Massey Ferguson 33 Grain Drill Parts Diagram Overview

In the world of agriculture, precision and efficiency play crucial roles in crop production. A specific type of implement is designed to streamline the sowing process, ensuring seeds are distributed uniformly across the field. This enhances overall yield and minimizes waste, which is vital for modern farming practices.

To optimize the functionality of this equipment, it is essential to comprehend the individual elements that contribute to its performance. Each component, from the mechanisms of seed distribution to the framework supporting the machine, has a unique role that impacts the effectiveness of planting operations.

For operators and maintenance personnel, having access to a detailed representation of these components can significantly aid in troubleshooting and repairs. Understanding how each part interacts with others ultimately leads to improved reliability and longevity of the equipment.

Massey Ferguson 33 Overview

This section provides a comprehensive insight into a specific agricultural implement renowned for its efficiency and reliability. Designed to enhance the cultivation process, it embodies advanced engineering and thoughtful design, making it a favored choice among farmers.

Features of this equipment include precision seed placement and adaptable configurations, allowing it to tackle various soil conditions and crop types. Its robust construction ensures durability, enabling it to withstand the rigors of fieldwork.

Moreover, the operation of this implement is user-friendly, providing ease of use for operators. The emphasis on performance and functionality makes it a vital asset in modern farming practices, ultimately contributing to higher productivity and crop yield.

Importance of Grain Drills

Implementing precise seeding techniques plays a crucial role in modern agriculture. Effective sowing tools ensure that seeds are distributed evenly and at the correct depth, leading to optimal growth conditions. This approach not only enhances yield but also conserves resources.

Efficiency is a primary benefit of these devices, allowing for quicker planting across large areas. By minimizing seed waste and maximizing coverage, they enable farmers to achieve more in less time. Additionally, uniformity in planting helps to create a consistent environment for crops, which is vital for successful harvests.

Moreover, utilizing advanced sowing technology contributes to soil health. These implements reduce soil disturbance, maintaining structure and supporting beneficial organisms. In the long run, this fosters sustainable practices that can benefit future generations of growers.

Key Components of the Drill

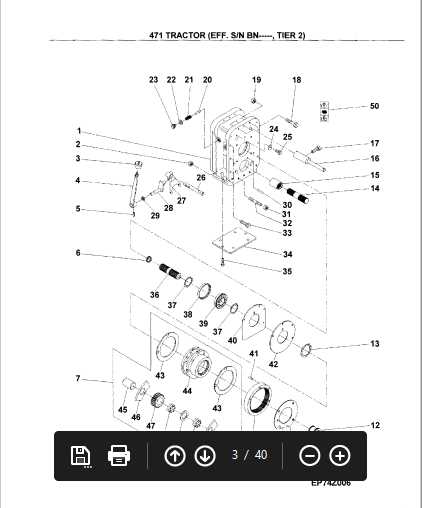

This section focuses on the essential elements that contribute to the functionality and efficiency of seeding machinery. Understanding these components is crucial for optimal operation and maintenance.

Primary Mechanisms

The primary mechanisms include systems that manage seed placement and soil interaction, ensuring effective sowing. Each element plays a vital role in achieving uniform distribution.

Supporting Structures

Supporting structures enhance stability and maneuverability, allowing the equipment to traverse various terrains seamlessly. These components are integral to overall performance.

| Component | Function |

|---|---|

| Seed Box | Holds and dispenses seeds uniformly |

| Openers | Creates furrows for seed placement |

| Press Wheels | Ensures proper soil contact for germination |

| Hitch | Connects to the towing vehicle |

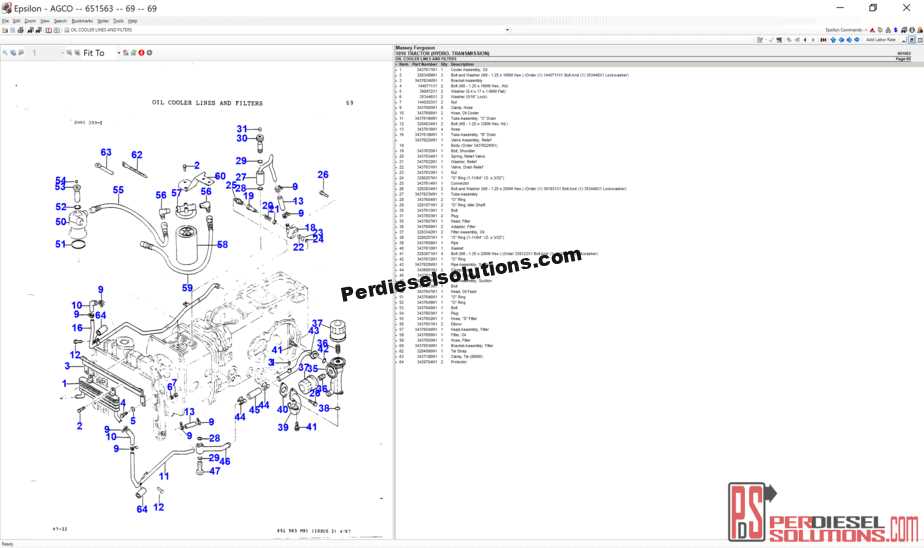

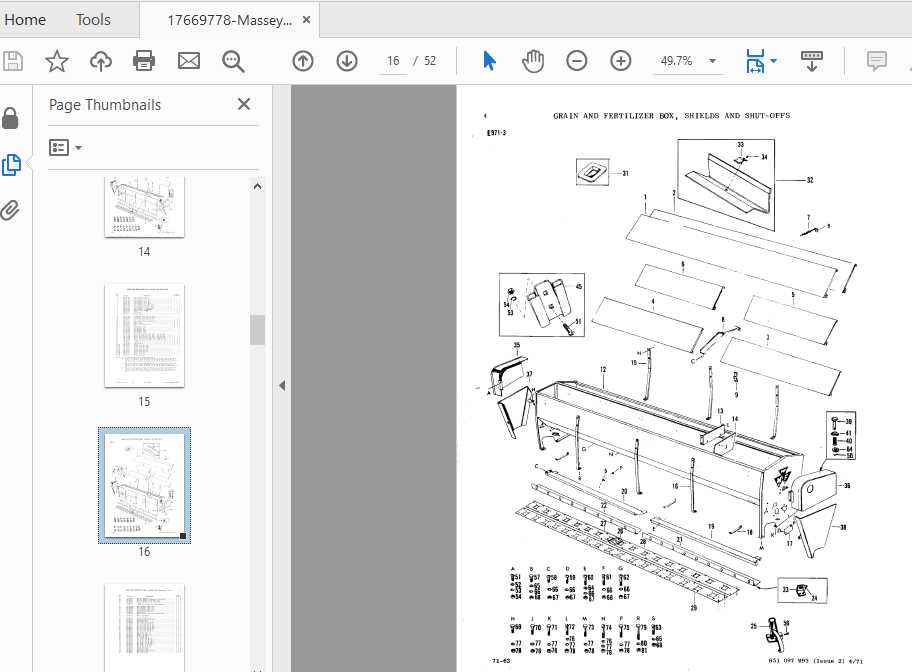

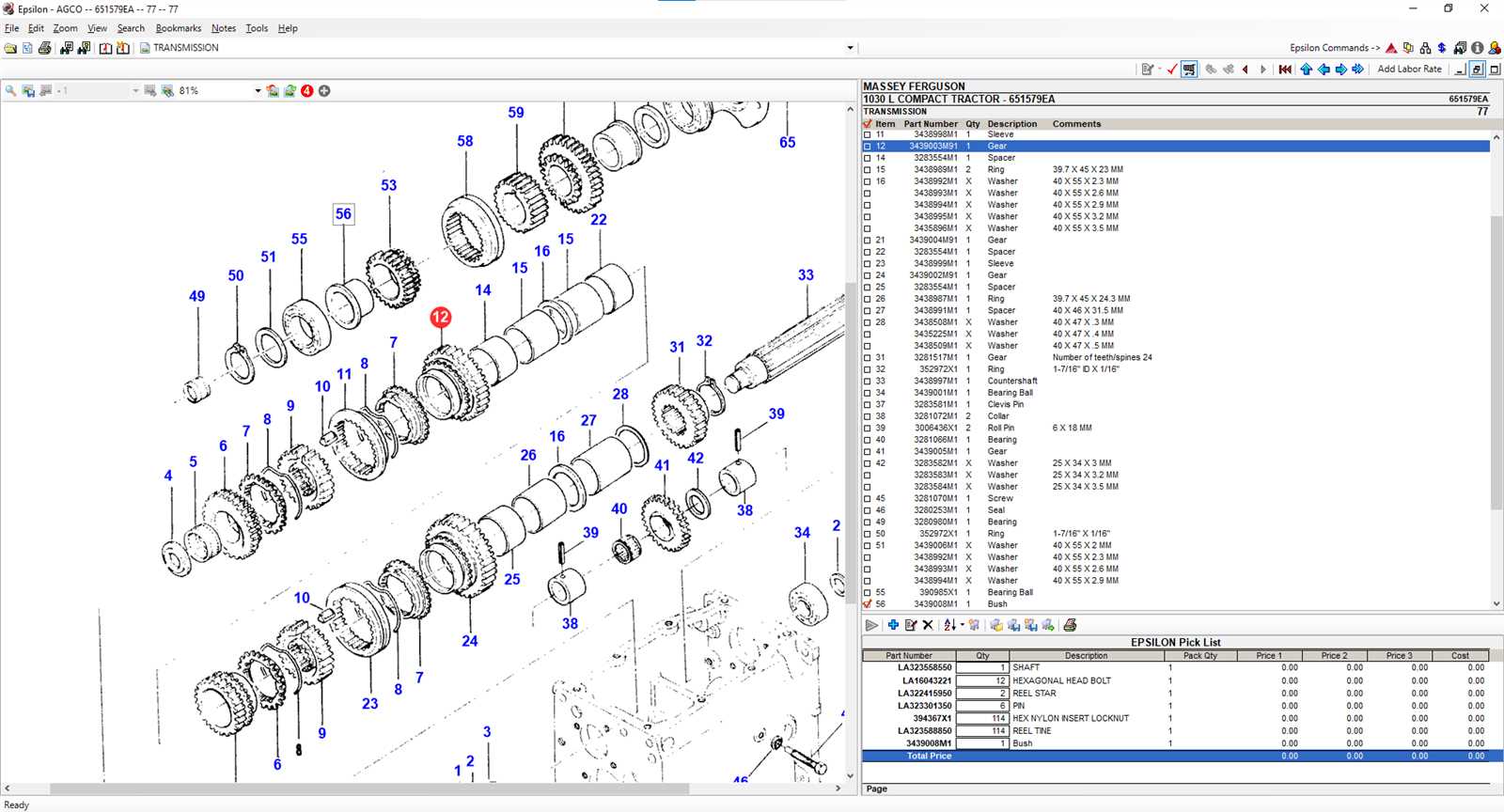

Parts Identification Guide

This section aims to assist users in recognizing and locating essential components of the equipment. Understanding the various elements is crucial for effective maintenance and operation, ensuring longevity and optimal performance.

1. Frame Assembly: The backbone of the machine, providing stability and support for all attached elements. It is vital for the alignment and overall function.

2. Seed Hoppers: These containers are responsible for holding the material. Proper identification ensures that the correct type is used for different seeds.

3. Distribution Mechanism: This system regulates the flow of material from the hoppers to the ground. Familiarity with its components is essential for efficient operation.

4. Coulters and Openers: These tools prepare the soil and create furrows for planting. Recognizing wear and tear is important for maintaining effectiveness.

5. Press Wheels: These components ensure proper soil contact and seed placement. Knowing their function aids in achieving the desired planting depth.

6. Adjustments and Controls: Familiarity with levers and settings allows for precise modifications according to specific field conditions, enhancing overall efficiency.

By gaining a comprehensive understanding of these components, operators can significantly improve the functioning and reliability of their machinery.

Understanding the Parts Diagram

The layout of components is crucial for effective maintenance and operation of agricultural machinery. A clear representation allows users to identify each element and its function, facilitating troubleshooting and repairs. Mastering this illustration is essential for maximizing the efficiency of the equipment.

| Component | Description |

|---|---|

| Frame | The main structure that supports all other components. |

| Hoppers | Containers for storing seed or fertilizer before distribution. |

| Distribution Mechanism | Ensures even placement of materials into the soil. |

| Wheel Assembly | Facilitates movement across fields and supports the machine’s weight. |

| Attachment Points | Connections for linking to tractors or other equipment. |

Maintenance Tips for Longevity

Ensuring the durability and efficient performance of agricultural equipment requires consistent attention and care. Regular maintenance not only extends the lifespan of your machinery but also enhances productivity in the field. Implementing a few simple practices can make a significant difference in the overall functionality and reliability of your tools.

Routine Inspections

Conducting periodic checks on your equipment is essential. Look for signs of wear and tear, such as rust, cracks, or loose components. Pay particular attention to moving parts and connections, as these areas are often prone to damage. Identifying issues early can prevent costly repairs and downtime.

Proper Lubrication

Keeping all moving elements well-lubricated is crucial for smooth operation. Use the recommended lubricants for your machinery, and ensure that grease points are attended to regularly. This will reduce friction and help prevent overheating, thus prolonging the life of your equipment.

Common Issues and Solutions

When operating agricultural machinery, users often encounter various challenges that can impact performance and efficiency. Understanding these common problems and their corresponding solutions is essential for maintaining optimal functionality. This section aims to highlight frequent issues and provide practical approaches to resolving them.

Performance Degradation

One of the most prevalent concerns is a noticeable drop in operational efficiency. This can manifest as uneven distribution of seeds or inconsistent tilling. Regular maintenance, including checking and cleaning components, can often rectify these issues. Additionally, ensuring that all settings are calibrated correctly according to the manufacturer’s recommendations can significantly improve performance.

Mechanical Failures

Mechanical breakdowns can occur due to wear and tear over time. Common symptoms include unusual noises or failure to engage. To address these problems, it is advisable to conduct routine inspections and replace worn parts promptly. Keeping a well-stocked inventory of essential components can minimize downtime and enhance reliability during critical periods of operation.

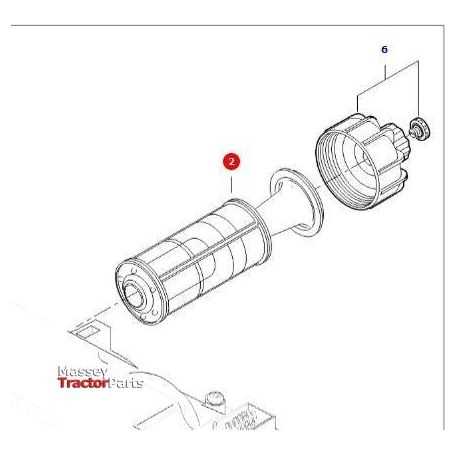

Replacement Parts Availability

Ensuring the continuous functionality of agricultural machinery is vital for productivity. Access to high-quality components is essential for maintaining operational efficiency and prolonging the lifespan of equipment. This section explores the options available for sourcing essential elements required for repairs and replacements.

Sources for Components

Various suppliers and distributors offer a wide range of components suitable for different models. Local agricultural equipment dealerships often have a selection of necessary items in stock, while online platforms provide an extensive inventory that can be shipped directly to your location. It’s advisable to compare prices and availability to secure the best deal.

Quality and Compatibility

When selecting components, prioritize quality and compatibility with your specific machinery. Genuine components typically ensure better performance and durability. However, reliable aftermarket options can also be a cost-effective alternative, provided they meet the required standards. Always verify specifications to ensure optimal functionality.

Assembly Process Explained

The assembly of agricultural equipment is a critical operation that requires careful attention to detail and a systematic approach. Each component must be meticulously fitted to ensure optimal performance and longevity.

Understanding the Sequence is essential. Begin by organizing all elements according to their specific roles. This makes it easier to identify what is needed at each stage of the assembly.

Tool Selection also plays a vital role. Having the right instruments at hand will facilitate a smoother process, allowing for precise fittings and adjustments.

Finally, Quality Checks throughout the assembly ensure that everything functions correctly. Regular inspections can prevent future issues and enhance overall reliability.

Operating the Massey Ferguson 33

Understanding the functionality of this agricultural implement is essential for achieving optimal performance in field operations. With its robust design and advanced features, it simplifies the planting process, ensuring efficient seed placement and depth control.

Preparation is crucial before commencing work. Ensure that all components are in good condition and properly calibrated to match the requirements of the soil and the seeds being used. Regular maintenance checks will enhance longevity and reliability.

During operation, monitoring the machine’s performance is vital. Pay attention to the seed flow and make necessary adjustments to the settings to maintain uniformity. Proper handling will minimize seed wastage and maximize crop yield.

After finishing the task, cleaning the equipment thoroughly will prevent any residue build-up, ensuring readiness for the next planting season. A well-maintained implement contributes significantly to overall productivity and efficiency.

Historical Significance of the Model

This model represents a pivotal moment in agricultural innovation, influencing farming practices and productivity in its time. Its design and functionality not only enhanced efficiency but also paved the way for future advancements in the field.

- Revolutionized seeding techniques, allowing for more uniform crop establishment.

- Played a crucial role in increasing agricultural output during the mid-20th century.

- Set a benchmark for quality and durability in agricultural machinery.

- Served as a foundation for subsequent models and technologies.

Understanding its legacy helps appreciate the evolution of modern farming equipment and the ongoing quest for enhanced agricultural efficiency.

Comparative Analysis with Other Models

In evaluating agricultural machinery, it is essential to explore how different models perform against each other in terms of efficiency, functionality, and design. By examining various equipment, farmers can make informed decisions that best suit their operational needs. This analysis focuses on key aspects that differentiate one model from another, providing insights into their unique strengths and weaknesses.

Performance and Efficiency

When assessing operational efficiency, some units excel in speed and precision, allowing for quicker planting and better seed placement. Others might offer enhanced durability and ease of maintenance, which are crucial for long-term use. Understanding these performance metrics helps users select machinery that aligns with their agricultural practices.

Design and Usability

Design elements, including user interface and ergonomic considerations, play a significant role in usability. Some models feature advanced technological integrations that facilitate ease of operation, while others may prioritize simplicity and robustness. Evaluating these aspects can greatly influence the day-to-day experience of operators in the field.

Customer Reviews and Experiences

This section highlights the valuable insights and feedback from users regarding their experiences with agricultural machinery. Understanding real-world applications and the performance of equipment can significantly assist potential buyers in making informed decisions.

Positive Feedback

Many users express satisfaction with the reliability and efficiency of their equipment. They appreciate the ease of operation and maintenance, which contributes to a smoother workflow during planting seasons. Users frequently mention that the machinery has helped them achieve better crop yields, making their investment worthwhile. One customer noted that the intuitive design allows even novice operators to achieve excellent results without extensive training.

Areas for Improvement

While feedback is largely positive, some users have pointed out areas for enhancement. Common concerns include the availability of specific accessories and the need for improved customer support. A few individuals shared experiences of delays in obtaining replacement components, which impacted their productivity. Constructive suggestions often revolve around enhancing user manuals and offering more comprehensive online resources for troubleshooting.