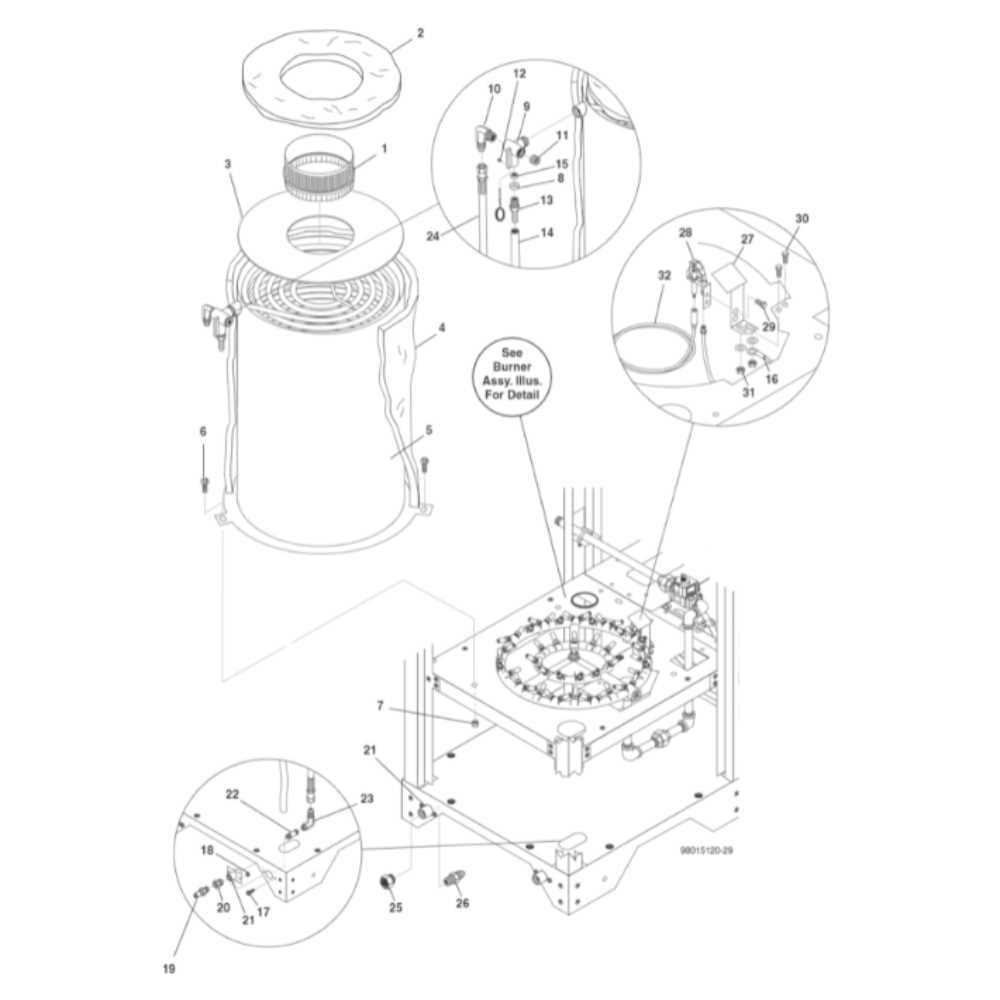

Mvwc565fw1 Parts Diagram Overview

In the realm of household machinery, comprehending the intricate elements that make up a device is essential for effective maintenance and repair. Each component plays a vital role, contributing to the overall functionality and efficiency of the unit. A clear understanding of these parts can empower users to troubleshoot issues and enhance performance.

Visual aids serve as invaluable tools in this educational journey, offering detailed representations of how various elements interact within the system. By exploring these illustrations, one can delve into the specifics of each part, understanding its function and importance. This knowledge not only facilitates repairs but also fosters a deeper appreciation for the engineering behind everyday appliances.

Ultimately, grasping the layout and organization of the individual components allows for a more informed approach to appliance care. With the right information at hand, anyone can confidently engage with their machinery, ensuring longevity and optimal performance.

Mvwc565fw1 Overview

This section provides a comprehensive look at a specific appliance model, highlighting its key features and functionality. Understanding its components and their interactions is essential for effective maintenance and operation.

- Design and Structure

- Performance Capabilities

- User-Friendly Features

- Common Issues and Solutions

Each aspect plays a vital role in ensuring optimal performance and longevity. Familiarizing yourself with these elements can enhance your overall experience.

Understanding Parts and Components

Every mechanical system comprises various elements that work together to achieve a specific function. Grasping the roles and interactions of these components is essential for effective maintenance and troubleshooting. Each element plays a crucial role in ensuring optimal performance, contributing to the overall efficiency and reliability of the assembly.

Identification of individual elements allows users to pinpoint issues and understand the assembly’s operational dynamics. Familiarity with each piece enhances comprehension of how they collectively contribute to the system’s functionality. This knowledge is vital for anyone involved in repairs or enhancements, as it facilitates informed decision-making.

Interconnections among components are equally important, as they dictate how forces and motions are transmitted throughout the system. Understanding these relationships helps in diagnosing malfunctions and implementing effective solutions. By examining how each part interacts, one can better appreciate the intricacies of mechanical design.

Importance of Diagrams in Repairs

Visual representations play a crucial role in the repair process, serving as essential tools for technicians and DIY enthusiasts alike. They provide clarity and guidance, ensuring that individuals can easily understand complex assemblies and identify components quickly. This enhances efficiency and reduces the likelihood of errors during maintenance tasks.

Enhancing Understanding

Clear illustrations simplify intricate systems, allowing users to grasp how various elements interact. By breaking down complicated machinery into manageable sections, these visual aids foster a deeper comprehension of the overall structure. This understanding is vital for diagnosing issues effectively and implementing the right solutions.

Streamlining the Repair Process

Having access to accurate representations significantly accelerates the repair timeline. Technicians can quickly locate specific parts and follow step-by-step procedures, minimizing downtime. Moreover, visual tools help in organizing the workflow, ensuring that all necessary tasks are completed in a systematic manner, which ultimately leads to higher productivity and successful outcomes.

How to Read Technical Diagrams

Understanding complex visual representations is crucial for effective problem-solving and maintenance. These illustrations provide essential insights into the structure and functionality of devices, allowing users to grasp intricate relationships between components.

1. Familiarize Yourself with Symbols: Each illustration contains specific symbols that represent different elements. Learning these symbols is the first step toward comprehension.

2. Follow the Flow: Identify the directional indicators, which often demonstrate how parts interact. This will help you trace the function and process within the system.

3. Pay Attention to Labels: Descriptive text accompanying the visuals can clarify the purpose and specifications of each element. Reading these carefully is essential.

4. Break It Down: Analyze the illustration in sections. Focus on one part at a time to avoid feeling overwhelmed by the overall complexity.

5. Cross-reference with Documentation: Utilize accompanying manuals or guides for additional context. This will enhance your understanding of the entire system.

By mastering these techniques, you can effectively interpret visual guides and apply this knowledge to your projects, ultimately increasing your technical proficiency.

Common Issues with Mvwc565fw1

Every appliance has its quirks, and certain models often encounter similar challenges. Understanding these common problems can help users maintain their equipment effectively and enhance longevity. From unusual noises to performance inconsistencies, being aware of potential pitfalls can save time and frustration.

Frequent Performance Problems

One of the most notable issues includes irregular washing cycles, where the machine may not complete its tasks as expected. This can be attributed to clogged filters or malfunctioning sensors. Regular maintenance is crucial to prevent such disruptions. Additionally, users may experience spinning problems, often caused by an unbalanced load or worn-out components.

Noise and Vibration Concerns

Unusual sounds during operation can indicate underlying issues. Rattling or grinding noises may stem from loose parts or foreign objects trapped within the mechanism. It’s advisable to check for any debris and ensure all components are securely fastened. Addressing these sounds promptly can prevent further damage and ensure smooth functionality.

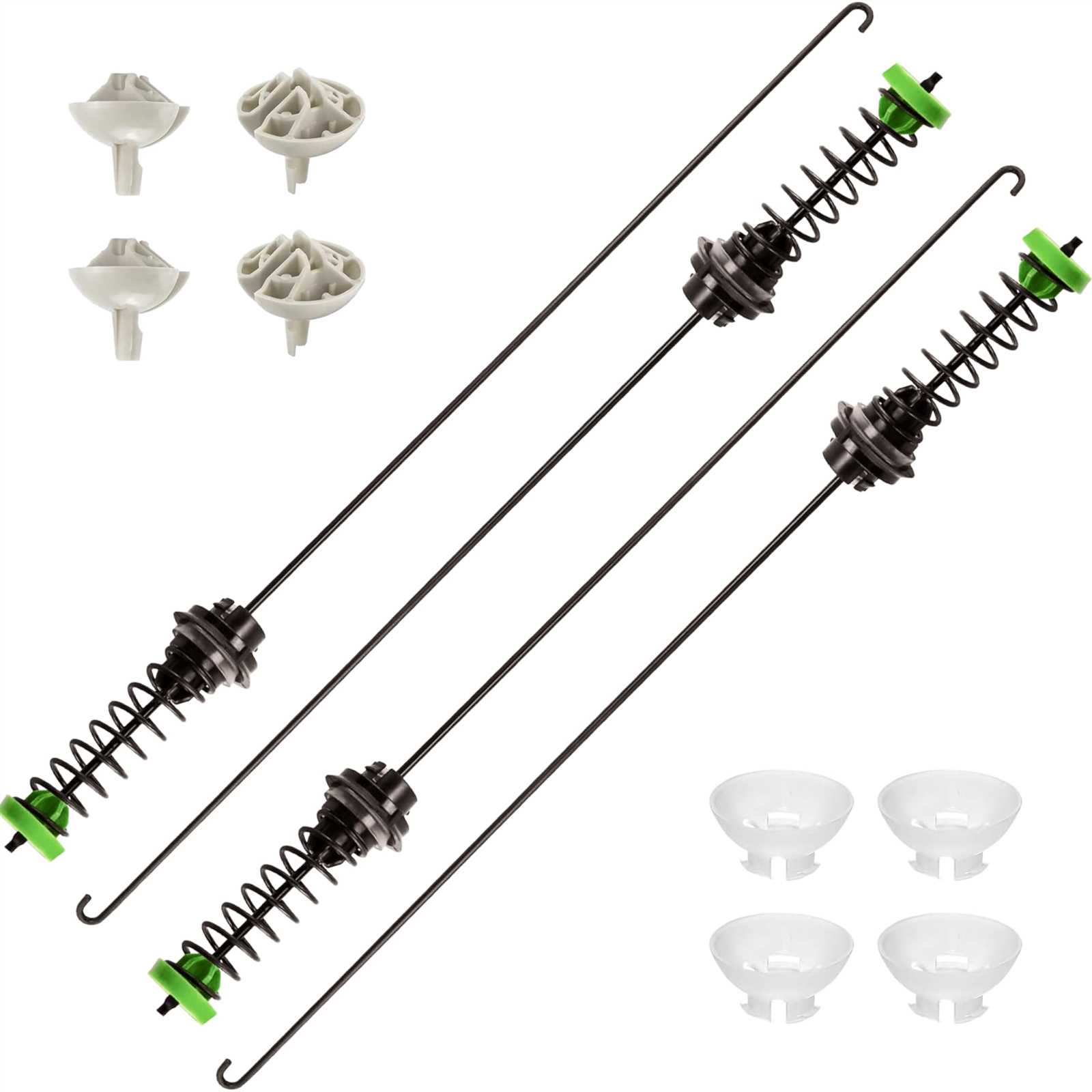

Replacing Worn-Out Parts Effectively

Maintaining the longevity and performance of your equipment often requires timely replacement of components that have experienced wear. Understanding when and how to swap out these essential pieces can significantly enhance overall efficiency and prevent potential malfunctions. This section aims to guide you through the effective process of replacing fatigued elements, ensuring optimal functionality and safety.

Identifying Signs of Wear

Recognizing the symptoms of deterioration is crucial. Look for unusual noises, leaks, or irregular performance as indicators that something may be amiss. Regular inspections can help pinpoint these issues before they escalate, allowing for proactive measures rather than reactive fixes.

Choosing Quality Replacements

When it comes to substitutions, selecting high-quality replacements is paramount. Consider factors such as compatibility, durability, and manufacturer recommendations. Investing in reliable components not only ensures better performance but also contributes to the overall lifespan of your equipment.

Tools Required for Maintenance

Effective upkeep of your appliance necessitates a range of specific instruments to ensure thorough service and longevity. Having the right tools not only simplifies the process but also enhances the efficiency of repairs, ultimately prolonging the life of your equipment.

Essential Instruments

For comprehensive maintenance, it is crucial to have a set of basic instruments at hand. This includes screwdrivers, wrenches, and pliers, which enable you to easily access and secure components. Additionally, a multimeter can be invaluable for diagnosing electrical issues, ensuring that every aspect is in optimal condition.

Safety Equipment

Incorporating safety measures is equally important. Equip yourself with gloves and goggles to protect against potential hazards during repairs. Utilizing a sturdy workbench can also provide stability and enhance safety, allowing you to focus on the task at hand without distraction.

Where to Find Replacement Parts

Finding the right components for your appliances can be crucial for maintaining their functionality. Whether you’re looking to replace a worn-out item or enhance performance, knowing where to look is essential. Various resources are available to help you track down the necessary elements without hassle.

Online Retailers

Many websites specialize in providing a wide range of components for various models. These platforms often feature user-friendly search tools that allow you to input your appliance’s model number, making it easier to locate the specific items you need. Popular online marketplaces often have customer reviews, which can help you assess the quality of the products before making a purchase.

Local Repair Shops

Visiting a nearby repair shop can be a beneficial option. Not only can you get immediate assistance from knowledgeable staff, but they may also have an inventory of essential items readily available. Additionally, some shops offer the opportunity to order specific components if they’re not in stock, ensuring you find exactly what you need. Establishing a relationship with local experts can also lead to valuable insights and recommendations for maintaining your equipment.

Preventive Maintenance Tips

Regular upkeep is essential for ensuring the longevity and efficiency of any machinery. By implementing proactive measures, you can reduce the likelihood of unexpected breakdowns and enhance overall performance. This section outlines effective strategies to maintain equipment in optimal condition.

Firstly, establish a consistent inspection schedule. Regularly examining components allows you to identify wear and tear early, enabling timely repairs. Utilize checklists to track vital areas that require attention, ensuring nothing is overlooked.

Secondly, ensure proper lubrication of moving parts. Adequate grease and oil reduce friction, preventing overheating and excessive wear. Adhere to manufacturer recommendations for lubricants and application frequency to achieve the best results.

Additionally, keep all areas clean and free of debris. Dirt and grime can accumulate, leading to inefficient operation and potential damage. Implement routine cleaning protocols to maintain a tidy workspace and protect equipment surfaces.

Lastly, train personnel on best practices for handling and operating machinery. Knowledgeable staff are less likely to make errors that could cause harm. Providing ongoing education and resources promotes a culture of safety and responsibility.

Expert Recommendations for Longevity

To ensure the prolonged performance and durability of your appliance, it’s essential to adopt best practices that prioritize care and maintenance. Experts emphasize the importance of routine inspections and timely replacements to prevent minor issues from escalating into major problems.

Regular Cleaning: Keeping the unit clean is crucial. Dust and debris can accumulate, leading to inefficiencies. Make it a habit to wipe down surfaces and check for blockages in airflow.

Proper Usage: Following the manufacturer’s guidelines on usage can significantly extend the lifespan. Avoid overloading and ensure that settings are appropriate for the task at hand.

Scheduled Maintenance: Implementing a schedule for professional check-ups can help identify potential issues early. Experts suggest at least annual inspections to keep everything running smoothly.

Environment Control: The surroundings can impact functionality. Ensure that the unit is kept in a stable environment, free from extreme temperatures and humidity levels that could affect performance.

Quality Parts: When replacements are necessary, always opt for high-quality components. Investing in superior materials will ultimately lead to better efficiency and longevity.