Comprehensive Guide to Lightnin Mixer Parts Diagram

The world of industrial mixing encompasses a range of complex machinery designed to blend substances efficiently. Within this realm, comprehending the various elements that contribute to optimal performance is crucial for operators and engineers alike. A clear visualization of these components can enhance maintenance, troubleshooting, and overall operation.

Each segment of the blending apparatus plays a vital role in ensuring uniformity and consistency in the final product. Familiarity with these essential components not only facilitates better understanding but also aids in the implementation of effective strategies for upgrades and repairs. Emphasizing the interconnectedness of these elements reveals how even minor adjustments can lead to significant improvements in productivity.

By exploring a detailed representation of the machinery’s structure, one can appreciate the design and functionality of each individual component. This insight can empower professionals to make informed decisions regarding their equipment, ultimately leading to enhanced efficiency and reduced downtime.

Understanding Lightnin Mixers

This section explores the fundamentals of advanced blending systems that are essential in various industrial applications. These devices facilitate efficient and uniform combinations of materials, ensuring quality and consistency in the final product.

Key Components

- Agitators: Crucial for creating movement within the vessel.

- Seals: Essential for preventing leaks and maintaining integrity.

- Drive Systems: Provide the necessary power for operation.

Applications

- Food and Beverage Production

- Pharmaceutical Manufacturing

- Chemical Processing

Components of Lightnin Mixers

This section explores the essential elements that contribute to the efficient functioning of mixing equipment. Understanding these components helps in optimizing performance and ensuring longevity in various applications.

Main Elements

- Motor

- Impeller

- Drive assembly

- Sealing mechanisms

Supporting Features

- Frame structure

- Control systems

- Mounting options

- Safety devices

Each of these components plays a critical role in achieving the ultimate efficiency and reliability of the equipment in diverse industrial settings.

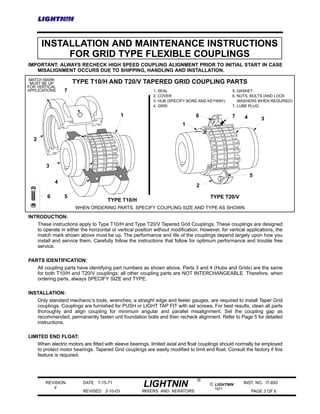

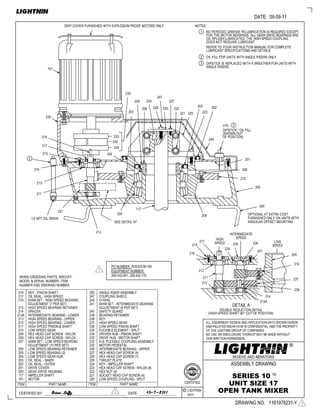

How to Read Mixer Diagrams

Understanding visual representations of equipment components is essential for effective operation and maintenance. These illustrations provide a wealth of information, detailing the arrangement and functionality of various elements. By familiarizing yourself with the symbols and layout, you can enhance your comprehension and ensure optimal performance.

Start by identifying the key symbols used in the illustration. Each symbol typically represents a specific component or function, allowing for quick recognition. Pay attention to the legend or key that accompanies the visual; it often clarifies the meaning of each icon. Additionally, noting the connections between elements can reveal the flow of processes and interactions.

Next, observe the layout carefully. Components are usually organized in a way that reflects their operational sequence or spatial relationship. Understanding this organization can help you troubleshoot issues and make informed decisions regarding maintenance or adjustments.

Finally, practice makes perfect. The more you engage with these representations, the more intuitive they will become. By honing your ability to interpret these visuals, you will ultimately enhance your proficiency and confidence in handling the equipment.

Common Parts and Their Functions

Understanding the components of a mixing system is essential for optimizing performance and ensuring efficient operation. Each element plays a crucial role in the overall functionality, contributing to the effective blending of materials. Below is a detailed look at some of the essential components and their respective functions.

Key Components

| Component | Function |

|---|---|

| Impeller | Generates fluid motion, facilitating the mixing process by creating turbulence. |

| Motor | Provides the necessary power to drive the impeller, ensuring adequate speed and efficiency. |

| Tank | Holds the materials being combined, designed to accommodate various volumes and types of substances. |

| Seals | Prevent leakage and contamination, maintaining the integrity of the contents during operation. |

Additional Elements

In addition to the main components, there are various supporting elements that enhance functionality. These may include control systems for adjusting speed and timing, as well as safety mechanisms to protect against malfunctions. Each element works in harmony to create a reliable and efficient mixing environment.

Maintenance Tips for Mixers

Proper upkeep of your blending equipment is essential for optimal performance and longevity. Regular attention can prevent common issues and ensure that your apparatus operates efficiently, saving both time and resources.

Regular Inspections

- Check for wear and tear on components.

- Inspect seals and gaskets for leaks.

- Look for any signs of corrosion or damage.

Lubrication and Cleaning

- Clean all surfaces after each use to prevent buildup.

- Apply appropriate lubricants to moving parts as recommended.

- Ensure electrical connections are free from dust and moisture.

Benefits of Using Lightnin Technology

Utilizing advanced mixing systems can significantly enhance efficiency and product quality in various industries. These innovations offer remarkable performance, ensuring optimal results in applications ranging from pharmaceuticals to food production.

One key advantage is the ability to achieve uniform consistency in mixtures, which is crucial for maintaining quality standards. This technology minimizes variations, resulting in a more reliable final product.

Additionally, energy efficiency plays a vital role. By optimizing power usage, these systems not only reduce operational costs but also contribute to sustainability efforts. This is particularly important in today’s environmentally conscious landscape.

Furthermore, the versatility of such systems allows for adaptability to different processes, making them suitable for a wide range of applications. Companies can benefit from this flexibility, adjusting their methods as needed without significant investment.

Ultimately, embracing these technological advancements can lead to improved productivity, reduced waste, and enhanced overall performance in industrial processes.

Applications in Various Industries

In numerous sectors, efficient blending equipment plays a pivotal role in optimizing processes and ensuring product quality. From food production to chemical manufacturing, the versatility of these devices enables them to meet diverse operational needs.

| Industry | Application |

|---|---|

| Food and Beverage | Emulsifying sauces, blending ingredients for uniformity. |

| Chemical | Mixing reactants to ensure consistent formulations. |

| Pharmaceutical | Creating homogenous solutions for drug production. |

| Cosmetics | Combining various substances for skincare products. |

| Construction | Mixing materials like cement and additives for optimal performance. |

Safety Considerations When Operating

Ensuring a secure environment during operation is essential to prevent accidents and injuries. Understanding the potential hazards associated with equipment use can greatly enhance safety protocols.

Before starting, always inspect the apparatus for any signs of wear or damage. Proper maintenance is crucial to avoid malfunctions that could lead to dangerous situations. Furthermore, it’s important to wear appropriate personal protective equipment (PPE) to safeguard against splashes and other risks.

Operators should be well-trained and familiar with the machinery’s controls and emergency shutdown procedures. Regular training sessions can reinforce safety practices and ensure readiness in case of an emergency.

Lastly, maintaining a clean and organized workspace reduces the likelihood of accidents. Clear pathways and proper storage of materials can prevent slips and trips, promoting a safer operational environment.

Upgrading Mixer Components

Enhancing the functionality and efficiency of mixing equipment can significantly improve production outcomes. This process often involves replacing outdated elements with modern alternatives that offer better performance and durability.

- Evaluate Current Components: Assess the condition and efficiency of existing elements to identify areas for improvement.

- Select Upgrades: Research and choose advanced options that align with specific operational needs.

- Compatibility Check: Ensure new components are compatible with the existing system to avoid operational disruptions.

Implementing these upgrades can lead to increased reliability, reduced maintenance costs, and enhanced overall performance.

Comparing Lightnin Mixers with Others

This section explores the distinctions between various blending technologies, focusing on efficiency, design, and application versatility. Different systems offer unique advantages and limitations, impacting industries ranging from food processing to pharmaceuticals.

While some alternatives may prioritize cost-effectiveness, others excel in performance under specific conditions. Factors such as shear rate, energy consumption, and maintenance requirements play crucial roles in determining the best fit for particular operational needs.

Additionally, advancements in technology have led to innovations in mixing solutions, allowing for enhanced precision and adaptability. A thorough understanding of these differences helps users make informed choices that align with their production goals.

Resources for Further Learning

Exploring advanced concepts in fluid mixing and equipment design can significantly enhance your understanding and expertise. There are numerous avenues to deepen your knowledge and refine your skills in this field.

- Online Courses:

- Coursera offers courses on process engineering.

- edX provides materials related to chemical processing and fluid dynamics.

- Books:

- “Mixing in the Process Industries” by G. T. M. A. van der Meer.

- “Fundamentals of Fluid Mechanics” by Munson, Rothmayer, and Rothmayer.

- Webinars and Workshops:

- American Institute of Chemical Engineers (AIChE) hosts regular sessions.

- Local universities often offer workshops for hands-on experience.

- Industry Journals:

- Journal of Fluid Mechanics.

- Chemical Engineering Science.