Massey Ferguson 1529 Parts Diagram Overview

In the realm of modern farming, the intricate machinery used plays a crucial role in enhancing productivity and efficiency. Familiarity with the various components of these machines allows operators to maintain optimal performance and minimize downtime. This section delves into the essential aspects of machinery construction, shedding light on how each element contributes to the overall functionality.

Comprehending the layout and arrangement of parts is vital for effective troubleshooting and repairs. By exploring the various sections of a machine, users can easily identify the relationships between components and their specific functions. This knowledge empowers operators to make informed decisions regarding maintenance and potential upgrades.

Whether you are an experienced technician or a newcomer to the agricultural industry, having access to a comprehensive overview of machinery configurations can significantly enhance your operational skills. By familiarizing yourself with the systematic organization of essential components, you will be better equipped to ensure the longevity and reliability of your equipment.

Understanding Massey Ferguson 1529 Parts

Gaining insight into the components of agricultural machinery is crucial for effective maintenance and operation. This section aims to enhance your comprehension of the essential elements that contribute to the functionality of these machines. By familiarizing yourself with various segments, you can ensure optimal performance and longevity.

Each component plays a vital role in the overall efficiency and reliability of the equipment. Recognizing how these elements interact allows operators to troubleshoot issues and perform necessary repairs with confidence. Below is a summary of key sections typically found in this type of machinery.

| Component | Description |

|---|---|

| Engine | Powers the machine and provides necessary torque for various tasks. |

| Transmission | Facilitates the transfer of power from the engine to the wheels. |

| Hydraulic System | Enables lifting and controlling attachments efficiently. |

| Chassis | Serves as the framework, supporting all other components. |

| Wheels and Tires | Provide mobility and traction on various terrains. |

Understanding these fundamental components empowers users to make informed decisions regarding maintenance and repairs, ultimately enhancing the productivity of their machinery.

Overview of the 1529 Model Features

This section delves into the essential characteristics of a notable agricultural machine, showcasing its design and functionality. With a focus on performance and reliability, this model is crafted to meet the diverse needs of modern farming, providing operators with enhanced efficiency and ease of use.

Engine Performance

The heart of this machinery lies in its powerful engine, designed for optimal torque and fuel efficiency. With robust specifications, it ensures seamless operation across various terrains, making it suitable for a wide range of agricultural tasks. The incorporation of advanced technology enhances responsiveness, allowing users to maximize productivity.

Operational Versatility

This model is equipped with a range of features that facilitate versatility in operation. Its adaptable attachments enable users to handle multiple tasks, from tilling to hauling, effortlessly. Additionally, the intuitive control systems simplify the user experience, ensuring that even those new to the equipment can operate it with confidence.

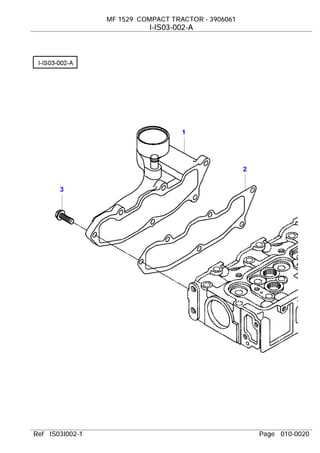

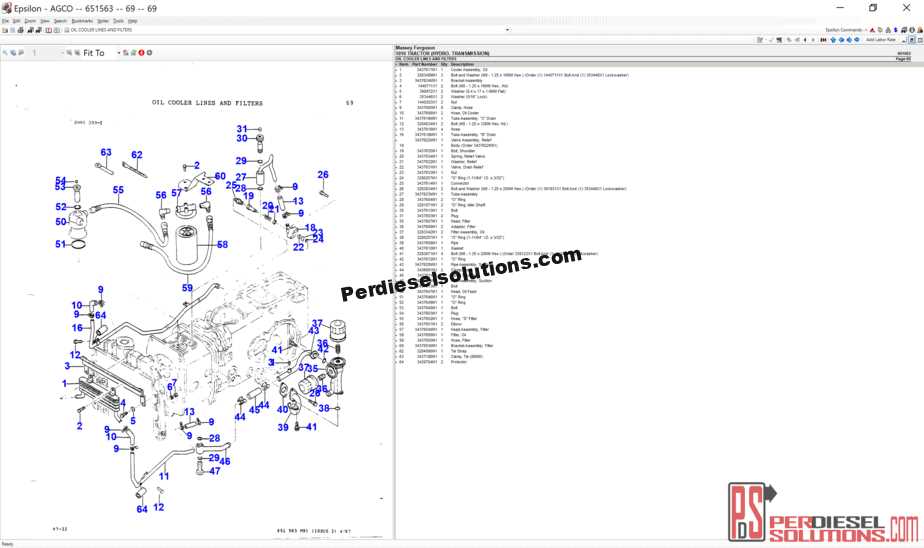

Importance of Parts Diagrams

Understanding the components of machinery is crucial for effective maintenance and repair. Visual representations of these elements provide clarity, ensuring that users can identify and address issues promptly. Such illustrations are essential tools for anyone working with equipment, enabling efficient troubleshooting and minimizing downtime.

Key benefits of these visual aids include:

- Enhanced Clarity: Illustrations simplify complex systems, making it easier to comprehend the relationships between different parts.

- Efficient Repairs: With a clear reference, technicians can quickly locate components that need attention, streamlining the repair process.

- Accurate Ordering: When replacements are necessary, visual guides ensure that the correct items are identified and ordered, reducing the risk of errors.

- Improved Training: New team members can learn faster by using visual references to understand machinery layout and function.

In summary, utilizing these illustrative resources not only facilitates better maintenance practices but also contributes to the longevity and performance of equipment. By having access to detailed visuals, users can ensure their machinery operates at peak efficiency.

Key Components of the 1529 Tractor

The efficient operation of a tractor relies heavily on its essential elements, which work in unison to provide optimal performance. Understanding these crucial components can help users maintain and troubleshoot their equipment effectively.

- Engine: The powerhouse of the machine, responsible for converting fuel into mechanical energy.

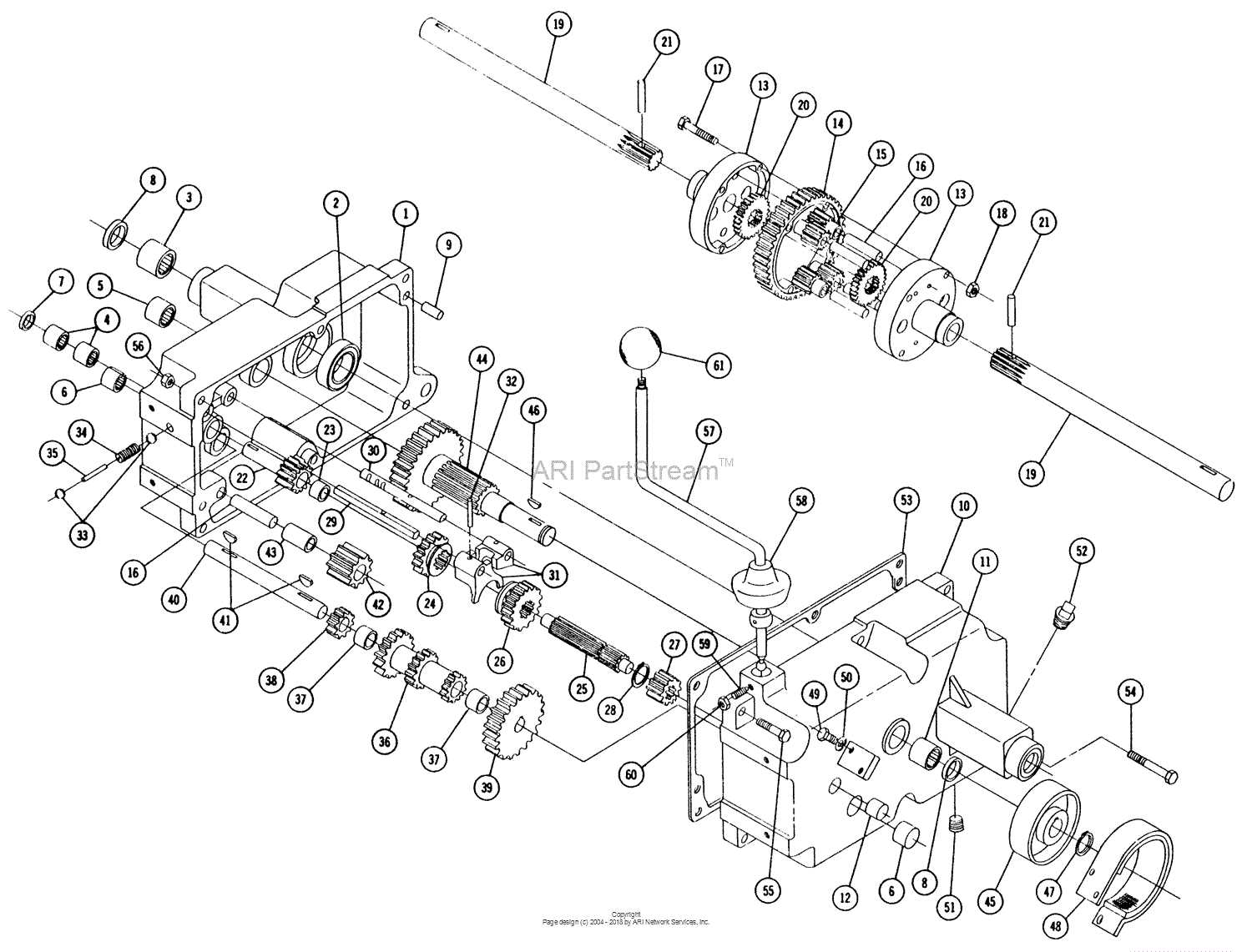

- Transmission: This system manages power transfer from the engine to the wheels, enabling movement and control.

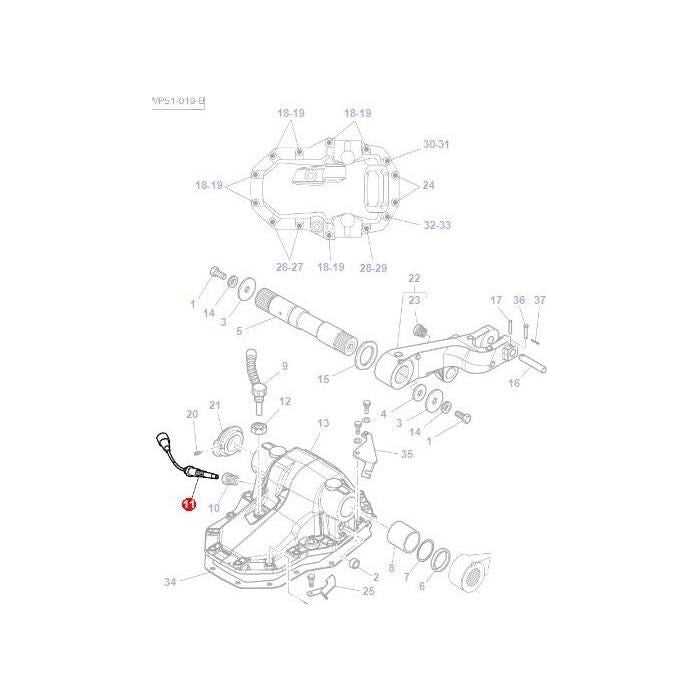

- Hydraulic System: Essential for operating attachments and implements, this system utilizes fluid pressure for lifting and moving tasks.

- Chassis: The framework that supports all other components, ensuring stability and strength during operation.

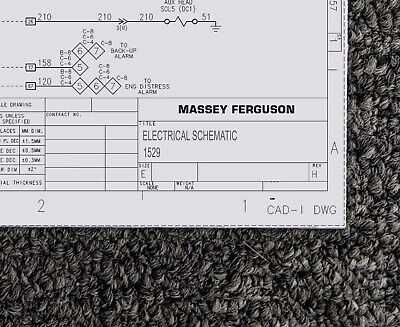

- Electrical System: Provides power for starting the engine and running various electronic components, enhancing functionality.

Each of these parts plays a pivotal role in the overall functionality and efficiency of the tractor. Regular inspection and maintenance of these elements can significantly extend the life of the machine.

- Routine oil changes to keep the engine running smoothly.

- Checking hydraulic fluid levels to ensure optimal operation of attachments.

- Inspecting the transmission for signs of wear and tear.

- Monitoring the electrical system for proper functionality.

By familiarizing oneself with these core components, operators can enhance their understanding and ensure their machinery remains in peak condition.

How to Read a Parts Diagram

Understanding a schematic representation of components is essential for effective maintenance and repair. These illustrations provide a visual guide that simplifies the identification of various elements, helping users locate and understand their function within a larger system. Familiarity with these visuals can enhance efficiency during assembly or disassembly tasks.

Key Elements to Observe

When examining a visual representation, pay attention to labels and numbering systems that indicate specific components. Each part is often assigned a unique identifier, making it easier to cross-reference with a list of items. Additionally, note the arrangement and connections, as they reveal how different pieces interact with one another.

Decoding Symbols and Legends

Many illustrations include a legend that explains various symbols used throughout the image. Familiarizing yourself with these symbols is crucial for accurate interpretation. This knowledge allows for quick identification of parts, whether they are mechanical, electrical, or structural, ensuring that any necessary replacements or repairs are performed correctly.

Common Issues with Massey Ferguson 1529

In the realm of agricultural machinery, certain challenges frequently arise that can hinder performance and efficiency. Understanding these common concerns is essential for ensuring smooth operations and prolonging the lifespan of the equipment.

- Engine Problems:

- Overheating due to coolant leaks.

- Starting difficulties, often linked to battery issues or fuel delivery problems.

- Transmission Issues:

- Gear slipping or difficulty in shifting, potentially caused by low fluid levels.

- Strange noises indicating wear or damage to internal components.

- Hydraulic System Failures:

- Loss of power steering or lifting capacity, often due to hydraulic fluid leaks.

- Slow or erratic response from hydraulic controls.

- Electrical Failures:

- Faulty wiring leading to intermittent electrical issues.

- Malfunctioning lights or indicators affecting visibility and operation.

Identifying and addressing these prevalent problems can significantly enhance functionality and reduce downtime. Regular maintenance checks and timely repairs play a crucial role in achieving optimal performance.

Where to Find Replacement Parts

Locating suitable components for machinery can be a straightforward process if you know where to look. Whether you’re in need of a specific item for maintenance or a complete overhaul, understanding your options is crucial. From online platforms to local suppliers, there are numerous avenues available to secure the necessary items efficiently.

Online Marketplaces

Digital platforms offer a vast selection of components, often at competitive prices. Websites dedicated to agricultural equipment frequently feature both new and refurbished items. Utilizing search filters can help you narrow down options based on compatibility and specifications.

Local Dealers and Repair Shops

Visiting local distributors and repair facilities can provide immediate access to high-quality components. These establishments often maintain a stock of essential items and can also assist in identifying the right ones for your machinery. Additionally, building a relationship with local experts can lead to valuable insights and recommendations.

Maintenance Tips for Your Tractor

Proper upkeep is essential to ensure the longevity and efficiency of your agricultural machinery. Regular maintenance not only helps prevent unexpected breakdowns but also enhances performance, ensuring that your equipment operates smoothly during critical tasks.

Here are some essential tips to maintain your tractor effectively:

- Regular Oil Changes: Change the engine oil and filters according to the manufacturer’s recommendations to keep the engine running smoothly.

- Check Fluid Levels: Regularly inspect and top off coolant, hydraulic fluid, and transmission fluid to prevent overheating and ensure proper operation.

- Tire Maintenance: Keep tires properly inflated and check for signs of wear. Rotate tires as needed to ensure even wear and extend their lifespan.

- Inspect Belts and Hoses: Regularly examine belts and hoses for cracks or signs of wear. Replace them promptly to avoid breakdowns during use.

- Battery Care: Check battery terminals for corrosion and ensure a good connection. Clean the terminals and check the battery’s charge regularly.

In addition to these tips, always refer to your owner’s manual for specific maintenance schedules and guidelines tailored to your equipment. Consistent attention to these details will result in improved performance and reliability.

Benefits of Using Genuine Parts

Opting for authentic components in machinery maintenance offers numerous advantages that enhance performance and longevity. These original items are designed specifically for the equipment, ensuring a seamless fit and optimal functionality. Relying on such quality not only reduces the likelihood of breakdowns but also contributes to overall efficiency.

Enhanced Reliability

Utilizing genuine components significantly boosts the reliability of your machinery. These products undergo rigorous testing and adhere to stringent manufacturing standards, guaranteeing that they can withstand demanding conditions. By choosing authentic items, operators minimize risks associated with inferior substitutes that may lead to unexpected failures.

Improved Resale Value

Investing in original components also preserves the resale value of the equipment. Potential buyers often prioritize well-maintained machinery with verified authenticity in its parts, as this reflects a commitment to quality and performance. Consequently, maintaining your equipment with genuine items can result in a higher return on investment in the future.

Comparing 1529 with Other Models

When evaluating different machinery options, it is essential to analyze how one model stacks up against its peers in terms of functionality, performance, and user satisfaction. Each model offers distinct features that cater to specific needs within the agricultural sector. By examining the differences and similarities, potential buyers can make informed decisions based on their requirements.

One notable aspect is the engine performance, where certain models may deliver higher horsepower, resulting in enhanced productivity. Additionally, the weight and size of the equipment can influence stability and maneuverability, especially in varied terrains. Furthermore, the ease of maintenance and the availability of service support are critical factors that contribute to long-term ownership satisfaction.

Another consideration is the array of attachments and compatibility with various implements. Some models boast a wider selection of accessories, allowing for greater versatility in tasks such as tilling, mowing, or transporting. Ultimately, understanding these differences helps users identify which machine aligns best with their operational demands.

Resources for Massey Ferguson Owners

For enthusiasts and operators of agricultural machinery, having access to reliable resources is essential for effective maintenance and operation. Whether you’re looking for manuals, community forums, or specialized shops, a wealth of information is available to help keep your equipment in peak condition.

Owner Manuals: Detailed guides provide vital insights into operational procedures and maintenance schedules. These documents are invaluable for understanding your machine’s specifications and troubleshooting common issues.

Online Forums: Engaging with fellow operators through dedicated online communities can be incredibly beneficial. These platforms allow you to share experiences, ask questions, and receive advice from those with similar equipment.

Parts Suppliers: Identifying reputable suppliers who specialize in components for your machinery can save time and ensure you get quality replacements. Many websites offer user-friendly catalogs to help you find what you need quickly.

Technical Support: Many manufacturers and authorized dealers provide customer support for troubleshooting and maintenance queries. Utilizing these resources can streamline repairs and enhance your machine’s longevity.

Video Tutorials: Platforms like YouTube host a variety of instructional videos that demonstrate repairs and maintenance procedures. Visual aids can greatly enhance your understanding and skills when working on your equipment.

By leveraging these resources, operators can enhance their knowledge, improve performance, and ensure their machinery operates smoothly for years to come.