Comprehensive Guide to Oregon 511a Parts Diagram

When it comes to maintaining outdoor machinery, having a clear grasp of its essential elements is vital for ensuring optimal performance and longevity. An organized approach to understanding these components allows users to troubleshoot effectively and make informed decisions regarding repairs and replacements.

In this exploration, we will break down the intricate parts that make up your tool, highlighting their functions and interrelations. This knowledge not only empowers users but also enhances the overall efficiency of the equipment, leading to more satisfying and successful operations.

By delving into the specifics of each element, enthusiasts and professionals alike can gain a deeper appreciation for their gear. The ultimate goal is to foster a connection between the user and the machine, making each task more manageable and enjoyable.

Understanding Oregon 511a Components

This section explores the essential elements that contribute to the functionality of a specific outdoor tool. Recognizing these components can enhance the user’s experience and improve overall performance.

Key components include:

- Engine System: Responsible for power generation and efficiency.

- Cutting Mechanism: Ensures precision in operation and effectiveness in various conditions.

- Handle Structure: Provides comfort and control during use.

- Safety Features: Critical for preventing accidents and ensuring user protection.

Understanding each element’s role allows users to make informed decisions and optimize their usage.

Importance of Accurate Parts Diagrams

Precise visual representations of components play a crucial role in the maintenance and repair of machinery. These illustrations serve as a guide, ensuring that users can identify the necessary elements for efficient assembly and troubleshooting. When each piece is clearly depicted, it minimizes the chances of errors during the service process, leading to improved performance and longevity of the equipment.

Benefits of Clear Visual Representations

Having well-defined images provides numerous advantages for technicians and users alike. Firstly, it streamlines the identification of specific components, which is vital when ordering replacements or conducting repairs. Secondly, accurate visual aids reduce the likelihood of misinterpretation, thereby enhancing safety during operation.

Impact on Maintenance Efficiency

Moreover, effective illustrations contribute significantly to maintenance efficiency. When users can easily locate and understand the function of each element, it facilitates quicker repairs and routine checks. This not only saves time but also cuts down on potential costs associated with prolonged downtimes.

| Aspect | Importance |

|---|---|

| Identification | Ensures correct parts are selected and ordered. |

| Safety | Minimizes risk of mishandling or incorrect assembly. |

| Efficiency | Reduces time needed for repairs and maintenance. |

How to Access Oregon 511a Schematics

Finding the necessary technical blueprints for equipment maintenance can greatly enhance your understanding of its components and functionality. With the right resources, you can easily obtain detailed schematics that aid in repairs and upgrades.

Online Resources

Start by exploring official websites and forums dedicated to gardening tools and machinery. These platforms often host a wealth of information, including downloadable files that detail the inner workings of various models.

Manufacturer Support

Another reliable method is to contact the manufacturer directly. They typically provide customer support that can guide you to the ultimate resources, ensuring you have access to the most accurate and updated schematics available.

Common Issues with Oregon 511a Parts

Many users encounter a variety of challenges with their equipment components, leading to performance issues and increased maintenance needs. Understanding these common problems can help in troubleshooting and ensuring optimal functionality.

Frequent Wear and Tear

One prevalent concern is the gradual deterioration of certain elements due to regular use. This can result in decreased efficiency and may require timely replacements to maintain performance. Inspecting these components regularly is crucial for longevity.

Compatibility Problems

Another issue arises from mismatched components that can hinder overall operation. Using non-compatible elements can lead to malfunctions or subpar performance. Ensuring proper fit and specifications is essential for seamless operation.

Essential Tools for Repairing Oregon 511a

When it comes to maintaining and fixing garden machinery, having the right tools at your disposal is crucial. These instruments not only streamline the repair process but also enhance the effectiveness of your efforts. A well-equipped workspace ensures that you can tackle any issue that arises efficiently and safely.

Basic Hand Tools

Start with a solid collection of hand tools, including wrenches, screwdrivers, and pliers. These essentials are vital for disassembling components and performing adjustments. Consider a toolkit that offers various sizes to accommodate different fittings, ensuring versatility for any task.

Specialized Equipment

In addition to standard tools, certain specialized equipment can greatly assist in more complex repairs. An adjustable torque wrench is indispensable for ensuring parts are tightened to the manufacturer’s specifications. A multimeter can also be invaluable for diagnosing electrical issues, making it easier to pinpoint faults quickly.

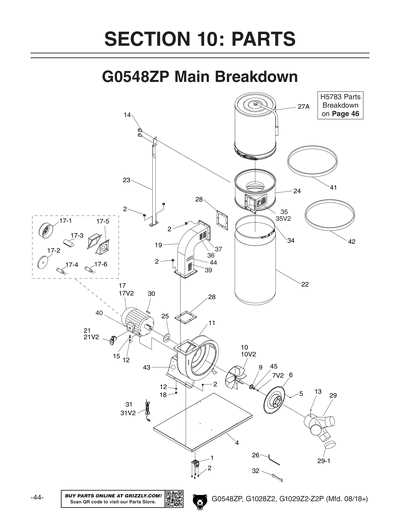

Identifying Parts in the Diagram

Understanding the components illustrated in a schematic is essential for effective maintenance and repair. Each element plays a vital role in the overall functionality, making it important to recognize and comprehend their specific purposes. By familiarizing oneself with the layout and symbols used, one can better navigate the complexities of the machinery.

Begin by examining the labeled sections, which often provide clues about the function of each item. Look for distinctive features that differentiate similar parts, and note any accompanying numbers or letters that may correlate with a reference guide. This systematic approach will enhance your ability to troubleshoot issues and optimize performance.

As you explore the visual representation, consider creating a checklist or a reference sheet to keep track of your findings. This practice not only aids memory but also serves as a valuable resource during future inspections. With careful attention, you will gain a deeper understanding of how each element contributes to the machinery’s operation.

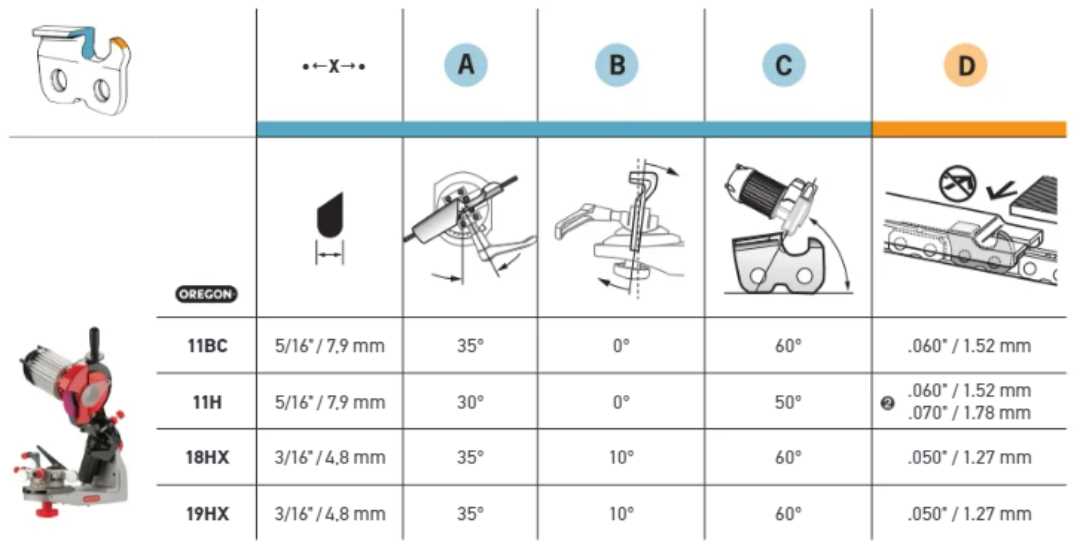

Comparison with Other Oregon Models

This section explores the distinctions and similarities among various models from the same brand, highlighting features that set them apart while emphasizing their commonalities. Understanding these differences can help users make informed decisions based on their specific needs.

Performance: Different models often cater to varying performance requirements. Some are designed for heavy-duty tasks, while others excel in lighter applications. Evaluating the intended use is crucial for selecting the most suitable option.

Design: Aesthetic and functional designs vary across models. Certain versions may incorporate advanced ergonomics, enhancing user comfort, whereas others might prioritize compactness for ease of storage.

Compatibility: Users should consider how well accessories and attachments from one model can integrate with others. Compatibility can significantly influence maintenance costs and overall user experience.

Pricing: Cost ranges differ widely, reflecting the features and capabilities of each model. It is essential to weigh the benefits against the price to determine which unit offers the best value for the intended tasks.

Ultimately, a thorough comparison enables potential buyers to delve into the specifics, ensuring they select a model that aligns perfectly with their requirements and preferences.

Maintenance Tips for Oregon 511a

Proper upkeep is essential for ensuring the longevity and performance of your equipment. Regular maintenance not only enhances efficiency but also prevents potential breakdowns, saving time and money in the long run. Here are some effective strategies to keep your device in optimal condition.

First, always clean the components after each use. Debris and residue can accumulate and negatively impact performance. Utilize a soft brush and a damp cloth to remove dirt and dust, ensuring that all moving parts are free from obstructions.

Next, inspect all connections and attachments regularly. Look for signs of wear, such as frayed edges or loosened fasteners. Tightening screws and replacing worn-out pieces can prevent larger issues down the road.

Additionally, lubrication is key. Apply appropriate grease or oil to moving parts as specified in the manufacturer’s guidelines. This helps reduce friction and wear, allowing the equipment to operate smoothly.

Lastly, store the unit in a dry, protected area when not in use. This prevents exposure to moisture and extreme temperatures, which can damage components and lead to rust. By following these simple maintenance tips, you can extend the life of your equipment and ensure it remains reliable for all your tasks.

Resources for Oregon Parts Replacement

This section offers a comprehensive overview of avenues available for obtaining essential components for machinery. Understanding where to find reliable replacements can streamline maintenance and enhance performance, ensuring optimal functionality.

Online Marketplaces

Numerous digital platforms provide a vast selection of components. Websites such as e-commerce giants often feature user-friendly interfaces, allowing for easy comparison of prices and availability.

Local Suppliers and Workshops

Engaging with local vendors can yield valuable insights. Strong relationships with nearby workshops often lead to personalized service, quick access to required items, and expert advice on installation and compatibility.

User Experiences and Reviews

This section highlights insights and feedback from individuals who have engaged with the product. Their perspectives offer valuable information for potential users and enthusiasts alike.

- Ease of Use: Many users appreciate the straightforward setup process, which allows for quick and efficient operation.

- Durability: Several reviews commend the robust design, emphasizing its ability to withstand regular use without significant wear.

- Performance: Feedback often highlights the reliable functionality, with users noting consistent results across various applications.

Overall, the shared experiences reveal a positive trend, with numerous users recommending the item for both novice and seasoned individuals.

Future Updates and Diagram Changes

As technology advances, it becomes essential to continually refine and enhance the visual representations of components. This ongoing evolution aims to improve clarity and accessibility for users, ensuring they have the most accurate information at their fingertips.

Regular revisions will address user feedback and incorporate the latest innovations, allowing for a more intuitive understanding of the mechanisms involved. Future iterations will not only update existing visuals but may also introduce entirely new elements to better serve the community’s needs.

Staying informed about these updates is crucial for maximizing functionality and efficiency. By actively engaging with new releases, users can ensure they are utilizing the most current resources available.