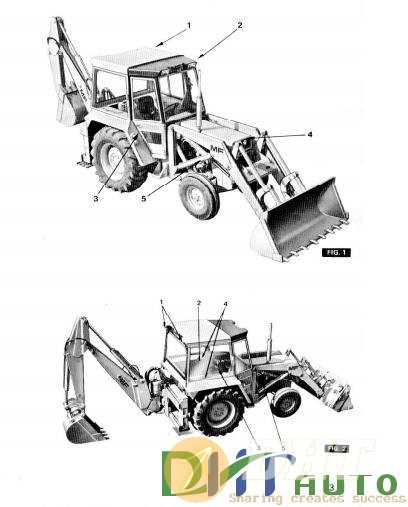

Massey Ferguson 50B Parts Diagram Overview

In the realm of agricultural machinery, a comprehensive understanding of the various components that make up a machine is essential for efficient maintenance and repair. This section delves into the intricate assembly of a specific model, showcasing the individual elements that contribute to its overall functionality. By familiarizing oneself with these components, operators can enhance their operational proficiency and ensure longevity in their equipment.

Every piece of machinery consists of numerous interconnected parts, each playing a vital role in the machine’s performance. Recognizing the significance of each component allows for better troubleshooting and optimization of operations. Whether it involves the transmission system, hydraulic mechanisms, or engine assembly, grasping the layout and function of these elements is crucial for effective machinery management.

In addition, visual references serve as invaluable tools for those seeking to enhance their understanding of machinery structures. Illustrations that depict the arrangement and function of various components facilitate a clearer comprehension of how each element interacts within the system. Such resources empower operators to undertake repairs confidently and make informed decisions regarding maintenance, ultimately contributing to improved productivity in agricultural tasks.

Massey Ferguson 50B Overview

This section provides a comprehensive introduction to a renowned agricultural machine known for its reliability and efficiency in various farming tasks. Designed for both small and large-scale operations, it combines robust engineering with user-friendly features to enhance productivity in the field. Understanding its structure and components is crucial for effective maintenance and optimal performance.

The machinery is equipped with a range of features that facilitate ease of use and adaptability to different farming conditions. Below is a summary table highlighting key specifications that define its functionality and suitability for diverse agricultural applications.

| Specification | Details |

|---|---|

| Engine Type | Diesel |

| Horsepower | Approximately 50 HP |

| Transmission | Manual, multiple speeds |

| Drive Type | Two-wheel drive (2WD) or four-wheel drive (4WD) |

| Weight | Roughly 2,500 kg |

| Lift Capacity | Up to 1,200 kg |

With a solid design and practical features, this machine stands out as an essential tool for modern farming, ensuring tasks are completed efficiently while minimizing operator fatigue.

Key Components of the 50B

This section provides an overview of the essential elements that contribute to the functionality and performance of the machine. Understanding these components is crucial for effective operation and maintenance, ensuring longevity and reliability in various tasks.

Core Functional Units

The operational efficiency of this equipment relies on several core units. Each element plays a vital role in the overall mechanism, working in harmony to achieve optimal performance.

| Component | Description |

|---|---|

| Engine | Powers the entire system, providing the necessary torque and horsepower for various applications. |

| Transmission | Facilitates the transfer of power from the engine to the wheels, allowing for smooth acceleration and deceleration. |

| Hydraulic System | Enables lifting and lowering of attachments, providing versatility in handling different tasks. |

| Chassis | Serves as the foundational structure, supporting all components and ensuring stability during operation. |

Additional Elements

Alongside the primary components, various additional elements enhance functionality. These units contribute to the overall efficiency and adaptability of the equipment, making it suitable for diverse working conditions.

| Component | Description |

|---|---|

| Steering System | Allows for precise maneuverability, facilitating navigation in tight spaces. |

| Braking System | Ensures safety and control, enabling the operator to stop the machine effectively. |

| Electrical System | Powers various electronic components, including lights and controls, enhancing usability. |

| Cooling System | Maintains optimal operating temperatures, preventing overheating during extended use. |

Understanding the Parts Diagram

Interpreting a technical illustration is essential for anyone involved in maintenance or repair tasks. These visual representations offer a comprehensive view of components and their relationships, facilitating easier identification and troubleshooting. By grasping how to read these visuals, users can enhance their understanding of machinery, leading to more efficient repairs and replacements.

Key Elements to Consider

When examining a technical illustration, it is crucial to focus on the various elements it includes. Each item is typically labeled with numbers or letters, corresponding to a legend or reference guide. Understanding these references allows users to pinpoint specific components quickly. Additionally, recognizing the layout and organization of the illustration can significantly aid in comprehending the overall structure of the equipment.

Benefits of Familiarity

Becoming adept at reading technical illustrations offers numerous advantages. It enables users to anticipate potential issues, plan maintenance more effectively, and ensure that any replacements are accurate. Moreover, familiarity with these visuals can foster confidence in performing repairs, ultimately leading to improved operational efficiency and longevity of the equipment.

Maintenance Tips for Owners

Proper upkeep is essential for ensuring the longevity and optimal performance of your machinery. Regular maintenance not only helps in identifying potential issues before they escalate but also enhances the overall efficiency and reliability of your equipment. This section provides valuable insights to help you maintain your vehicle effectively.

Regular Inspections

Conducting routine checks is crucial. Look for signs of wear and tear, including leaks, unusual noises, and any changes in performance. Regular inspections allow you to spot minor issues that can be addressed promptly, preventing them from turning into significant problems.

Fluid Levels and Quality

Ensure that all essential fluids, such as oil, coolant, and hydraulic fluid, are at appropriate levels and in good condition. Replace fluids according to the manufacturer’s recommendations. This practice helps maintain proper function and prevents damage to critical components.

Following these maintenance tips can lead to a smoother operation and extended life for your machinery.

Common Issues and Solutions

In the realm of machinery maintenance, various challenges can arise, impacting the performance and reliability of equipment. Understanding these common issues and their corresponding solutions is essential for ensuring optimal operation and longevity. Below, we explore several frequent complications encountered and practical approaches to resolve them.

1. Engine Overheating

Overheating is a prevalent issue that can stem from inadequate coolant levels, blocked radiators, or malfunctioning thermostats. To address this, regularly check coolant levels, ensure that the radiator is free of debris, and inspect the thermostat for proper functionality. Keeping the cooling system in good condition is vital to prevent overheating.

2. Hydraulic System Failures

Hydraulic systems may experience failures due to leaks, contaminated fluid, or faulty pumps. Regularly inspect hydraulic lines for signs of wear and leaks, and replace any damaged components promptly. Additionally, maintaining clean hydraulic fluid is crucial to ensure efficient operation and prevent system failures.

3. Electrical Issues

Electrical problems can arise from corroded connections, blown fuses, or malfunctioning switches. To resolve these, routinely inspect wiring and connections for corrosion, clean terminals, and replace any damaged fuses. A thorough electrical check can help prevent unexpected shutdowns and improve reliability.

4. Poor Fuel Efficiency

Decreased fuel efficiency may be caused by clogged filters, improper tire pressure, or engine tuning issues. Regular maintenance of fuel filters, ensuring correct tire pressure, and performing routine engine diagnostics can significantly enhance fuel economy and overall performance.

5. Steering Difficulties

Issues with steering can be a result of worn components, low fluid levels, or misalignment. It is important to check the power steering fluid regularly and inspect the steering mechanism for wear. Addressing these factors can restore smooth steering and enhance maneuverability.

By identifying and addressing these common challenges, operators can maintain the efficiency and reliability of their machinery, ultimately leading to better performance and reduced downtime.

How to Order Replacement Parts

Replacing components in agricultural machinery can be a straightforward process if you follow the right steps. Whether you are maintaining equipment or undertaking repairs, understanding how to source the necessary items is crucial for ensuring optimal performance.

Here are some effective strategies to facilitate the ordering process:

- Identify the Needed Component:

Before making a purchase, accurately determine the specific component you require. This may involve checking existing items for serial numbers or model specifications. - Consult the Manual:

The operator’s manual often contains valuable information regarding components, including details on compatibility and installation procedures. - Research Reputable Suppliers:

Look for suppliers that specialize in machinery components. Reliable vendors typically offer a wide range of options and can provide assistance if needed. - Verify Part Numbers:

Once you have identified potential suppliers, cross-reference part numbers to ensure you are ordering the correct item. This minimizes the chances of receiving the wrong component. - Consider OEM vs. Aftermarket:

Decide whether you prefer original equipment manufacturer (OEM) components or aftermarket alternatives. Each option has its pros and cons regarding quality and price. - Check Availability:

Inquire about the availability of the components you need. Some suppliers may have stock on hand, while others might need to order them from a manufacturer. - Request a Quote:

When you find the required components, ask for a detailed quote. This should include pricing, shipping costs, and estimated delivery times. - Place Your Order:

After reviewing the quote, proceed with placing your order. Ensure that all information is accurate to avoid delays.

Following these steps will help streamline the process of sourcing and acquiring the necessary components, ensuring your machinery remains in excellent working condition.

Illustrations for Easy Reference

Visual aids serve as invaluable tools for enhancing comprehension and facilitating quick identification of components within complex machinery. These representations simplify the process of locating specific elements and understanding their interconnections. By providing a clear visual reference, users can quickly navigate through various assemblies, making maintenance and repairs more efficient.

Incorporating detailed illustrations can significantly reduce the time spent searching for particular elements or troubleshooting issues. They offer a straightforward way to familiarize oneself with the layout and functionality of individual components, thereby streamlining workflow. Furthermore, utilizing such visual resources aids in ensuring that all necessary items are accounted for during assembly or disassembly.

Overall, integrating comprehensive visual representations enhances the user experience, providing a reliable guide for those working with intricate mechanical systems. This approach not only promotes better understanding but also fosters confidence in performing tasks related to upkeep and repair.

Differences Between 50B Models

When exploring the variations within a specific line of agricultural machinery, it is essential to recognize the nuances that distinguish different models. These variations can impact performance, efficiency, and user experience, making it vital for operators and enthusiasts to understand their differences.

Several key aspects contribute to the distinction among the models:

- Engine Specifications: Each variant may feature different engine configurations, affecting horsepower, torque, and fuel efficiency.

- Transmission Types: Variations in transmission systems can lead to differences in speed, control, and ease of use.

- Hydraulic Systems: The capacity and efficiency of hydraulic components can vary, influencing the ability to operate attachments effectively.

- Dimensions and Weight: Differences in size and weight can impact stability and maneuverability in various agricultural settings.

- Optional Features: Some models may offer additional features or accessories, such as advanced technology for monitoring performance or enhanced comfort for the operator.

Understanding these distinctions helps users select the appropriate model for their specific needs, ensuring optimal performance and satisfaction in various agricultural tasks.

Accessories to Enhance Performance

Optimizing equipment functionality often involves incorporating various enhancements designed to improve efficiency and effectiveness. By integrating suitable accessories, operators can experience increased productivity, improved handling, and overall better performance in diverse tasks.

Upgraded Implements

Utilizing advanced attachments can significantly boost operational capabilities. Whether it’s a more efficient plow or a specialized mower, these implements are engineered to perform better under demanding conditions, providing superior results and reducing time spent on each task.

Advanced Monitoring Systems

Implementing modern monitoring solutions allows for real-time assessment of performance metrics. These systems can track fuel consumption, operational hours, and other critical data, enabling informed decision-making and maintenance planning. As a result, equipment longevity and reliability are enhanced.

Expert Advice on Repairs

When it comes to maintaining and fixing agricultural machinery, having a solid understanding of the components involved is crucial. Familiarity with the structure and functionality of various elements can greatly enhance the efficiency of repair tasks. Proper guidance and knowledge can help prevent common mistakes and lead to more successful outcomes in restoration efforts.

One essential tip is to always refer to a detailed reference guide when troubleshooting issues. Such resources provide valuable insights into the assembly and interconnectivity of parts, allowing for a more systematic approach to repairs. It’s also beneficial to keep an organized workspace, as this can reduce confusion and streamline the repair process.

Additionally, don’t hesitate to seek advice from experienced technicians or join online forums where fellow enthusiasts share their insights. Learning from others’ experiences can provide unique perspectives and innovative solutions to persistent problems. Remember, investing time in understanding the machinery will pay off in the long run, ensuring longevity and optimal performance.

Resources for Further Learning

Expanding your knowledge in machinery maintenance and repair can significantly enhance your skills and understanding of various components. The following resources provide valuable insights and detailed information that can aid in mastering the intricacies of equipment functionality and service procedures.

Online Platforms

- YouTube – A rich source of instructional videos and tutorials covering various maintenance techniques and repair tips.

- Reddit – Engaging forums where enthusiasts share experiences, solutions, and advice on troubleshooting machinery issues.

- TractorByNet – A community dedicated to discussions on equipment, providing forums for advice, reviews, and parts exchange.

Books and Manuals

- Amazon – Search for manuals specific to your equipment, which can offer diagrams, specifications, and troubleshooting guides.

- LibraryThing – A platform to find and borrow books related to machinery, maintenance techniques, and repair strategies.

- AbeBooks – A marketplace for purchasing used and rare manuals that provide in-depth technical knowledge.