Understanding the Lt80 Parts Diagram for Efficient Maintenance

Unveiling the inner workings of this remarkable vehicle unveils a labyrinth of interconnected components, each contributing uniquely to its mechanical symphony. Imagine dissecting a sophisticated blueprint where every element serves a pivotal role in the overall orchestration.

Delving into the intricacies of its structure reveals a tapestry woven with gears, levers, and mechanisms, each imbued with purpose. This is not just a mere collection of parts but a meticulous assembly engineered to deliver precision and performance.

Peering beneath the surface uncovers a landscape where form meets function, where every facet seamlessly integrates into a unified whole. It’s a testament to engineering prowess and the artistry of design, where efficiency and reliability converge.

Understanding the Lt80 Parts Diagram

Comprehending the intricate layout of components is essential for effective maintenance and repair. A well-structured visual representation aids in identifying individual elements and their interrelations, streamlining the troubleshooting process. This section delves into the significance of such illustrations and how they enhance understanding for enthusiasts and technicians alike.

The Importance of Component Visuals

Visual representations serve multiple purposes:

- Facilitate quick identification of parts

- Assist in recognizing connections between elements

- Enhance communication among users and professionals

How to Use the Visual Guide Effectively

To maximize the benefits of these visual guides, consider the following tips:

- Familiarize yourself with each component’s function.

- Cross-reference with manuals for detailed specifications.

- Use the visuals during disassembly and assembly for accuracy.

- Take notes on any modifications for future reference.

By integrating these practices, users can ensure efficient handling of the various elements depicted, leading to improved performance and longevity of the equipment.

Importance of Parts Diagrams in Maintenance

Understanding the components of machinery is crucial for effective upkeep and repair. Visual representations of these elements provide clarity, enabling technicians to identify parts and their relationships within the system. This knowledge facilitates more efficient diagnostics and enhances the overall maintenance process.

One key advantage of these illustrations is that they streamline the identification of issues. When a technician can quickly pinpoint the exact location of a malfunctioning piece, they can focus their efforts on resolving the problem without unnecessary delays. Furthermore, these visuals aid in inventory management, ensuring that the right replacements are available when needed.

| Benefit | Description |

|---|---|

| Efficiency | Quick identification of malfunctioning components reduces downtime. |

| Accuracy | Visual aids minimize the risk of errors in assembly or repair. |

| Training | New technicians can learn the system structure more effectively. |

| Inventory Management | Helps ensure the availability of necessary replacements. |

In conclusion, having clear visual references significantly enhances the maintenance process, leading to more effective repairs and prolonged machinery lifespan. Emphasizing their importance can contribute to overall operational success.

Key Components of the Lt80 Vehicle

Understanding the essential elements of this vehicle is crucial for both maintenance and enhancement. Each part plays a vital role in ensuring optimal performance and reliability, contributing to the overall functionality and user experience.

Main Structural Elements

- Chassis: The foundation that supports the entire vehicle, providing strength and stability.

- Engine: The heart of the machine, responsible for power generation and movement.

- Transmission: Transmits power from the engine to the wheels, enabling smooth acceleration and deceleration.

Control and Safety Features

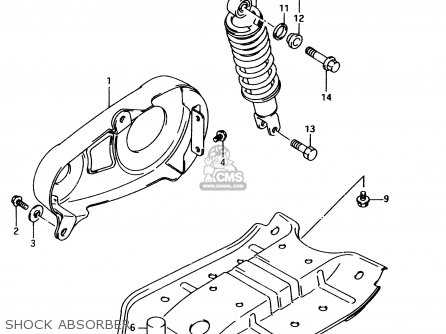

- Braking System: Essential for safe stopping, consisting of various components that work together to reduce speed.

- Steering Mechanism: Allows for maneuverability and control, ensuring the driver can navigate effectively.

- Suspension: Enhances ride quality by absorbing shocks from uneven terrain, providing comfort to the operator.

How to Read the Parts Diagram

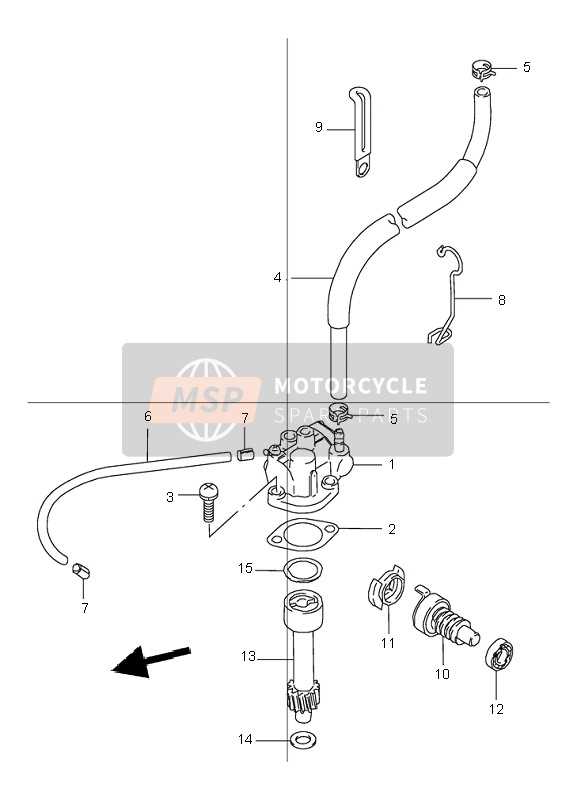

Understanding the visual representation of components is crucial for effective maintenance and repairs. This guide will help you interpret the illustrations that display various elements of a machine, enabling you to identify and locate each part accurately.

To begin, familiarize yourself with the overall layout. Typically, these visuals are organized systematically, with each section highlighting different groups of components. Pay attention to the numbering or labeling system, as this often corresponds to a reference list.

Here’s a basic structure of what to look for:

| Element | Description |

|---|---|

| Component Identification | Each item is usually marked with a unique identifier that links it to detailed information. |

| Groupings | Parts are often categorized by function or location, making it easier to find what you need. |

| Connections | Look for lines or arrows indicating how elements are connected or interact with each other. |

| Scale | Check for any scale indicators that provide insight into the relative size of the components. |

By mastering these elements, you’ll enhance your ability to navigate the illustration effectively, ensuring a smoother process for repairs and replacements.

Common Issues Identified in Diagrams

When examining visual representations of machinery and their components, several recurring challenges can emerge. These difficulties may stem from unclear labeling, incomplete representations, or inconsistencies between different resources. Addressing these problems is crucial for effective troubleshooting and maintenance.

Unclear Labeling

A frequent issue in visual schematics is vague or ambiguous labeling. This can lead to confusion when trying to identify specific elements. Common pitfalls include:

- Labels that are too small or poorly placed

- Use of non-standard terminology

- Inconsistent naming conventions across different illustrations

Incomplete Representations

Another significant concern is the lack of comprehensive illustrations that cover all necessary components. This may result in:

- Missing parts that are critical for understanding functionality

- Overly simplified visuals that do not represent real-world complexity

- Absence of important connections and interactions between components

Identifying Parts by Diagram Numbers

Understanding the components of machinery is essential for effective maintenance and repair. By utilizing reference numbers associated with visual representations, individuals can easily locate and distinguish various elements within a system. This process enhances accuracy in ordering replacements and conducting repairs.

To effectively identify components using reference numbers, follow these steps:

- Familiarize Yourself with the Visual Guide: Begin by examining the visual representation carefully to understand its layout.

- Locate the Reference Numbers: Identify the unique identifiers assigned to each component within the illustration.

- Consult the Corresponding List: Use the reference numbers to find detailed descriptions and specifications in the accompanying documentation.

- Verify Compatibility: Ensure that the identified component matches the required specifications for your specific needs.

By following these steps, you can streamline the process of identifying necessary components and facilitate efficient maintenance or repair tasks.

Remember to keep a record of the reference numbers for future use, as this can save time and reduce frustration in subsequent repairs or replacements.

Replacement Parts: What You Need to Know

When maintaining your vehicle, understanding the components that may require substitution is essential for ensuring optimal performance. Knowing which items to replace and how to identify them can save time and prevent unnecessary expenses.

Here are some key points to consider:

- Compatibility: Always ensure that the new component is suitable for your specific model. Check manufacturer recommendations and specifications.

- Quality: Opt for high-quality items, as inferior substitutes may lead to more significant issues down the line.

- Tools Required: Familiarize yourself with the necessary tools for installation. Some replacements may require specialized equipment.

Additionally, you might find it helpful to follow these steps when seeking a substitute:

- Identify the component that needs replacement.

- Consult your owner’s manual for details on the specifications.

- Research trusted suppliers to find quality options.

- Read reviews or seek recommendations from fellow enthusiasts.

- Consider professional assistance if you are unsure about the installation process.

Staying informed about your vehicle’s needs will enhance its longevity and performance, allowing for a more enjoyable riding experience.

Tips for Ordering Lt80 Parts

When it comes to acquiring components for your vehicle, having a clear strategy can save you time and ensure you get the right items. Here are some practical suggestions to enhance your ordering experience and avoid common pitfalls.

Research Before You Buy

Before placing an order, gather as much information as possible about the components you need. This can help you make informed decisions.

- Check the manufacturer’s website for specifications and recommendations.

- Read reviews and feedback from other users to understand the performance and reliability of the components.

- Consult forums or groups dedicated to your vehicle model for advice and insights.

Choosing the Right Supplier

Selecting a reputable supplier is crucial for ensuring quality and timely delivery.

- Look for vendors with a proven track record in the industry.

- Compare prices from different sources to ensure you are getting a fair deal.

- Inquire about warranties or return policies in case the items do not meet your expectations.

Where to Find Official Diagrams

In the pursuit of accurate visual representations aiding in the understanding of mechanical components, locating official schematics can greatly enhance your maintenance and repair processes. These detailed illustrations serve as visual blueprints, enabling precise identification and assembly of intricate parts.

Authorized Sources

Official diagrams are typically accessible through authorized channels endorsed by manufacturers and their certified distributors. These sources ensure the authenticity and reliability of the diagrams, safeguarding against inaccuracies that could compromise repair procedures.

Online Repositories and Manuals

Many manufacturers provide digital repositories and comprehensive manuals that include interactive diagrams. These resources are invaluable for both novice and experienced technicians, offering searchable databases and downloadable files for convenience.

| 1. Direct from Manufacturer | Ensures authenticity and accuracy |

| 2. Certified Distributors | Authorized access points for official documentation |

| 3. Digital Repositories | Accessible online databases for easy retrieval |

| 4. Comprehensive Manuals | In-depth guides often including interactive components |

Comparing Diagrams with Other Models

In this section, we explore how diagrams of similar machines can be juxtaposed to identify similarities and differences. By examining illustrations of analogous equipment, we can discern variations in structural components and functional mechanisms. Such comparative analysis provides insights into the nuanced design aspects and technological variations present among different models. This approach aids in understanding the distinctive features and configurations inherent in various models, facilitating informed decision-making and comprehensive comprehension of machine specifications.

Identifying Structural Variances

Structural variances encompass diverse physical configurations and assembly details that distinguish one model from another. These discrepancies are crucial in determining the operational suitability and specific maintenance requirements of each machine type. By closely examining diagrams, engineers and enthusiasts alike can discern subtle modifications in component layout and integration, thus appreciating the design evolution across different models.

Comparing diagrams provides a visual framework for evaluating component placement and spatial relationships within the machinery. This methodical approach enhances the clarity of technical documentation and aids in troubleshooting by highlighting potential compatibility issues or upgrade paths. Ultimately, this analytical process fosters a deeper understanding of mechanical intricacies and fosters advancements in machine design and maintenance practices.

Tools Required for Lt80 Repairs

When undertaking maintenance or repairs on specific vehicles, having the right tools is crucial for ensuring efficiency and effectiveness. A well-equipped toolkit can significantly simplify the process, allowing for a smoother experience whether you’re fixing, replacing, or upgrading components.

Essential Tools

- Socket Set: A comprehensive socket set is vital for loosening and tightening various fasteners.

- Wrenches: Both adjustable and fixed wrenches are necessary for different sizes of nuts and bolts.

- Screwdrivers: A variety of screwdrivers, including flathead and Phillips, will cover most fastening needs.

- Pliers: Needle-nose and standard pliers are useful for gripping, twisting, and cutting wires.

- Torque Wrench: This tool ensures that fasteners are tightened to the manufacturer’s specifications.

Additional Equipment

- Jack and Stands: Essential for lifting the vehicle safely for undercarriage access.

- Multimeter: Helpful for diagnosing electrical issues and ensuring proper connectivity.

- Work Light: Adequate lighting is crucial for visibility during repairs, especially in dim areas.

- Parts Cleaner: Keeping components clean helps in identifying wear and prolonging lifespan.

Equipping yourself with these tools will enhance your capability to perform repairs efficiently and confidently, ensuring that your vehicle remains in optimal condition.

DIY Maintenance Using the Diagram

Engaging in self-service upkeep can significantly enhance the performance and longevity of your vehicle. By utilizing a visual reference, enthusiasts can efficiently identify components and understand their functions, making repairs and maintenance tasks more manageable. This proactive approach not only saves time and money but also fosters a deeper connection with your machine.

Understanding the Components

Before diving into maintenance, it’s crucial to familiarize yourself with the various elements involved. Each section illustrated in the reference provides insights into the role of specific parts. This knowledge equips you to diagnose issues effectively, ensuring you can pinpoint problems quickly and accurately.

Step-by-Step Maintenance Guide

Once you’re acquainted with the elements, follow a systematic approach to upkeep. Start by gathering the necessary tools and supplies. Referencing the visual aid, methodically check each area for wear and tear. Regular inspections can prevent minor issues from escalating into major repairs. Always document your findings and the steps taken, as this practice will help in future maintenance sessions.

Embracing this hands-on methodology not only empowers you as a vehicle owner but also promotes a greater appreciation for the intricacies of its design.

Resources for Further Learning

In the realm of exploring mechanical assemblies and their intricate configurations, there exists a wealth of educational materials that delve into the anatomy and composition of machinery. These resources comprehensively cover the inner workings, structural components, and interactive elements of mechanical systems. They provide detailed insights into the intricate interplay of parts, offering visual aids and explanatory texts that illuminate the complexity and functionality of various assemblies.

For those seeking deeper understanding, there are specialized texts that elucidate the diverse facets of mechanical engineering, offering nuanced perspectives on the arrangement and interaction of components within dynamic systems. Additionally, online repositories and digital libraries host a multitude of scholarly articles and technical papers that dissect the principles governing mechanical structures, shedding light on their operational principles and interdependencies.

Moreover, educational videos and interactive tutorials facilitate an immersive learning experience, allowing enthusiasts to observe real-time demonstrations and simulations that showcase the application of theoretical concepts in practical scenarios. These multimedia resources provide a hands-on approach to understanding the dynamics of mechanical assemblies, fostering a deeper appreciation for the intricate craftsmanship and functional intricacies that underpin mechanical engineering.