Lennox Furnace Parts Diagram Explained for Better Understanding

Maintaining a reliable heating system is essential for comfort during cold months. A thorough understanding of its various components can enhance both performance and longevity. Each element plays a crucial role, contributing to the overall functionality and efficiency of the unit.

To optimize the performance of your heating apparatus, it’s vital to familiarize yourself with the arrangement and function of its individual sections. Identifying the key components will allow for better troubleshooting and maintenance practices, ensuring that your system operates smoothly when needed most.

In this exploration, we will delve into the various segments of the heating apparatus, outlining their specific roles and interconnections. Gaining insight into these elements is the ultimate way to ensure efficient operation and to extend the life of your equipment.

Lennox Furnace Overview

This section provides an insightful look into a renowned heating appliance known for its reliability and efficiency. Designed to deliver consistent warmth, this system incorporates advanced technology and quality materials to ensure optimal performance throughout the colder months.

The equipment is engineered with several key components that work harmoniously to generate and distribute heat. These elements are crucial for maintaining a comfortable indoor environment, especially in harsh weather conditions. Users appreciate the blend of innovation and tradition that characterizes this brand, making it a popular choice among homeowners.

Maintenance and understanding of the unit’s structure can greatly enhance its longevity and efficiency. Familiarizing oneself with the inner workings not only aids in troubleshooting but also ensures that the appliance runs smoothly, maximizing energy savings and reducing potential issues.

Key Components of Lennox Furnaces

Understanding the essential elements of a heating system is crucial for optimal performance and maintenance. Each component plays a vital role in ensuring efficient operation and longevity.

- Heat Exchanger: Facilitates heat transfer from combustion to the air, enhancing efficiency.

- Blower Motor: Responsible for circulating warm air throughout the space.

- Thermostat: Regulates temperature settings and system operations.

- Gas Valve: Controls the flow of gas to the burner, ensuring safe ignition.

- Burner Assembly: Responsible for igniting the fuel to generate heat.

By delving into each of these components, homeowners can make informed decisions regarding maintenance and repairs, ultimately leading to a more reliable heating solution.

Understanding Furnace Functionality

The operation of heating systems is a complex interplay of various components working harmoniously to create a comfortable environment. Each element plays a specific role, contributing to the overall efficiency and effectiveness of the system. A comprehensive grasp of these functions can lead to better maintenance and optimal performance.

Key Components and Their Roles

- Heat Exchanger: Transfers heat to the air, ensuring efficient warmth distribution.

- Blower Motor: Circulates heated air throughout the space.

- Thermostat: Monitors and regulates temperature settings for comfort.

- Flame Sensor: Detects the presence of a flame for safety and operation.

Operational Process

- The thermostat signals the system to activate.

- The burner ignites, creating heat.

- Heat transfers to the exchanger.

- The blower motor distributes warm air.

- Temperature is maintained until the desired setting is reached.

Importance of Regular Maintenance

Ensuring the longevity and efficiency of heating systems is crucial for any homeowner. Regular upkeep not only enhances performance but also prevents unexpected breakdowns, which can lead to costly repairs and discomfort during harsh weather conditions.

Consistent care plays a vital role in identifying potential issues before they escalate. By routinely inspecting and servicing essential components, you can maintain optimal functionality and safeguard against operational failures.

Moreover, preventative measures can improve energy efficiency, resulting in lower utility bills. A well-maintained system operates more effectively, utilizing less energy to achieve desired temperatures, thereby benefiting both your wallet and the environment.

Lastly, regular attention to your system can enhance safety. Malfunctions may lead to hazardous situations, such as gas leaks or carbon monoxide buildup. Timely maintenance minimizes these risks, providing peace of mind for you and your family.

Common Issues and Troubleshooting

When operating a heating system, several typical problems may arise that can affect performance and efficiency. Identifying these issues early on is crucial for maintaining a comfortable environment and preventing costly repairs. This section outlines common malfunctions and provides guidance for effective resolution.

Frequent Malfunctions

One of the most common challenges is insufficient heat output, which can result from various factors such as dirty filters, blocked vents, or malfunctioning thermostats. Another prevalent issue is unusual noises, including banging or rattling, often indicating loose components or wear. Additionally, the system may frequently cycle on and off, which can be caused by thermostat miscalibration or airflow restrictions.

Troubleshooting Steps

To address these issues, start by inspecting and replacing air filters regularly to ensure optimal airflow. Check vents for obstructions and ensure that the thermostat is set correctly. If noises persist, examine accessible components for looseness and tighten as needed. For systems that cycle excessively, consider having a professional inspect the unit to assess airflow and thermostat functionality. Taking these proactive measures can enhance the longevity and reliability of your heating system.

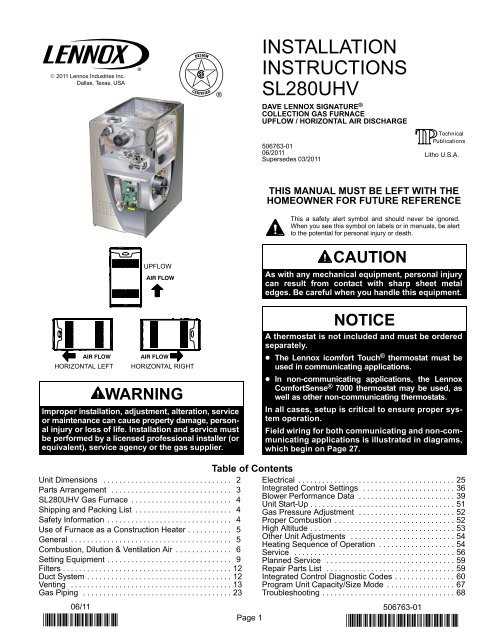

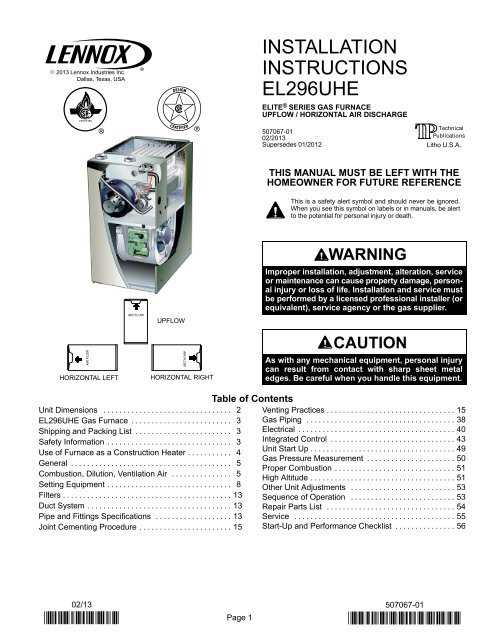

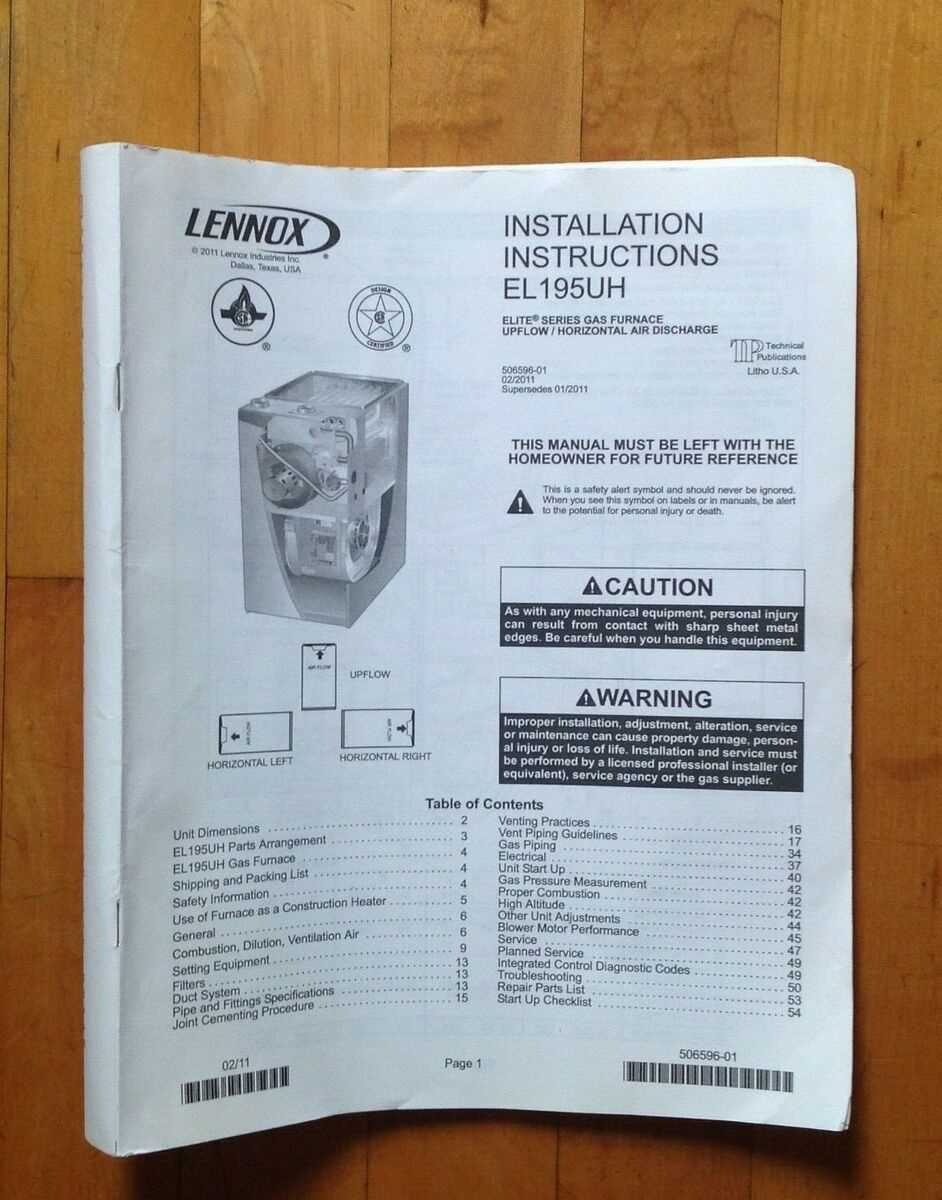

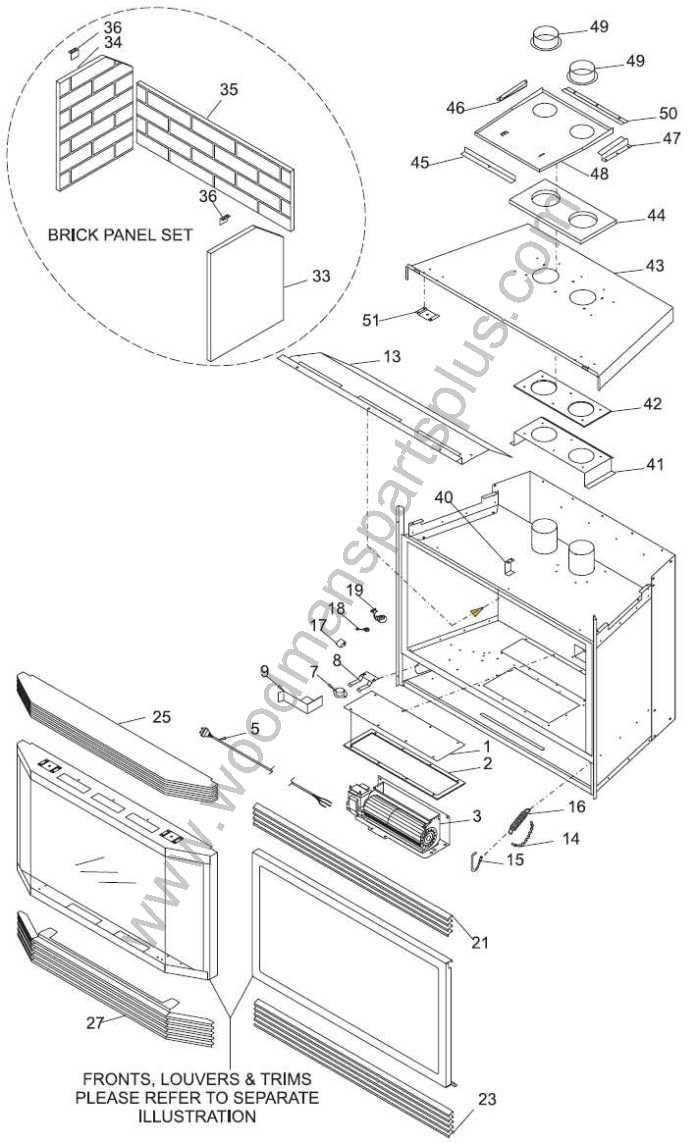

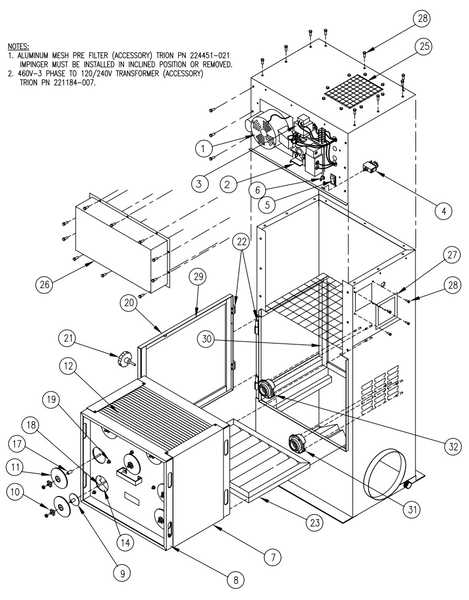

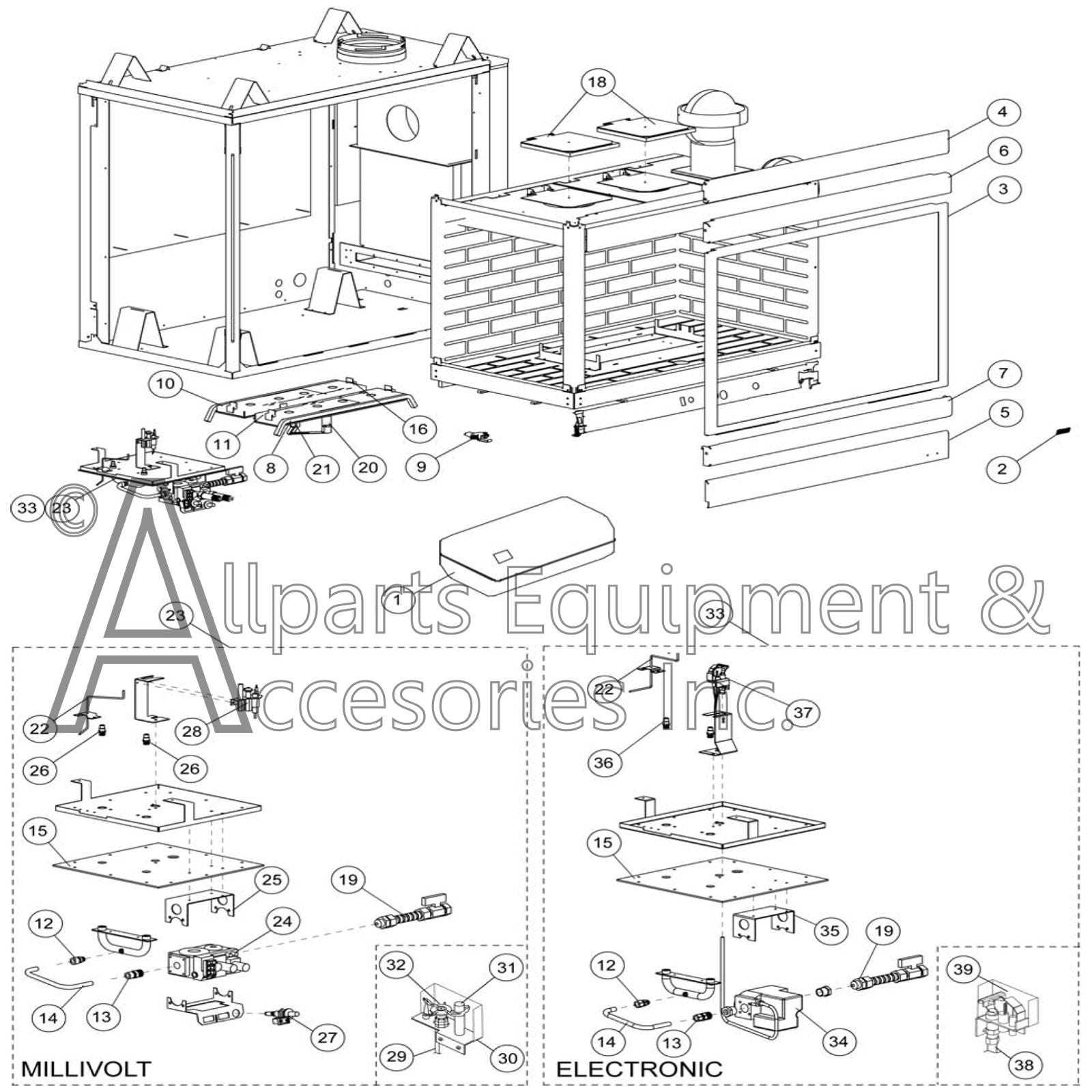

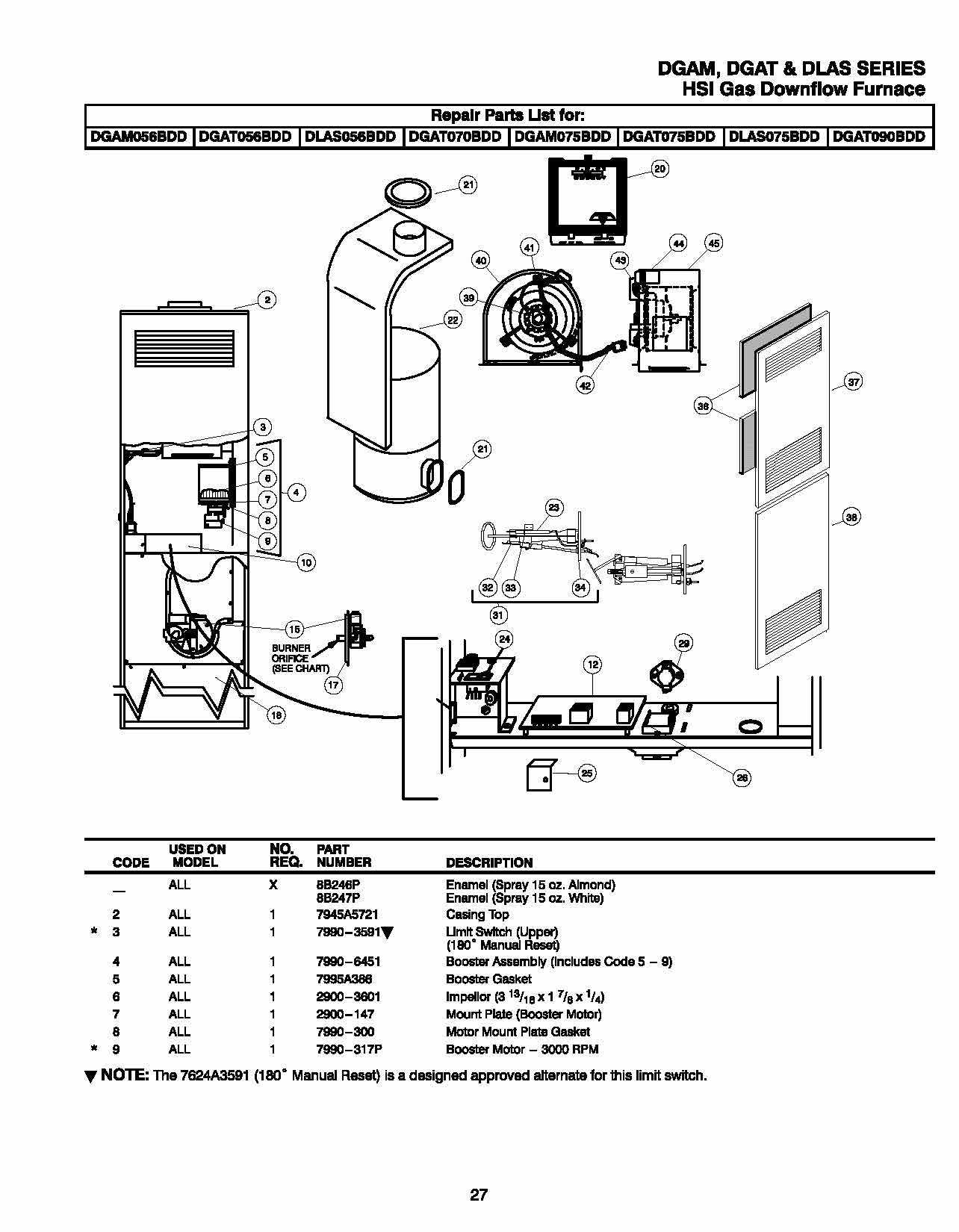

Parts Identification in Diagrams

Understanding the layout of various components is crucial for effective maintenance and troubleshooting. Visual representations serve as valuable tools for identifying individual elements, ensuring that users can easily recognize their functions and placements within a system. Accurate identification leads to more efficient repairs and a deeper comprehension of the overall mechanism.

Importance of Accurate Recognition

Properly identifying each element in a schematic helps in diagnosing issues promptly. Recognizing the specific function of each piece allows for targeted interventions, minimizing downtime and enhancing overall performance. Familiarity with these visual guides empowers users to perform maintenance tasks confidently.

Common Symbols and Annotations

Diagrams often utilize standardized symbols and annotations to represent different components. Learning these conventions aids in quicker comprehension and reduces the likelihood of errors during repairs. By familiarizing oneself with these symbols, technicians can navigate through the visuals with greater ease, ultimately leading to more effective service outcomes.

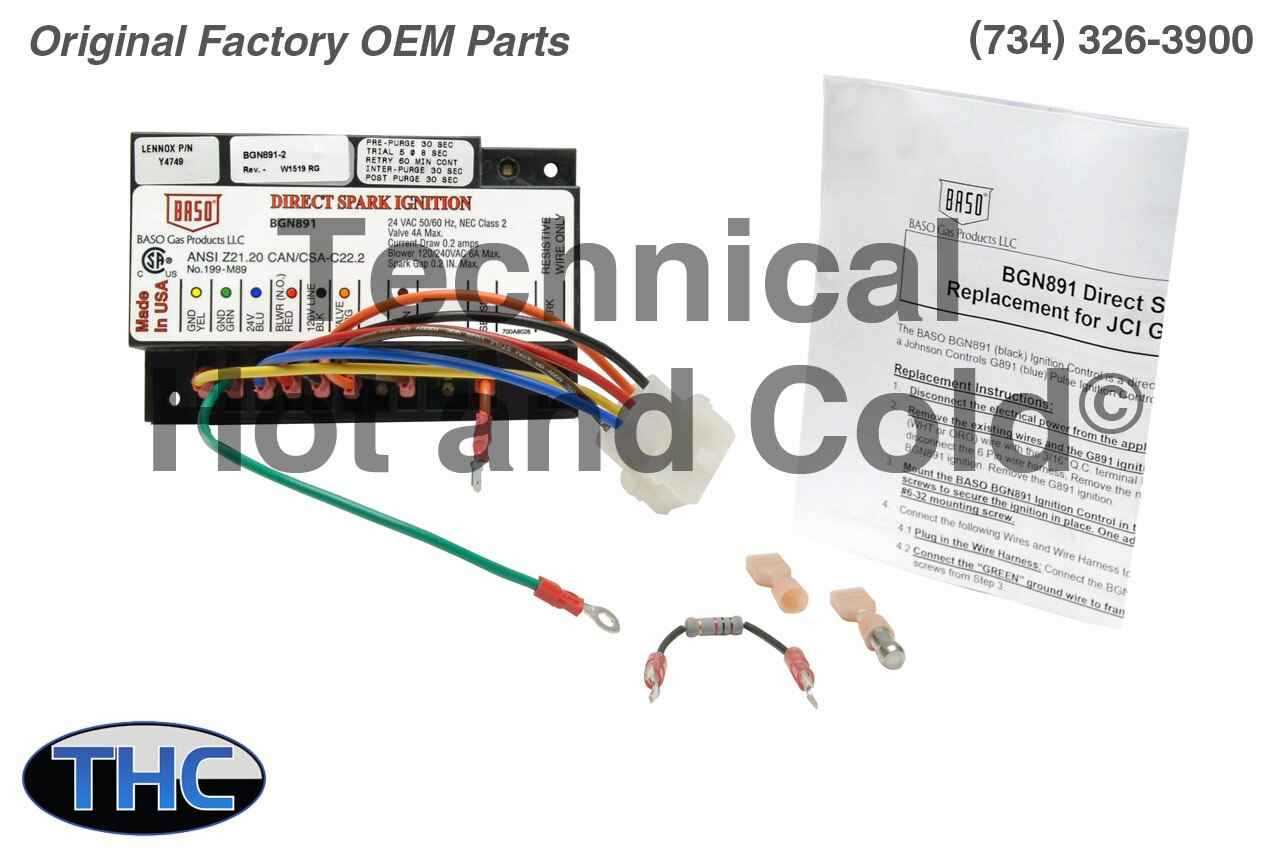

How to Order Replacement Parts

When the need arises for new components to restore the efficiency of your heating system, knowing how to procure them effectively is essential. This guide outlines the steps to ensure you acquire the correct elements promptly and efficiently.

Step-by-Step Process

- Identify the Required Components

- Gather Product Information

- Choose a Reliable Supplier

Tips for Successful Ordering

- Double-check model numbers and specifications to avoid mistakes.

- Consider buying from authorized dealers for quality assurance.

- Keep a record of past purchases for future reference.

- Inquire about warranties or return policies to protect your investment.

DIY Repairs: Safety First

When engaging in home maintenance, prioritizing safety is paramount. Understanding the potential risks and preparing adequately can prevent accidents and ensure a smooth repair process. From electrical hazards to sharp tools, being aware of your surroundings and taking precautionary measures can make all the difference.

Before starting any project, always wear appropriate protective gear such as gloves and goggles. Ensure that the area is well-ventilated and free from any flammable materials. Additionally, disconnecting power sources and shutting off gas supplies will help mitigate any unexpected dangers.

Lastly, familiarizing yourself with the tools you’ll be using and following the manufacturer’s guidelines can further enhance safety. Taking these steps will not only protect you but also contribute to the success of your home improvement endeavors.

When to Call a Professional

Understanding when to seek expert assistance is crucial for maintaining an efficient heating system. Certain issues may seem minor, but they can lead to more significant complications if not addressed promptly. It’s essential to recognize the signs that indicate a need for professional intervention.

Signs of Trouble: If you notice unusual noises, inconsistent temperature control, or strange odors, these could be red flags. Additionally, if the unit fails to operate altogether, it’s time to consult a specialist.

Safety Concerns: If you suspect a gas leak or experience electrical problems, do not hesitate to call an expert. Prioritizing safety is paramount, and professionals have the necessary skills to handle hazardous situations.

In summary, recognizing these indicators can prevent further damage and ensure the ultimate efficiency of your heating system.

Enhancing Efficiency with Upgrades

Improving operational effectiveness is essential for maximizing performance and reducing energy consumption in heating systems. Upgrading certain components can lead to significant benefits, including lower utility bills and enhanced reliability. This section explores key modifications that can optimize functionality and sustainability.

Key Upgrades to Consider

- High-Efficiency Heat Exchangers: Replacing older models with modern, high-efficiency alternatives can significantly enhance heat transfer.

- Smart Thermostats: Implementing advanced control systems allows for better temperature regulation and remote management.

- Variable Speed Blowers: These systems adjust airflow based on demand, leading to quieter operation and energy savings.

- Insulation Improvements: Enhancing insulation around ducts and units helps retain heat and reduces energy waste.

Benefits of Upgrading

- Improved energy efficiency, resulting in reduced operational costs.

- Enhanced system reliability and extended lifespan of equipment.

- Increased comfort levels through more consistent heating.

- Lower environmental impact due to reduced emissions.

Investing in these enhancements not only boosts system performance but also contributes to long-term savings and sustainability goals. Consider evaluating your current setup and exploring these upgrades to achieve optimal results.