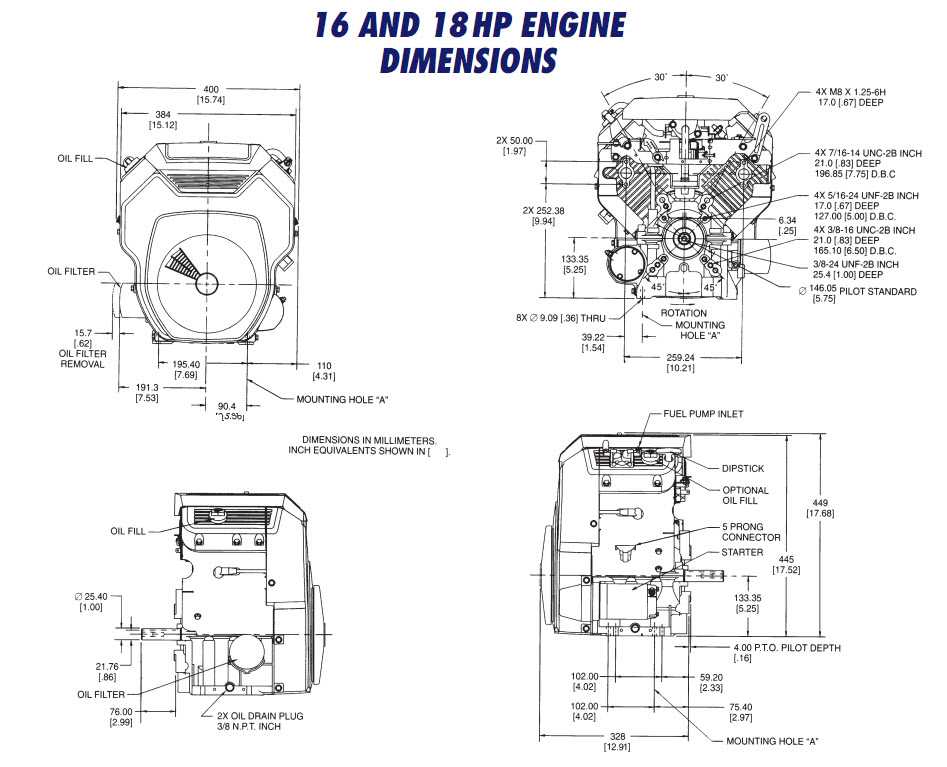

Kohler SV600 Overview

This section provides an insight into a well-regarded engine model known for its reliability and performance in various applications. With a robust design, it caters to diverse machinery needs, ensuring efficient operation in demanding environments.

Key Features

- Powerful engine performance

- Durable construction for extended lifespan

- Efficient fuel consumption

- Easy maintenance and serviceability

Applications

- Lawn and garden equipment

- Construction machinery

- Commercial landscaping tools

- Various outdoor power equipment

This engine’s versatility and strength make it a popular choice among professionals and enthusiasts alike, contributing to its reputation as a reliable power source.

Understanding Engine Components

Engines are complex machines composed of various elements, each playing a critical role in their overall function. By examining these components, one can gain insight into how power is generated and transferred to facilitate movement. Understanding these parts is essential for effective maintenance and troubleshooting.

| Component | Function |

|---|---|

| Cylinder | Holds the piston, where combustion occurs. |

| Piston | Moves up and down to create power from combustion. |

| Crankshaft | Converts linear motion of the piston into rotational motion. |

| Camshaft | Controls the opening and closing of intake and exhaust valves. |

| Fuel Injector | Delivers fuel into the combustion chamber. |

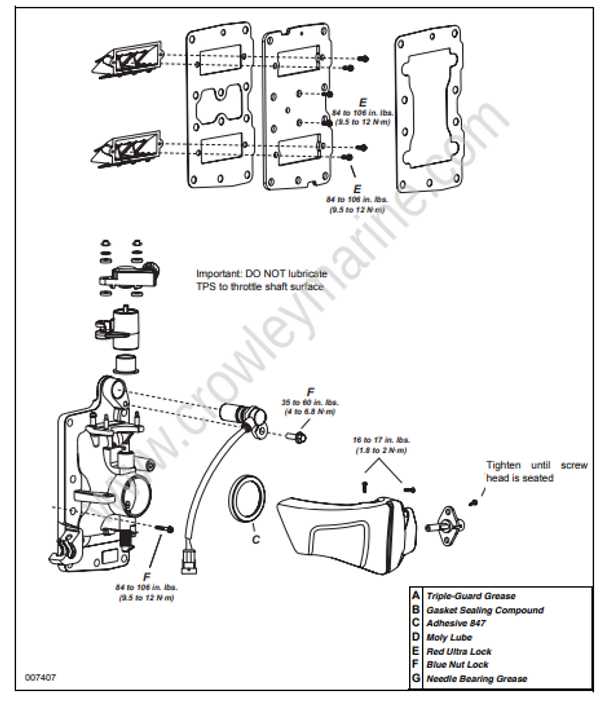

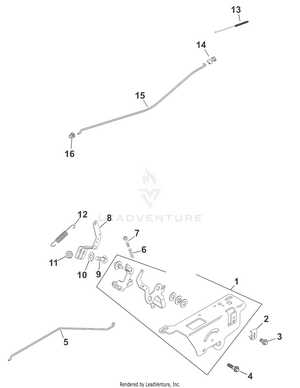

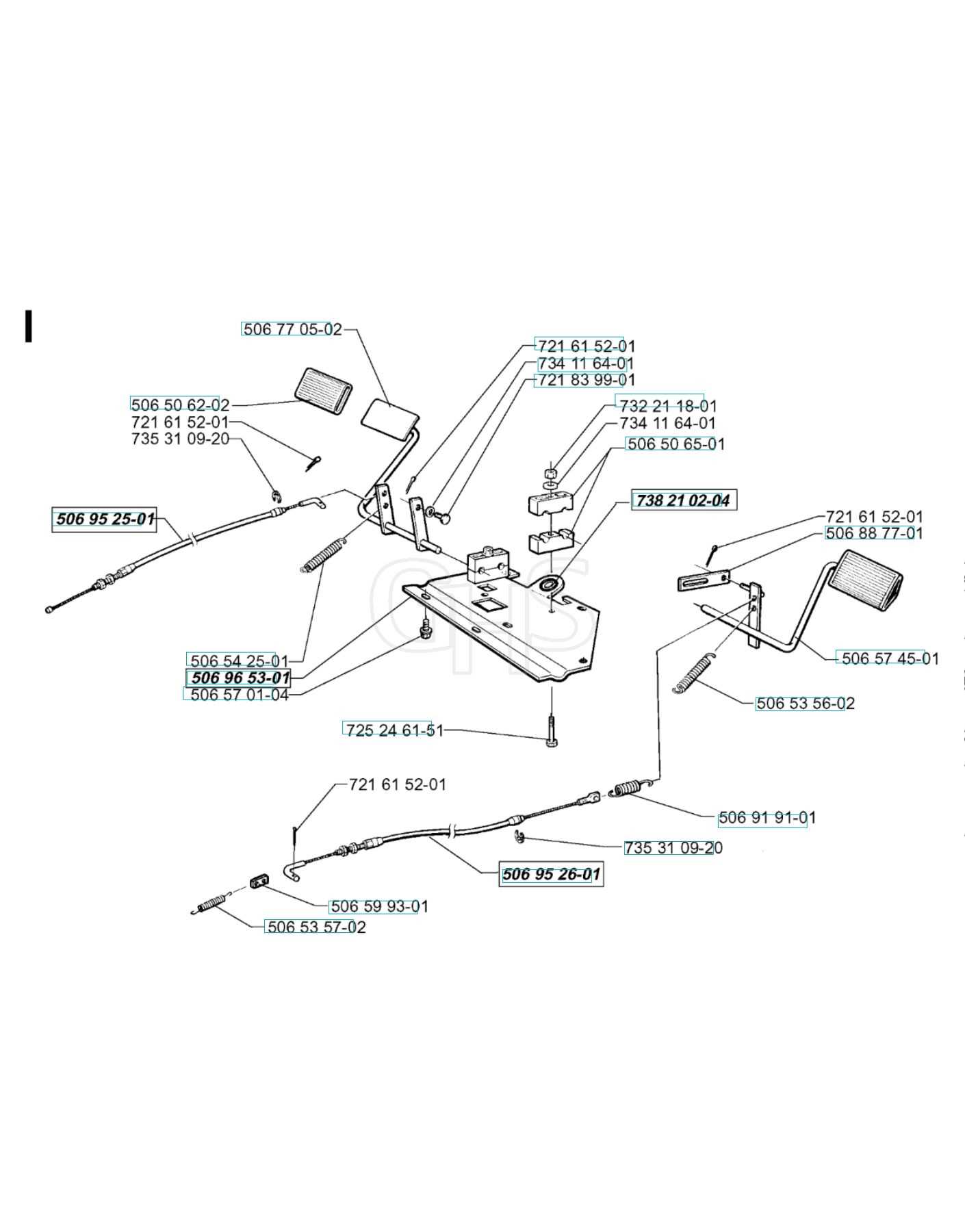

Importance of Parts Diagrams

Understanding the layout and components of machinery is essential for effective maintenance and repair. Visual representations of each element provide clarity, ensuring that users can identify and manage every necessary component with confidence.

Enhanced Troubleshooting

By utilizing these visual aids, individuals can quickly locate issues within the system. This streamlined approach not only saves time but also minimizes the risk of overlooking critical elements during the assessment process.

Efficient Replacement Process

When it comes to replacing components, having a clear illustration significantly reduces errors. Knowing exactly what to look for ensures that the correct items are sourced and installed, leading to optimal performance and longevity.

Common Issues with SV600 Engines

Engines of this type can experience a variety of problems that may affect their performance and longevity. Understanding these issues is crucial for effective maintenance and repair.

- Fuel delivery problems: Clogged filters or damaged lines can restrict flow.

- Overheating: Insufficient cooling can lead to significant engine damage.

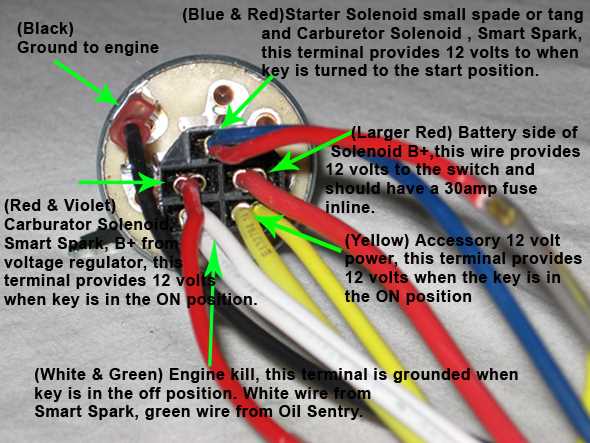

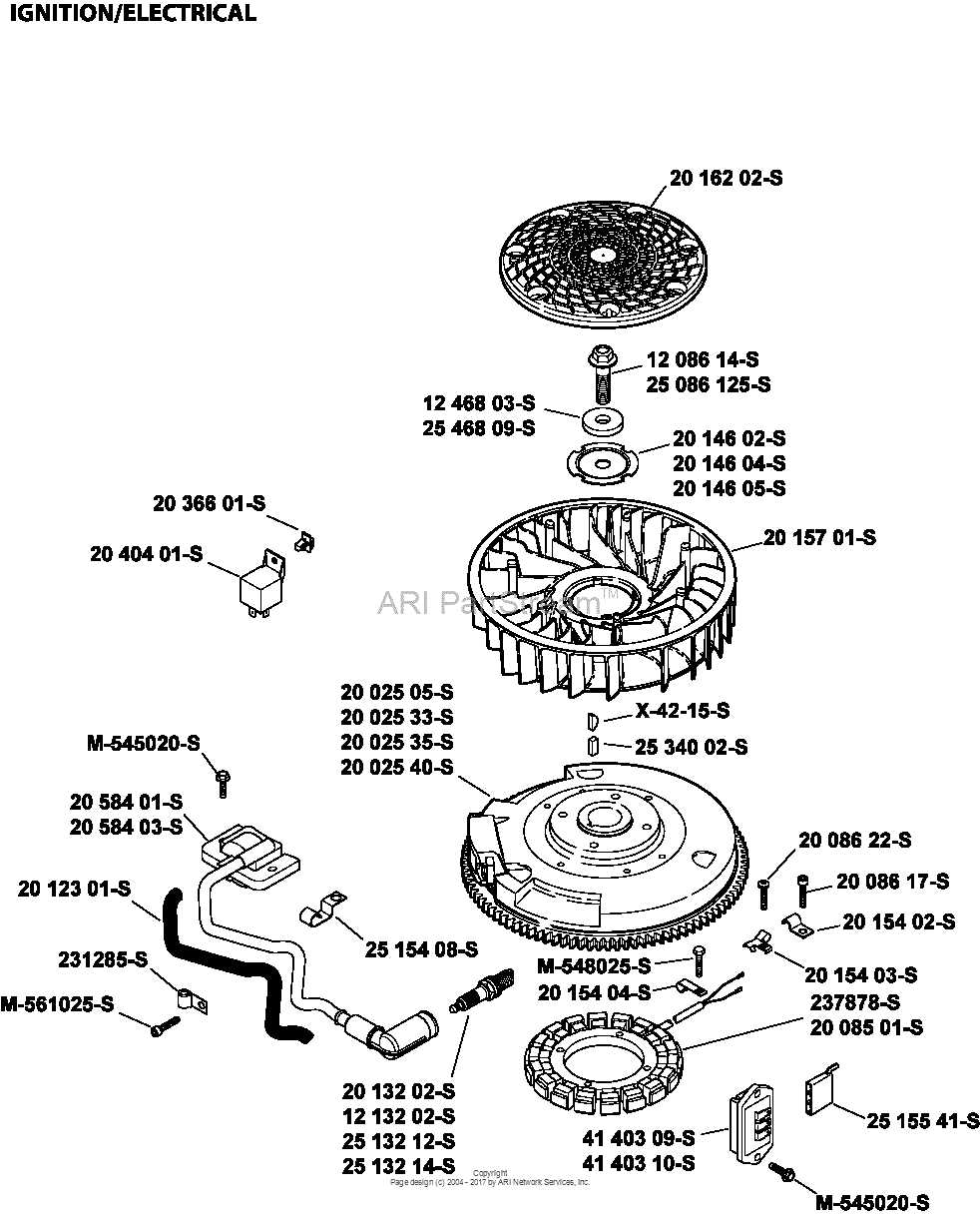

- Electrical failures: Faulty wiring or defective components may cause ignition issues.

- Oil leaks: Deteriorated gaskets or seals can result in loss of lubrication.

- Starting difficulties: Weak batteries or worn starters can hinder engine ignition.

Regular maintenance and timely diagnostics can help prevent these common issues and ensure optimal performance.

Where to Find Diagrams

Locating detailed schematics for machinery components can be essential for maintenance and repairs. These resources provide invaluable visual guidance, helping users understand the assembly and functionality of various parts. Fortunately, there are several reliable sources where one can access these illustrations effectively.

Online Resources

The internet hosts a wealth of platforms dedicated to technical information. Manufacturer websites often offer downloadable content, including comprehensive visuals. Additionally, forums and communities focused on equipment maintenance can be goldmines for shared diagrams and troubleshooting advice.

Printed Manuals

For those who prefer tangible resources, printed manuals remain a practical option. Many retailers provide physical copies of maintenance guides upon purchase of equipment. These documents typically contain not only schematics but also valuable instructions that enhance understanding and facilitate repairs.

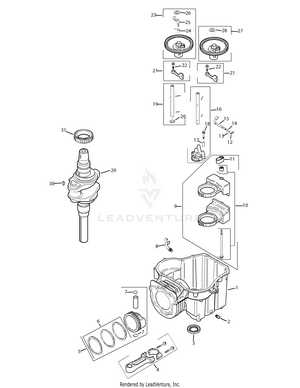

Key Components of the SV600

Understanding the essential elements of this engine model is crucial for effective maintenance and operation. Each component plays a vital role in ensuring optimal performance and longevity.

- Engine Block: The foundation that houses all the internal mechanisms.

- Piston Assembly: Integral for converting combustion energy into mechanical work.

- Crankshaft: Transforms the linear motion of the pistons into rotational energy.

- Valvetrain: Manages air and fuel intake and exhaust processes.

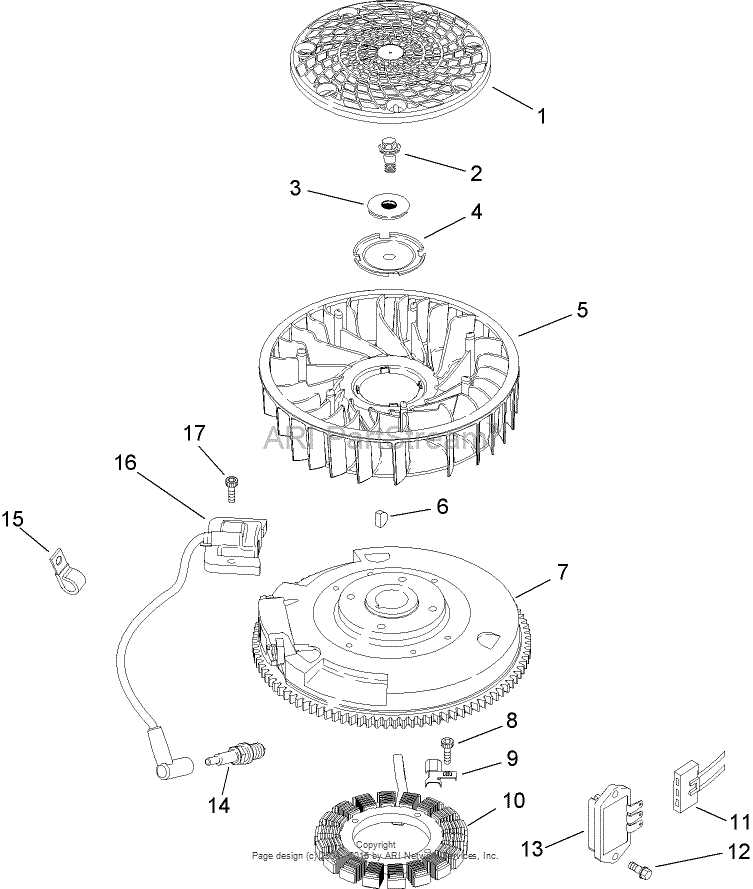

- Ignition System: Responsible for initiating the combustion process.

Each of these parts contributes to the engine’s overall functionality and efficiency, making knowledge of them essential for users seeking to enhance their operational experience.

Maintaining Your Kohler Engine

Proper upkeep of your power unit is essential for optimal performance and longevity. Regular maintenance not only ensures smooth operation but also helps prevent costly repairs. By following a consistent maintenance routine, you can extend the lifespan of your engine and maintain its efficiency.

Regular Inspections

Conducting routine inspections is crucial. Check for any signs of wear, leaks, or damage. Pay attention to the air filter, oil levels, and spark plugs. Keeping these components in good condition will enhance overall functionality and prevent potential breakdowns.

Routine Cleaning and Lubrication

Cleaning your equipment regularly is vital for preventing dirt buildup and corrosion. Ensure that all moving parts are adequately lubricated to reduce friction and wear. Use appropriate cleaning agents and lubricants as specified in the manufacturer’s guidelines for best results.

Aftermarket vs. OEM Parts

The choice between alternative and original components can significantly impact performance and longevity. Each option presents distinct advantages and drawbacks, making it crucial for users to understand their needs and preferences.

Alternative components often offer cost savings and greater availability, appealing to those seeking budget-friendly solutions. However, variations in quality can affect reliability and performance, potentially leading to unexpected issues down the line.

In contrast, original components are designed specifically for certain applications, ensuring compatibility and reliability. While they may come at a higher price, the assurance of performance and durability can outweigh the initial investment for many users.

Ultimately, the decision hinges on individual priorities, whether that be cost, quality, or peace of mind. Evaluating both options can lead to informed choices that best suit specific requirements.

Tools for Engine Repairs

Effective engine maintenance requires a variety of instruments designed to address specific tasks. Having the right tools on hand not only streamlines the repair process but also enhances precision and safety. Understanding the essential equipment is crucial for anyone looking to perform engine service efficiently.

Essential Tools

- Socket Set: A versatile range of sizes for removing and tightening bolts.

- Wrenches: Adjustable and fixed types for different fasteners.

- Screwdrivers: Both flathead and Phillips for various screws.

- Torque Wrench: Ensures proper tension on bolts and nuts.

- Pliers: Useful for gripping, twisting, and cutting wires.

Specialized Equipment

- Compression Tester: Measures engine cylinder pressure.

- Fuel Pressure Gauge: Assesses the fuel system’s health.

- Timing Light: Used to check ignition timing.

- Oil Filter Wrench: Simplifies oil filter removal.

- Engine Hoist: Assists in lifting heavy components safely.

Step-by-Step Repair Guide

Embarking on a repair journey can seem daunting, but with a systematic approach, it becomes manageable and rewarding. This guide provides a clear roadmap to navigate the essential tasks, ensuring that your equipment runs smoothly once again.

1. Gather Tools and Materials: Before starting, collect all necessary tools and components. Having everything at hand will streamline the process and minimize interruptions.

2. Safety First: Always prioritize safety. Disconnect the power source and wear appropriate protective gear to avoid injuries during the repair.

3. Disassemble the Unit: Carefully take apart the equipment, noting the position of each component. This will aid in reassembly and help you identify any damaged parts.

4. Inspect for Damage: Examine each piece for wear or breaks. Make a list of items that need replacement, and consult a reference for specifications.

5. Replace Faulty Parts: Install new components as necessary, ensuring they fit securely. Double-check compatibility to avoid future issues.

6. Reassemble: Rebuild the unit in reverse order of disassembly. Pay attention to details to ensure everything is positioned correctly.

7. Test the Equipment: Once reassembled, reconnect the power and run a test. Monitor for any unusual sounds or functions to confirm everything is working properly.

8. Final Check: Perform a thorough inspection after testing. Ensure all tools are removed and that the work area is clean.

Following these steps will not only help restore your equipment but also enhance your confidence in handling future repairs.

Upgrading Kohler SV600 Performance

Enhancing the performance of small engines can lead to improved efficiency and greater power output. Focusing on key components and modifications can result in a noticeable difference in operation, making the engine more responsive and reliable.

Essential Modifications

- Upgrade the air intake system for better airflow.

- Install a high-performance exhaust to reduce back pressure.

- Consider using a tuned carburetor for optimal fuel delivery.

Regular Maintenance Tips

- Change the oil regularly to keep the engine running smoothly.

- Inspect and replace spark plugs as needed to ensure efficient combustion.

- Clean or replace air filters to maintain airflow quality.

Frequently Asked Questions

This section aims to address common inquiries related to engine components and their functionalities. Understanding these elements is crucial for effective maintenance and troubleshooting.

What should I do if a part is missing?

If you discover that a component is absent, it is essential to check your assembly process or consult a reliable supplier for replacements.

How can I identify specific components?

Referencing a visual guide can significantly assist in pinpointing individual parts and their respective roles within the system.

Are there recommended maintenance practices?

Regular checks, cleaning, and timely replacements can enhance the longevity and performance of your engine.

Where can I find high-quality replacement components?

Opt for authorized dealers or reputable online platforms that specialize in engine supplies to ensure you receive authentic items.