Understanding the Ms260 Parts Diagram for Efficient Maintenance

When delving into the intricacies of a particular machine, one must explore its various elements that contribute to its overall functionality. This exploration unveils how each section operates in harmony, ensuring that the equipment performs optimally. By gaining insight into the structure and arrangement of these features, users can enhance their operational efficiency and troubleshooting skills.

In this discussion, we will dissect the various segments that make up the unit, highlighting their roles and interactions. Analyzing these components not only sheds light on their individual purposes but also on how they collectively contribute to the machine’s performance. Understanding these connections can empower users to make informed decisions regarding maintenance and repairs.

As we proceed, expect to encounter detailed representations and illustrations that clarify the layout and organization of these critical elements. Whether for a seasoned technician or a curious novice, this examination will serve as a valuable resource for navigating the complexities of the equipment in question.

Understanding the Ms260 Parts Diagram

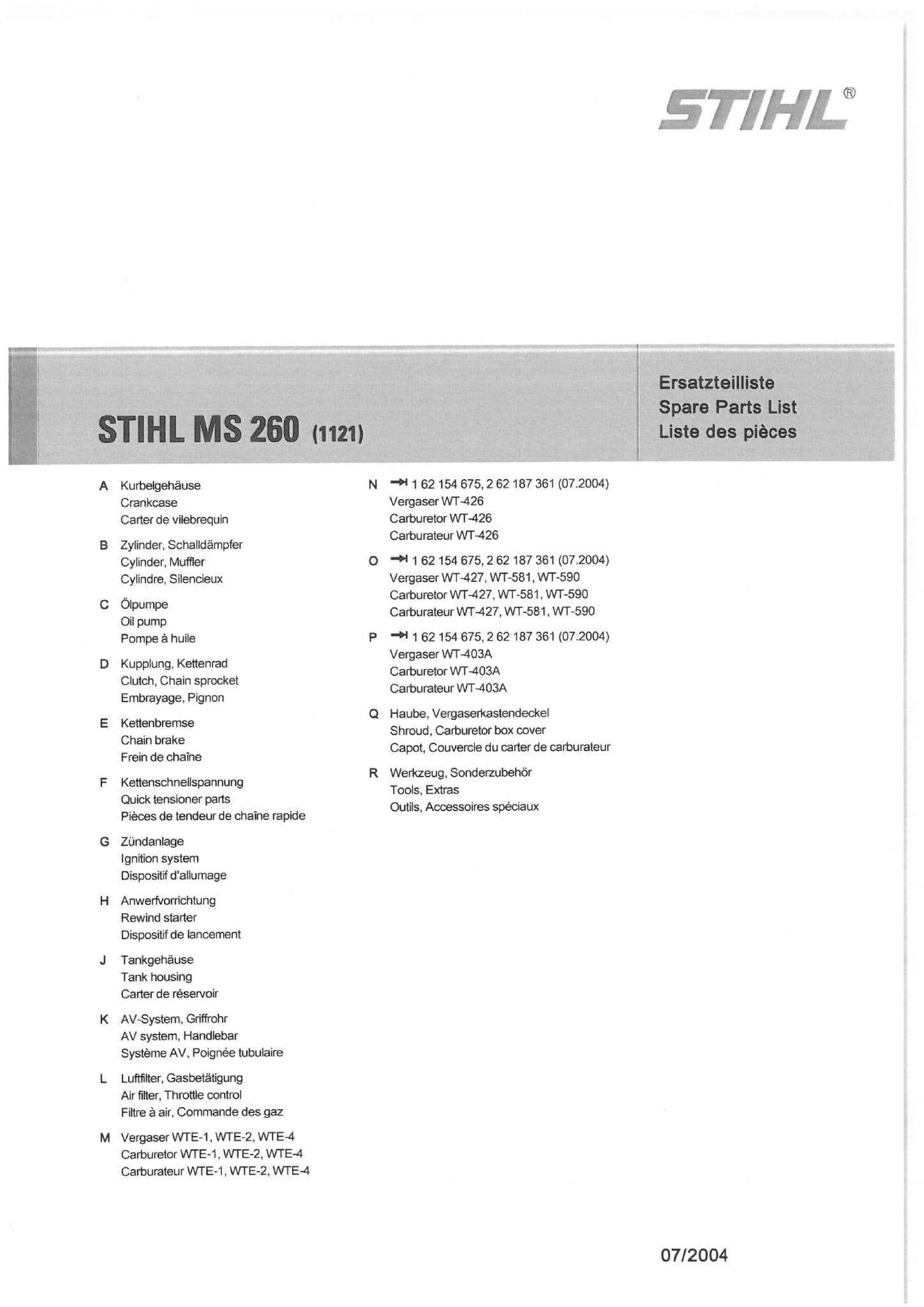

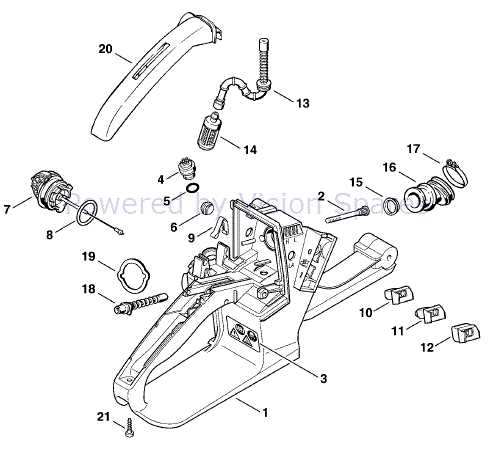

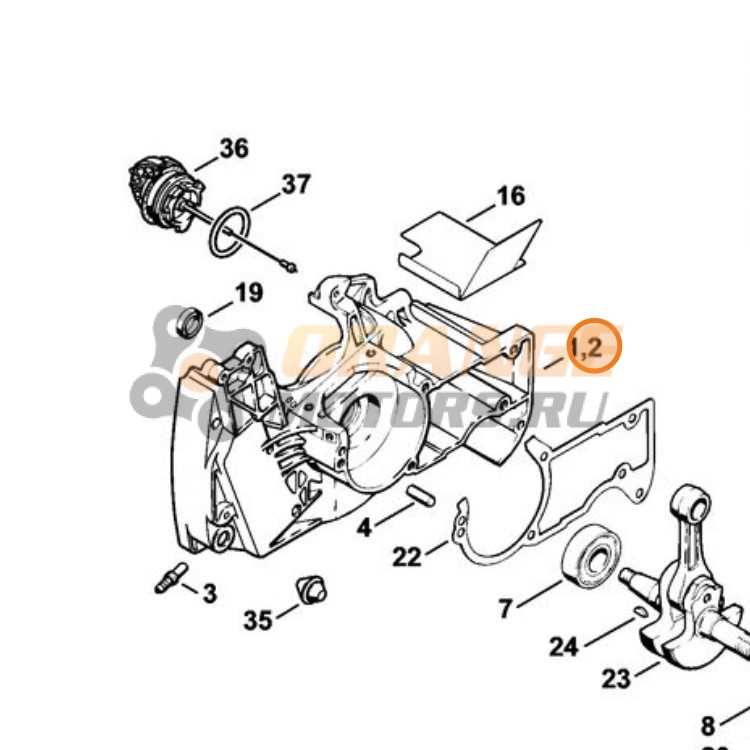

Grasping the layout of components in machinery is essential for effective maintenance and repair. This visual representation serves as a crucial guide, illustrating how various elements fit together and function as a cohesive unit. Familiarity with this schematic can significantly enhance one’s ability to troubleshoot issues and perform necessary replacements.

Key Elements of the Schematic

- Components: Each part is typically labeled with a unique identifier, making it easier to reference during repairs.

- Connections: The lines between elements indicate how they interact, highlighting pathways for energy or fluid movement.

- Specifications: Additional notes or legends may provide information on dimensions, materials, or compatible substitutes.

Benefits of Understanding the Layout

- Enhanced Troubleshooting: Quickly identify malfunctioning elements by cross-referencing the visual guide with symptoms.

- Efficient Repairs: Knowing the exact placement of components streamlines the replacement process.

- Improved Safety: Understanding how different parts interact helps in recognizing potential hazards.

Overview of Ms260 Model Features

This section explores the distinctive characteristics and functionalities of a specific model, highlighting its design and utility. The following features contribute to its reputation for reliability and efficiency, making it a preferred choice for various applications.

| Feature | Description |

|---|---|

| Engine Power | Equipped with a robust engine, delivering superior performance for demanding tasks. |

| Lightweight Design | Designed to be easy to handle, reducing user fatigue during extended use. |

| Durability | Constructed with high-quality materials to withstand harsh working conditions. |

| Ergonomic Features | Incorporates a user-friendly design with comfortable grips and controls. |

| Maintenance Accessibility | Designed for easy access to essential components, simplifying upkeep tasks. |

These attributes combine to enhance the overall user experience, making the model suitable for both professional and recreational use.

Key Components in Ms260 Assembly

Understanding the essential elements of an assembly is crucial for ensuring optimal performance and longevity. Each component plays a vital role, contributing to the overall functionality and efficiency of the system. A thorough knowledge of these parts facilitates proper maintenance and repairs, ultimately enhancing user experience.

Engine serves as the heart of the assembly, providing the necessary power for operation. It is essential for users to be familiar with its specifications and maintenance requirements to ensure seamless performance.

Fuel System is responsible for delivering energy to the engine. This includes various elements such as the tank, filter, and lines that must be regularly checked for any signs of wear or blockage to prevent performance issues.

Cooling Mechanism plays a crucial role in regulating temperature during operation. Components like the radiator and fan work together to dissipate heat effectively, safeguarding the engine from potential damage.

Transmission is key for power transfer between the engine and the working parts. Understanding its configuration and any adjustments needed can greatly impact the overall efficiency of the machinery.

Chassis provides the structural integrity necessary for stability. Its design must accommodate various loads and stresses, highlighting the importance of proper assembly and material quality.

Each of these components requires careful consideration and regular inspection to maintain peak performance. Familiarity with their functions and interrelations is essential for anyone involved in the operation or upkeep of the equipment.

Benefits of Using Parts Diagrams

Utilizing visual representations of components offers numerous advantages, enhancing both understanding and efficiency in maintenance and repair tasks. These illustrations serve as a crucial resource, providing clarity and detailed insights into the assembly and functionality of various elements within a system.

Improved Understanding

Visual aids allow technicians and users to quickly grasp the arrangement and relationship between individual elements. This clear depiction reduces confusion, enabling faster identification of components and their respective functions. Consequently, users can make informed decisions during troubleshooting and repairs.

Enhanced Efficiency

Having a well-organized visual reference streamlines the process of locating specific components, significantly decreasing the time spent on repairs. This efficiency not only boosts productivity but also minimizes the risk of errors, ensuring that tasks are completed correctly and in a timely manner.

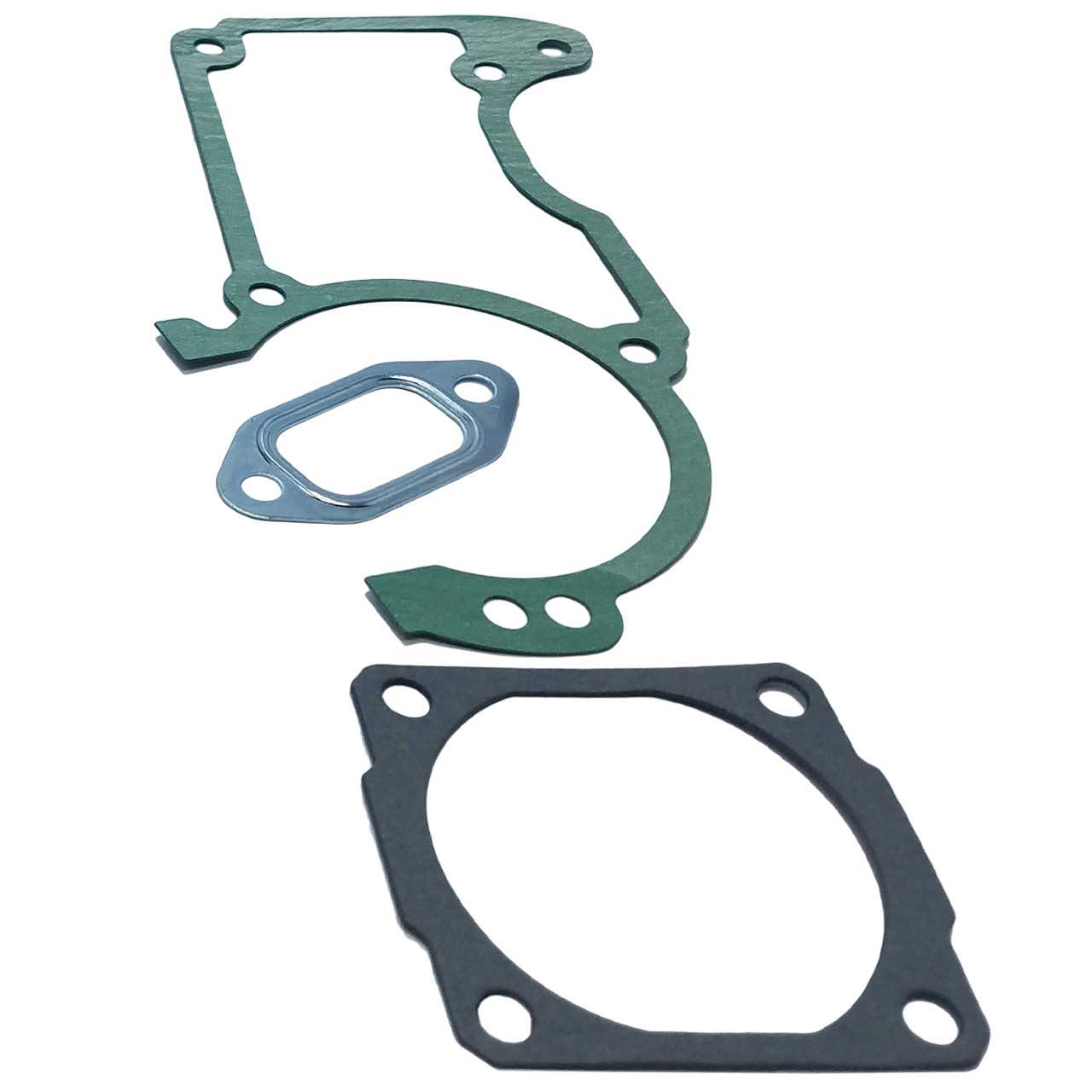

Common Repairs for Ms260 Equipment

Regular maintenance is crucial for ensuring the longevity and optimal performance of outdoor machinery. Familiarizing oneself with typical repair tasks can help users identify issues early and take corrective actions promptly. Here are some common repair tasks that often arise with this type of equipment.

-

Fuel System Issues:

- Clogged fuel filters may require replacement.

- Cleaning or replacing the fuel lines can resolve flow issues.

- Inspecting the carburetor for blockages is essential for proper operation.

-

Electrical Components:

- Check spark plugs for wear and replace if necessary.

- Inspect wiring for any signs of damage or corrosion.

- Testing the ignition coil can help diagnose starting problems.

-

Blade Maintenance:

- Sharpening dull blades enhances cutting efficiency.

- Replacing worn or damaged blades is crucial for safety.

- Adjusting blade tension can prevent unnecessary wear.

-

Cooling System:

- Cleaning air filters helps maintain proper airflow.

- Inspecting the cooling fins for debris is important for engine temperature control.

- Replacing the cooling fan if damaged ensures optimal performance.

By addressing these common issues, users can extend the lifespan of their machinery and enhance its efficiency. Regular inspections and proactive repairs contribute significantly to reliable operation.

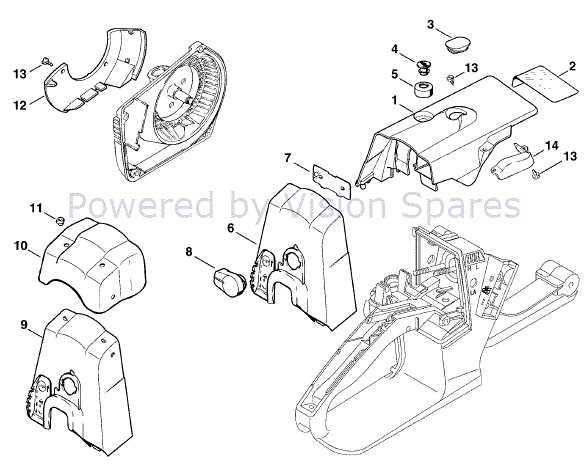

Identifying Components in the Diagram

Understanding the layout of various elements is crucial for effective maintenance and repair. A well-organized representation allows users to pinpoint specific items easily, enhancing the overall efficiency of their tasks. Each segment within the visual guide serves a unique purpose, contributing to the overall functionality of the machinery.

To navigate the visual representation effectively, it is essential to familiarize oneself with the labeling conventions. Components are typically identified through alphanumeric codes or descriptive tags, making it easier to locate the necessary parts. This structured approach minimizes confusion and facilitates swift identification.

Additionally, observing the relationships between different elements can provide insight into their interactions. Understanding how one component influences another can aid in troubleshooting and assembly. By recognizing these connections, users can develop a comprehensive view of the system’s operation, leading to more informed decisions during repairs or upgrades.

Tips for Maintaining Ms260 Parts

Proper upkeep of mechanical components is essential for ensuring optimal performance and longevity. By following a few best practices, you can significantly enhance the functionality and durability of your equipment.

Regular Cleaning: Keeping the components clean is crucial. Debris and residue can hinder performance and lead to wear. Use a soft brush or cloth to remove dirt, and ensure that any openings are free from blockages.

Frequent Inspections: Routine checks allow you to identify wear and tear early. Look for signs of damage, such as cracks or rust. Addressing these issues promptly can prevent more serious problems down the line.

Proper Lubrication: Lubrication minimizes friction between moving parts. Use the recommended lubricant for your specific components, applying it as needed to ensure smooth operation.

Temperature Management: Overheating can cause significant damage. Make sure your equipment is used within its specified temperature range, and allow it to cool down as necessary.

Storage Practices: When not in use, store your items in a dry, protected environment. Avoid exposure to harsh weather conditions, which can lead to deterioration.

Follow Manufacturer Guidelines: Always refer to the manufacturer’s recommendations for maintenance schedules and procedures. Adhering to these guidelines can help you maintain peak performance.

Where to Find Quality Replacement Parts

Finding high-quality components for your equipment is essential for maintaining performance and longevity. Whether you need a specific item for a repair or an upgrade, knowing where to look can save you time and money. Below are some reliable sources to consider when searching for premium replacements.

| Source | Description | Benefits |

|---|---|---|

| Authorized Dealers | Official retailers offering genuine items. | Quality assurance and warranty coverage. |

| Online Marketplaces | Websites that aggregate various sellers. | Wide selection and competitive pricing. |

| Local Repair Shops | Businesses specializing in repairs and replacements. | Expert advice and installation services. |

| Manufacturer Websites | Direct online resources from original makers. | Access to the latest products and updates. |

| Forums and Communities | Online groups where users share experiences. | Recommendations based on real-world usage. |

Exploring these avenues can help ensure you find the right components that meet your needs and standards. Prioritize quality to avoid potential issues down the line.

Understanding Part Numbering Systems

In various industries, the method of identifying components plays a crucial role in ensuring efficiency and accuracy in manufacturing and maintenance processes. A structured numbering approach facilitates quick recognition, ordering, and inventory management of items. By utilizing a systematic framework, organizations can streamline operations and minimize errors.

The Importance of Consistency

Consistency in a coding scheme is vital. A well-defined system enables users to decode the identifier easily, providing insight into the specifications or features of the item. This standardization aids in both communication and logistics, as all stakeholders can rely on a uniform language for referencing components.

Common Formats and Structures

Typically, identification systems may include a combination of letters and numbers, often reflecting attributes such as type, size, or material. For example, an identifier might begin with a letter denoting the category followed by digits indicating specific characteristics. This hierarchical structure allows for both broad and detailed classification, enhancing the organization’s ability to manage its inventory effectively.

In summary, understanding and implementing a coherent numbering methodology is essential for optimizing operational workflows. By adopting a structured approach, businesses can improve accuracy in component handling, ultimately leading to better productivity and reduced downtime.

Visualizing the Ms260 Engine Layout

Understanding the arrangement of components within an engine is crucial for maintenance and performance optimization. By examining the layout, one can gain insights into how various elements interact and contribute to overall functionality. This knowledge is essential for both novice enthusiasts and experienced technicians alike.

| Component | Description |

|---|---|

| Cylinder Block | The main structure housing the cylinders where combustion occurs. |

| Pistons | Movable parts that convert pressure from combustion into mechanical energy. |

| Crankshaft | Transforms the linear motion of the pistons into rotational motion. |

| Camshaft | Controls the timing of valve openings and closings during the combustion cycle. |

| Intake Manifold | Distributes the air-fuel mixture to each cylinder. |

| Exhaust Manifold | Collects exhaust gases from multiple cylinders and directs them to the exhaust system. |

Visual representations can greatly enhance comprehension of these interrelations, allowing for more effective troubleshooting and enhancements. Utilizing schematics or illustrations can further clarify the positions and connections of each component, fostering a deeper understanding of engine dynamics.

Common Issues and Troubleshooting Steps

When dealing with mechanical equipment, encountering challenges is not uncommon. Identifying the root cause of a malfunction can be crucial for effective resolution. This section outlines typical problems that may arise and provides systematic approaches to rectify them, ensuring optimal performance and longevity of the device.

Typical Challenges

Users often face various operational difficulties, which may stem from mechanical failures, improper maintenance, or environmental factors. Understanding these issues can simplify the troubleshooting process and enhance user experience.

Troubleshooting Guidelines

Here are some common issues along with their corresponding troubleshooting steps:

| Issue | Troubleshooting Steps |

|---|---|

| Inconsistent performance | Check for blockages, inspect the power source, and ensure all connections are secure. |

| Unusual noises | Examine moving parts for wear and tear, lubricate as necessary, and tighten loose components. |

| Difficulty starting | Verify fuel levels, check spark plugs, and clean the air filter. |

| Overheating | Inspect the cooling system, ensure proper ventilation, and clean debris from air intakes. |

By following these guidelines, users can effectively address common challenges and maintain the reliability of their equipment. Regular maintenance and prompt attention to issues can significantly prolong the lifespan of the machinery.

Comparing Ms260 with Similar Models

When evaluating a specific chainsaw model, it is essential to examine its features and specifications in relation to other comparable tools within the same category. This analysis not only highlights the strengths and weaknesses of the chosen equipment but also provides valuable insights for potential buyers who seek the best fit for their needs.

One notable competitor in this segment offers a lightweight design and enhanced ergonomics, making it an appealing choice for users who prioritize ease of handling during extended use. In contrast, another similar option boasts a more powerful engine, which may cater to professionals requiring robust performance for demanding tasks. Each of these alternatives presents distinct advantages, such as varying cutting capacities and maintenance requirements, influencing the overall user experience.

Moreover, aspects like fuel efficiency and noise levels can significantly impact user preference. While some models focus on delivering high power, others aim for a balance between performance and environmental considerations. Ultimately, understanding these differences allows prospective owners to make informed decisions based on their specific application needs and personal preferences.

FAQs About Ms260 Parts and Diagrams

This section addresses common inquiries regarding components and their visual representations. Understanding these elements can enhance your knowledge and improve maintenance and repair tasks.

Common Questions

- What should I consider when selecting replacement components?

- Are there any specific tools required for assembly and disassembly?

- How can I find reliable sources for obtaining quality replacements?

Visual Aids and Their Importance

- What role do illustrations play in the understanding of the assembly process?

- How can I use diagrams to troubleshoot issues effectively?

- Where can I access detailed visuals for better clarity on component arrangement?

These frequently asked questions serve as a guide for users seeking clarity and assistance in navigating the intricacies of various elements and their configurations.