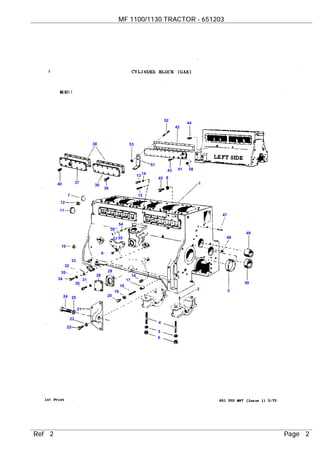

Massey Ferguson 1100 Parts Diagram Overview

In the realm of agricultural equipment, a thorough comprehension of the various components is essential for efficient operation and maintenance. By delving into the intricate layout of machinery, operators can ensure optimal performance and longevity. This section aims to illuminate the intricacies involved in recognizing and understanding essential elements within a specific model.

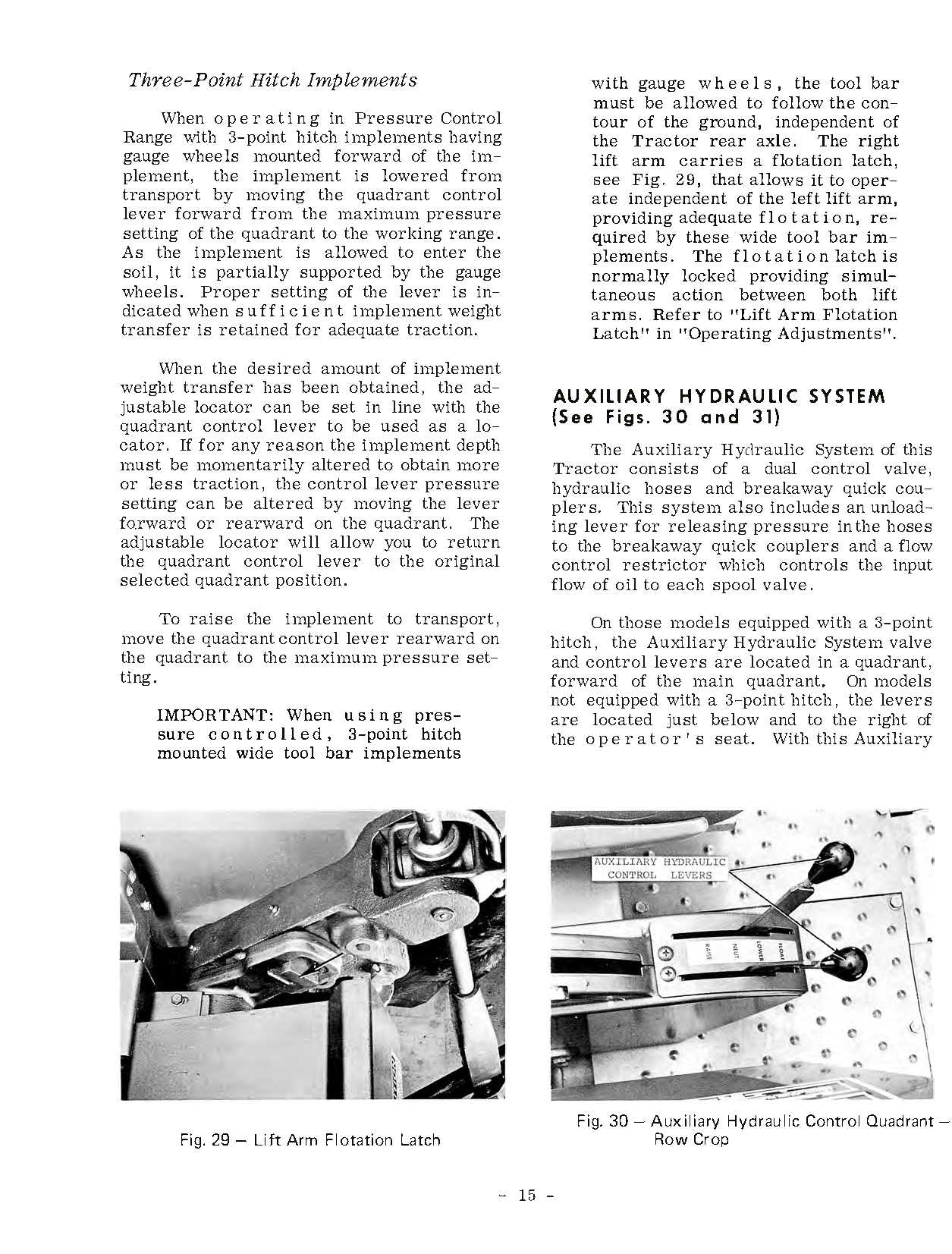

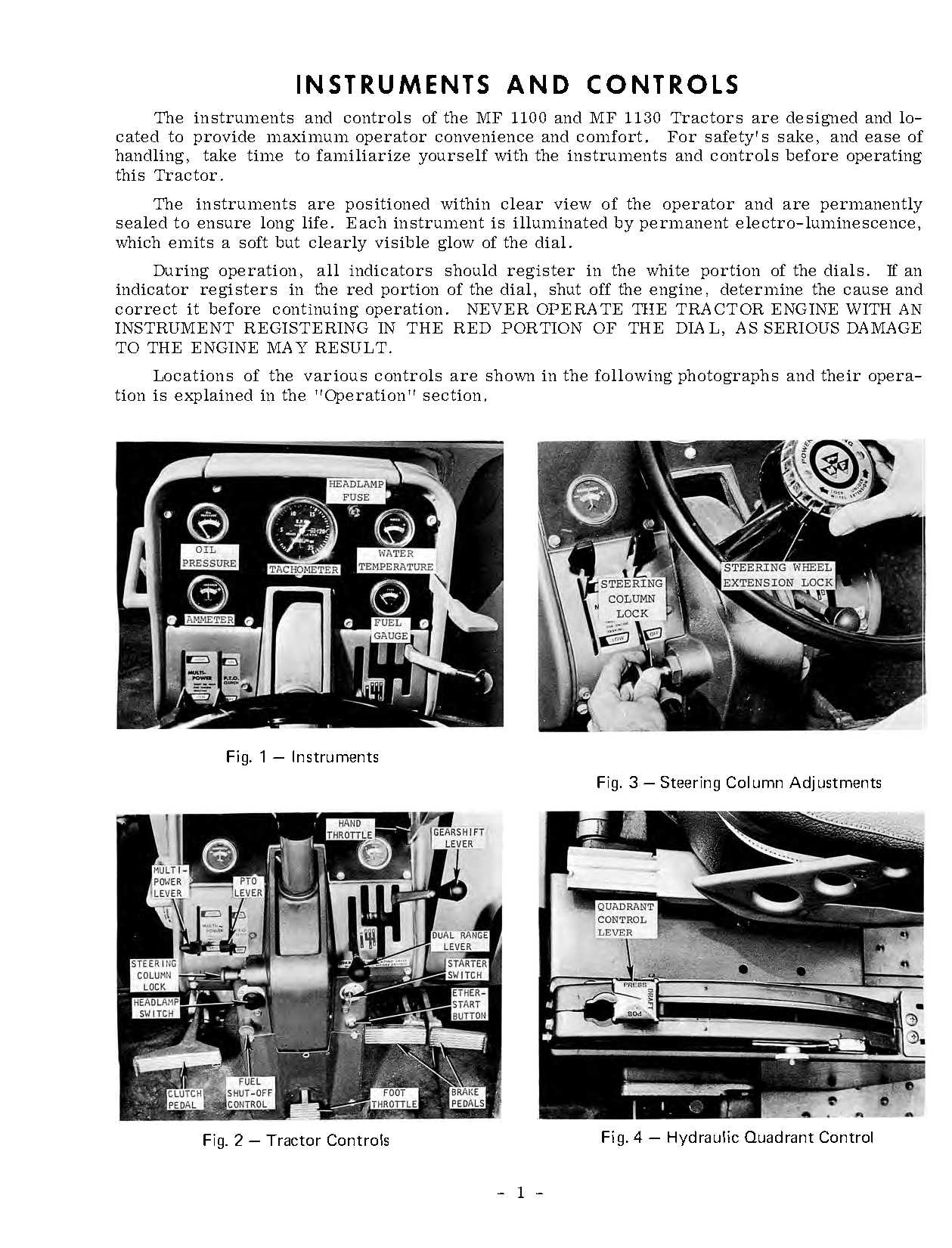

Visual aids serve as invaluable tools for technicians and enthusiasts alike, allowing for quick identification and troubleshooting. An organized representation of machine components not only simplifies the repair process but also enhances overall knowledge of the equipment’s functionality. By examining these detailed illustrations, one can gain insights into the assembly and relationships between different parts.

Moreover, familiarizing oneself with these schematics can lead to more informed decisions regarding repairs and upgrades. Understanding how each element interacts contributes to a deeper appreciation of the machinery’s engineering. Thus, a comprehensive overview of the structural elements becomes indispensable for anyone involved in agricultural operations.

Massey Ferguson 1100 Overview

This section provides a comprehensive understanding of a renowned agricultural machine designed for efficiency and reliability. Known for its robust construction and advanced features, this model has become a staple in the farming community, enabling operators to tackle a wide range of tasks with ease.

Equipped with a powerful engine, the vehicle ensures optimal performance even in challenging conditions. Its user-friendly interface allows for seamless operation, making it accessible for both seasoned professionals and newcomers in the field.

Additionally, the design emphasizes durability, with high-quality materials that withstand the rigors of daily use. This aspect not only extends the lifespan of the equipment but also reduces maintenance needs, ensuring that users can focus on their agricultural activities without interruption.

Moreover, the versatility of this machinery is noteworthy. It can be fitted with various attachments, allowing it to perform multiple functions, from plowing to harvesting. This adaptability makes it a valuable investment for any farming operation.

Overall, this agricultural powerhouse represents a perfect blend of innovation and tradition, contributing significantly to enhancing productivity on farms worldwide.

Importance of Parts Diagrams

Visual representations of components play a crucial role in the maintenance and repair of machinery. These illustrations serve as essential tools for understanding the assembly and functionality of various elements within a system. They enable users to identify individual parts, ensuring accurate replacements and repairs.

Furthermore, such visual aids streamline the troubleshooting process. When an issue arises, technicians can quickly reference these images to locate the faulty section, saving valuable time and reducing frustration. The clarity provided by these resources enhances overall efficiency in both professional and DIY settings.

| Benefits | Description |

|---|---|

| Clarity | Offers a clear view of how components fit together. |

| Efficiency | Speeds up the identification and replacement of faulty elements. |

| Training | Assists in educating new technicians on assembly processes. |

| Accuracy | Ensures precise alignment during repairs. |

Common Issues with Massey Ferguson 1100

Understanding the frequent challenges encountered with agricultural machinery can significantly enhance performance and longevity. Operators often face various mechanical and operational difficulties that may arise from wear and tear, maintenance neglect, or environmental factors. Addressing these issues promptly can help maintain optimal functionality and reduce downtime.

Mechanical Failures

One of the primary concerns involves mechanical breakdowns. Components such as the engine, transmission, and hydraulic systems are subject to fatigue and may require regular inspections. Signs of wear can manifest as unusual noises, leaks, or decreased power output.

Electrical Problems

Electrical malfunctions are another common issue. Faulty wiring, corroded connections, or failing batteries can lead to starting difficulties or erratic behavior of electronic systems. Regular checks and timely replacements are essential to avoid disruptions in operation.

| Issue Type | Description | Solution |

|---|---|---|

| Mechanical | Engine or transmission failure. | Regular maintenance and inspections. |

| Electrical | Starting difficulties due to wiring issues. | Inspect and replace corroded connections. |

| Hydraulic | Leakage or loss of pressure. | Check seals and hoses for wear. |

Key Components of the 1100 Series

This section explores the essential elements that contribute to the functionality and performance of this series of agricultural machinery. Each component plays a crucial role in ensuring the overall efficiency and reliability of the equipment, making it vital for users to understand their significance.

Engine and Transmission

The heart of any agricultural vehicle lies in its engine and transmission system. The powertrain is designed to deliver optimal performance under various working conditions. Key features include:

| Component | Description |

|---|---|

| Engine | High-torque engine designed for robust performance. |

| Transmission | Advanced transmission system ensuring smooth power delivery. |

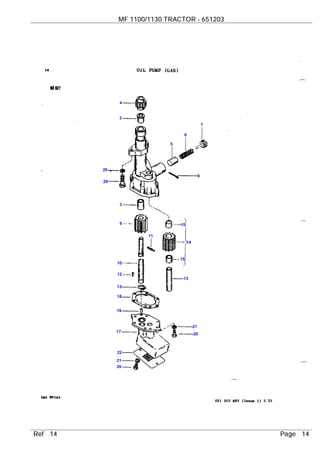

Hydraulic System

The hydraulic system enhances operational versatility, allowing for precise control over attachments and implements. Its design focuses on efficiency and responsiveness. Key aspects include:

| Component | Description |

|---|---|

| Hydraulic Pump | Delivers consistent hydraulic flow for effective operation. |

| Control Valves | Enable precise manipulation of hydraulic functions. |

Where to Find Parts Diagrams

Finding the right visual resources for machinery can greatly enhance the repair and maintenance process. Numerous platforms and tools are available to help users locate detailed illustrations that outline components and assemblies. Understanding where to look can save time and ensure that tasks are completed efficiently.

Here are some of the best sources to explore:

| Source | Description |

|---|---|

| Manufacturer Websites | Official sites often provide downloadable resources, including comprehensive visual guides and specifications. |

| Online Forums | Communities of enthusiasts and professionals share valuable insights, links, and even personal collections of visuals. |

| Retailer Catalogs | Authorized dealers frequently offer catalogs with illustrations that assist in identifying various components for purchase. |

| Technical Manuals | Service and repair manuals contain detailed drawings and are an excellent reference for assembly and disassembly procedures. |

| Third-Party Websites | Various websites specialize in aftermarket parts and often include detailed visuals for easier navigation and selection. |

Utilizing these resources will streamline the process of finding the necessary visual aids for machinery repair, ensuring a smoother experience for users at any skill level.

Understanding the Diagram Symbols

Interpreting visual representations of machinery components is essential for effective maintenance and repair. These illustrations employ a variety of symbols to convey complex information succinctly. Familiarity with these symbols enables users to navigate the technical details with greater ease, ensuring proper identification and understanding of each element involved.

Common Symbols and Their Meanings

- Circles: Typically represent connectors or junctions in a system.

- Arrows: Indicate the direction of fluid flow or movement.

- Squares: Often denote various types of components, such as valves or filters.

- Dashed Lines: Represent optional or alternate pathways in the layout.

Importance of Symbol Knowledge

Understanding these symbols not only facilitates efficient troubleshooting but also enhances safety during operations. Recognizing the various components helps technicians perform their tasks accurately, minimizing the risk of errors. Thus, a comprehensive grasp of the visual language used in technical illustrations is invaluable for anyone working with complex machinery.

Maintenance Tips for Massey Ferguson 1100

Regular upkeep is essential for ensuring the longevity and efficiency of agricultural machinery. By following a structured maintenance routine, operators can prevent costly repairs and enhance the performance of their equipment. This section offers practical advice on how to maintain your tractor effectively.

Routine Maintenance Checklist

| Task | Frequency |

|---|---|

| Check engine oil level | Daily |

| Inspect coolant level | Weekly |

| Clean air filter | Monthly |

| Check hydraulic fluid | Every 50 hours |

| Inspect belts and hoses | Every 100 hours |

| Replace fuel filter | Every 500 hours |

Seasonal Maintenance Tips

In addition to routine checks, specific tasks should be performed at the change of each season. Preparing machinery for extreme weather conditions can significantly enhance performance. Before winter, ensure that antifreeze levels are adequate and battery terminals are clean. Before spring planting, check tire pressure and inspect the tillage equipment for wear and tear.

Ordering Replacement Parts Online

In today’s digital age, acquiring components for machinery has become a streamlined process. With just a few clicks, operators can access a wide array of options to ensure their equipment runs smoothly. Understanding how to navigate online platforms can greatly enhance the efficiency of sourcing necessary items.

Here are some key steps to follow when purchasing components online:

- Research Suppliers: Identify reputable online retailers that specialize in machinery components. Look for reviews and ratings to ensure quality and reliability.

- Check Availability: Ensure the specific components you need are in stock. Some websites offer real-time inventory updates.

- Verify Compatibility: Use the model and serial numbers of your equipment to confirm that the components will fit correctly.

- Compare Prices: Shop around to find competitive pricing. Don’t forget to factor in shipping costs.

- Review Return Policies: Understand the return and exchange policies in case the items do not meet your expectations.

- Place Your Order: Once you’ve found the right components, proceed to checkout, ensuring all details are accurate before finalizing the purchase.

By following these steps, you can confidently navigate the online marketplace for your machinery needs, ensuring optimal performance and longevity of your equipment.

How to Read Parts Diagrams

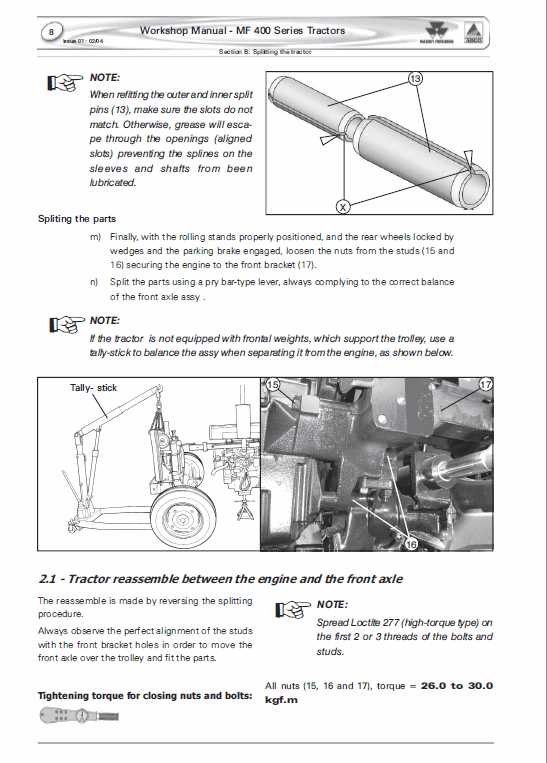

Understanding technical illustrations is crucial for effective maintenance and repairs. These visual aids simplify complex machinery, allowing users to identify components and their relationships. Mastering the interpretation of these visuals can greatly enhance your repair efficiency and accuracy.

Here are some key elements to consider when analyzing these illustrations:

- Symbols: Familiarize yourself with common icons that represent different elements. Each symbol typically has a specific meaning, such as electrical parts, fasteners, or hydraulic components.

- Numbering: Pay attention to the numbering system used in the illustration. Each part is usually labeled with a unique identifier that corresponds to a list, making it easier to locate items in catalogs or inventory.

- Sections: Diagrams may be divided into sections for clarity. Understanding how these sections relate to each other is essential for comprehensive understanding.

- Scale: Be aware of the scale used in the illustration. This can affect how you perceive the size and fit of each component, which is critical for accurate assembly or replacement.

- Orientation: Check the orientation of the parts. Some diagrams may present components from various angles, impacting how they fit together in real life.

By keeping these aspects in mind, you can effectively navigate technical illustrations, ensuring you can identify and order the right components for any repair task.

Popular Upgrades for the 1100 Model

Enhancing the performance and functionality of agricultural machinery can significantly improve efficiency and user experience. Various modifications can be made to optimize power, control, and overall durability. Below are some of the most sought-after enhancements that users commonly consider.

| Upgrade | Description |

|---|---|

| Improved Hydraulics | Upgrading the hydraulic system can increase lifting capacity and responsiveness, enabling better handling of attachments. |

| Enhanced Exhaust Systems | Installing a performance exhaust can improve engine efficiency and reduce emissions, leading to a cleaner operation. |

| Better Tires | Switching to high-traction tires can enhance grip and stability, particularly in challenging terrains. |

| Advanced Lighting | Adding LED work lights increases visibility during nighttime operations, ensuring safety and productivity. |

| Comfort Seats | Upgrading to ergonomic seating improves operator comfort, reducing fatigue during long hours of use. |

| GPS Guidance Systems | Integrating GPS technology assists with precise navigation and field mapping, optimizing workflow. |

| Performance Tuners | Utilizing tuners can enhance engine performance and fuel efficiency, maximizing power output. |

By investing in these upgrades, operators can significantly enhance the performance and longevity of their machinery, ensuring they remain competitive and efficient in their agricultural endeavors.