Understanding the Parts Diagram of Paslode Framing Guns

In the realm of construction and woodworking, having a clear grasp of the various elements that make up a specific tool is essential for effective usage and maintenance. Each component plays a critical role in the overall functionality, ensuring precision and efficiency in tasks. This exploration delves into the intricate details of these essential mechanisms, providing insights that can enhance both knowledge and skills.

Through detailed illustrations and descriptions, readers will gain a profound understanding of how each segment contributes to the tool’s performance. By dissecting the assembly, one can appreciate the engineering behind its design, fostering better troubleshooting and repair capabilities. This comprehensive analysis aims to empower users, transforming their approach to tool management and enhancing their craftsmanship.

Whether you’re a seasoned professional or a novice enthusiast, familiarity with the inner workings of your equipment is invaluable. Equipped with this knowledge, you’ll not only improve your efficiency but also extend the lifespan of your tools, ensuring they remain reliable allies in your projects.

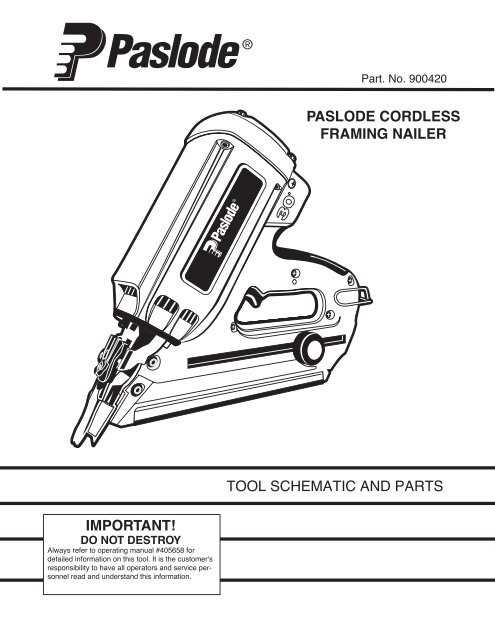

Understanding Paslode Framing Guns

This section explores the essential features and functions of popular construction tools designed for fastening materials efficiently. These devices are vital for professionals and DIY enthusiasts alike, offering speed and precision in various projects.

Key elements that define these tools include:

- Mechanism of operation, which enhances performance and reduces manual effort.

- Type of fasteners used, ensuring compatibility with different applications.

- Design aspects that improve usability and control during operation.

- Safety features that protect users from potential hazards.

Understanding these components can significantly improve user experience and project outcomes. Knowledge of the specific characteristics can aid in selecting the right tool for any given task.

Common maintenance tips for optimal performance include:

- Regular cleaning to prevent buildup of debris.

- Checking and replacing worn components to ensure reliability.

- Lubricating moving parts for smooth operation.

- Storing the device properly to extend its lifespan.

By familiarizing oneself with these aspects, users can maximize the effectiveness of their fastening tools, resulting in successful and timely completion of construction projects.

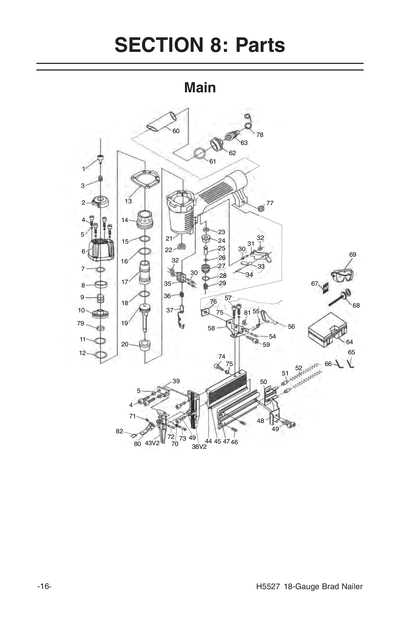

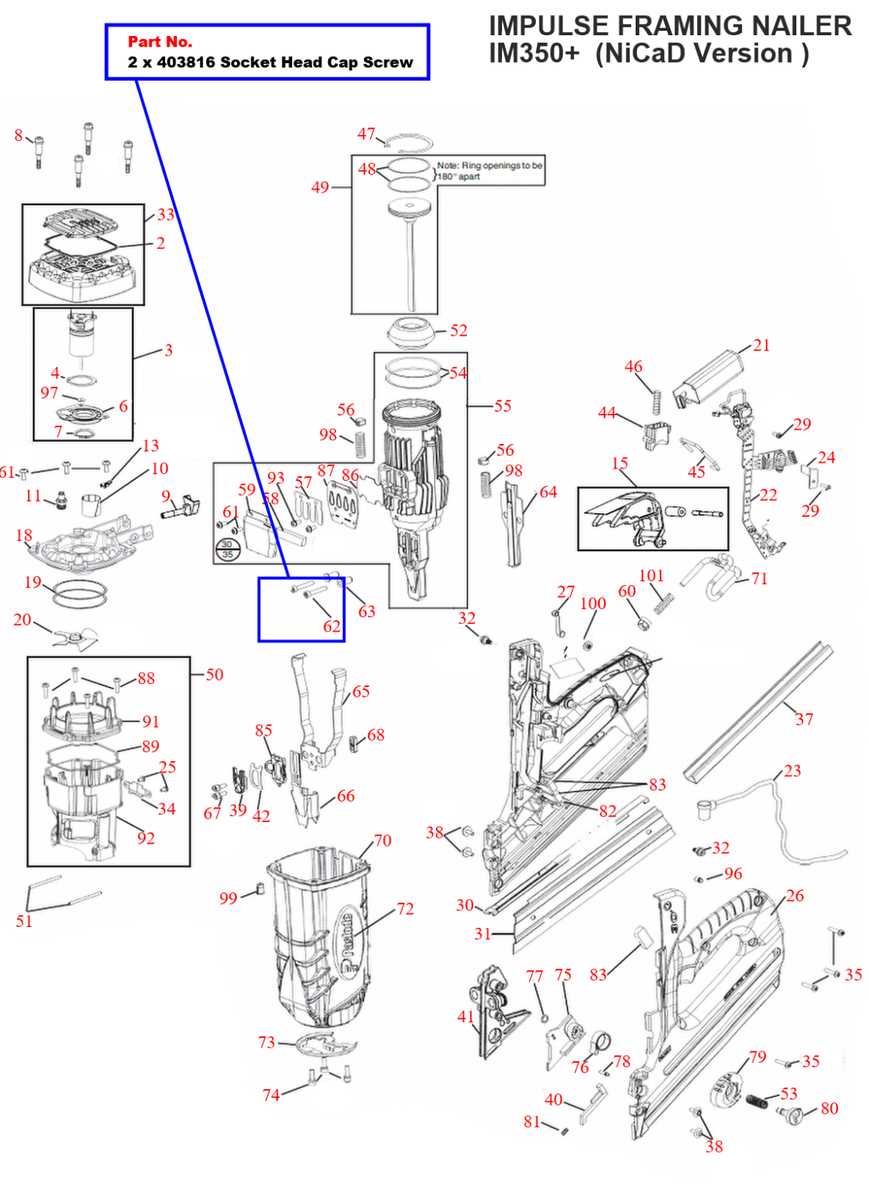

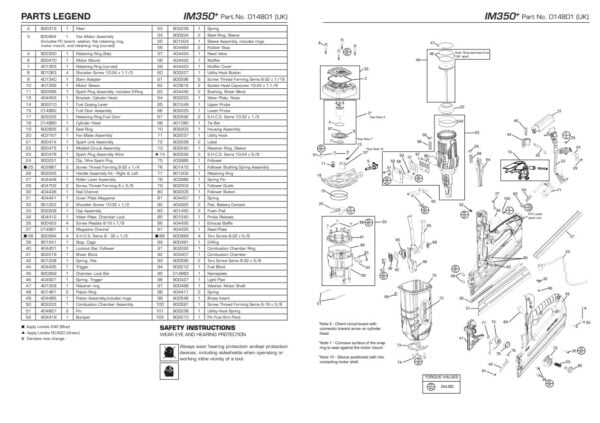

Components of a Framing Gun

Understanding the essential elements of a nailing tool is crucial for effective usage and maintenance. Each component plays a significant role in ensuring the tool operates smoothly and efficiently, allowing for precise and reliable fastening tasks. Below is a detailed overview of the main constituents commonly found in these tools.

| Component | Description |

|---|---|

| Trigger | Controls the firing mechanism, allowing the user to initiate the nailing process. |

| Magazine | Holds and feeds the fasteners into the firing chamber for continuous operation. |

| Firing Mechanism | Responsible for driving the fastener into the material upon activation of the trigger. |

| Housing | Encases the internal components, providing protection and structural integrity. |

| Pneumatic System | Utilizes compressed air to power the tool, ensuring high efficiency and performance. |

| Depth Adjustment | Allows the user to set how deep the fastener is driven, accommodating various materials. |

| Safety Mechanism | Prevents accidental firing, ensuring safe operation during use. |

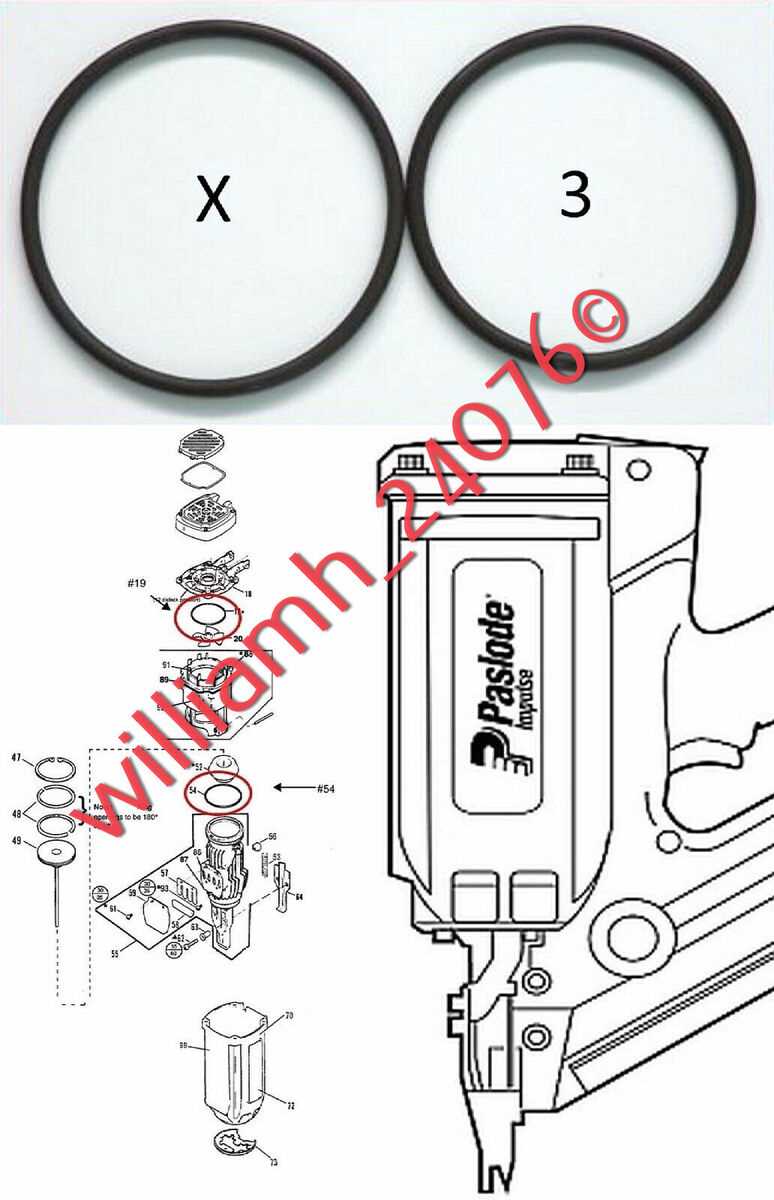

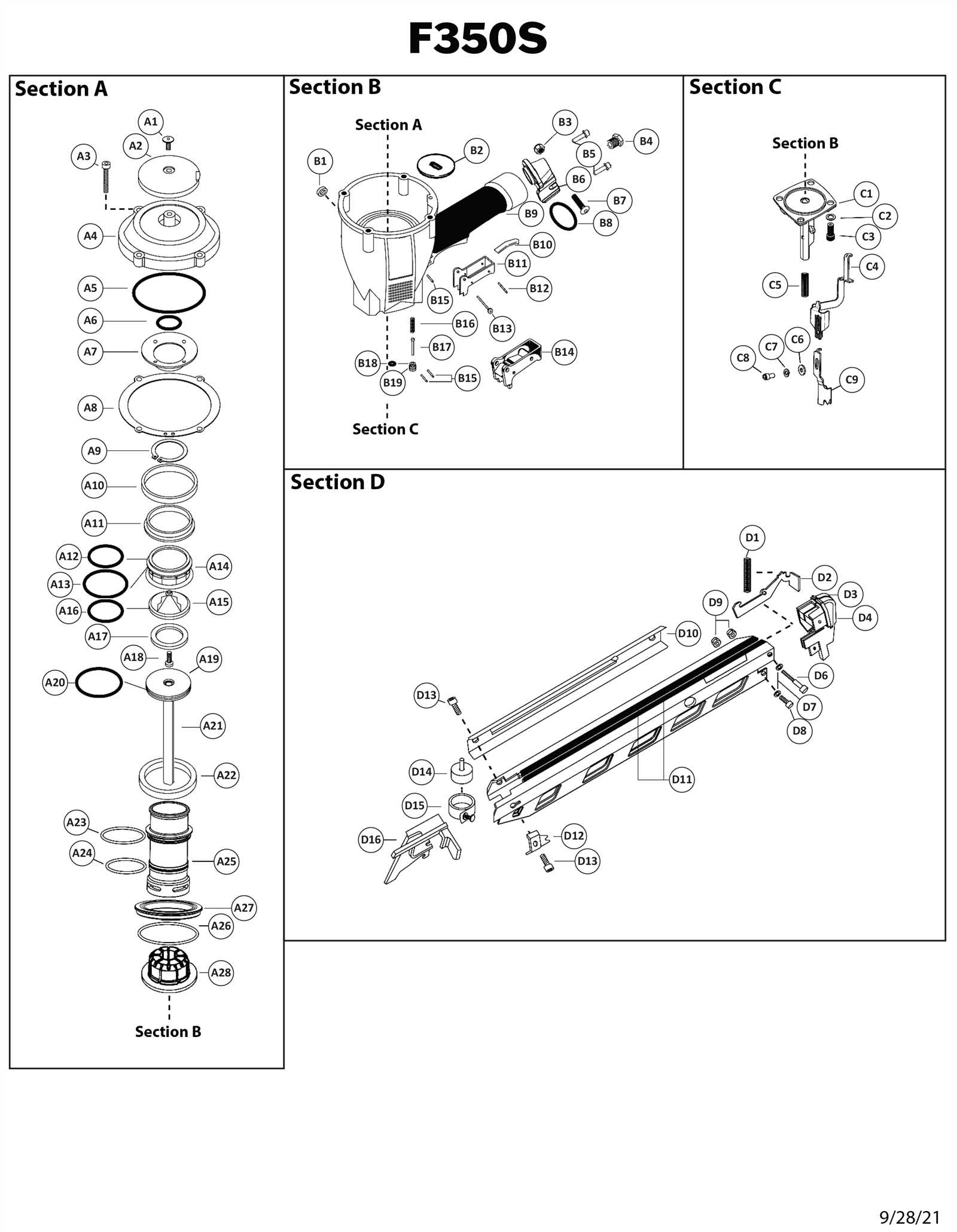

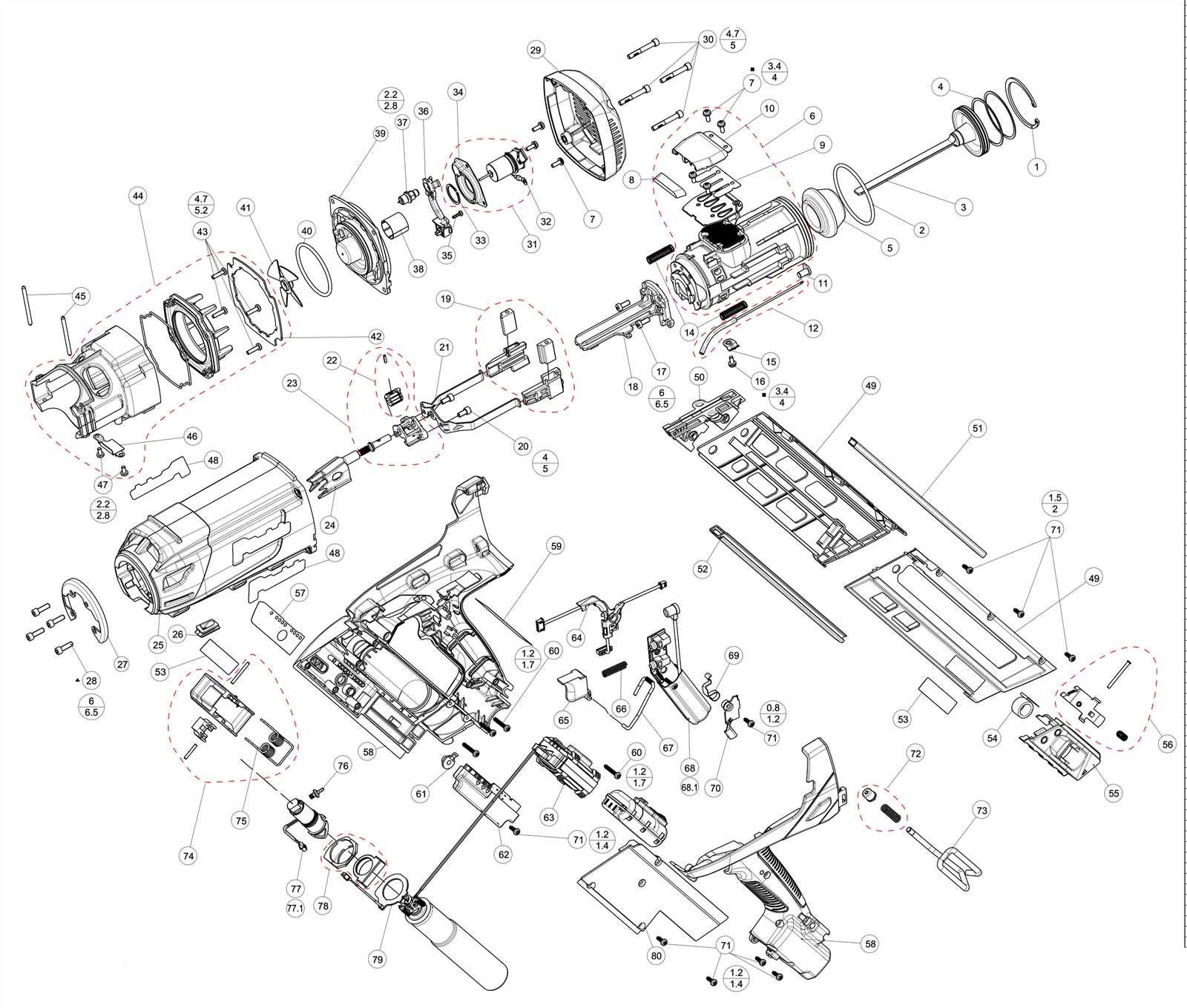

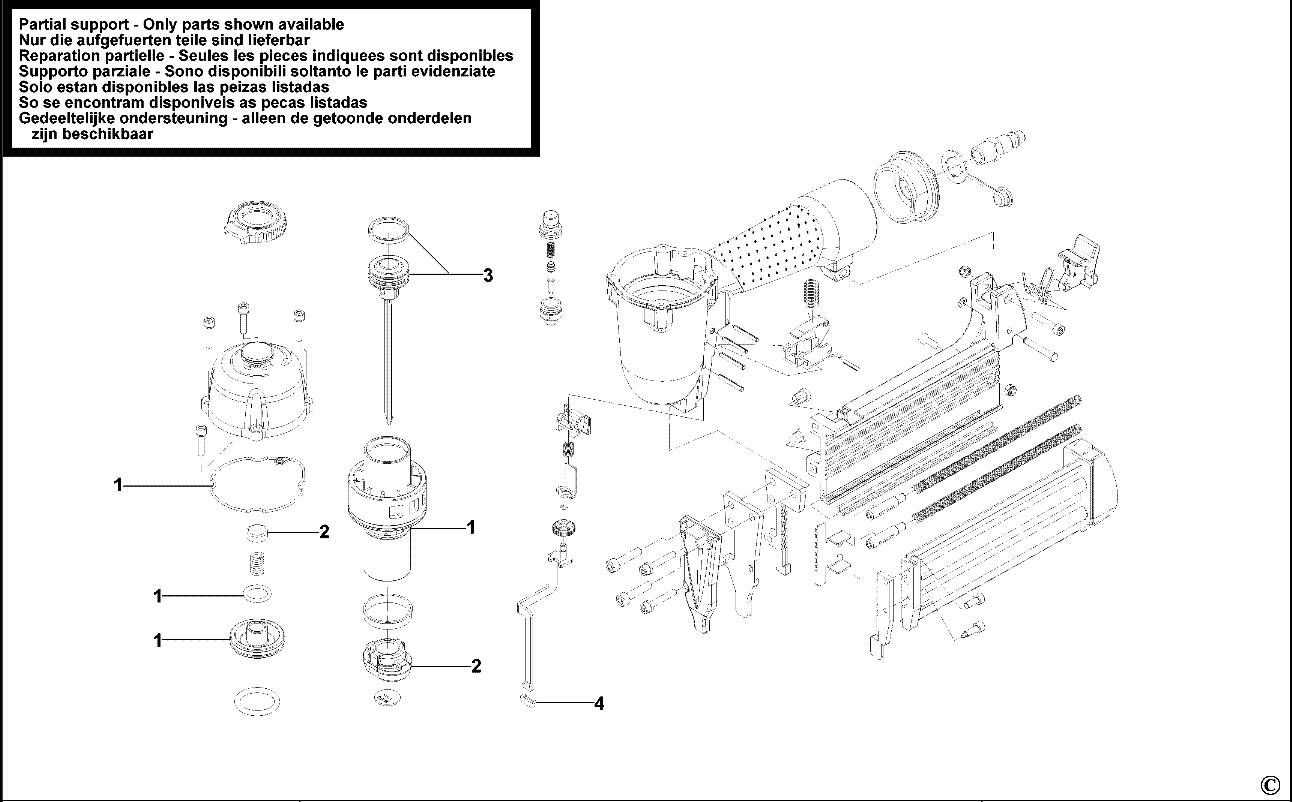

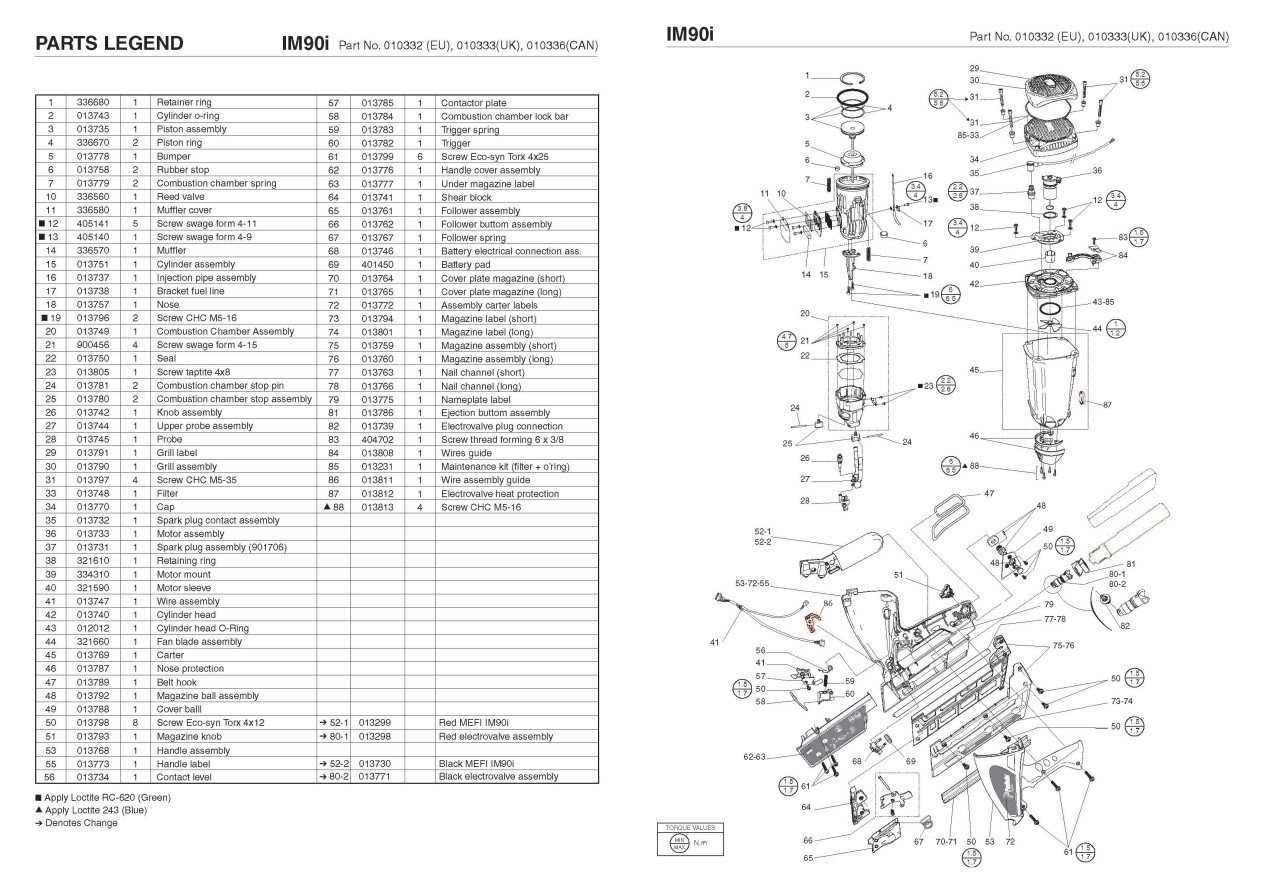

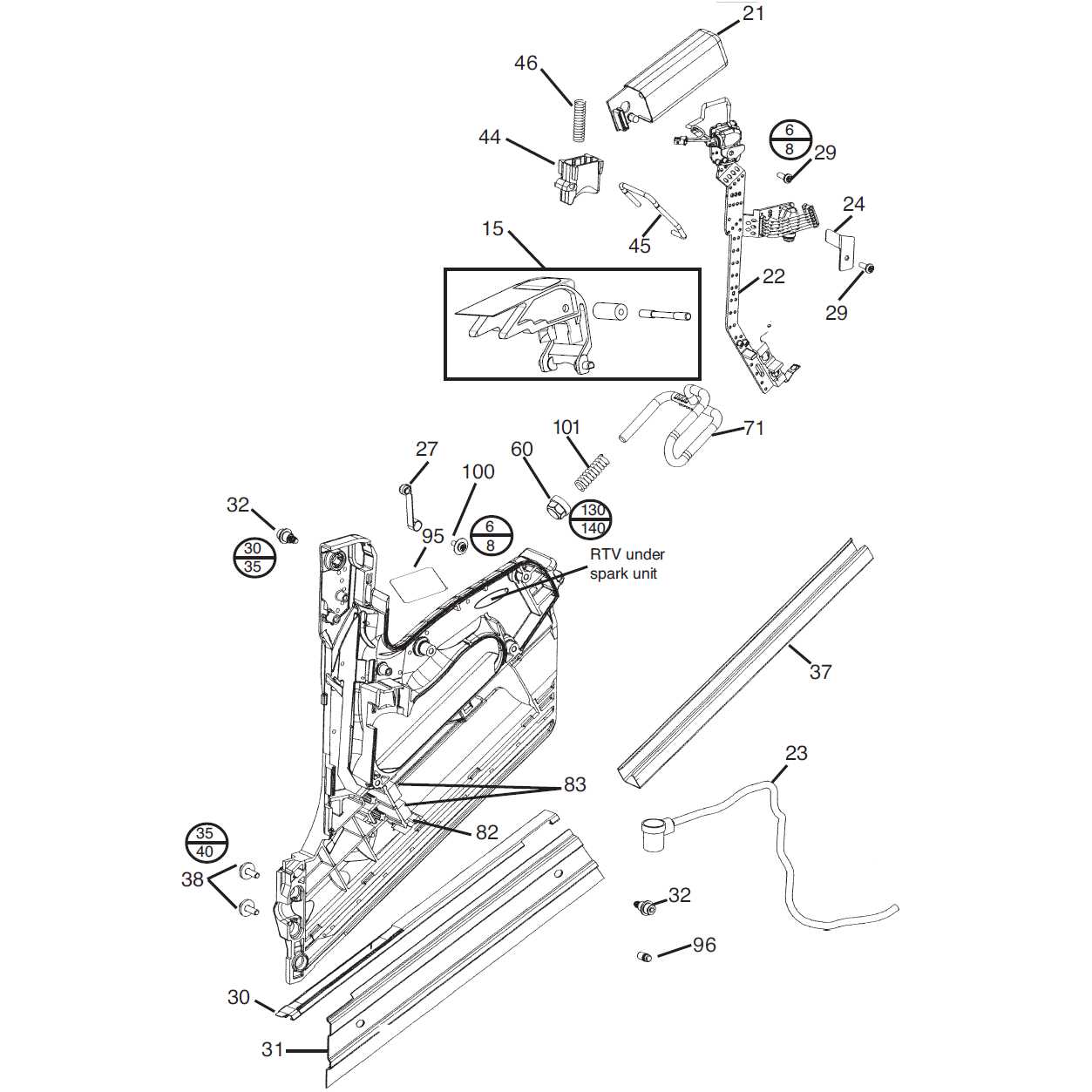

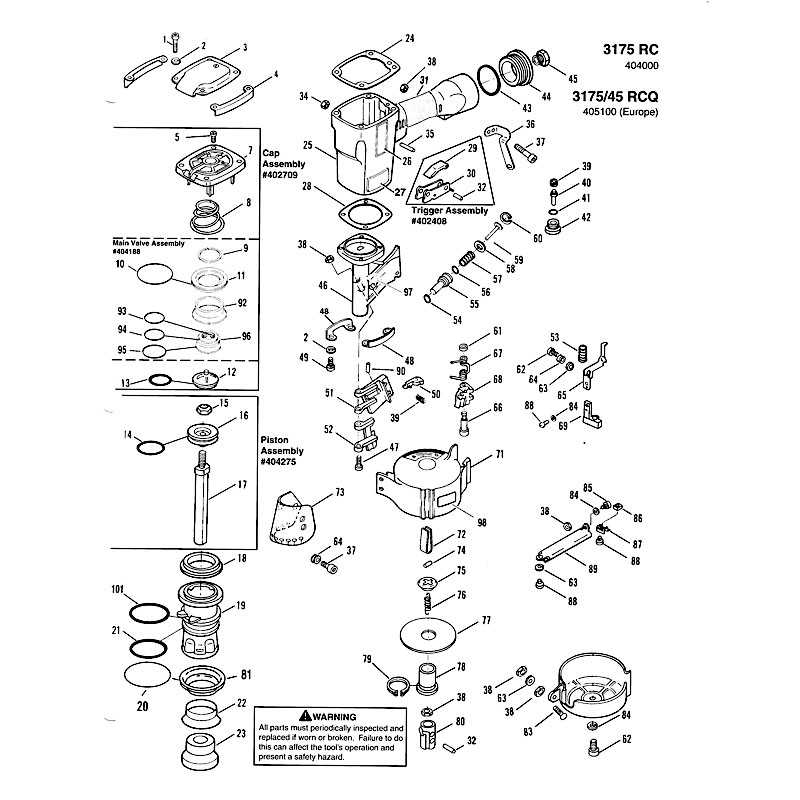

How to Read Parts Diagrams

Understanding visual schematics is essential for effective maintenance and repair tasks. These illustrations provide a comprehensive overview of components and their interconnections, allowing users to identify and source specific items efficiently.

Key Components of Visual Schematics

- Labels: Clearly indicate each element, often with corresponding numbers or letters.

- Connections: Show how components fit together, helping to understand their relationships.

- Legends: Provide explanations for symbols or color codes used within the illustration.

Steps to Interpret Diagrams

- Begin by familiarizing yourself with the legend and any notations.

- Identify major components and their corresponding identifiers.

- Trace connections to understand assembly or disassembly processes.

- Refer to the diagram as you work to ensure accuracy and efficiency.

Common Issues with Paslode Tools

Users often encounter various challenges when operating pneumatic fastening devices. Understanding these issues is essential for maintaining optimal performance and prolonging the lifespan of the equipment.

Frequent Mechanical Failures

Mechanical breakdowns can occur due to wear and tear. Common symptoms include misfires and jams, which may be attributed to inadequate lubrication or damaged internal components. Regular inspection and maintenance can significantly reduce these occurrences.

Battery and Power Problems

Power-related issues often arise with cordless models, leading to intermittent operation or complete failure. Battery depletion and connection failures are typical culprits. Ensuring batteries are fully charged and connections are secure can help mitigate these issues.

Maintaining Your Framing Gun

Proper upkeep of your tool is essential for ensuring optimal performance and longevity. Regular maintenance not only enhances efficiency but also prevents unexpected breakdowns during crucial tasks. This section provides insights into effective practices for keeping your equipment in top shape.

Regular Cleaning: After each use, it is important to clean your device thoroughly. Remove dust, debris, and any residue that may have accumulated. Use a soft cloth and appropriate cleaning solutions to avoid damaging the internal components.

Lubrication: Keeping moving parts well-lubricated is vital for smooth operation. Utilize manufacturer-recommended oils and greases, applying them to hinges, pivots, and any areas subject to friction. Regular lubrication reduces wear and tear, extending the life of your tool.

Inspecting Components: Periodically check all elements for signs of wear, damage, or misalignment. Pay close attention to seals and gaskets, as these can affect overall functionality. Timely replacement of worn parts prevents larger issues from developing.

Storing Properly: When not in use, store your tool in a dry, protected environment. This helps to shield it from moisture and extreme temperatures, both of which can lead to rust and other forms of deterioration. Utilize a case or cover for added protection.

Consulting Manuals: Always refer to the user manual for specific maintenance guidelines and recommendations. Familiarizing yourself with the manufacturer’s instructions ensures that you are following best practices and using appropriate products.

By implementing these maintenance strategies, you can ensure that your equipment remains reliable, efficient, and ready for any project you undertake.

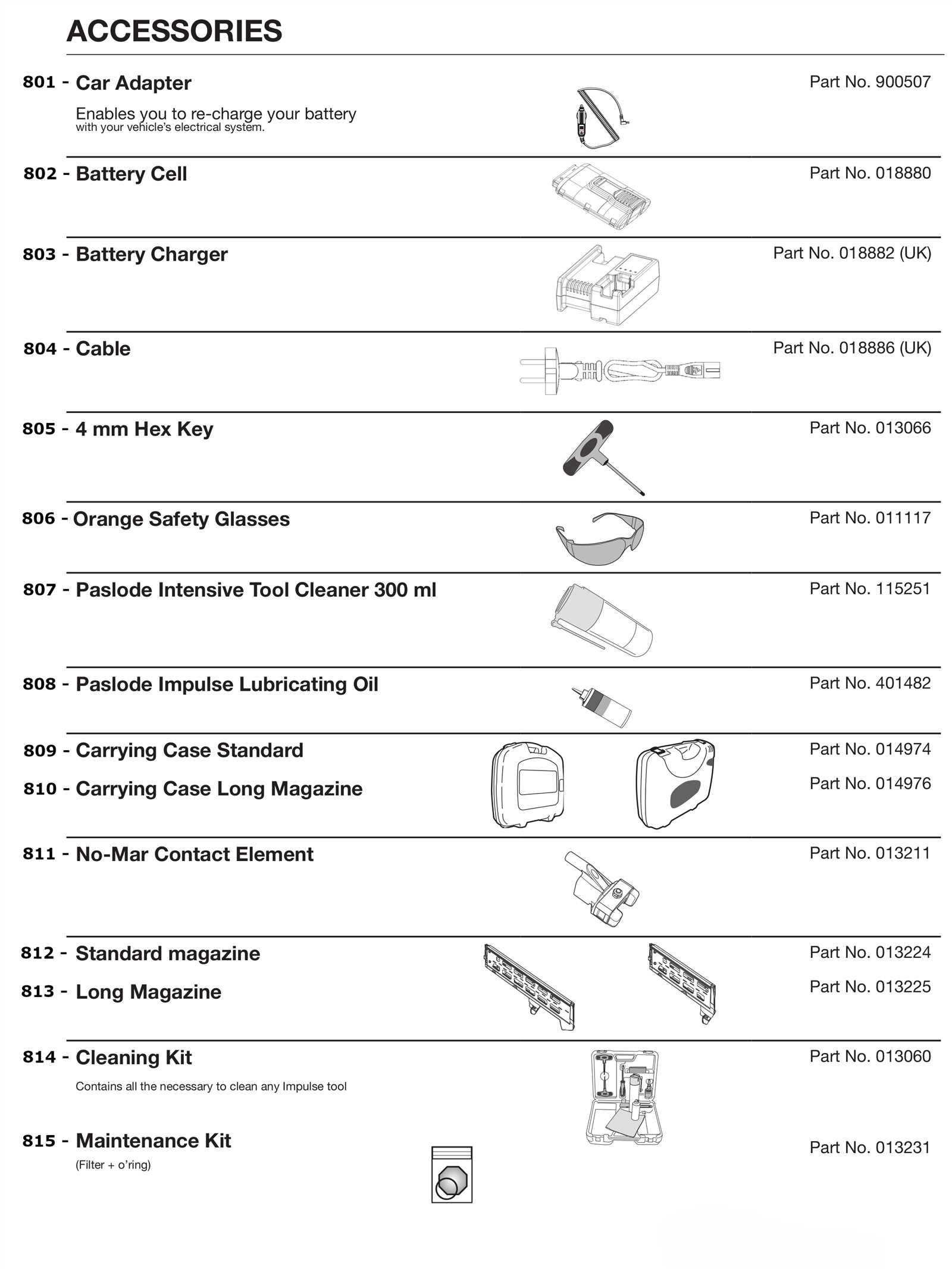

Finding Replacement Parts Easily

Locating suitable components for your equipment can be a daunting task, especially when faced with numerous options. However, with the right strategies, the process can be streamlined significantly, ensuring you get what you need without hassle.

Utilizing Online Resources

- Visit official manufacturer websites for accurate information.

- Explore online marketplaces for a variety of options.

- Check user forums and communities for recommendations.

Local Suppliers and Retailers

- Contact local hardware stores to inquire about availability.

- Visit specialty shops that focus on similar equipment.

- Build relationships with suppliers for future needs.

Safety Tips for Framing Gun Use

Using powerful tools for construction tasks requires strict adherence to safety protocols to prevent accidents and ensure a secure working environment. Understanding how to operate these devices correctly is essential for maintaining safety both for the user and those nearby. This section outlines crucial safety guidelines to follow during operation.

Personal Protective Equipment

Always wear appropriate personal protective equipment (PPE). This includes safety goggles to shield your eyes from debris, ear protection to guard against noise, and steel-toed boots to protect your feet. Additionally, consider using gloves for a better grip, but ensure they do not interfere with the tool’s operation.

Operational Precautions

Before starting work, inspect the equipment thoroughly. Ensure it is free from damage and that all safety features are functioning correctly. Never point the tool at yourself or others, even when not in use. Maintain a safe distance from coworkers and bystanders to minimize risk. Always follow the manufacturer’s instructions for operation and maintenance to ensure safe usage.

Comparison of Paslode Models

This section delves into the various models offered by a well-known manufacturer, highlighting their unique features and applications. Each version is designed to cater to specific needs within the construction industry, showcasing advancements in technology and usability.

Key Features Across Models

- Power Source Options: Various models offer different energy sources, including battery-powered and gas-powered variants.

- Weight and Portability: Some units are designed for lightweight portability, while others prioritize durability and robustness.

- Nail Compatibility: Different models support varying nail sizes and types, making them suitable for diverse tasks.

- Depth Adjustment: Most versions provide adjustable depth settings to ensure precision in fastening.

Popular Models and Their Uses

- Model A: Ideal for framing and structural applications, it offers enhanced power and depth control.

- Model B: Lightweight and portable, perfect for trim work and lighter projects.

- Model C: Versatile with multiple nail types, suitable for various construction tasks.

In conclusion, understanding the differences among these models helps professionals choose the right tool for their specific needs, ensuring efficiency and effectiveness on the job site.

Upgrading Your Framing Gun Parts

Enhancing the components of your tool can significantly improve its performance and longevity. By selecting high-quality replacements or innovative upgrades, you can ensure that your equipment operates at its peak efficiency, leading to better results in your projects.

| Component | Benefits of Upgrading |

|---|---|

| Trigger Mechanism | Improved responsiveness and reduced fatigue during use. |

| Magazine | Higher capacity and faster loading times, increasing productivity. |

| Housing | Enhanced durability and resistance to wear and tear in tough conditions. |

| Drive Blade | Better penetration and precision, ensuring cleaner finishes. |

Investing in these enhancements not only elevates your tool’s efficiency but also contributes to achieving ultimate quality in your work.

Benefits of Regular Maintenance

Consistent upkeep of your tools is essential for their longevity and optimal performance. By dedicating time to routine checks and servicing, you can ensure that equipment operates smoothly and efficiently, reducing the risk of unexpected failures.

Enhanced Performance: Regular maintenance allows for adjustments and replacements of worn components, which ultimately leads to improved functionality and precision during use.

Cost Savings: Investing in periodic servicing can prevent major repairs and prolong the life of your tools, saving money in the long run.

Safety Assurance: Well-maintained equipment is less likely to malfunction, reducing the risk of accidents and injuries on the job site.

Increased Productivity: Tools that function reliably enable users to complete tasks efficiently, maximizing work output and minimizing downtime.

In conclusion, committing to regular maintenance is a proactive approach that yields numerous benefits, enhancing both the user experience and the longevity of your equipment.

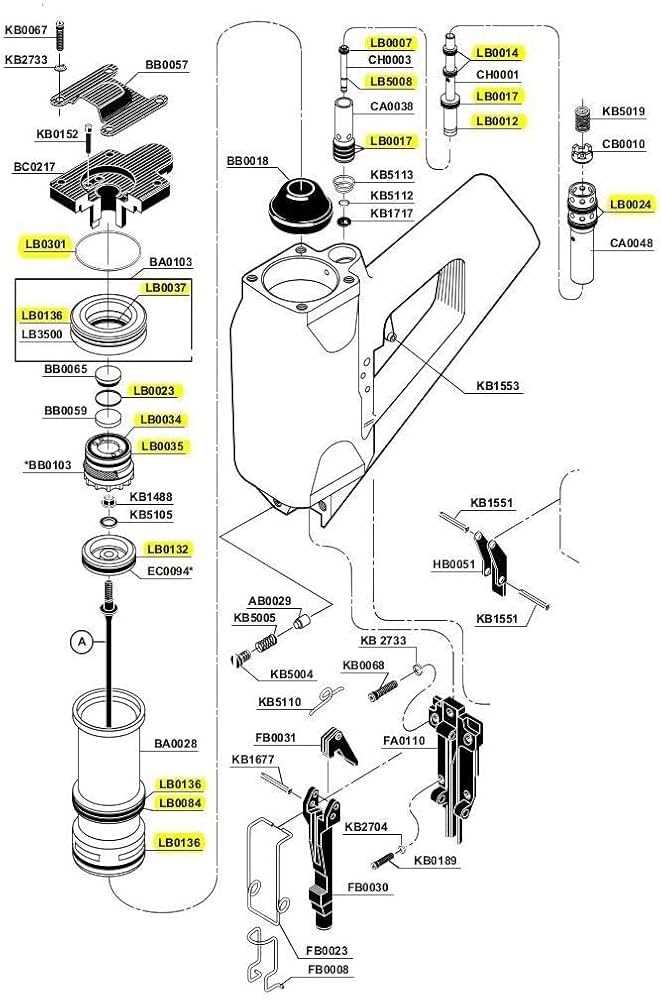

DIY Repairs for Framing Tools

Maintaining and repairing your construction equipment can save time and money while ensuring that your projects run smoothly. Understanding the common issues that arise with these devices allows you to tackle repairs yourself, fostering both skill development and a sense of accomplishment.

Identifying Common Issues

Before attempting any fixes, it’s crucial to identify the typical problems associated with these tools. Frequent issues may include misfires, air leaks, or jammed mechanisms. Conducting a thorough inspection can help pinpoint the exact cause, allowing for more efficient troubleshooting.

Essential Repair Techniques

Once you’ve identified the issue, several basic techniques can be employed to resolve it. For instance, cleaning the internal components can eliminate debris that hinders operation. Replacing worn-out seals is also essential to prevent air leaks. Ensure you have the proper tools and follow safety precautions to achieve effective repairs.

In summary, taking the initiative to repair your equipment not only extends its lifespan but also enhances your expertise. Embrace the challenge and enjoy the satisfaction of a job well done.