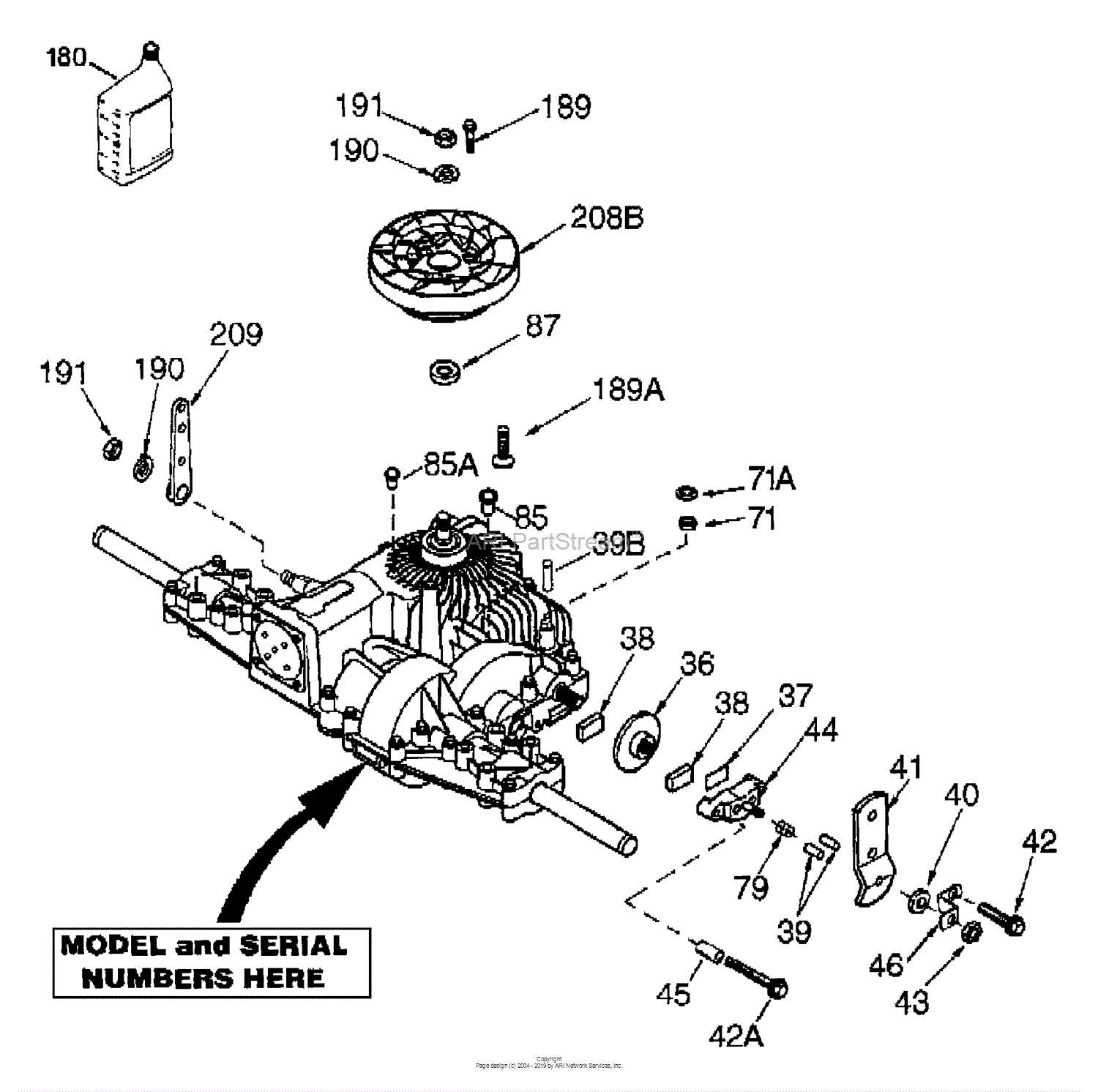

Lth130 Parts Diagram Overview

Exploring the intricate arrangement of mechanical elements is essential for anyone involved in engineering or repair tasks. A well-structured visual representation aids in grasping the relationships and functionalities of each individual piece within a larger assembly. This knowledge not only enhances efficiency but also minimizes the potential for errors during installation or maintenance.

In technical fields, detailed illustrations serve as valuable references. They provide insight into how various units interact and work together seamlessly. By analyzing these representations, one can quickly identify the specific components necessary for troubleshooting or replacement, ensuring that operations run smoothly.

Whether you are a seasoned professional or an enthusiastic novice, familiarizing yourself with these visual guides is crucial. They not only streamline processes but also deepen your understanding of complex machinery, ultimately leading to more informed decisions and better outcomes in your projects.

LTH130 Parts Diagram Overview

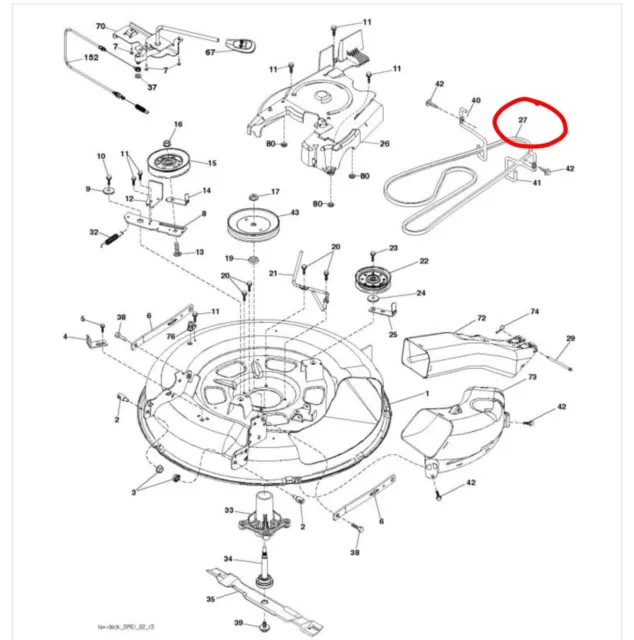

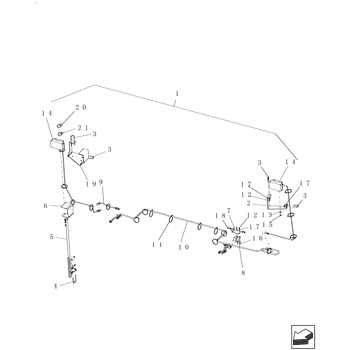

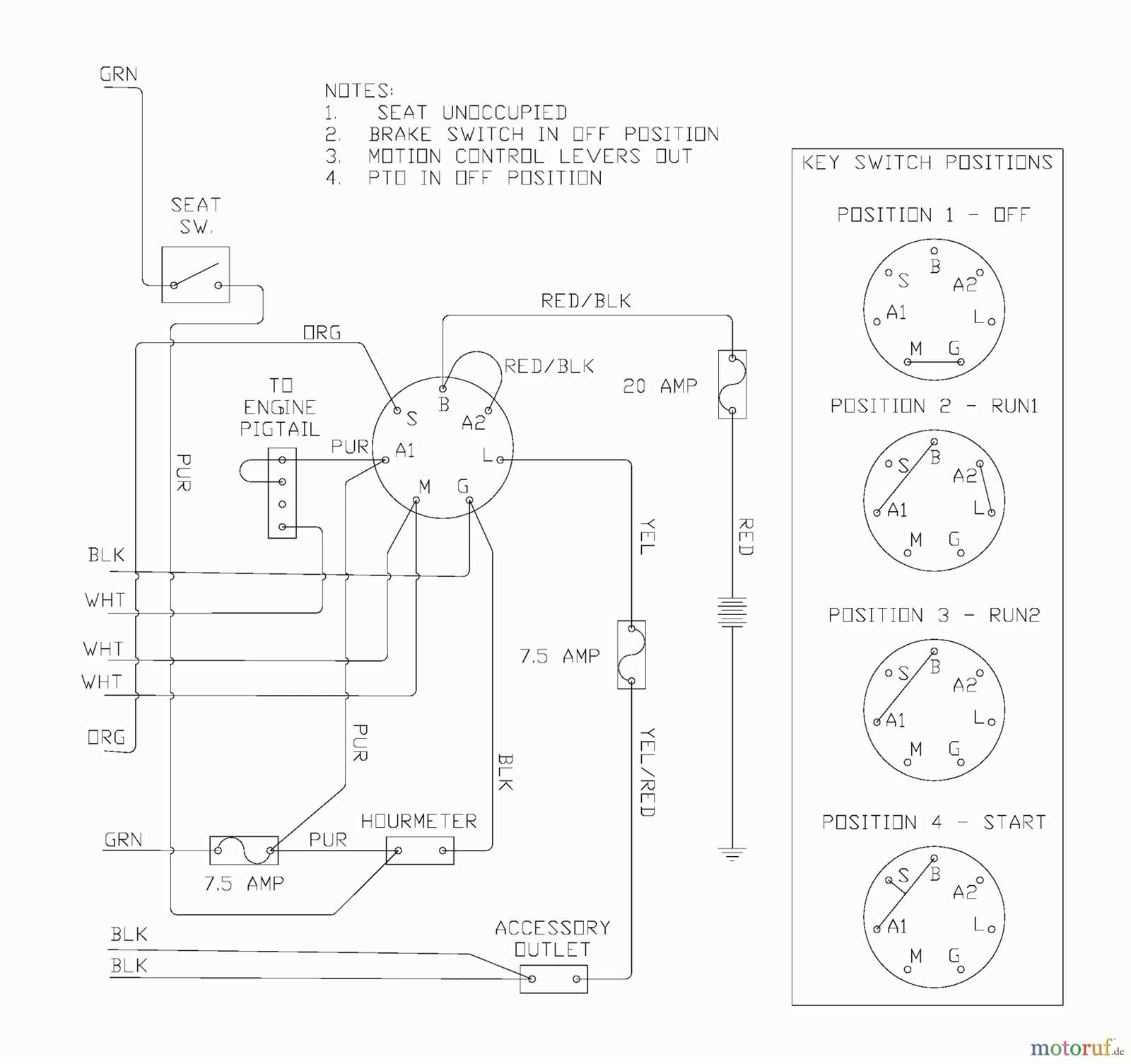

This section provides a comprehensive look at the essential components and their arrangement in the LTH130 system. Understanding how these elements interact is crucial for effective maintenance and repair. A clear visual representation can greatly aid technicians in identifying each piece and its function within the overall assembly.

Importance of Understanding Component Layout

Familiarity with the layout of these components ensures efficient troubleshooting and enhances the ability to perform repairs with precision. Each element plays a pivotal role, and recognizing their placement can prevent potential issues during service.

Key Features of the Visual Representation

The illustration highlights critical aspects, including the connectivity and orientation of each segment. This clarity helps in both training new technicians and providing seasoned professionals with a quick reference for complex tasks.

Understanding LTH130 Components

In any mechanical system, the intricate interplay of various elements is crucial for optimal performance. Each component serves a specific role, contributing to the overall functionality and efficiency of the assembly. Gaining insight into these individual pieces can greatly enhance one’s ability to maintain and troubleshoot the entire system.

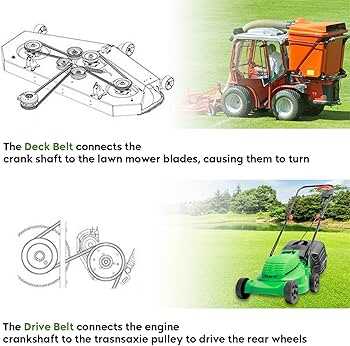

Key Elements and Their Functions

The assembly consists of several vital elements, each designed to fulfill distinct purposes. For instance, certain pieces are responsible for facilitating movement, while others ensure stability and support. Understanding these roles allows users to appreciate how the system operates as a cohesive unit. Familiarity with each component’s function can also aid in identifying potential issues that may arise during operation.

Interconnectivity and Maintenance

Another important aspect to consider is the interconnectivity between the various elements. Each part influences the performance of others, and any malfunction in one can lead to a cascade of problems. Regular maintenance and inspection are essential to ensure that all components remain in good condition. Being aware of their relationships will empower users to take proactive measures in preserving the integrity of the entire mechanism.

Importance of Accurate Diagrams

Clear representations are essential for understanding complex systems and ensuring efficient communication among users. When components are accurately depicted, it minimizes confusion and streamlines the assembly or repair processes. This clarity ultimately enhances productivity and safety in various applications.

| Benefits | Description |

|---|---|

| Enhanced Clarity | Precise visuals help users quickly grasp the relationships between elements. |

| Improved Efficiency | Accurate representations reduce the time spent on troubleshooting and assembly. |

| Increased Safety | Understanding the layout of components lowers the risk of errors during handling. |

| Effective Training | Clear illustrations serve as valuable tools for educating new users. |

Common Issues with LTH130 Parts

When dealing with specific machinery components, various challenges may arise that can affect performance and reliability. Understanding these common difficulties can help in addressing potential problems before they escalate.

- Wear and tear due to frequent use can lead to diminished efficiency.

- Improper installation often results in misalignment or failure of components.

- Corrosion from environmental factors may compromise the integrity of parts.

- Incompatibility with other components can cause operational issues.

Regular maintenance and inspections are crucial for identifying these issues early, ensuring optimal functioning.

How to Read the Diagram Effectively

Understanding a visual representation of components can significantly enhance your ability to troubleshoot and assemble machinery. By familiarizing yourself with the layout and symbols, you can navigate the information more efficiently.

Key Steps to Interpret the Visual Layout

- Familiarize with Symbols: Recognize common icons used to denote different elements.

- Identify Sections: Break down the visual into manageable areas for easier analysis.

- Follow Connections: Trace lines or arrows to understand how each part interacts.

Tips for Efficient Reading

- Take notes while you analyze to solidify your understanding.

- Consult accompanying manuals for additional context.

- Practice with similar visuals to enhance your skills.

Identifying Replacement Parts Easily

When it comes to maintaining equipment, recognizing the components that need substitution can significantly streamline the process. A clear understanding of each element involved is essential for effective identification and procurement. This knowledge enables individuals to ensure their machinery operates at peak performance while avoiding unnecessary delays.

Utilizing detailed visual guides can enhance one’s ability to locate specific items swiftly. These illustrations serve as invaluable references, allowing users to match components accurately. Familiarity with various shapes and functions can further aid in quick assessments, minimizing the time spent searching for replacements.

Incorporating a systematic approach when analyzing equipment will simplify the task of recognizing which elements require attention. Documenting any discrepancies or wear can also provide clarity, ensuring that decisions regarding replacements are informed and timely. Ultimately, an organized strategy is key to maintaining operational efficiency.

Tips for Maintaining LTH130 Equipment

Regular upkeep is essential for ensuring optimal performance and longevity of machinery. By adhering to a structured maintenance routine, operators can prevent breakdowns and enhance efficiency. Here are some key strategies to consider.

1. Routine Inspections: Conduct frequent examinations to identify wear and tear. Early detection of issues can save time and resources.

2. Lubrication: Keep moving parts well-lubricated to minimize friction. Use the recommended oils and greases to ensure smooth operation.

3. Cleanliness: Maintain a clean environment around the equipment. Regularly remove debris and dirt to prevent damage and facilitate better functionality.

4. Replacement of Worn Components: Monitor components closely and replace any that show signs of significant wear. This proactive approach can avert more serious issues.

5. Training and Awareness: Ensure that all personnel are properly trained in handling and maintaining the equipment. Awareness of best practices leads to better care.

6. Documentation: Keep a detailed log of maintenance activities, including inspections and repairs. This record can be invaluable for tracking performance trends over time.

Implementing these tips can significantly enhance the reliability and efficiency of your machinery, leading to better overall results.

Where to Find Official Diagrams

Accessing accurate technical illustrations is essential for anyone looking to maintain or repair machinery. These resources provide a clear visual representation of components, facilitating a better understanding of assembly and disassembly processes. Fortunately, there are several reliable avenues to explore when searching for these essential resources.

Official Manufacturer Websites

One of the most straightforward ways to locate authentic technical illustrations is through the official websites of manufacturers. These platforms often have dedicated sections for resources, including:

- Technical manuals

- Service guides

- Parts catalogs

Visiting these sites ensures that you receive the most accurate and up-to-date information directly from the source.

Authorized Dealers and Service Centers

Another reliable source for obtaining official visuals is through authorized dealers and service centers. They often have access to proprietary information that may not be readily available online. Consider the following options:

- Contacting a local dealer for specific requests.

- Inquiring with service centers for any manuals they might have.

- Exploring training resources that may include detailed visuals.

These avenues can provide valuable insights and documentation that are crucial for effective maintenance and repair work.

Comparing LTH130 to Similar Models

This section explores the differences and similarities between a particular model and its contemporaries in the market. By analyzing key features, performance metrics, and design elements, we can better understand how this unit stands out among competitors.

- Performance: Examine the power output and efficiency ratings compared to similar devices.

- Design: Look at the construction quality, materials used, and ergonomic aspects that enhance usability.

- Features: Identify unique functionalities that might appeal to specific user needs.

- Price Point: Compare cost structures to assess overall value for money.

Through this analysis, potential buyers can make informed decisions by identifying which model best suits their requirements and preferences.

Safety Considerations for Repairs

When undertaking maintenance tasks, it is crucial to prioritize safety to prevent accidents and ensure a smooth repair process. Understanding potential hazards and implementing appropriate precautions can significantly reduce the risk of injury or damage to equipment. A well-planned approach not only safeguards the individual performing the task but also protects the surrounding environment.

Personal Protective Equipment (PPE)

Utilizing personal protective equipment is essential when engaging in repair activities. Items such as gloves, safety goggles, and sturdy footwear can shield against various risks, including sharp edges, hazardous materials, and falling objects. Always ensure that the PPE is suitable for the specific tasks at hand and is in good condition to maximize effectiveness.

Work Environment Safety

Creating a safe workspace is equally important. Ensure the area is well-lit and free from clutter, which can lead to slips or falls. Additionally, securing any loose tools and materials can help maintain an organized environment, reducing the chances of accidents. Regularly inspecting the surroundings and keeping emergency equipment readily accessible contributes to a safer working experience.

Frequently Asked Questions about LTH130

This section addresses common inquiries related to the specific model in question, providing clarity on various aspects. Here, you will find answers to typical concerns that users may have, helping to enhance understanding and streamline the experience with this equipment.

General Inquiries

- What are the key features of this model?

- How does it compare to similar options available?

- What maintenance practices are recommended for optimal performance?

Operational Questions

- How do I install the unit properly?

- What troubleshooting steps should I follow if I encounter issues?

- Are there any specific safety precautions I need to observe?

Resources for Further Learning

Enhancing your understanding of mechanical components and their configurations can significantly improve your skills in various fields. This section provides a collection of valuable materials that can deepen your knowledge and expertise.

-

Books:

- Mechanical Engineering Design by Joseph Shigley

- Fundamentals of Machine Component Design by Robert C. Juvinall

-

Online Courses:

- Introduction to Mechanical Engineering on Coursera

- Engineering Mechanics: Statics on edX

-

Web Resources:

- Engineering Toolbox – A comprehensive resource for engineering data and tools.

- National Geographic Education – Insights into engineering principles and applications.

-

Forums and Communities:

- Eng-Tips – A community for engineers to discuss various topics and share insights.

- Reddit Engineering – A platform to engage with fellow enthusiasts and professionals.

Utilizing these resources can provide a solid foundation for further exploration and mastery in the field.