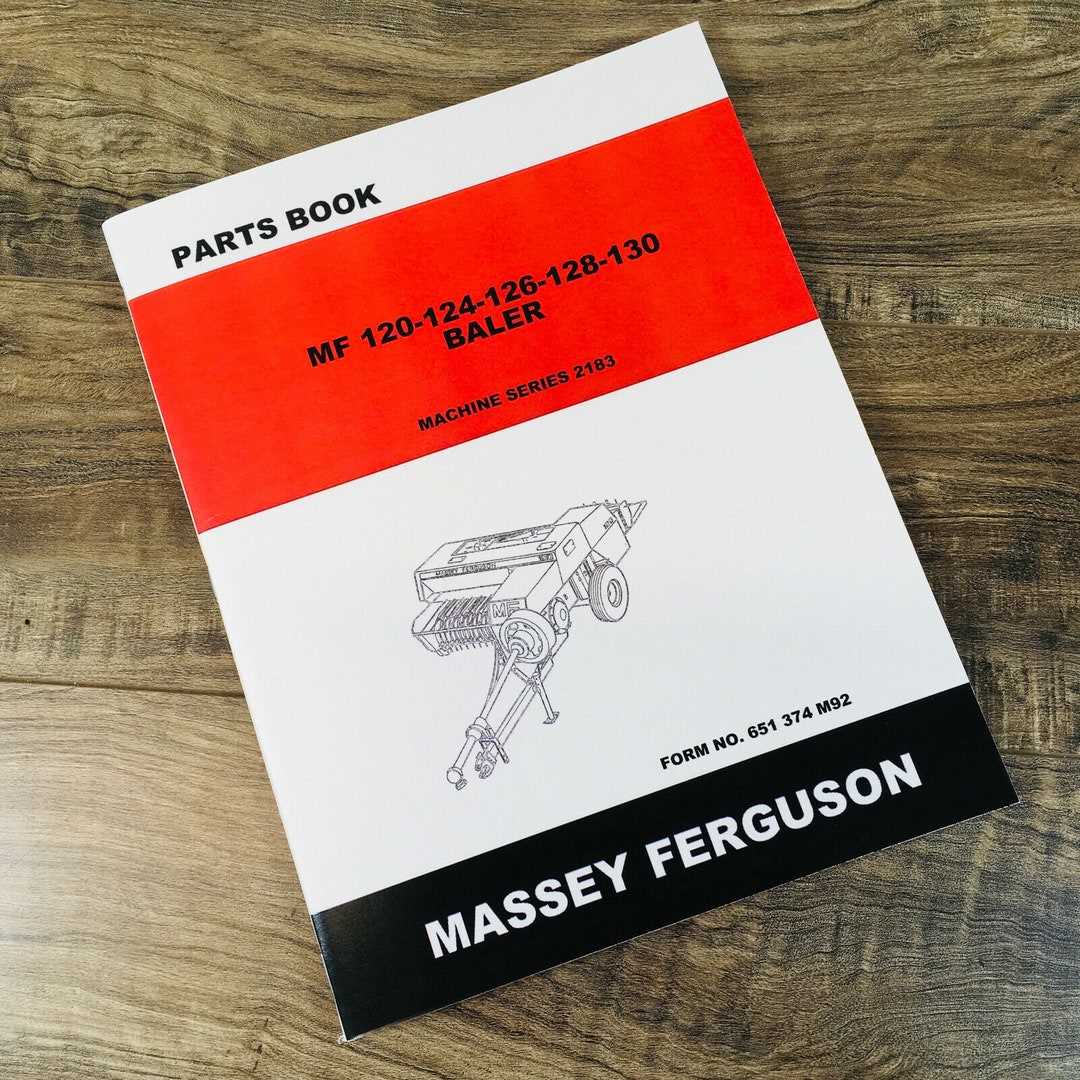

Massey Ferguson 128 Baler Parts Diagram Overview

In the world of farming machinery, having a clear understanding of how each element operates is crucial for maintaining efficiency and productivity. Every piece of equipment is made up of numerous intricate components that work together to perform specific tasks. Knowing the layout and function of these elements can significantly enhance troubleshooting and repair processes, ensuring that machinery runs smoothly throughout its lifecycle.

Visual aids, such as schematic representations, provide valuable insight into the configuration and interconnections of various parts. These illustrations not only help in identifying individual components but also facilitate a deeper comprehension of their roles within the larger system. Whether you’re a seasoned operator or new to agricultural tools, familiarizing yourself with these essential visuals can lead to more informed maintenance decisions.

Moreover, understanding the mechanical relationships between different parts can aid in diagnosing issues more effectively. When a machine malfunctions, having a reference to its structural layout can simplify the troubleshooting process. By equipping oneself with this knowledge, operators can ensure their equipment remains in optimal condition, thereby maximizing output and reducing downtime.

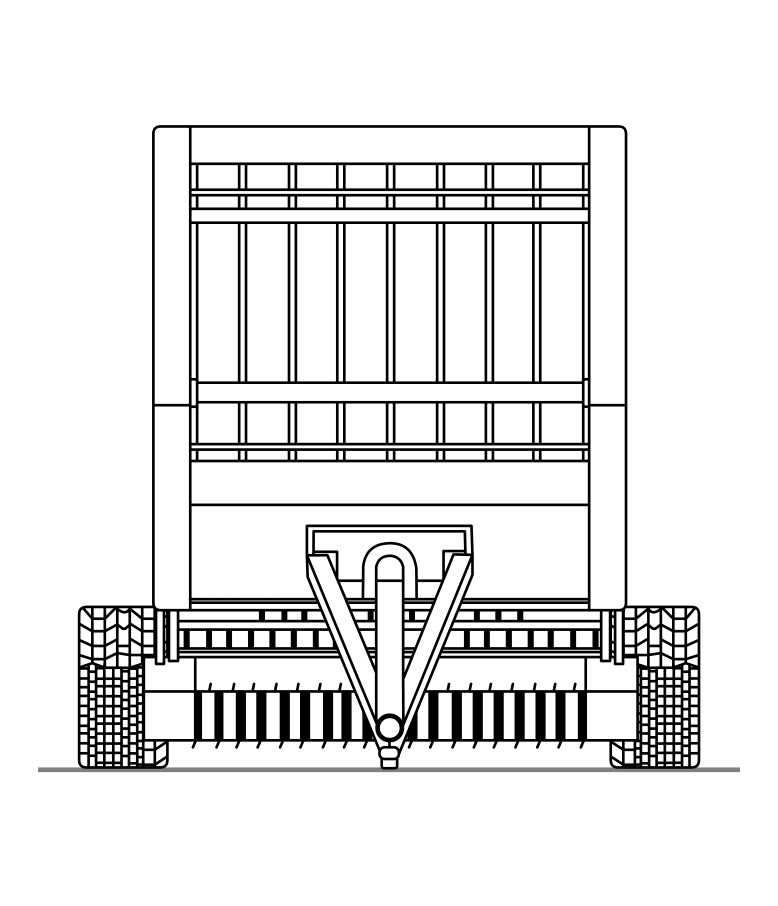

Massey Ferguson 128 Baler Overview

This section presents a comprehensive look at a widely recognized agricultural machine, known for its efficiency and reliability in the field. It is designed to streamline the process of collecting and compacting various types of forage and straw, making it an essential tool for modern farming practices.

Key Features

One of the standout characteristics of this machine is its robust construction, which ensures durability even under the most demanding conditions. Its innovative mechanisms allow for seamless operation, enhancing productivity while minimizing downtime. Additionally, the user-friendly interface enables operators to easily adjust settings to suit specific tasks, improving overall efficiency.

Applications and Benefits

The versatility of this implement makes it suitable for a variety of crops, from hay to silage. By effectively compressing materials into bales, it not only simplifies storage and transportation but also promotes better feed quality for livestock. The investment in such machinery ultimately supports sustainable farming practices, contributing to enhanced yield and profitability.

Key Features of the 128 Baler

This exceptional agricultural implement is designed to optimize the process of creating compact and manageable bundles of hay or straw. Its innovative engineering ensures efficiency and reliability, making it a favorite among farmers who prioritize productivity.

One of the standout characteristics is its high-capacity chamber, which allows for larger volumes to be processed in a shorter timeframe. This feature significantly reduces the time spent in the field, enabling operators to cover more ground swiftly.

Durability is another important aspect, as the equipment is constructed with robust materials that withstand the rigors of continuous use. This resilience ensures longevity, providing a solid return on investment for agricultural professionals.

Additionally, the user-friendly controls enhance operational ease, allowing for quick adjustments and minimal downtime. Operators can maintain optimal performance with less hassle, contributing to a smoother workflow.

Moreover, the adjustable settings cater to various crop types and conditions, offering versatility that adapts to different farming needs. This flexibility empowers users to achieve the best results regardless of the circumstances.

Finally, the overall design prioritizes maintenance simplicity, ensuring that routine checks and repairs can be conducted without excessive effort. This practicality helps keep the machine in peak condition, ensuring consistent output and performance.

Importance of Proper Maintenance

Ensuring the longevity and efficiency of agricultural machinery is crucial for optimal performance. Regular upkeep not only extends the lifespan of equipment but also enhances productivity and safety during operations. Neglecting maintenance can lead to unexpected breakdowns, costly repairs, and decreased output.

Adhering to a proper maintenance schedule offers several key benefits:

- Increased Reliability: Regular checks and repairs prevent sudden failures.

- Enhanced Performance: Well-maintained machinery operates more efficiently and effectively.

- Cost Savings: Preventive care reduces the likelihood of expensive emergency repairs.

- Safety Assurance: Regular inspections help identify potential hazards, protecting operators.

- Improved Resale Value: Well-maintained equipment retains its value better over time.

By investing time and resources in proper care, operators can ensure their machinery remains in peak condition, ultimately leading to better productivity and a more successful farming operation.

Common Issues with Baler Parts

When operating agricultural machinery, several challenges may arise related to various components. Understanding these common issues can enhance performance and reduce downtime. Identifying and addressing problems early can lead to more efficient operation and longevity of the equipment.

Wear and Tear

One of the most prevalent concerns is the natural deterioration of components over time. Friction and heavy loads can cause parts to wear out, leading to decreased efficiency and potential failure. Regular inspection and timely replacement are crucial to maintaining optimal functionality.

Clogging and Jamming

Another frequent issue involves blockages caused by material buildup. This can occur due to excessive moisture or improper loading techniques. Clearing jams promptly and ensuring materials are processed correctly can help prevent further complications and maintain smooth operation.

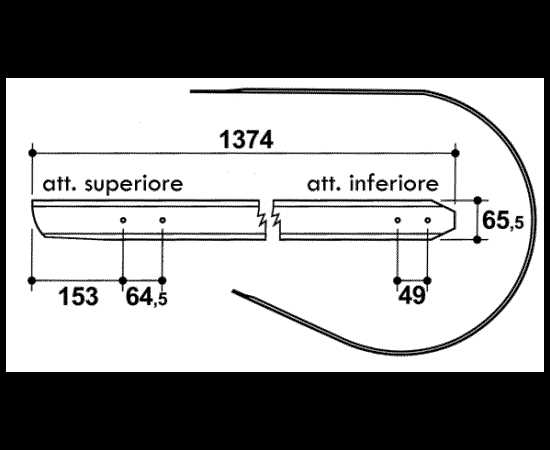

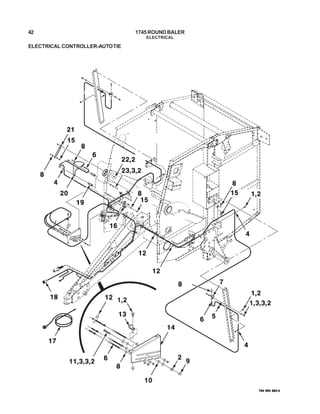

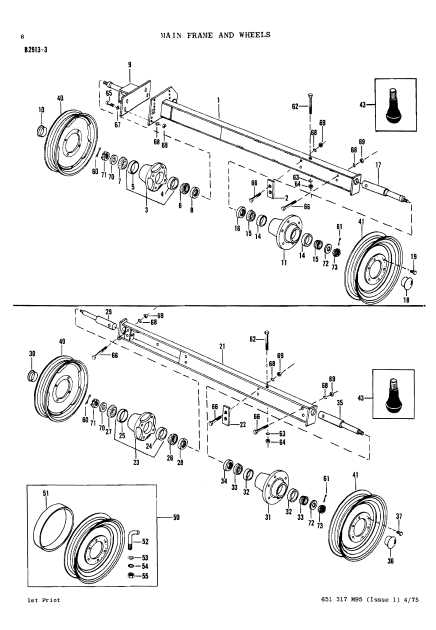

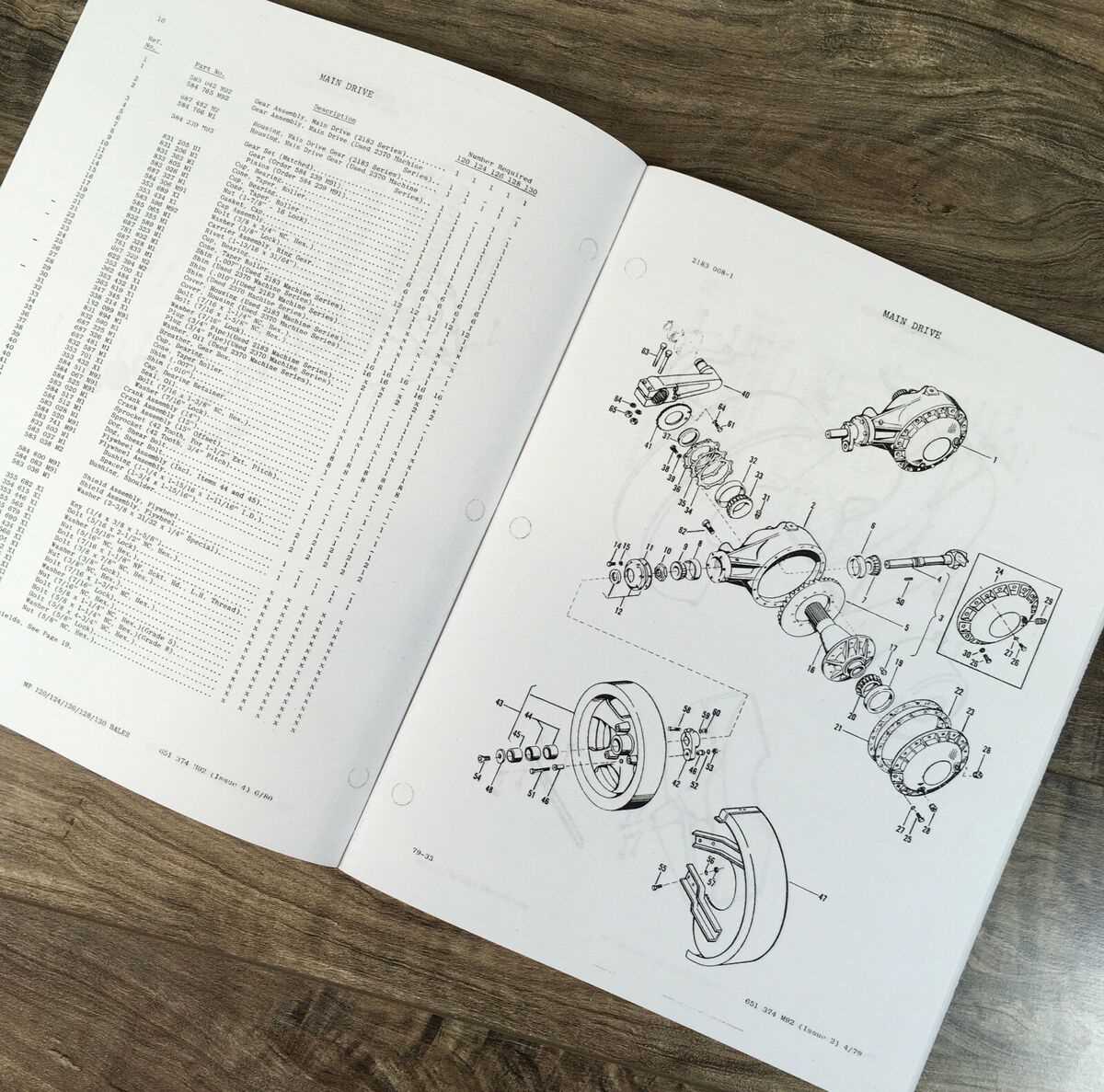

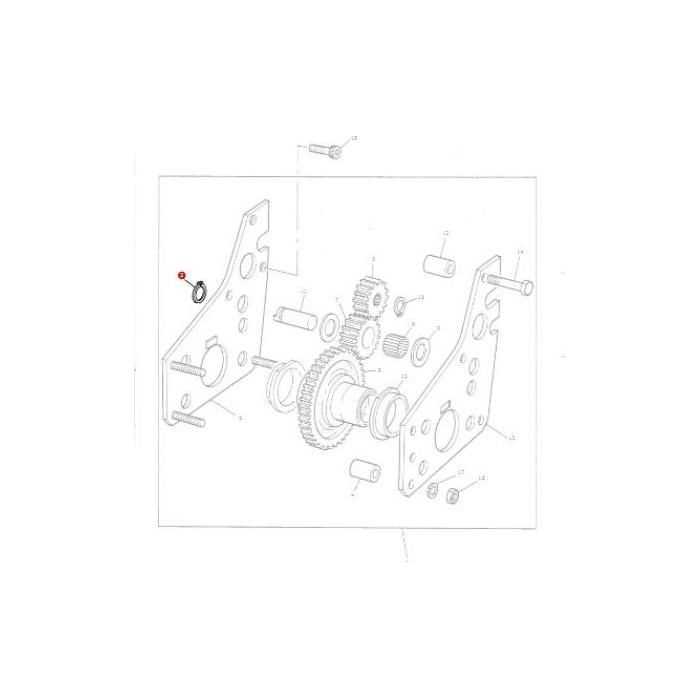

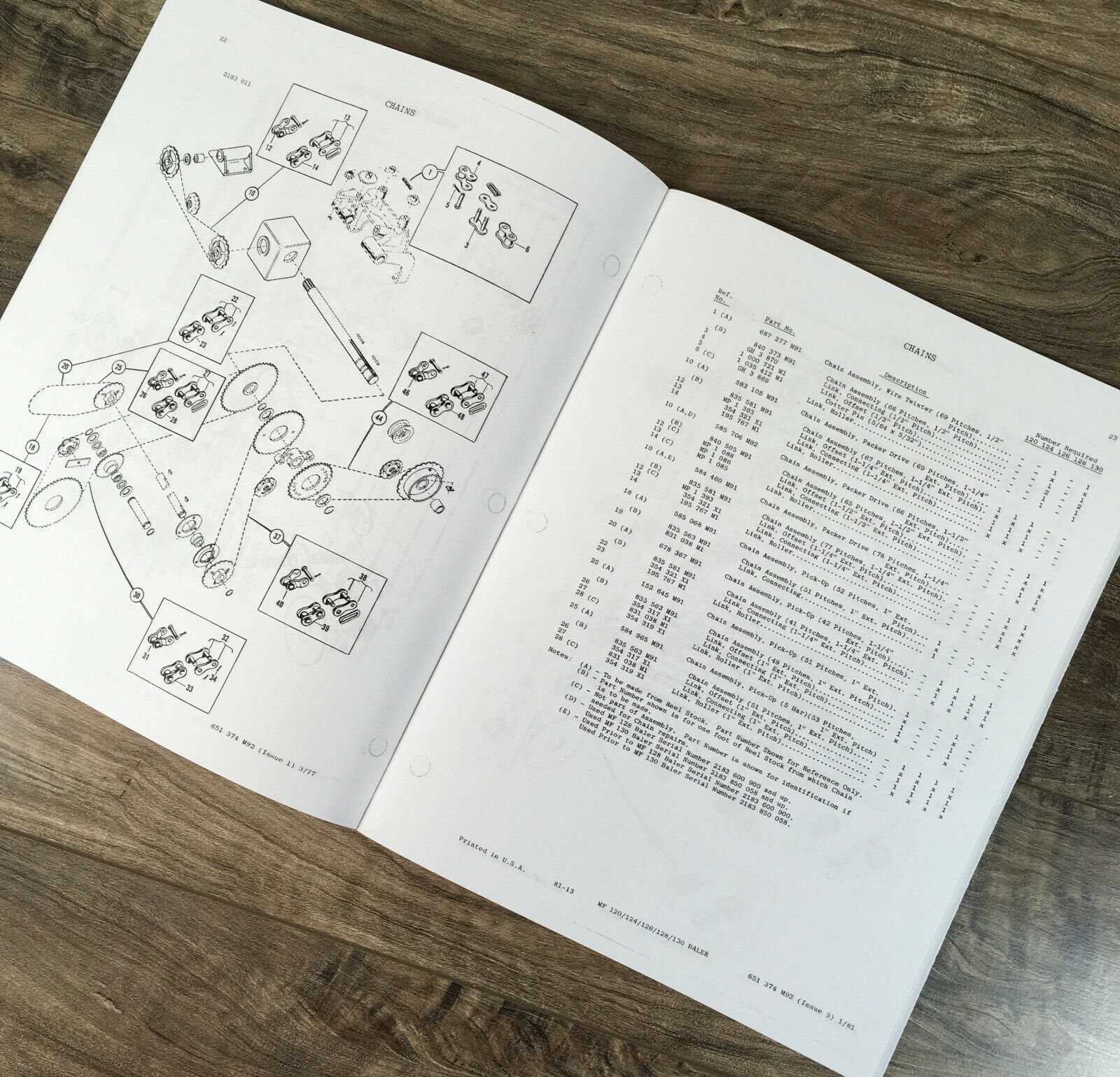

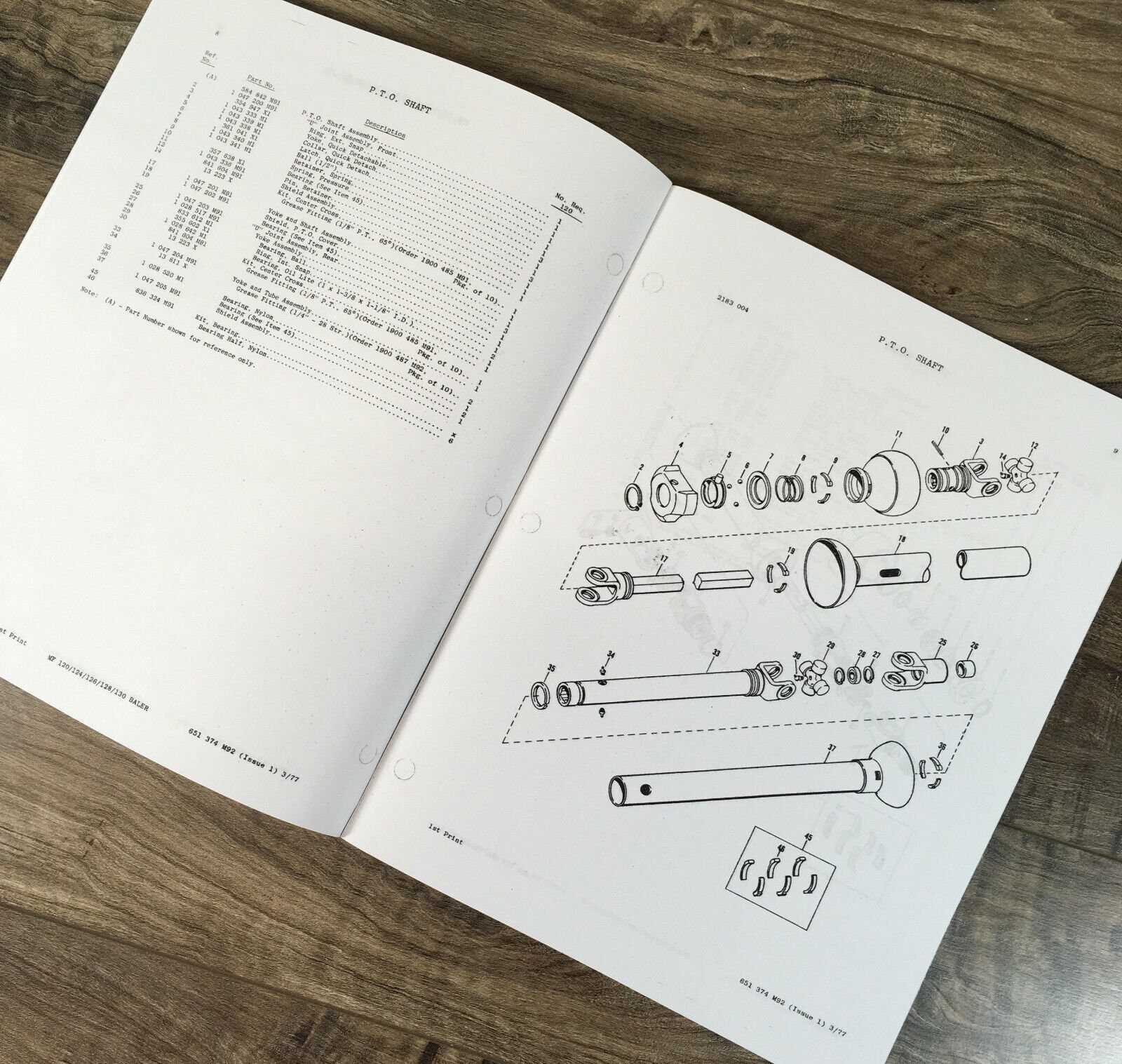

Understanding the Parts Diagram

Interpreting a schematic representation of machinery is essential for effective maintenance and repair. Such illustrations provide a visual guide to the various components, showcasing their arrangement and how they interact with one another. Grasping this visual language can greatly enhance one’s ability to troubleshoot and perform necessary upkeep.

Components Overview

A thorough examination of each element depicted in the illustration is crucial. Every component plays a significant role in the overall functionality of the equipment. By familiarizing oneself with the names and locations of these parts, operators can quickly identify potential issues and streamline their repair processes.

Benefits of Familiarity

Understanding the schematic not only aids in effective repairs but also empowers users to optimize performance. Knowledge of how components work together allows for better adjustments and enhancements, leading to improved efficiency and longevity of the machinery. This expertise fosters a proactive approach to maintenance, ultimately saving time and resources.

Where to Find Replacement Parts

Locating suitable components for agricultural machinery can be a crucial task for ensuring optimal performance and longevity. Fortunately, there are numerous avenues to explore when seeking high-quality replacements. From online marketplaces to specialized retailers, options abound to meet your specific needs.

Online Marketplaces are a popular choice for many. Websites such as eBay or Amazon offer a vast selection of equipment and accessories. Be sure to check seller ratings and reviews to ensure reliability and authenticity.

Local Dealers often provide an extensive inventory of necessary components. Building a relationship with your local supplier can also lead to better service and support when it comes to finding the right fit for your machinery.

Salvage Yards can be a treasure trove of usable items. Many operators find that second-hand components can be just as effective, and often at a fraction of the cost. Visiting these locations can yield unexpected finds.

Online Forums and Communities can also be beneficial. Engaging with other enthusiasts or professionals in these spaces can provide recommendations and insights into where to source parts efficiently.

Ultimately, being resourceful and exploring multiple channels can significantly enhance your chances of finding the exact components you require.

DIY Repair Tips for Owners

Maintaining agricultural machinery can be a rewarding endeavor, allowing owners to save money and gain valuable skills. Understanding the components of your equipment and how they work together is essential for effective upkeep. This section offers practical advice for those looking to tackle repairs themselves, ensuring their machines run smoothly and efficiently.

Essential Tools and Supplies

Before starting any maintenance or repair task, gather the necessary tools and materials. A basic toolkit should include wrenches, screwdrivers, pliers, and a socket set. Additionally, having safety gear, such as gloves and goggles, is crucial to protect yourself while working. Keep replacement components and lubricants on hand to expedite the repair process and minimize downtime.

Common Issues and Solutions

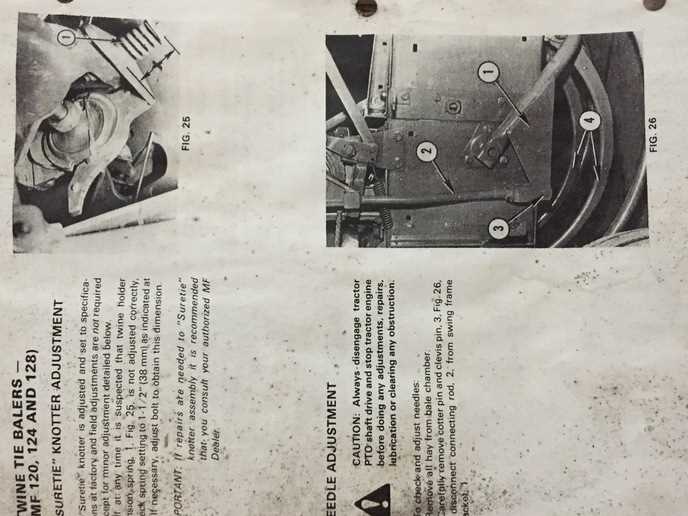

Familiarize yourself with frequent problems that may arise with your equipment. Issues such as blockages, worn belts, or loose connections can often be resolved with simple troubleshooting. Regularly inspect your machinery to identify wear and tear before it leads to more significant malfunctions. Consulting the manufacturer’s manual can provide valuable insights into specific challenges and maintenance schedules tailored to your model.

Cost Factors for Replacement Parts

When considering the acquisition of new components for agricultural machinery, various elements can influence the overall expenses. Understanding these factors is essential for making informed decisions and ensuring optimal performance of equipment.

Quality and Brand Reputation

The reputation of the manufacturer plays a significant role in determining the price. Well-established brands often charge a premium for their goods due to their commitment to quality and reliability. Investing in higher-quality items can lead to longer lifespans and fewer replacements, ultimately saving money in the long run.

Availability and Demand

The market availability of specific components can greatly impact their cost. Parts that are in high demand or are less readily available typically see increased prices. Furthermore, geographic location can affect shipping costs and lead times, making some items more expensive based on where they are sourced.

In summary, evaluating the factors influencing the costs of replacement components is crucial for effective budgeting and maintenance planning. By considering quality, brand reputation, and market dynamics, one can make smarter choices that enhance the longevity and efficiency of their agricultural machinery.

Comparison with Other Baler Models

When evaluating different models in the realm of hay handling machinery, it’s crucial to analyze their features, efficiency, and usability. Each model has unique attributes that cater to various farming needs, making it essential to compare their specifications and performance to determine the best fit for specific agricultural tasks.

| Feature | Model A | Model B | Model C |

|---|---|---|---|

| Weight | 1,500 lbs | 1,700 lbs | 1,600 lbs |

| Capacity (bales/hour) | 20 | 18 | 22 |

| Width | 72 inches | 78 inches | 75 inches |

| Power Requirement | 50 HP | 55 HP | 52 HP |

| Price | $10,000 | $12,000 | $11,500 |

In conclusion, by comparing different models, users can better understand the strengths and weaknesses of each, ensuring they make an informed decision that aligns with their operational needs and budgetary constraints.

Customer Reviews and Experiences

This section focuses on the insights and feedback shared by users regarding their machinery. The perspectives provided by actual users can offer valuable information about the performance, reliability, and maintenance of equipment. Understanding their experiences can assist potential buyers in making informed decisions.

Many users have expressed satisfaction with the efficiency and durability of their equipment. Common themes in reviews include:

- High operational efficiency, leading to increased productivity.

- Ease of maintenance and availability of replacement components.

- Reliability during peak usage seasons.

However, some reviews highlight areas for improvement:

- Initial setup and calibration can be time-consuming.

- Specific components may require frequent attention.

- Noise levels during operation could be reduced.

Overall, customer feedback emphasizes the importance of understanding both strengths and weaknesses before investing in agricultural machinery. Engaging with user experiences can provide insights that go beyond technical specifications, leading to more confident purchasing decisions.

Recommended Tools for Maintenance

Proper upkeep of agricultural machinery is essential for ensuring optimal performance and longevity. Utilizing the right tools can make maintenance tasks more efficient and effective. Below is a list of essential instruments and equipment that every operator should consider having on hand for routine care.

- Wrenches: Adjustable and socket wrenches are crucial for tightening or loosening bolts and nuts.

- Screwdrivers: A variety of flathead and Phillips screwdrivers will aid in accessing different components.

- Pliers: Needle-nose and slip-joint pliers can help with gripping and bending tasks.

- Grease Gun: For lubricating moving parts, a grease gun is indispensable to maintain smooth operation.

- Oil Filter Wrench: This tool simplifies the process of changing oil filters, ensuring clean oil circulation.

- Jack Stands: Essential for safely lifting and supporting equipment during maintenance checks.

- Cleaning Supplies: Brushes, rags, and degreasers keep surfaces clean and free of debris.

- Torque Wrench: Ensures that bolts are tightened to the manufacturer’s specifications, preventing damage.

- Measuring Tools: Calipers and rulers help in assessing wear and ensuring proper fit of components.

Investing in these tools will enhance maintenance efficiency and help keep machinery in peak working condition, ultimately leading to improved productivity in the field.

Safety Precautions When Repairing

Engaging in maintenance and repair tasks can be inherently risky. It is crucial to prioritize safety to prevent accidents and injuries while working with heavy machinery. Implementing proper precautions not only ensures personal safety but also enhances the longevity of the equipment.

Always wear appropriate personal protective equipment. This includes gloves, goggles, and sturdy footwear to protect against potential hazards such as sharp edges and falling objects. Ensuring that clothing is fitted and not loose will also minimize the risk of entanglement in moving parts.

Before beginning any repair work, make certain that the machinery is turned off and disconnected from any power source. This will help eliminate the possibility of accidental starts that could lead to severe injuries. Additionally, take the time to familiarize yourself with the equipment’s manual and understand its components.

When lifting or moving heavy parts, always use proper techniques. Utilize tools such as hoists or jacks to assist in handling bulky items safely. If unsure about the weight, seek assistance from a colleague.

Lastly, keep the workspace organized and free of clutter. A tidy environment reduces the likelihood of tripping and makes it easier to access tools and materials when needed. Regularly inspect your tools and equipment for any signs of wear or damage to maintain a safe working environment.

Manufacturer Support and Resources

Accessing reliable support and resources from the manufacturer can significantly enhance the longevity and efficiency of agricultural equipment. It is essential for operators to familiarize themselves with available tools and assistance to ensure optimal performance and maintenance of their machinery.

Key support options include:

- Technical Assistance: Manufacturers often provide dedicated helplines where experts can address specific queries regarding equipment operation and troubleshooting.

- Online Resources: Many companies offer comprehensive websites with downloadable manuals, instructional videos, and maintenance tips that facilitate self-service support.

- Authorized Service Centers: Utilizing certified repair locations ensures that your equipment is serviced by trained professionals familiar with the specific models and their requirements.

Additional resources to consider:

- Community Forums: Engaging in discussions with fellow operators can yield valuable insights and shared experiences, often revealing solutions to common issues.

- Spare Parts Catalogs: Access to detailed catalogs helps in identifying necessary components for repairs or upgrades, ensuring compatibility and reliability.

- Workshops and Training Sessions: Many manufacturers offer periodic training for operators and technicians, enhancing skills and knowledge about the latest technologies and practices.

By leveraging these resources, users can maintain their equipment effectively, reducing downtime and enhancing productivity on the field.