Massey Ferguson 10 Baler Parts Diagram Overview

The intricate workings of agricultural equipment are fundamental to efficient farming operations. A comprehensive understanding of the various elements that contribute to the performance of these machines can enhance productivity and reduce downtime. This section will delve into the essential components of a specific type of harvesting equipment, providing valuable insights for operators and technicians alike.

When examining the functionality of such machinery, it is crucial to recognize how each element interacts within the system. Identifying the roles of individual pieces can facilitate better maintenance practices and troubleshooting techniques. Moreover, gaining familiarity with these components can lead to improved operational efficiency and longevity of the equipment.

By exploring the layout and relationships among the different elements, users can develop a more profound appreciation for the engineering behind these tools. This exploration not only aids in routine upkeep but also empowers operators to make informed decisions regarding repairs and replacements, ensuring that their agricultural tasks are carried out smoothly and effectively.

Massey Ferguson Baler Overview

This section provides an in-depth look at the essential machinery used in agricultural practices. Designed for efficiency, this equipment plays a crucial role in the harvesting process, helping farmers manage and store crops effectively.

Understanding the functionality and components of such machinery is vital for optimizing performance. Here are some key features:

- Efficiency: Streamlined processes reduce time and labor costs.

- Durability: Built to withstand harsh conditions and heavy use.

- Versatility: Suitable for various types of crops and terrains.

Regular maintenance and familiarity with the machine’s construction can significantly enhance productivity. Key areas of focus include:

- Operational Mechanisms: Understanding how each component works together is essential for seamless operation.

- Maintenance Routines: Regular checks and servicing prevent breakdowns and extend lifespan.

- Adaptability: Knowing how to adjust settings for different crops can lead to better results.

In conclusion, effective utilization of this machinery can lead to improved crop management and enhanced agricultural output.

Importance of Baler Maintenance

Regular upkeep of agricultural machinery is essential for ensuring optimal performance and longevity. Neglecting maintenance can lead to various issues that not only affect productivity but also increase operational costs. Understanding the significance of maintaining this equipment can help operators make informed decisions and implement effective strategies.

Benefits of Regular Maintenance

- Increased Efficiency: Well-maintained machinery operates smoothly, allowing for faster and more efficient processing.

- Extended Lifespan: Routine checks and repairs can significantly prolong the life of equipment, reducing the need for costly replacements.

- Safety: Regular inspections help identify potential hazards, ensuring a safer working environment for operators.

- Cost Savings: Preventive maintenance can minimize unexpected breakdowns, ultimately saving money in repairs and downtime.

Key Maintenance Practices

- Regularly check and replace worn components to prevent further damage.

- Keep machinery clean to avoid build-up that can impede performance.

- Lubricate moving parts according to manufacturer guidelines.

- Monitor and adjust tension settings to ensure optimal operation.

By prioritizing the care of agricultural equipment, operators can enjoy improved functionality, enhanced safety, and increased profitability, making maintenance a vital aspect of farm management.

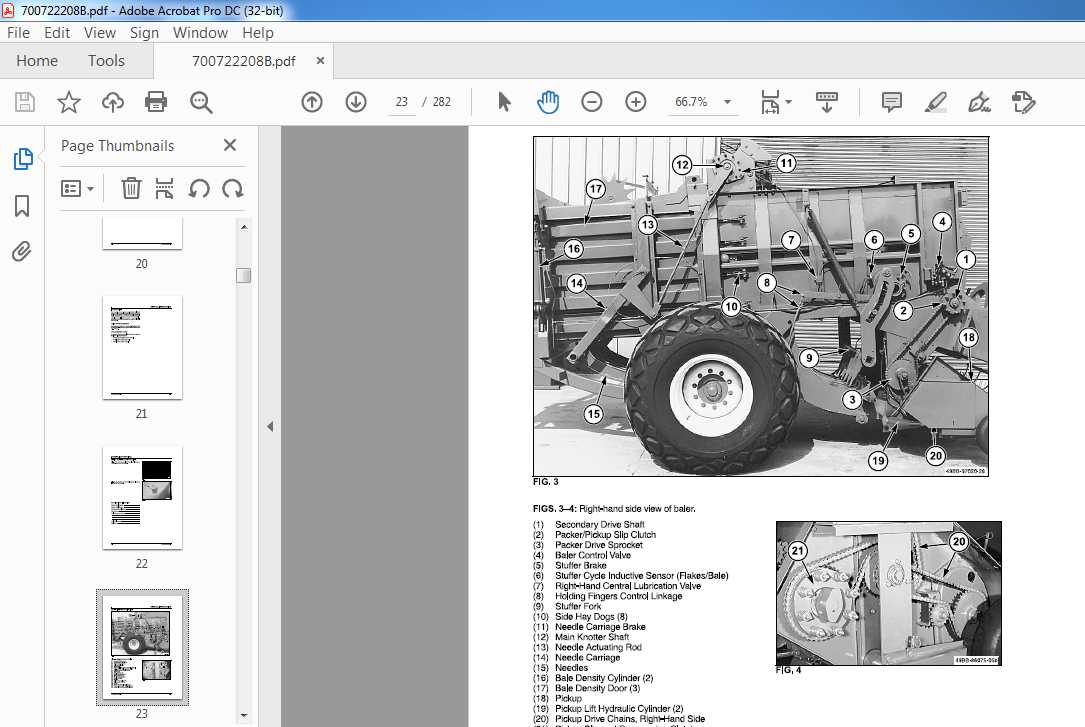

Common Parts of Massey Ferguson Baler

Understanding the essential components of agricultural machinery is crucial for effective operation and maintenance. Each element plays a significant role in the overall functionality, ensuring efficiency during harvesting and processing. Below, we explore the vital elements that contribute to the performance of this type of equipment.

Key Components

One of the primary elements is the cutter bar, responsible for slicing through crops, allowing for a clean and efficient harvest. The feed mechanism follows, guiding the material into the machine for processing. Additionally, the compression chamber plays a critical role in shaping the collected material into compact units, enhancing ease of handling and storage.

Additional Features

Another important feature is the twine system, which secures the formed units, ensuring they maintain their shape during transport. Furthermore, the drive system provides the necessary power to operate all moving parts, making it an essential aspect of the overall design. Understanding these components can significantly aid in maintenance and troubleshooting, leading to improved productivity on the farm.

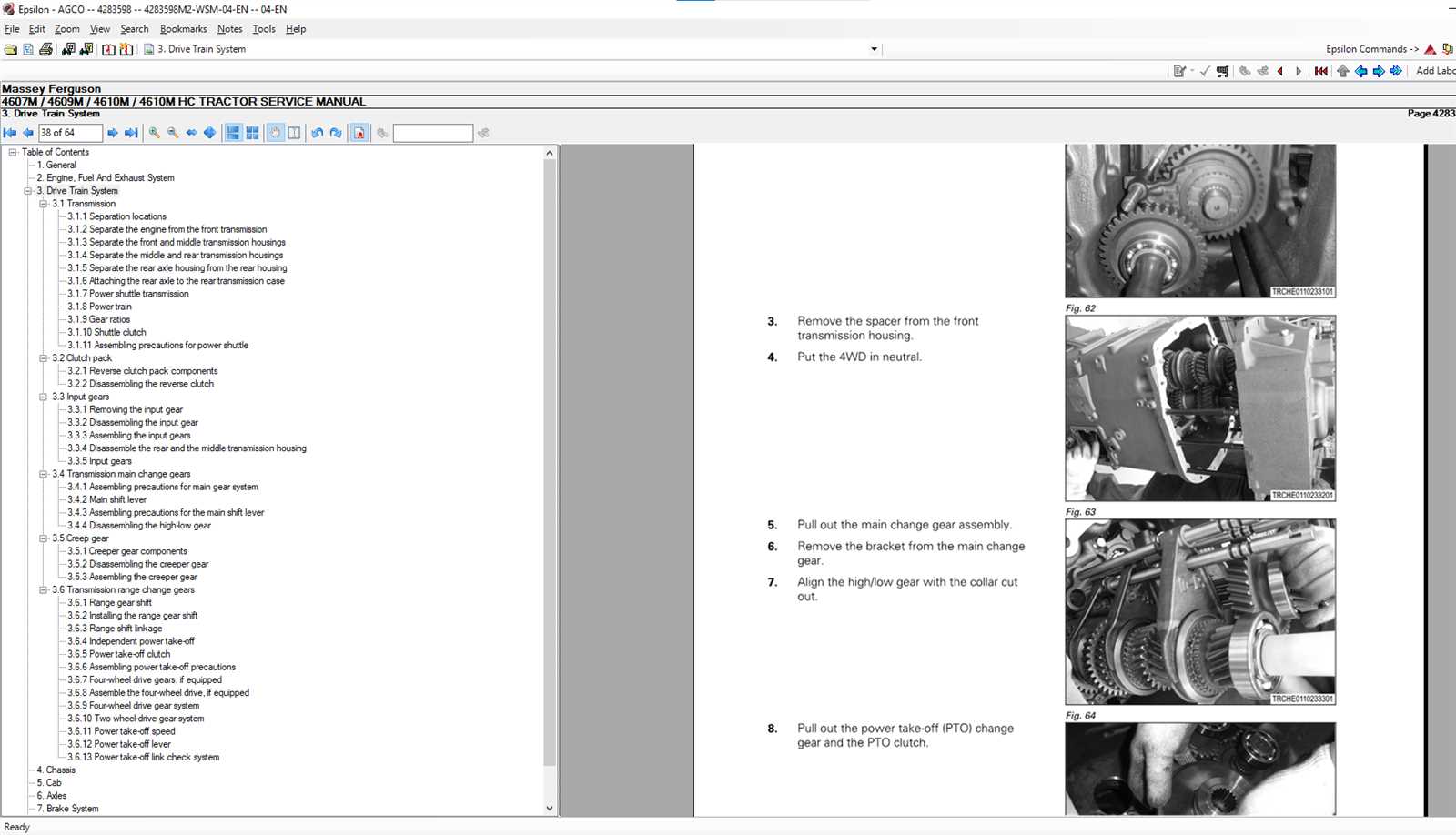

Understanding Baler Parts Functionality

Efficient agricultural machinery relies on various components that work in harmony to achieve optimal performance. Each element plays a specific role in the overall operation, contributing to the seamless processing of materials. Understanding these functionalities is crucial for maintenance and troubleshooting.

Key Components and Their Roles

- Chamber: This is where the compression of material occurs, creating bales of consistent size and density.

- Feed System: Responsible for guiding the materials into the chamber, ensuring a steady flow for effective processing.

- Knives: Essential for cutting and shredding the material, allowing for better compaction within the chamber.

- Wrapping Mechanism: This element secures the finished product, often using twine or netting to keep bales intact.

- Drive System: Powers the entire machine, coordinating the movement of all components for synchronized operation.

Importance of Maintenance

Regular upkeep of each component ensures longevity and efficiency. Neglecting any part can lead to diminished performance or even complete breakdowns. Key maintenance practices include:

- Regularly inspecting and lubricating moving parts.

- Checking for wear and tear on knives and other critical elements.

- Ensuring proper alignment of the feed system for optimal material flow.

- Cleaning the chamber to prevent buildup that could hinder operation.

By understanding the specific functionalities and maintaining each component, operators can enhance the reliability and effectiveness of their agricultural machinery.

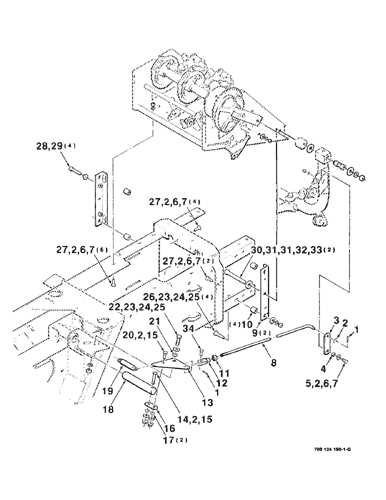

How to Read a Parts Diagram

Understanding a visual representation of components can significantly enhance your ability to repair or maintain machinery. This guide aims to equip you with the knowledge needed to interpret these illustrations effectively, making it easier to identify the necessary elements for your task.

To begin, familiarize yourself with the common features of such illustrations:

- Numbering System: Each item is usually labeled with a unique identifier. These numbers correspond to a list that provides further details.

- Legends and Symbols: Often, there will be a key explaining any symbols used in the representation. Understanding these is crucial for accurate interpretation.

- Views: Components may be shown from different angles. Pay attention to how items are presented, as this can provide insights into their function and orientation.

When analyzing the illustration, follow these steps:

- Identify Components: Start by locating the main elements you need. Use the identifiers to cross-reference with the accompanying list.

- Note Interconnections: Observe how different components are linked. Understanding their relationships can assist in troubleshooting issues.

- Check Compatibility: Ensure that the components you are examining match your specific model or version, as variations may exist.

By mastering the art of reading these visual aids, you will improve your efficiency in handling repairs and maintenance tasks, ensuring a smoother workflow.

Replacing Worn-Out Components

Regular maintenance of agricultural machinery is essential for ensuring optimal performance and longevity. Over time, various elements of your equipment may experience wear and tear, leading to decreased efficiency. Identifying and replacing these components in a timely manner can prevent more significant issues and enhance overall functionality.

When considering the replacement of aging parts, it’s crucial to follow a systematic approach:

- Inspection: Regularly examine your equipment for signs of wear, including cracks, corrosion, or abnormal noises.

- Documentation: Keep records of the condition of each component to identify patterns of wear over time.

- Replacement Schedule: Establish a routine schedule for replacements based on usage and wear rates.

Common components that often require replacement include:

- Belts and Chains: Check for fraying or stretching.

- Bearings: Listen for grinding noises indicating failure.

- Blades: Ensure they are sharp and free from chips.

Investing in high-quality replacements and adhering to a maintenance schedule will ensure your machinery operates efficiently, minimizing downtime and maximizing productivity.

Safety Tips for Baler Operation

Ensuring a safe working environment while operating agricultural machinery is crucial for the well-being of all personnel involved. Proper safety measures not only protect the operator but also minimize the risk of accidents that can affect bystanders and equipment. This section outlines essential guidelines to follow for secure and effective machinery use.

Pre-Operation Checks

Before starting any equipment, it is vital to conduct thorough inspections. Check for any signs of wear, damage, or loose components. Ensure that safety guards are in place and functioning properly. Additionally, confirm that the area is clear of obstacles and personnel to avoid any unforeseen hazards.

Operational Guidelines

During operation, always adhere to established safety protocols. Maintain a safe distance from moving parts, and avoid wearing loose clothing that could become entangled. Operators should also be aware of their surroundings and ensure proper communication with team members. In case of an emergency, knowing how to quickly shut down the machine can prevent serious injuries.

Remember: Safety is a continuous commitment that requires vigilance and adherence to established practices.

Diagnosing Common Baler Issues

Understanding and resolving frequent problems with harvesting equipment is crucial for maintaining efficiency in the field. This section focuses on identifying typical malfunctions, their potential causes, and suggested solutions. Recognizing symptoms early can prevent further damage and costly repairs, ensuring smooth operation throughout the season.

Common Symptoms and Causes

| Symptom | Possible Causes | Suggested Solutions |

|---|---|---|

| Jamming | Overloading, worn-out components, or improper feeding | Reduce load, inspect and replace worn parts, adjust feed rate |

| Poor Bale Density | Incorrect tension settings or damaged rollers | Adjust tension settings, check and repair roller surfaces |

| Unusual Noises | Lack of lubrication or misalignment | Lubricate moving parts, realign components as needed |

| Inconsistent Bale Size | Faulty sensors or mechanical issues | Test and replace sensors, inspect mechanical linkages |

Preventive Maintenance Tips

Regular maintenance is key to avoiding unexpected failures. Schedule routine inspections, lubricate moving parts, and keep an eye on wear indicators. By taking proactive steps, operators can extend the lifespan of their equipment and improve overall performance.

Upgrades for Improved Baler Performance

Enhancing the efficiency and functionality of your agricultural equipment can significantly boost productivity and reduce downtime. Investing in modern improvements not only optimizes performance but also extends the lifespan of your machinery. Here are some key upgrades to consider for better results in the field.

1. Enhanced Cutting Mechanisms

Upgrading to sharper, more durable cutting blades can improve the quality of the harvested material. High-carbon steel or hardened alloys are excellent choices that maintain their edge longer, ensuring cleaner cuts and less strain on the entire system.

2. Advanced Control Systems

Implementing digital control systems can allow for precise adjustments and monitoring during operation. Features like automatic tensioning and moisture sensors can help in adapting to varying conditions, resulting in optimal processing and better quality output.

Resources for Parts and Repair

Maintaining and restoring agricultural machinery requires access to reliable resources that provide essential components and guidance. These tools and materials play a vital role in ensuring that equipment operates efficiently and effectively, minimizing downtime during critical farming seasons.

Online marketplaces and specialized retailers offer a wide array of components, catering to both original and aftermarket needs. Many platforms feature user-friendly interfaces that allow for easy searching by model or part number, ensuring that users can quickly find what they need. Additionally, forums and community groups often serve as invaluable resources for sharing tips, troubleshooting advice, and recommendations on suppliers.

For those looking to undertake repairs themselves, instructional videos and manuals can be incredibly helpful. Numerous websites host detailed guides that break down the repair process into manageable steps, enabling even novice users to tackle complex tasks with confidence. Furthermore, local workshops and repair services can provide professional assistance when needed, ensuring that machinery remains in top condition.

In summary, accessing the right resources for component acquisition and maintenance is crucial for anyone involved in agricultural operations. Utilizing a combination of online tools, community support, and professional services can significantly enhance the longevity and performance of essential equipment.