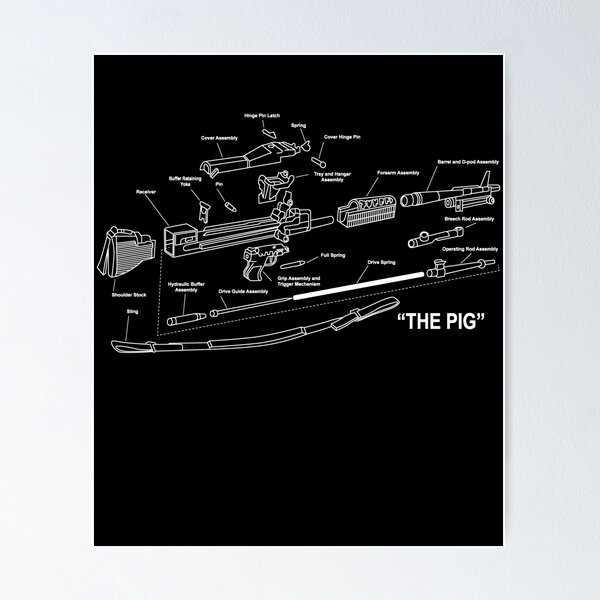

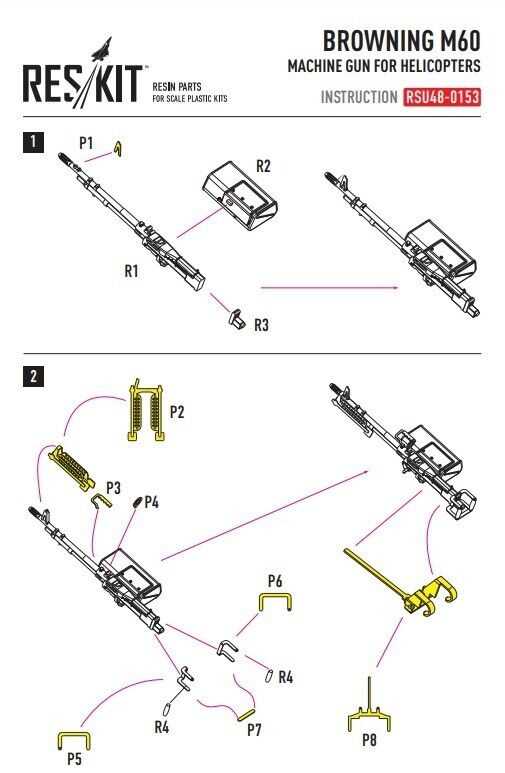

M60 Components Overview

The study of intricate mechanical designs has long fascinated engineers and enthusiasts alike. Understanding how various elements interact within a complex assembly can reveal the ingenuity behind its functionality. These assemblies consist of multiple segments, each contributing to the overall operation. Examining these configurations provides valuable insights into the principles of motion, force distribution, and efficiency.

At the heart of this analysis lies the detailed examination of interconnected sections that work in harmony to achieve precise performance. Each piece, no matter how small, plays a crucial role in ensuring the system operates smoothly. From internal mechanisms to external fixtures, every element serves a distinct purpose, contributing to the robustness and reliability of the design.

This exploration of mechanical systems also highlights the importance of understanding individual components in relation to the whole. By dissecting the structure and analyzing its various sections, one can appreciate the balance between form and function. This approach

M60 Parts Diagram Overview

Understanding the layout and structure of this mechanism is crucial for grasping how it functions. The system is composed of various components, each serving a specific role in ensuring the overall performance and reliability. A clear representation of the inner workings offers valuable insight into how the different elements are connected and interact with each other.

This guide aims to break down the individual sections, highlighting key features and their relationships. By examining the configuration, one can better appreciate how precision and engineering contribute to the system’s efficient operation.

Main Components of the M60

The system is composed of several key assemblies that work together to ensure smooth operation and functionality. Each section plays a crucial role, contributing to both stability and performance, making it an effective tool in various situations.

-

Barrel Assembly: This element serves as the central pathway for projectiles, designed for sustained use and quick replacement during overheating.

-

Receiver Group: The core of the system, housing important mechanisms responsible for loading and firing.

-

Feeding Mechanism: Ensures a continuous flow of ammunition, reducing downtime between operations and supporting efficiency in action.

-

Trigger Unit: Controls the release of the firing sequence, offering both precision and control in vari

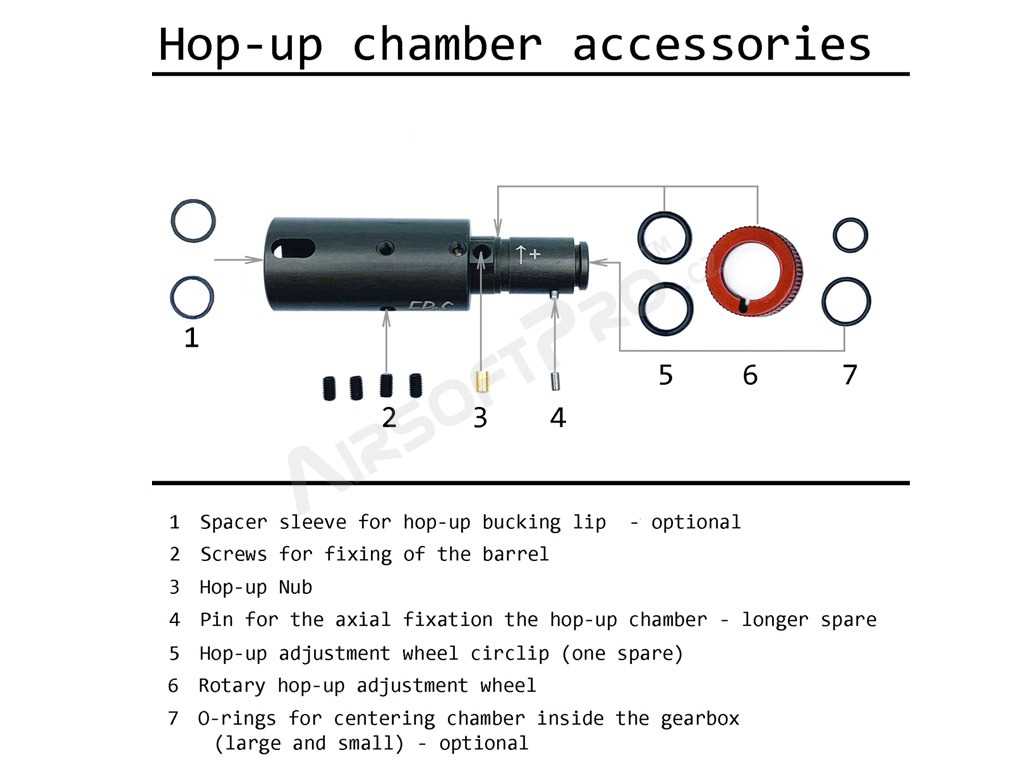

Internal Mechanisms and Their Functions

The internal components play a vital role in ensuring the efficiency and reliability of the entire system. These elements interact seamlessly, allowing for smooth operation and optimal performance. Understanding how each part functions within the assembly is crucial for both maintenance and effective usage.

Below is an overview of key components and their specific roles:

Component Function Operating lever Responsible for initiating movement and controlling the system’s actions during operation. Recoil spring Absorbs energy during motion and assists in resetting components to their original position after each cycle. Feeding mechanism Ensures continuous supply of materials, maintaining steady operation without interruption. Trigger assembly Activates the system when engaged, allowing for controlled release of stored energy. Understanding the Firing Assembly

The firing mechanism plays a crucial role in ensuring the overall functionality and efficiency of a weapon system. It is responsible for triggering the discharge process, a vital operation that requires precision and coordination of several interconnected components. This assembly initiates the sequence that allows for the controlled release of energy, which propels the projectile forward, making it an essential part of the system’s performance.

At the core of this assembly lies a complex interaction between mechanical elements. These components work in harmony to ensure that each shot is fired accurately and consistently. The firing mechanism typically involves a trigger, a hammer, and a firing pin, which together coordinate the release of stored energy to ignite the propellant, driving the ammunition forward.

Maintenance and regular inspection of these elements are vital to ensuring the reliability and longevity of the weapon system. Proper understanding of how the firing mechanism operate

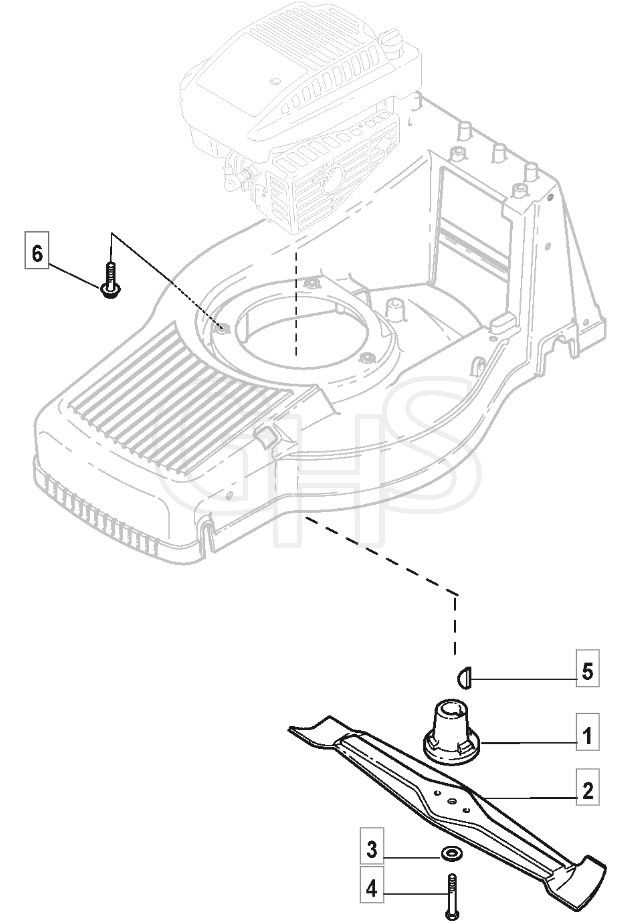

Barrel and Chamber Structure Explained

The barrel and chamber serve as critical components that directly impact the operation and performance of any firing mechanism. These two elements are responsible for guiding the projectile and containing the pressure generated during discharge. Understanding the interaction between these components is essential for grasping the overall function of the system.

The barrel is the long, cylindrical tube through which the projectile travels after ignition. Its internal surface is designed to provide precision and stability, ensuring the projectile maintains an accurate trajectory. The quality of the rifling inside affects the speed and direction, offering enhanced control over each shot.

The chamber, located at the rear of the barrel, is where the ammunition is seated and primed for firing. This section of the structure must withstand significant pressure when the firing process is initiated. Its design ensures that the c

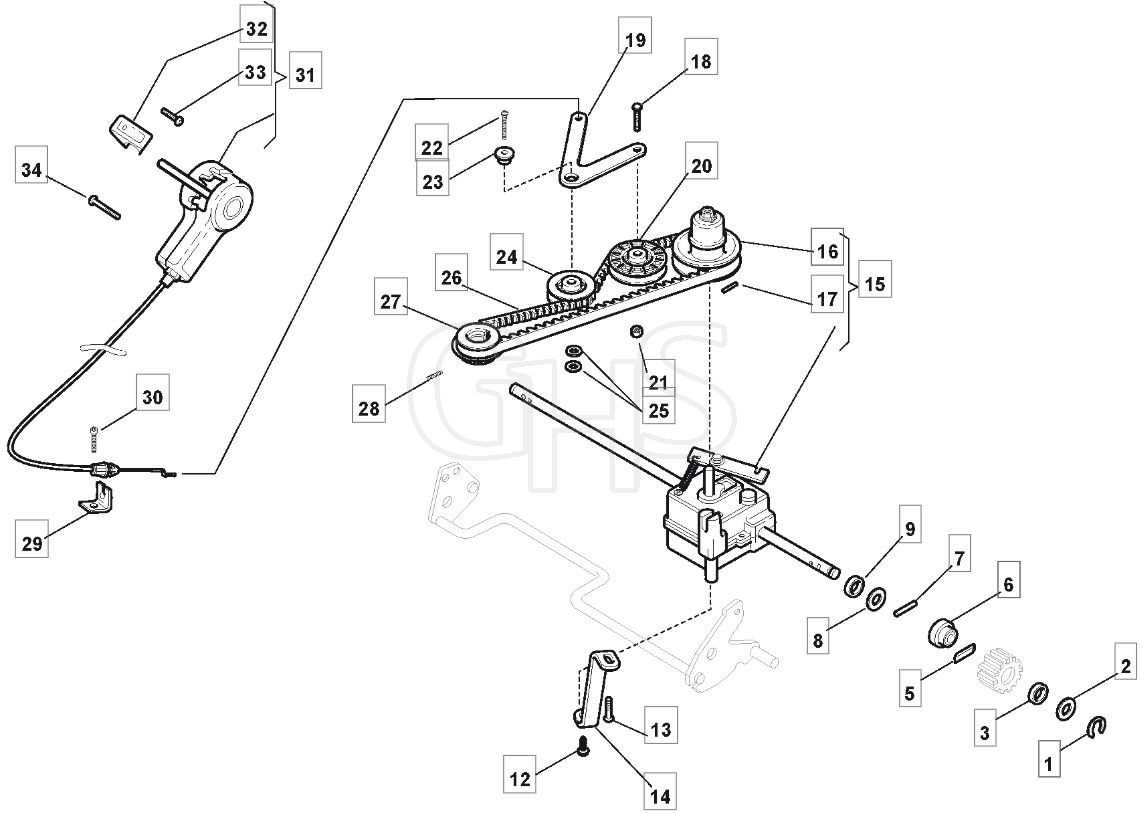

Feeding Mechanism and Ammunition Belt

The feeding system is a crucial component that ensures the continuous supply of rounds to the firing mechanism, allowing for sustained operation during combat scenarios. This system is designed to handle various types of ammunition, ensuring reliability and efficiency in different conditions.

The ammunition belt plays a vital role in the overall functionality of this system. It consists of linked cartridges that facilitate quick and smooth loading into the firing chamber. The design of the belt allows for easy handling and swift replacement, which is essential during high-intensity situations.

Additionally, the feeding mechanism incorporates features that prevent misfeeds and jams, enhancing the weapon’s operational reliability. By utilizing advanced materials and engineering principles, the system ensures that rounds are delivered consistently, allowing the user to maintain focus on their tactical objectives.

Overall, the interplay between the feeding system and ammunition belt is integral to the performance of the weapon, providing the necessary support for effective firing while minimizing the potential for disruptions in operation.

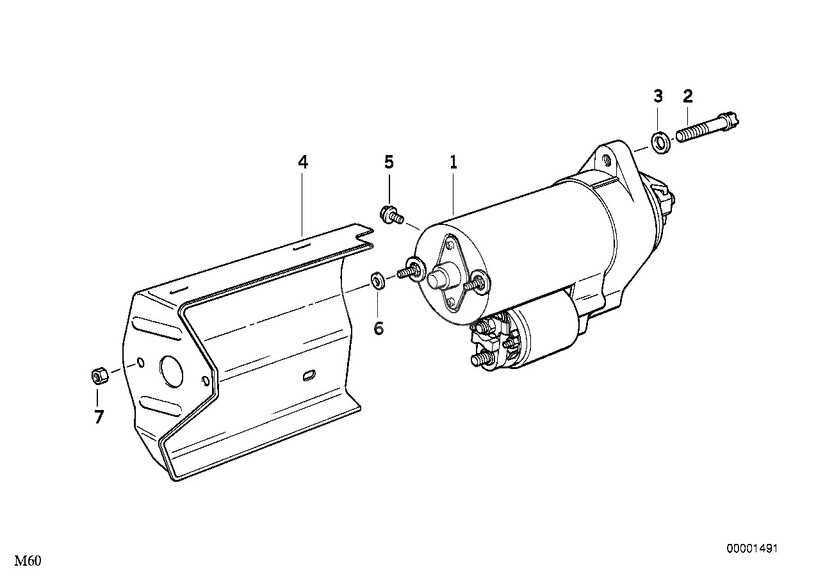

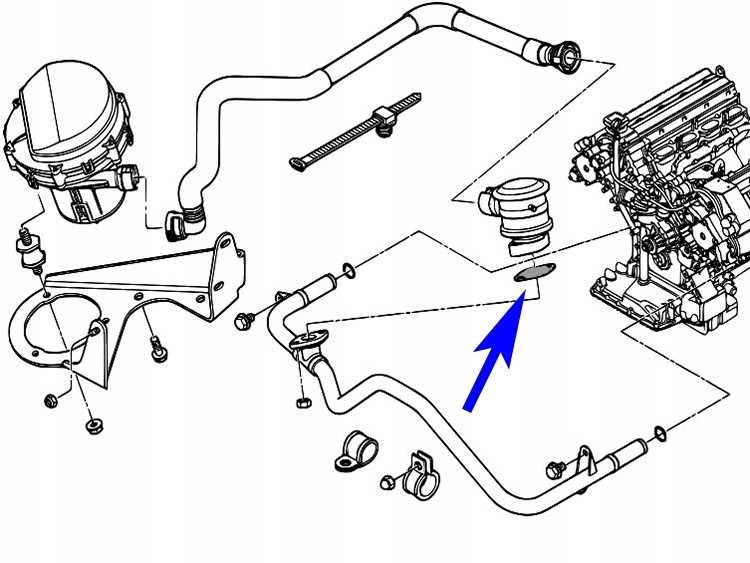

Cooling System and Heat Dissipation

The efficiency of machinery relies significantly on its ability to manage temperature effectively. Proper thermal management ensures that components operate within their optimal temperature ranges, thus enhancing performance and longevity. The cooling mechanisms employed play a crucial role in dissipating excess heat generated during operation, preventing overheating and potential damage.

To achieve effective heat removal, various methods and components are utilized. These may include liquid cooling systems, air-cooled radiators, and heat sinks, each designed to facilitate the transfer of heat away from critical areas. The selection of an appropriate cooling system depends on the specific requirements of the machinery and the operational environment it faces.

Furthermore, the layout and design of the cooling elements are critical. Strategically positioned vents and ducts can enhance airflow, while thermal interface materials improve heat transfer between surfaces. Continuous monitoring of temperature is also essential to ensure that the cooling system functions effectively, allowing for timely adjustments as necessary.

Ultimately, an efficient cooling system is vital for maintaining operational reliability and preventing failures. By prioritizing effective heat dissipation, machinery can perform at its best, ensuring safety and efficiency in demanding conditions.

Trigger Assembly and Safety Features

The mechanism responsible for firing a weapon plays a crucial role in ensuring both functionality and safety. This assembly is designed to facilitate the firing process while incorporating essential safety measures to prevent accidental discharges. Understanding its components and how they interact is vital for proper handling and maintenance.

Components of the Firing Mechanism

The firing mechanism consists of several key elements, including the trigger, sear, and hammer. Each component is intricately designed to work in harmony, ensuring that the firearm operates smoothly. The trigger initiates the firing sequence, while the sear holds the hammer in a ready position until the trigger is pulled. This arrangement allows for a reliable and responsive firing experience.

Safety Mechanisms

Safety is paramount in any firearm design. Various features are implemented within the firing mechanism to enhance user protection. For instance, a manual safety lever allows the operator to disengage the trigger mechanism when not in use. Additionally, some designs incorporate a disconnect feature that prevents the hammer from falling unless the trigger is intentionally pulled. These precautions are vital for ensuring safe handling and reducing the risk of accidental discharges.

Maintenance Points for Key Parts

Regular upkeep of essential components is crucial for ensuring optimal performance and longevity of any complex machinery. This section outlines vital maintenance considerations that can help prevent potential issues, enhance efficiency, and extend the service life of each significant element. By adhering to these guidelines, operators can minimize downtime and costly repairs.

Inspection and Cleaning

Routine inspection and cleaning are fundamental to maintaining the functionality of critical elements. Accumulated dirt, debris, and corrosion can hinder performance and lead to failures. It is recommended to follow a structured schedule for examining these components and removing any contaminants that may affect their operation.

Lubrication and Adjustments

Proper lubrication is essential for reducing friction and wear on moving parts. Using the correct type of lubricant and applying it at recommended intervals can greatly enhance efficiency. Additionally, regular adjustments may be necessary to ensure components operate smoothly and effectively.

Component Maintenance Task Frequency Drive System Inspect for wear and clean Monthly Hydraulic System Check fluid levels and replace filters Quarterly Electrical Connections Inspect for corrosion and secure fittings Biannually Cooling System Flush and refill coolant Annually Transmission Change oil and check seals Every 500 hours Stock and Grip Details

The stock and grip of a firearm play crucial roles in user comfort, control, and overall handling. These components are designed to enhance stability while aiming and firing, ensuring that the shooter can maintain accuracy and manage recoil effectively. A well-constructed stock can significantly impact the shooter’s experience, making it essential to consider various designs and materials used in their construction.

Typically, stocks come in different configurations, including fixed and adjustable models. Fixed stocks provide a solid and consistent length, while adjustable options allow users to modify the length to suit personal preferences or specific shooting scenarios. The choice of material also influences weight, durability, and overall feel, with options ranging from wood to synthetic composites.

Grips are another vital element, influencing how the firearm is held and maneuvered. Ergonomically designed grips can enhance the shooter’s ability to maintain a firm hold, especially during rapid firing or challenging conditions. Textured surfaces may also be incorporated to improve traction and prevent slipping, thereby ensuring a secure grasp under various circumstances.

Ultimately, understanding the characteristics and functionalities of these components is essential for anyone looking to optimize their experience with a firearm. Selecting the right stock and grip can make a significant difference in handling, comfort, and performance, contributing to a more enjoyable and efficient shooting experience.

Sight System and Adjustments

The optical aiming mechanism of a firearm plays a crucial role in enhancing accuracy and precision during operation. This system consists of various components that work together to provide a clear view of the target while allowing for necessary adjustments to accommodate different shooting conditions and distances. Understanding the configuration and calibration of this aiming device is essential for optimal performance in the field.

Components of the Optical System

The sighting mechanism typically includes the following elements:

Component Function Reticle Provides a reference point for aiming Elevation Adjustment Alters the vertical alignment for distance accuracy Windage Adjustment Modifies horizontal alignment to counteract wind Objective Lens Collects light to enhance image clarity Eyepiece Facilitates focus and clarity of the sight picture Adjustment Procedures

Proper calibration of the optical aiming system is essential for achieving desired accuracy. The adjustment procedures typically involve the following steps:

- Establish a stable shooting position.

- Align the firearm with the target at a predetermined distance.

- Make initial windage and elevation adjustments based on environmental conditions.

- Fire a group of shots to assess alignment and precision.

- Fine-tune adjustments as necessary to achieve optimal results.