Understanding the Key Components of a Radiator Diagram

In the realm of home heating, the intricate interplay of various elements ensures efficiency and comfort. Each component plays a crucial role, contributing to the overall functionality of the system. A comprehensive grasp of these individual units enables homeowners and technicians alike to maintain and optimize performance effectively.

Familiarity with the distinct features of each segment can illuminate how they work together to provide warmth during colder months. The design and arrangement of these units are pivotal, as they dictate the flow of heated fluid and its distribution throughout a space.

Moreover, understanding the relationships among these elements aids in troubleshooting potential issues, ultimately enhancing the longevity of the system. By exploring the specifics of each unit, one can appreciate the sophisticated engineering that underpins reliable heating solutions.

Understanding Radiator Components

In any heating system, certain essential elements work together to ensure efficient warmth distribution. Grasping the function and interrelation of these components is crucial for both maintenance and optimization. This knowledge empowers users to identify issues and enhance the overall performance of their heating solution.

Key Elements and Their Functions

Each component serves a specific role, contributing to the effective transfer of heat. For instance, the main body acts as the core where thermal energy is released into the surrounding environment. Meanwhile, the fittings and valves regulate the flow of hot fluid, ensuring that the system operates smoothly and responds to the desired settings.

Importance of Maintenance

Regular upkeep of these essential components is vital for longevity and efficiency. Inspecting connections for leaks and ensuring that no air is trapped within the system are critical steps. Understanding these elements not only aids in effective maintenance but also enhances energy efficiency, ultimately leading to cost savings and improved comfort.

Function of a Radiator in Heating

The primary role of this essential component in a heating system is to transfer warmth into the surrounding environment. By efficiently managing the flow of heated fluid, it ensures that indoor spaces maintain a comfortable temperature, contributing to overall comfort during colder months.

This device operates on the principle of convection and conduction, allowing heat to radiate outward and circulate within the room. As the heated fluid passes through, it warms the surface, which in turn heats the air in contact with it. This process creates a continuous movement of warm air, effectively distributing heat throughout the area.

In addition to providing comfort, the unit plays a vital role in energy efficiency. By optimizing heat distribution, it minimizes energy consumption, making it an integral part of modern heating solutions. Proper placement and maintenance further enhance its performance, ensuring that every corner of a space benefits from the warmth it generates.

Main Parts of a Radiator

Understanding the essential components of a heating system is crucial for effective maintenance and operation. Each element plays a specific role in ensuring efficient heat distribution and overall functionality. This overview highlights the key elements that contribute to the performance of these essential appliances.

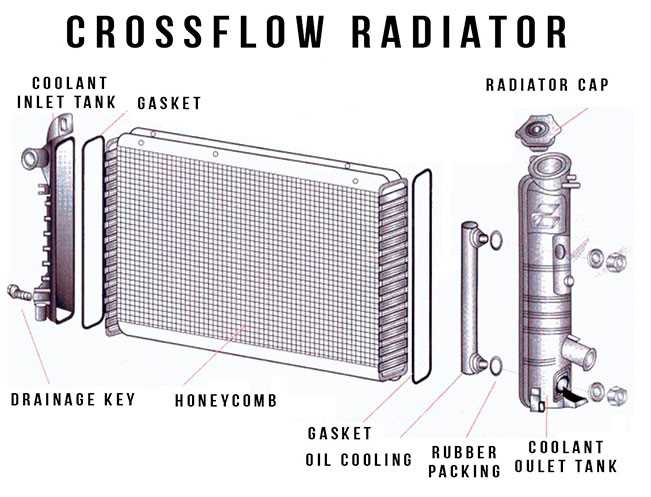

Heat Exchanger: This core element facilitates the transfer of thermal energy from the heating medium to the surrounding air. Its design maximizes surface area, enhancing the efficiency of heat transfer.

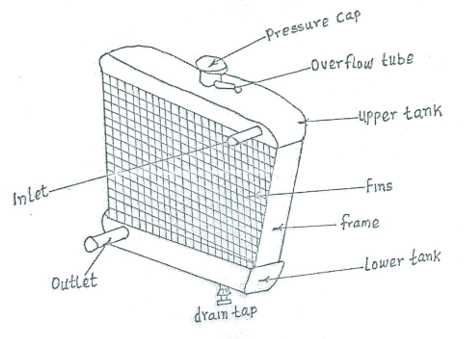

Inlet and Outlet Valves: These mechanisms regulate the flow of the heating medium into and out of the unit. Proper functioning of these valves is vital for maintaining optimal pressure and temperature levels.

Body: The main structure holds the heating medium and provides the necessary surface area for heat emission. Its material and design influence both durability and thermal efficiency.

Mounting Brackets: These support structures ensure stability and secure positioning. They are essential for safe installation and alignment with the heating system.

Thermostatic Controls: These devices allow users to set and maintain desired temperature levels, providing convenience and enhancing energy efficiency. They respond to temperature changes by adjusting the flow of the heating medium accordingly.

Types of Radiators Explained

Understanding the various heating elements available can enhance comfort and efficiency in any space. Each design has unique characteristics that cater to different needs, styles, and installation requirements. By exploring these options, one can make an informed choice suited to specific environments.

Convection Heaters are among the most common types. They function by circulating warm air throughout a room, creating a cozy atmosphere. These models are often compact and can fit seamlessly into various settings, making them a popular choice for both residential and commercial use.

Infrared Units operate differently, emitting heat directly to objects and individuals in the vicinity. This type is particularly effective for spot heating and can provide instant warmth. Ideal for outdoor spaces or areas with high ceilings, they deliver a unique experience of comfort.

Steam Models utilize heated water that transforms into steam, distributing warmth effectively. While traditional, they remain a favored option in older buildings and are known for their longevity and reliability.

Electric Variants offer flexibility and ease of use. With no need for complex installation, these devices can be plugged in and operated in various locations. They are perfect for those who seek convenience and targeted heating solutions.

Each type presents distinct advantages and considerations. By evaluating individual requirements and preferences, one can select the most suitable option for effective heating solutions.

How Coolant Flows Through a Radiator

The process of fluid circulation within a heat exchange system is crucial for maintaining optimal operating temperatures in engines. This intricate flow mechanism ensures that excess heat is effectively dissipated, allowing the machinery to function efficiently and reliably.

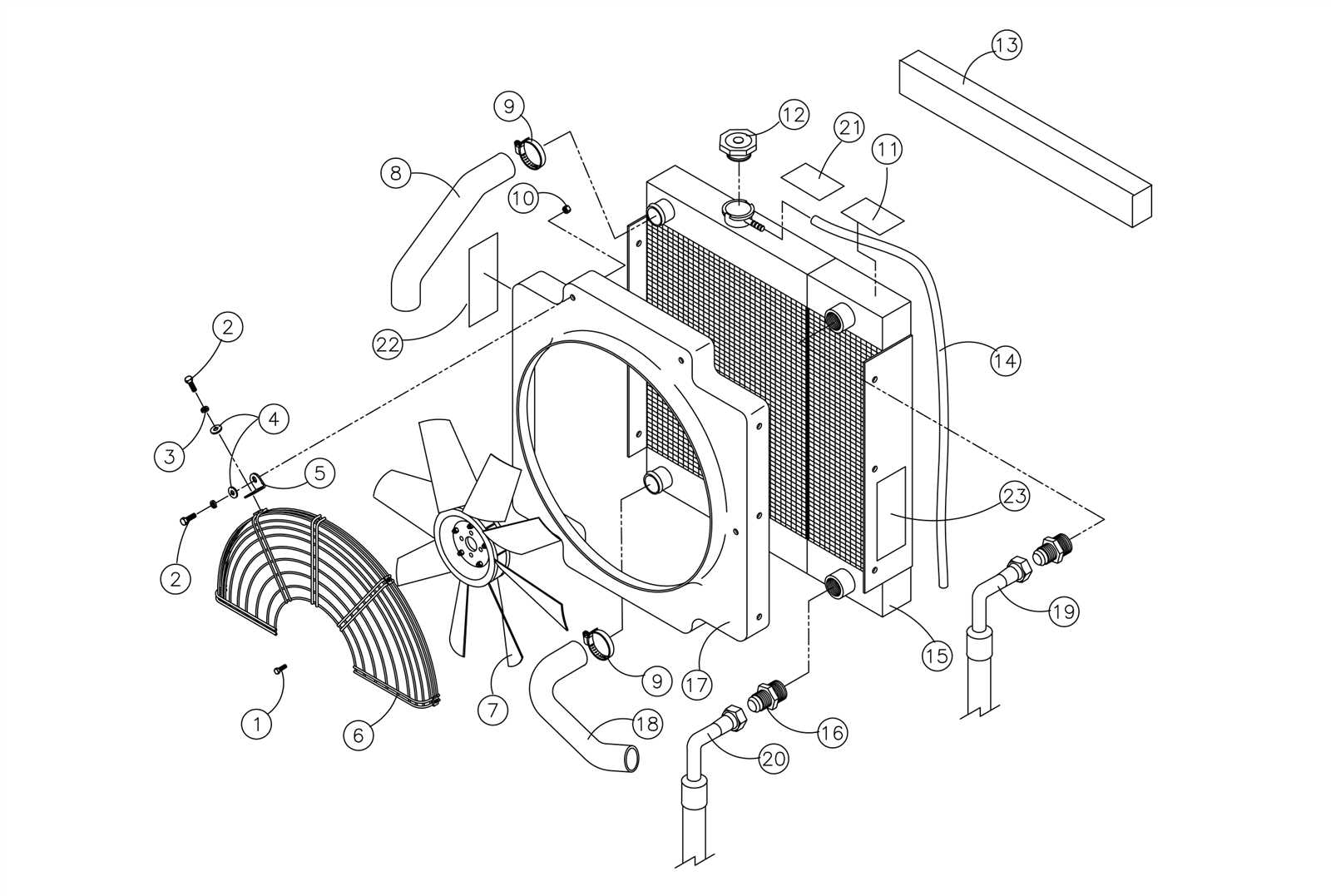

Initially, the heated liquid emerges from the engine block, where it absorbs thermal energy generated during combustion. As it travels through the connected channels, the fluid reaches the cooling unit, where its temperature begins to decrease. The movement is driven by a pump that creates pressure, facilitating a continuous loop.

Upon entering the cooling unit, the liquid disperses through a network of tubes. Here, it encounters ambient air, which helps to reduce its temperature. The design of the cooling unit maximizes contact with the surrounding air, enhancing the heat exchange process. As the fluid loses heat, it cools down significantly before returning to the engine to repeat the cycle.

Overall, this continuous circulation not only prevents overheating but also enhances the performance and longevity of the engine. Understanding the flow dynamics of the coolant is essential for anyone interested in the efficient operation of thermal management systems.

Importance of Radiator Fins

The efficiency of heat exchange systems relies heavily on specific components that enhance the overall performance. Among these, certain extensions play a crucial role in maximizing surface area and promoting optimal thermal conductivity. Their design is key to ensuring effective dissipation of heat, which is vital in various applications, from automotive engines to heating systems in buildings.

Enhancing Heat Transfer

Fins significantly improve the transfer of heat from a fluid to the surrounding environment. By increasing the surface area, they allow for greater interaction with airflow, leading to enhanced cooling performance. This feature is particularly important in scenarios where high temperatures need to be managed efficiently to prevent overheating.

Energy Efficiency

Utilizing well-designed extensions can lead to improved energy efficiency. When the heat removal process is streamlined, it minimizes the energy required to maintain optimal operating temperatures. This not only reduces operational costs but also contributes to a more sustainable approach in various industries.

Role of the Radiator Cap

The cap on a cooling system plays a crucial role in maintaining optimal performance and efficiency. It acts as a barrier that regulates pressure within the system, ensuring that fluids circulate effectively and preventing overheating. Understanding its function is essential for anyone interested in the inner workings of a vehicle’s cooling mechanism.

Pressure Regulation

One of the primary functions of this component is to control the pressure inside the cooling system. By maintaining the appropriate pressure levels, it helps prevent the coolant from boiling and ensures a consistent flow. This regulation is vital for the system to operate efficiently and protect the engine from damage.

Sealing and Safety

In addition to pressure control, the cap also provides a seal that keeps the cooling fluid from escaping. This sealing function helps to maintain the necessary fluid levels, which is essential for effective temperature regulation. Furthermore, modern designs often include safety features that release pressure if it becomes too high, thereby protecting the system from catastrophic failure.

| Function | Description |

|---|---|

| Pressure Control | Maintains optimal pressure to prevent coolant from boiling. |

| Fluid Sealing | Prevents coolant loss, ensuring effective temperature management. |

| Safety Release | Releases excess pressure to protect the system from damage. |

Connecting Pipes and Their Functions

In any heating system, the network of tubes plays a crucial role in ensuring efficient thermal transfer and circulation of heated fluid. These conduits facilitate the movement of hot liquid from the source to various areas, promoting even distribution and optimal comfort within a space. Understanding their configurations and roles is essential for effective system design and maintenance.

The layout of these conduits can vary significantly, depending on the specific needs of the environment. Each type of tube serves distinct purposes, from supplying heated fluid to returning cooler liquid for reheating. Here’s a brief overview of their main functions:

| Type of Pipe | Function |

|---|---|

| Supply Pipe | Delivers heated fluid from the source to the heating units. |

| Return Pipe | Transports cooled fluid back to the heating source for reheating. |

| Bypass Pipe | Allows fluid to bypass certain areas, maintaining flow and pressure. |

| Drain Pipe | Facilitates the removal of liquid for maintenance or system flushing. |

Each connection point along these conduits must be carefully considered to ensure maximum efficiency and reliability in the overall system. Proper installation and maintenance can lead to enhanced performance and longevity of the entire heating arrangement.

Understanding Radiator Valves

In the realm of heating systems, control mechanisms play a crucial role in regulating the flow of warmth throughout a space. These devices allow users to adjust temperatures according to their preferences and ensure optimal energy efficiency. Familiarity with these control units enhances the overall experience of any heating setup.

Types of Control Mechanisms

There are several types of control devices commonly found in heating systems:

- Manual Valves: These require physical adjustment to control temperature.

- Thermostatic Valves: These automatically adjust flow based on the room temperature.

- Electronic Valves: These provide precise control through digital interfaces.

Benefits of Proper Control

Utilizing the right type of control mechanism offers numerous advantages:

- Improved energy efficiency by minimizing waste.

- Enhanced comfort by maintaining consistent temperatures.

- Extended lifespan of the entire heating system.

Understanding the different types and benefits of these control devices is essential for optimizing heating solutions and achieving a comfortable living environment.

What Is a Radiator Core?

The core serves as the heart of the cooling system, playing a crucial role in dissipating heat generated by the engine. Its efficient design ensures optimal temperature regulation, allowing the entire mechanism to function smoothly. Understanding this component is essential for grasping how vehicles maintain operational efficiency.

Structure and Functionality

This central element typically consists of multiple channels through which coolant flows, facilitating heat exchange with the surrounding air. The arrangement maximizes surface area, enhancing the cooling effect and ensuring that the liquid is adequately cooled before it circulates back to the engine.

Materials and Efficiency

Constructed from materials like aluminum or copper, this component is designed to withstand high temperatures and pressures. Its efficiency is influenced by factors such as design, surface area, and the type of coolant used. Regular maintenance of this crucial element can significantly impact the overall performance and longevity of the entire cooling system.

Identifying the Outlet and Inlet

Understanding the flow of fluid within a heating or cooling unit is essential for ensuring optimal performance. Recognizing the entry and exit points can significantly enhance efficiency and maintenance processes. This section aims to clarify how to distinguish these critical connections.

| Feature | Outlet | Inlet |

|---|---|---|

| Location | Typically found at the top or side | Usually located at the bottom or side |

| Function | Releases heated or cooled fluid | Receives incoming fluid for processing |

| Temperature | Often warmer or cooler depending on the cycle | Generally at the initial temperature of the system |

| Identification Tip | Feel for warmth; check for flow direction | Look for coldness; inspect for signs of fluid entry |

By familiarizing oneself with these characteristics, one can easily identify the correct points for fluid entry and exit, ensuring the unit operates smoothly and efficiently.

Radiator Maintenance Tips

Regular upkeep is essential for ensuring optimal performance and longevity of your heating system. Implementing a few simple practices can significantly enhance efficiency and reduce the likelihood of costly repairs. This section provides valuable insights on maintaining your unit effectively.

Routine Inspections

Performing periodic checks is crucial. Look for signs of wear or leaks that may indicate underlying issues. Ensure that all connections are secure and that no obstructions block airflow. Addressing minor problems promptly can prevent major breakdowns in the future.

Cleaning Techniques

Keeping the exterior clean is vital for efficient operation. Dust and debris can accumulate over time, hindering performance. Use a soft cloth or vacuum attachment to gently remove dirt. For deeper cleaning, consider using a mild detergent solution, ensuring that all surfaces are well-maintained.

Pro tip: Always turn off power before conducting any maintenance to ensure safety.

By following these guidelines, you can extend the lifespan of your heating system and maintain a comfortable environment in your space.

Common Issues and Solutions

In any heating system, various challenges can arise that affect performance and efficiency. Understanding these common problems and their solutions is essential for maintaining optimal functionality. Whether it’s related to circulation, temperature fluctuations, or unusual noises, identifying the root cause is the first step toward resolution.

Insufficient Heat Output: One prevalent issue is the lack of adequate warmth in the space. This can often be traced back to trapped air within the system. To address this, bleeding the system to release air can significantly improve heat distribution.

Leaking Fluid: Another concern is the presence of leaks, which can lead to decreased efficiency and potential damage. Inspecting connections and seals regularly can help identify and remedy leaks before they become severe.

Noisy Operation: Sounds such as banging or gurgling may indicate air pockets or water hammer. Ensuring proper water levels and adjusting flow rates can help mitigate these disturbances.

Inconsistent Temperatures: If different areas experience uneven heating, it may signal issues with the control mechanism or balancing. Adjusting valves or seeking professional calibration can lead to more uniform warmth throughout the environment.