Understanding the Mercruiser Lower Unit Parts Diagram

Understanding the structure and layout of various mechanical assemblies is essential for effective maintenance and repair work. In the context of marine propulsion systems, having a clear representation of how key elements fit together provides valuable insights into their functionality and potential areas of attention during servicing.

In this section, we will explore a specific system integral to watercraft operation. We will break down the arrangement of its crucial mechanical elements, offering an in-depth look at how these components interact. Whether you are working on repairs or simply aiming to deepen your knowledge, this detailed examination will serve as a helpful guide.

Focus will be placed on the assembly responsible for driving the vessel through water, highlighting each individual element and its role in the overall mechanism. By understanding the complete layout, you’ll be better equipped to address any c

Understanding Mercruiser Lower Unit

The propulsion system in marine engines plays a critical role in ensuring smooth movement and efficient power transfer. It comprises several interconnected mechanisms that work in harmony to manage the flow of energy from the motor to the propeller. Understanding how these components interact is key to maintaining optimal performance.

Key Functions of the Drive Mechanism

At the heart of this system lies the task of converting engine output into forward or reverse motion. By managing torque and adjusting gear ratios, the structure helps to control

Components of the Lower Unit

The mechanisms within the propulsion system of a boat play a vital role in transferring power from the engine to the water. These elements work together to ensure smooth movement, efficient performance, and stability on the water. Understanding the key components of this section is essential for both maintenance and troubleshooting.

Driveshaft: This shaft is responsible for delivering rotational force from the engine to the propeller, enabling forward and reverse motion.

Propeller: The propeller converts the rotational force into thrust, pushing the vessel through the water. It is a critical element for speed and maneuverability.

Gears: A set of gears inside this system allows for the adjustment of speed an

Importance of Key Components

Understanding the essential elements of a marine propulsion system is crucial for maintaining overall performance and longevity. These components play a vital role in ensuring smooth operation, efficient power transmission, and proper alignment. Regular inspection and maintenance can help avoid costly repairs and extend the life of the machinery.

Core Elements

The primary elements responsible for the propulsion system’s functionality are designed to work together seamlessly. Each element must function optimally to avoid disruptions. Proper care and timely replacements when needed are essential to maintain balance in the system.

Maintenance and Inspection

Frequent checks on these components ensure that they are free from damage, corrosion, or wear. By maintaining these essential parts in good condition, boat owners can guarantee safe and reliable operation, even under harsh

Common Issues with Lower Units

Problems related to the mechanical drive system can often cause significant performance disruptions, leading to various symptoms and operational issues. Understanding common failures is essential for identifying and addressing them before they lead to more serious damage.

Signs of Wear and Tear

Regular usage can lead to wear on critical components, which may manifest in various ways. Some indicators of this wear include unusual noises, vibrations, and decreased efficiency during operation. Catching these early can prevent costly repairs.

- Strange sounds during gear shifts

- Increased vibration while in motion

- Noticeable reduction in power output

Fluid Leaks and Overheating

Leaks from the drive system and overheating are common problems that can ind

How to Identify Lower Unit Problems

When dealing with mechanical issues in a marine system, it’s important to recognize the early signs of malfunction. Understanding the basic symptoms can help in diagnosing potential issues and prevent more significant damage. Identifying unusual sounds, vibrations, or changes in performance can provide the first clues that something isn’t functioning as it should.

Begin by paying attention to any strange noises during operation, such as grinding or clunking. These may indicate worn-out components. A decrease in responsiveness, especially during gear shifts, is another red flag. Inspecting for visible damage or excessive wear can also reveal underlying problems. Regular monitoring and addressing small signs early will ensure the longevity of the system.

Mercruiser Lower Unit Maintenance Tips

Regular upkeep of marine propulsion systems is essential to ensure smooth and efficient operation. By following a consistent care routine, you can extend the lifespan of your equipment and prevent costly repairs. Here, we offer some practical advice on maintaining critical components of your marine setup.

Inspecting the Propulsion System

Routine inspections are crucial to identify any signs of wear or potential issues. Check for unusual noises, vibrations, or leaks. It’s recommended to visually inspect seals, bearings, and other key areas to ensure everything is functioning as it should. Early detection can prevent major damage.

Fluid Levels and Lubrication

Maintaining

Parts Replacement Guidelines

When maintaining marine systems, it is essential to follow certain procedures for replacing key components to ensure smooth and efficient operation. Replacing worn or damaged elements not only extends the lifespan of the system but also prevents further complications.

Steps to Follow

- Identify the component that requires replacement. Ensure that the surrounding elements are not affected during removal.

- Gather the necessary tools and reference materials for the task to avoid delays during the process.

- Carefully disconnect any connections or fastenings related to the component.

- Replace the old element with a new, compatible one, ensuring a proper fit.

- Reassemble and secure all connections, checking for any loose fittings.

Additional Tips

- Use original

Tools Needed for Repairs

When undertaking any mechanical repair, having the right set of tools is crucial to ensure the job is done efficiently and correctly. Proper equipment not only makes the task easier but also helps avoid potential damage to delicate components. Below is a comprehensive list of essential tools you should have on hand before starting your work.

Basic Hand Tools

The most common tools required include a selection of wrenches, screwdrivers, and pliers. These are necessary for loosening, tightening, and adjusting various fasteners and fittings during the repair process.

Specialty Tools

Certain tasks may require specialized tools that are designed for more specific operations. These include pullers, torque wrenches, and alignment gauges. Each of these is tailored to handle specific parts and ensure proper reassembly after the repair is completed.

Tool Purpose Cost Factors for Lower Unit Repairs

When considering the expenses associated with repairs, it’s important to understand that multiple elements contribute to the overall cost. From labor fees to replacement materials, the financial outlay can vary significantly depending on the type of service required. Evaluating these factors in advance can help avoid unexpected expenses and ensure a smooth repair process.

Labor and Expertise

The level of expertise required for the repair plays a significant role in determining the overall price. Highly skilled technicians often charge more for their services due to the specialized knowledge involved. Additionally, the complexity of the mechanical issue can increase the amount of time needed for repairs, further influencing labor costs.

Replacement Materials and Tools

The quality and type of replacement materials also impact the total cost. Using higher-grade materials might lead to longer-lasting results but at a higher price point. Availability and the need for specific tools can also affect the pricing, especially if unique or rare parts are involved.

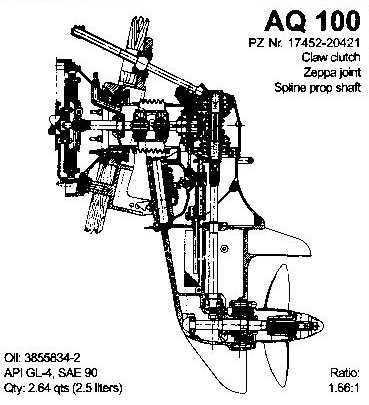

Cost Factor Impact on Total Cost Comparing Different Lower Unit Models

Understanding the variations among various drive components is crucial for optimal performance and maintenance. Each model presents unique features and specifications that cater to diverse boating needs. This section aims to highlight the differences in design, functionality, and application to assist users in making informed decisions.

Design Variations

Different designs reflect the distinct operational requirements of marine vessels. For instance, some models may prioritize durability and strength, while others focus on enhanced hydrodynamics for better fuel efficiency. Assessing the structural integrity of each design is essential for ensuring long-term reliability and effectiveness in various water conditions.

Functionality and Performance

Performance can vary significantly between different configurations. Some components are engineered for high-speed applications, while others are optimized for torque and power delivery. Evaluating these functional attributes will aid users in selecting the most suitable option for their specific boating activities, whether for leisure or professional use.

Where to Find Replacement Parts

When it comes to maintaining your watercraft, sourcing quality components is essential for optimal performance. Various avenues are available for locating reliable substitutes that ensure your vessel operates smoothly. Exploring these options will help you identify the best sources for your needs.

Online Retailers

The internet offers a plethora of online shops specializing in marine accessories. These retailers often provide detailed descriptions and customer reviews, allowing you to compare and select the most suitable items. Ensure you choose a reputable vendor to guarantee product authenticity and quality.

Local Marine Supply Stores

Visiting a nearby marine supply shop can also be beneficial. Local establishments often have knowledgeable staff who can assist you in finding the correct components. Moreover, purchasing in person allows you to inspect the items before buying, ensuring they meet your requirements.

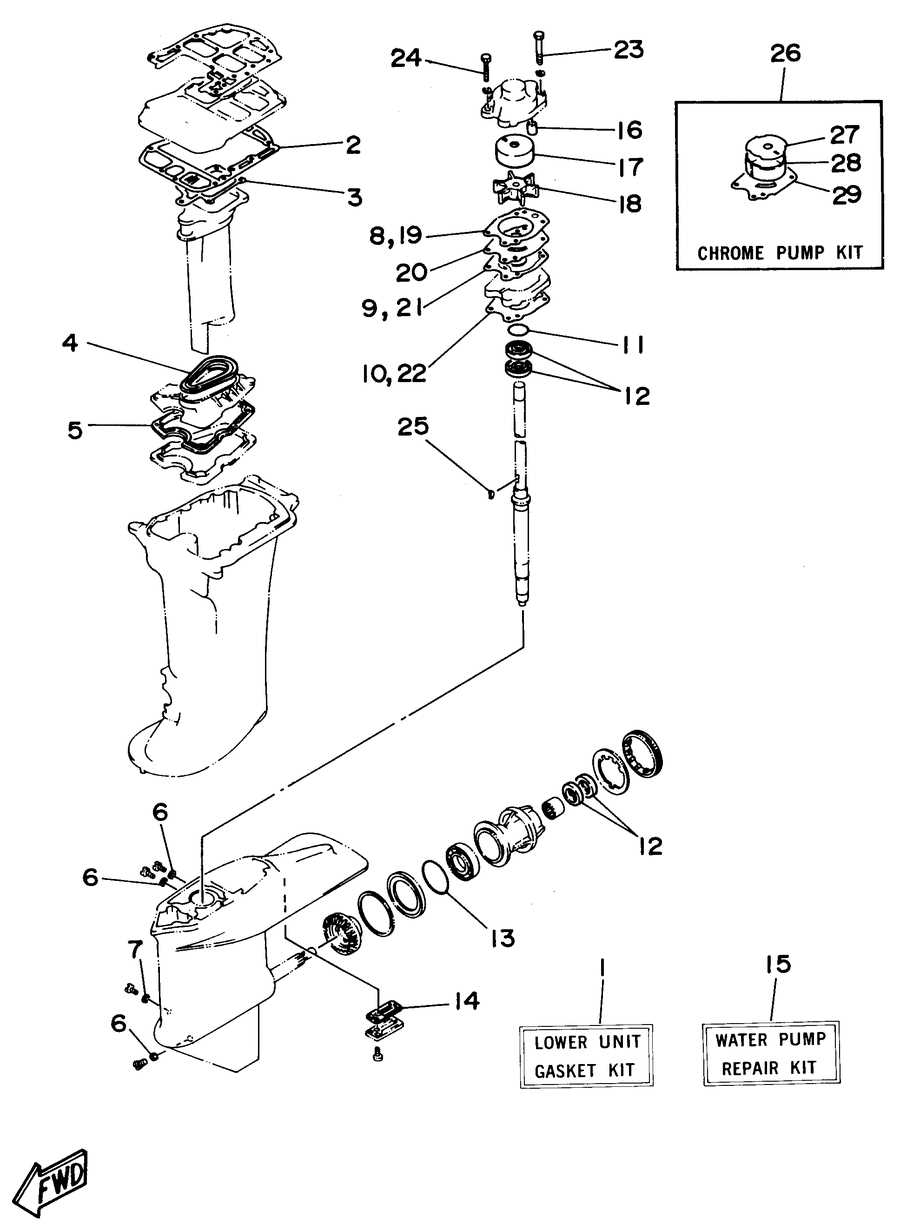

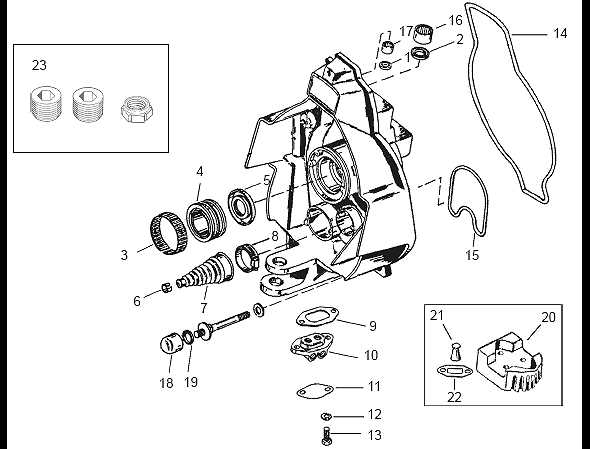

Understanding the Parts Diagram

Exploring the visual representation of components is essential for comprehending the assembly and function of any mechanical system. These illustrations serve as valuable tools for both novice and experienced individuals, providing insights into how various elements interact within a specific machinery framework.

Importance of Visual Representations

Visual guides offer several advantages:

- Enhance comprehension of complex structures.

- Facilitate troubleshooting by identifying specific elements.

- Assist in efficient assembly and disassembly processes.

Key Elements to Consider

When examining such illustrations, focus on the following aspects:

- Labeling: Ensure all components are clearly identified.

- Relationships: Understand how different elements connect and interact.

- Scale: Pay attention to the proportions, as they can affect installation and maintenance.

DIY Repair vs. Professional Service

When it comes to maintaining and fixing your aquatic propulsion system, enthusiasts often face a dilemma: whether to tackle repairs themselves or seek the expertise of professionals. Each option has its advantages and challenges, and the choice largely depends on individual skills, tools available, and the complexity of the issue at hand.

Advantages of DIY Repair

Taking on repairs independently can be a rewarding experience. DIY repairs often allow for cost savings and a deeper understanding of the equipment’s mechanics. By investing time and effort, one can enhance their technical skills and feel a sense of accomplishment upon completion. Additionally, many resources and communities exist to support those who choose this path, offering tutorials and guidance.

Benefits of Professional Service

On the other hand, opting for professional assistance ensures that the job is handled by experienced technicians. Professional service can save time and mitigate the risks of improper repairs, which could lead to further complications. Experts are equipped with specialized tools and knowledge, often resulting in a quicker and more reliable resolution to issues.