Exploring the Makita BHP452 Parts Diagram for Optimal Maintenance

The intricate design of modern power tools often requires a comprehensive understanding of their individual elements. Each component plays a crucial role in ensuring optimal performance, safety, and longevity. Familiarizing oneself with the layout and functionality of these parts can significantly enhance maintenance and repair efforts.

Whether you are a seasoned professional or a DIY enthusiast, grasping the anatomy of these machines empowers users to make informed decisions. Identifying specific components not only aids in troubleshooting but also fosters a deeper appreciation for engineering precision and innovation in the industry.

This exploration into the structural details highlights the importance of each element. Understanding how they interact and contribute to overall functionality can lead to better care practices, ensuring that tools remain reliable and efficient throughout their lifespan.

Understanding Makita BHP452 Components

Grasping the intricacies of power tool components is essential for both maintenance and efficient usage. Each element plays a vital role in ensuring optimal performance, allowing users to achieve their tasks with precision.

Key Elements

- Motor: The heart of the tool, responsible for driving various functions.

- Gearbox: Transmits power and adjusts torque for different applications.

- Batteries: Provide the necessary energy supply for operation.

- Switch: Controls the activation and deactivation of the device.

Importance of Each Component

- Understanding the motor’s capacity can enhance work efficiency.

- A well-maintained gearbox reduces wear and prolongs tool life.

- Regular battery checks ensure consistent performance.

- Familiarity with the switch aids in safe operation.

Overview of Makita BHP452 Model

This powerful tool is designed for efficiency and versatility in various applications. With its robust construction and ergonomic features, it provides users with the ultimate experience in performance and comfort.

Key features include a high-torque motor that enables quick drilling and driving, making it suitable for both professional and DIY projects. The compact design enhances maneuverability, allowing access to tight spaces.

Durability is a significant aspect of this model, with components engineered to withstand rigorous use. Whether tackling wood, metal, or masonry, this tool delivers consistent results, ensuring reliability for users in diverse environments.

Importance of Parts Diagrams

Understanding the structure and components of a tool is essential for efficient maintenance and repair. Visual representations of these elements facilitate easier identification and organization, ultimately enhancing the user’s ability to manage their equipment effectively.

Clarity in communication is crucial when discussing repairs. A well-illustrated reference enables technicians and users to pinpoint specific sections, ensuring that everyone is on the same page. This reduces the likelihood of errors during assembly or disassembly.

Furthermore, these visual aids serve as educational resources. They allow newcomers to delve into the mechanics of a tool, fostering a deeper appreciation and understanding of its functionality. This knowledge is ultimately empowering for users, as it builds confidence in their ability to perform repairs independently.

Identifying Key Parts of BHP452

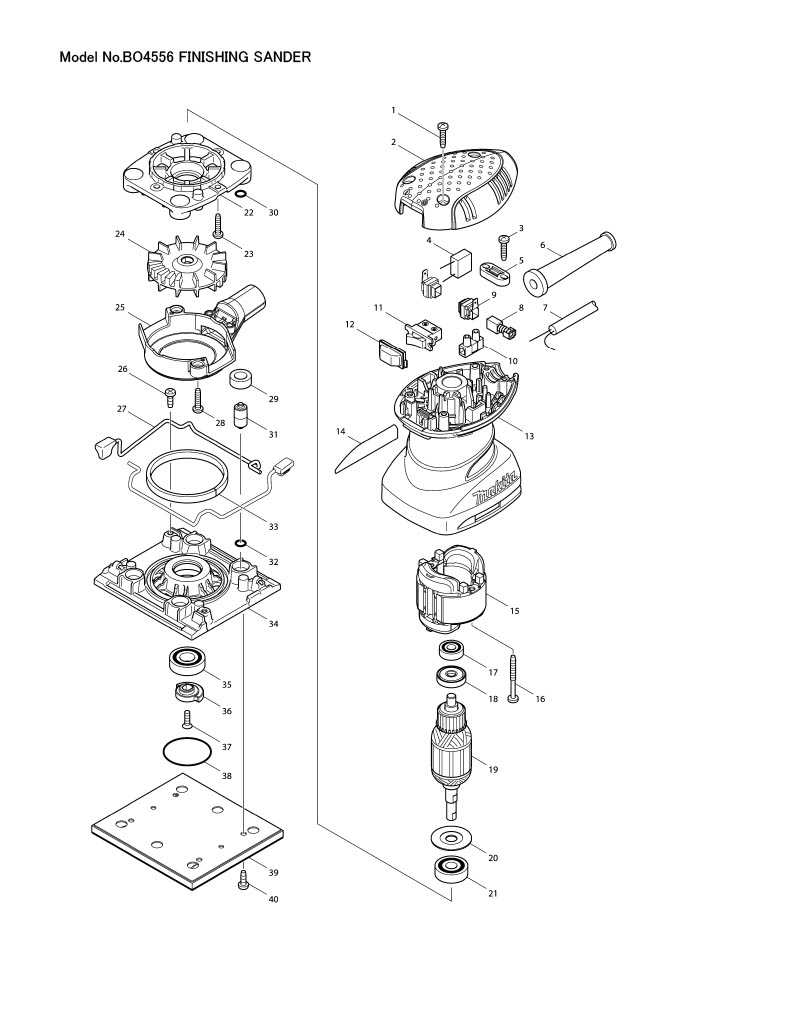

Understanding the essential components of a powerful tool is crucial for effective usage and maintenance. Familiarity with each element enhances operational efficiency and prolongs the lifespan of the equipment. This section aims to highlight the main features and their functions, enabling users to recognize what contributes to the tool’s performance.

Main Components

- Motor Assembly – The core element that provides the necessary power for operation.

- Chassis – The structural framework that supports all other components and ensures stability.

- Gear Mechanism – A system that translates motor power into usable torque and speed.

- Battery Unit – Supplies energy, allowing for cordless functionality and mobility.

- Trigger Switch – Controls the activation and deactivation of the tool.

Additional Features

- Chuck – Holds various attachments securely in place.

- Handle Grip – Provides comfort and control during use.

- Safety Lock – Prevents accidental activation for user safety.

- Cooling Ventilation – Maintains optimal operating temperature to prevent overheating.

Recognizing these critical components not only aids in troubleshooting but also empowers users to perform routine maintenance effectively. By understanding how each part contributes to overall function, users can ensure their tools operate at peak performance for years to come.

Common Issues with Makita Tools

When it comes to power equipment, users often encounter various challenges that can hinder performance. Understanding these common problems can help in maintenance and prolonging the life of the tools. This section delves into frequent issues that many experience with their devices.

Battery and Power Concerns

One of the ultimate frustrations is dealing with battery-related issues. Many users report diminished power over time or difficulties in charging. This can be attributed to age, improper storage, or even faulty connections. Regular checks and maintenance can mitigate these concerns.

Wear and Tear on Components

Another prevalent problem involves the deterioration of parts due to heavy usage. Commonly affected areas include gears, switches, and drill bits. These components often require replacement to maintain optimal functionality. Identifying signs of wear early can save time and ensure efficient operation.

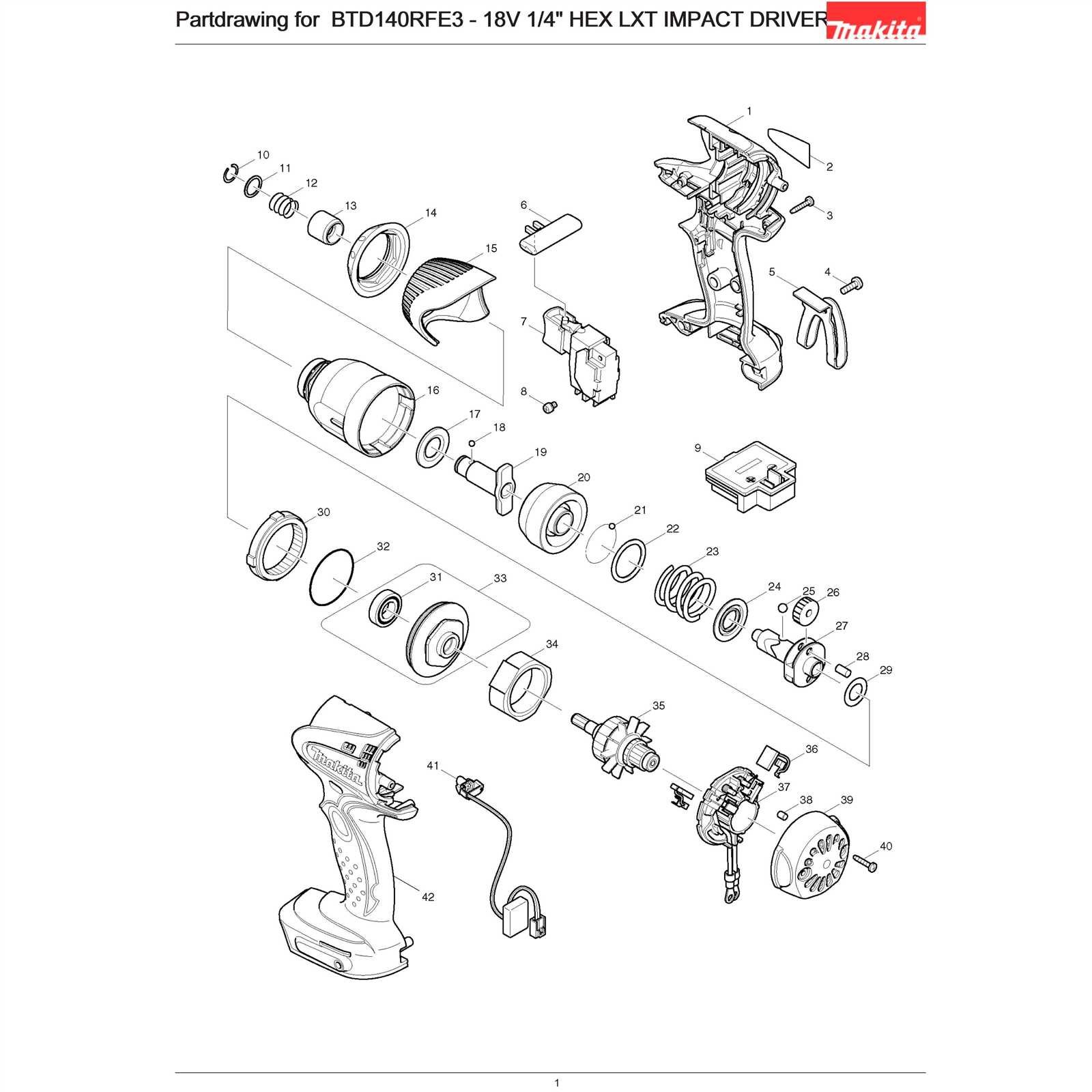

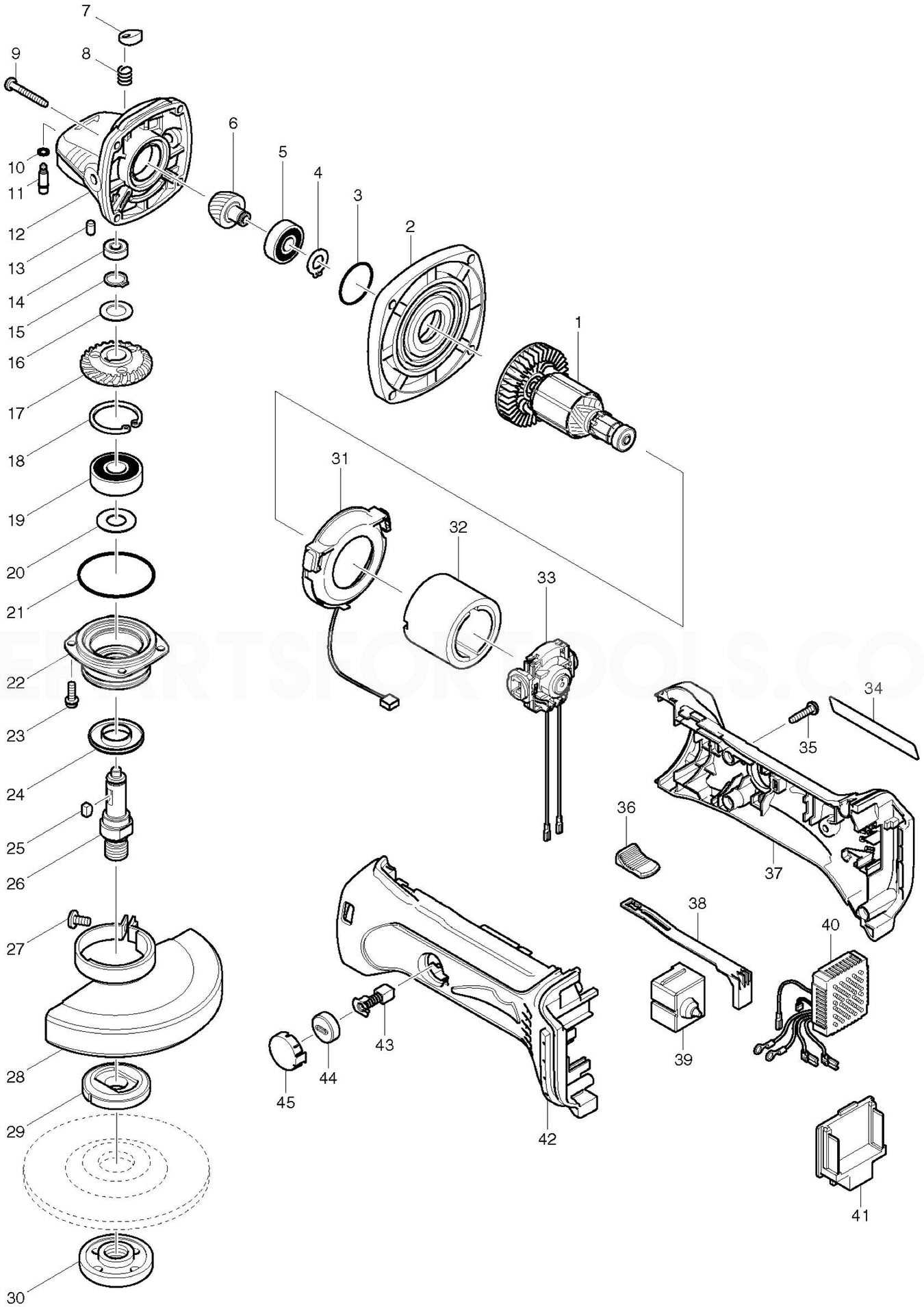

How to Read Parts Diagrams

Understanding assembly illustrations is crucial for anyone looking to repair or maintain equipment. These visual aids provide a detailed view of components and their arrangement, making it easier to identify what you need for repairs or replacements.

Here are some key steps to effectively interpret these illustrations:

- Familiarize Yourself with Symbols:

- Each symbol represents a specific component. Take time to learn what each symbol means.

- Look for a legend or key that explains the symbols used in the illustration.

- Understand the Layout:

- Components are often grouped logically. Identifying sections can simplify your search.

- Pay attention to the orientation; it can indicate how parts fit together.

- Check for Item Numbers:

- Each part typically has a unique identifier. Use this number to find the exact replacement.

- Cross-reference with a catalog or inventory list for availability.

- Look for Notes:

- Additional information may be provided, including installation tips or compatibility details.

- Read through any highlighted sections that indicate special instructions.

By following these guidelines, you can effectively navigate assembly illustrations, ensuring you have the necessary information for your repair or maintenance tasks.

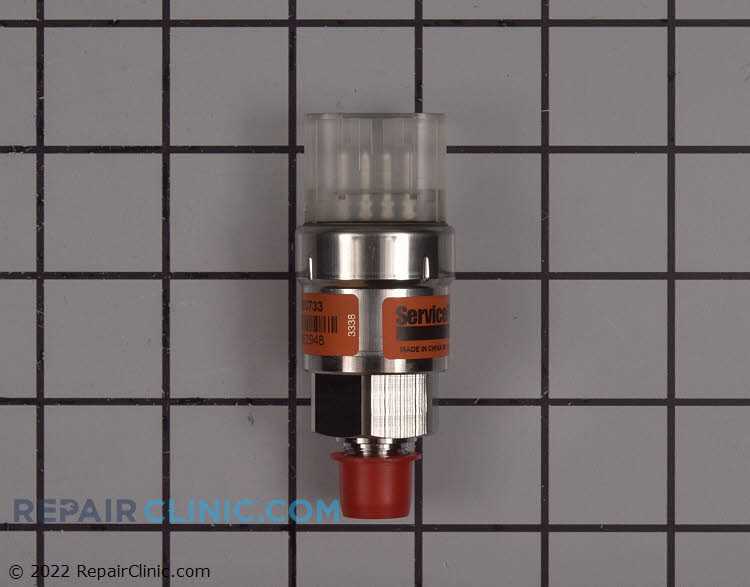

Where to Find Replacement Parts

Locating components for your tools can be essential for maintaining performance and extending their lifespan. Fortunately, there are several reliable sources to explore when searching for suitable replacements. These options range from online platforms to local retailers, ensuring you can find exactly what you need.

Online Resources

- Manufacturer’s Website: The official site often provides a comprehensive catalog of available components along with ordering options.

- Authorized Dealers: Many certified retailers offer an array of original items, ensuring compatibility and quality.

- E-commerce Platforms: Websites like Amazon, eBay, and specialized tool retailers often stock a variety of compatible components.

- Forums and Community Groups: Online communities focused on tool maintenance can offer advice and sources for hard-to-find items.

Local Options

- Hardware Stores: Many local shops carry a selection of parts or can order them for you.

- Repair Shops: Professionals often have access to components and can assist in sourcing them for you.

- Trade Shows: These events can be a great opportunity to find various suppliers and learn about new products.

Maintenance Tips for BHP452

Proper upkeep is essential for ensuring the longevity and efficiency of your power tool. Regular attention can prevent wear and tear, enhancing performance and reducing the likelihood of breakdowns. Implementing a consistent maintenance routine will allow you to get the most out of your equipment.

Start by regularly inspecting the device for any signs of damage or wear. Check the housing for cracks and ensure that all moving parts are functioning smoothly. Cleaning the exterior and interior components will help maintain optimal operation and prevent debris from affecting performance.

Lubrication is crucial; apply the appropriate oil to moving parts to minimize friction and heat buildup. Be sure to replace any worn-out components promptly to avoid further damage. Regularly check the battery and charging system to ensure efficiency and longevity.

Finally, consult the manufacturer’s guidelines for specific maintenance recommendations. Keeping a detailed log of maintenance activities will help you track performance and anticipate future needs. By prioritizing these practices, you can maximize the lifespan and effectiveness of your tool.

Upgrading Your Makita Drill

Enhancing your power tool can significantly improve its performance and extend its lifespan. By focusing on key components, you can achieve better efficiency and functionality. Whether you’re looking to boost power, increase versatility, or improve user comfort, targeted upgrades can make a noticeable difference in your projects.

Consider replacing the battery with a higher-capacity option to extend runtime and enhance productivity. Additionally, upgrading the chuck can facilitate quicker bit changes and provide a more secure grip. Investing in quality drill bits tailored for specific materials can also yield superior results and smoother operation.

Finally, ergonomic grips and accessories can improve handling and reduce fatigue during extended use. By strategically enhancing your tool, you can unlock its full potential and elevate your work quality.

Customer Support for Makita Users

Ensuring customer satisfaction is paramount for any brand, especially for those offering power tools and equipment. A robust support system not only aids in resolving issues but also enhances the overall experience of users. This section highlights various ways in which customers can receive assistance and information about their tools.

Support Channels Available

- Official Website: Access a wealth of information including manuals, FAQs, and troubleshooting guides.

- Customer Service Hotline: Speak directly with a representative to resolve specific issues or inquiries.

- Email Support: Reach out for assistance through detailed queries for a prompt response.

- Live Chat: Utilize real-time chat options for immediate assistance.

Additional Resources

- Online Community Forums: Engage with fellow users for tips, advice, and shared experiences.

- Instructional Videos: Explore video tutorials that provide step-by-step guidance on various tools.

- Service Centers: Locate authorized service locations for repairs and maintenance.

- Social Media: Follow official channels for updates, promotions, and customer interaction.

DIY Repairs for Makita Tools

Repairing power tools can be a rewarding experience, allowing users to save money and extend the lifespan of their equipment. Whether it’s a battery-operated drill or a corded saw, understanding common issues and how to address them can enhance your DIY skills and keep your tools in optimal condition.

Before starting any repair, it’s essential to gather the necessary tools and materials. Here are some general steps to follow:

- Identify the problem: Listen for unusual noises or check for performance issues.

- Consult the manual: Refer to the user guide for troubleshooting tips and safety precautions.

- Gather tools: Basic items like screwdrivers, pliers, and wrenches may be needed.

Common repairs can include:

- Replacing worn brushes

- Fixing electrical connections

- Cleaning and lubricating moving parts

- Changing out faulty switches

Always prioritize safety. Unplug tools before starting repairs and wear appropriate protective gear. If unsure about a repair, consulting a professional or seeking guidance from online resources can be beneficial.