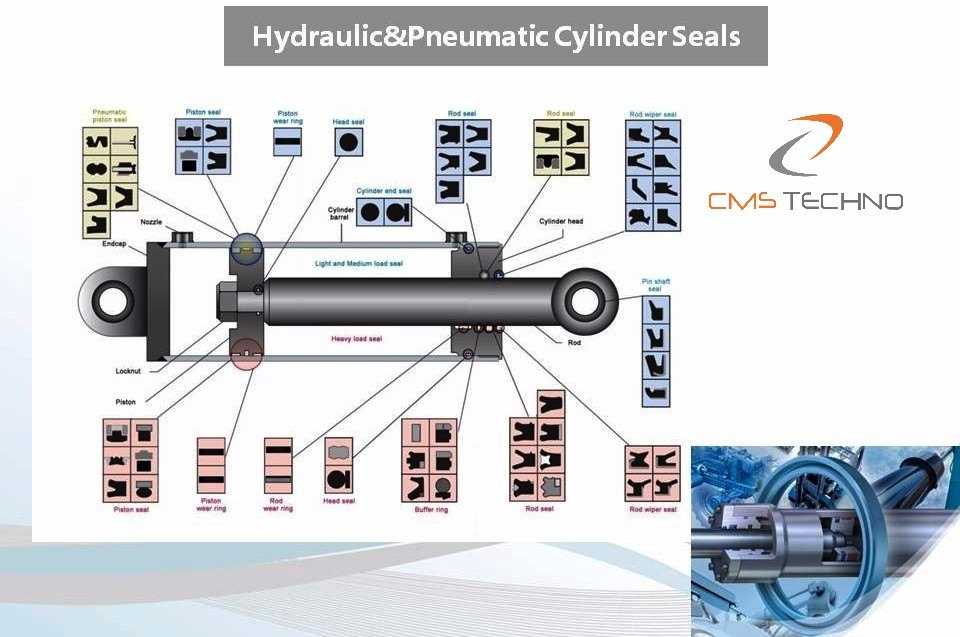

Pneumatic Cylinder Components Diagram

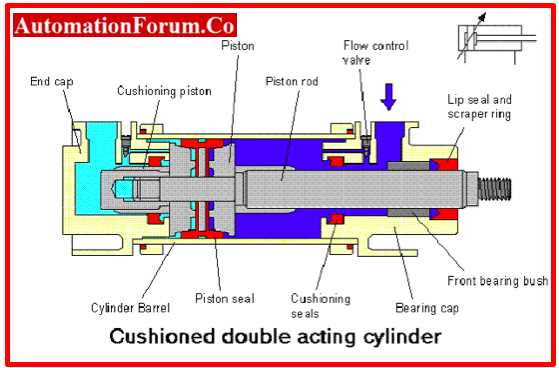

In many industrial applications, certain mechanical devices are essential for transforming energy into motion. These tools are widely used across various sectors, providing reliable and controlled movements. The efficiency of these mechanisms depends on how their individual elements interact and perform their roles in unison.

Each part of the system contributes to its overall functionality, ensuring smooth operation and precision. Understanding the structure and the purpose of these elements is crucial for proper maintenance and troubleshooting. This knowledge helps optimize performance and prolong the life of the machinery.

By exploring the detailed layout of such systems, users can gain insights into how specific components work together, improving their ability to diagnose issues and enhance performance. Let’s delve into the essential building blocks that make up these vital mechanical devices

Components Overview

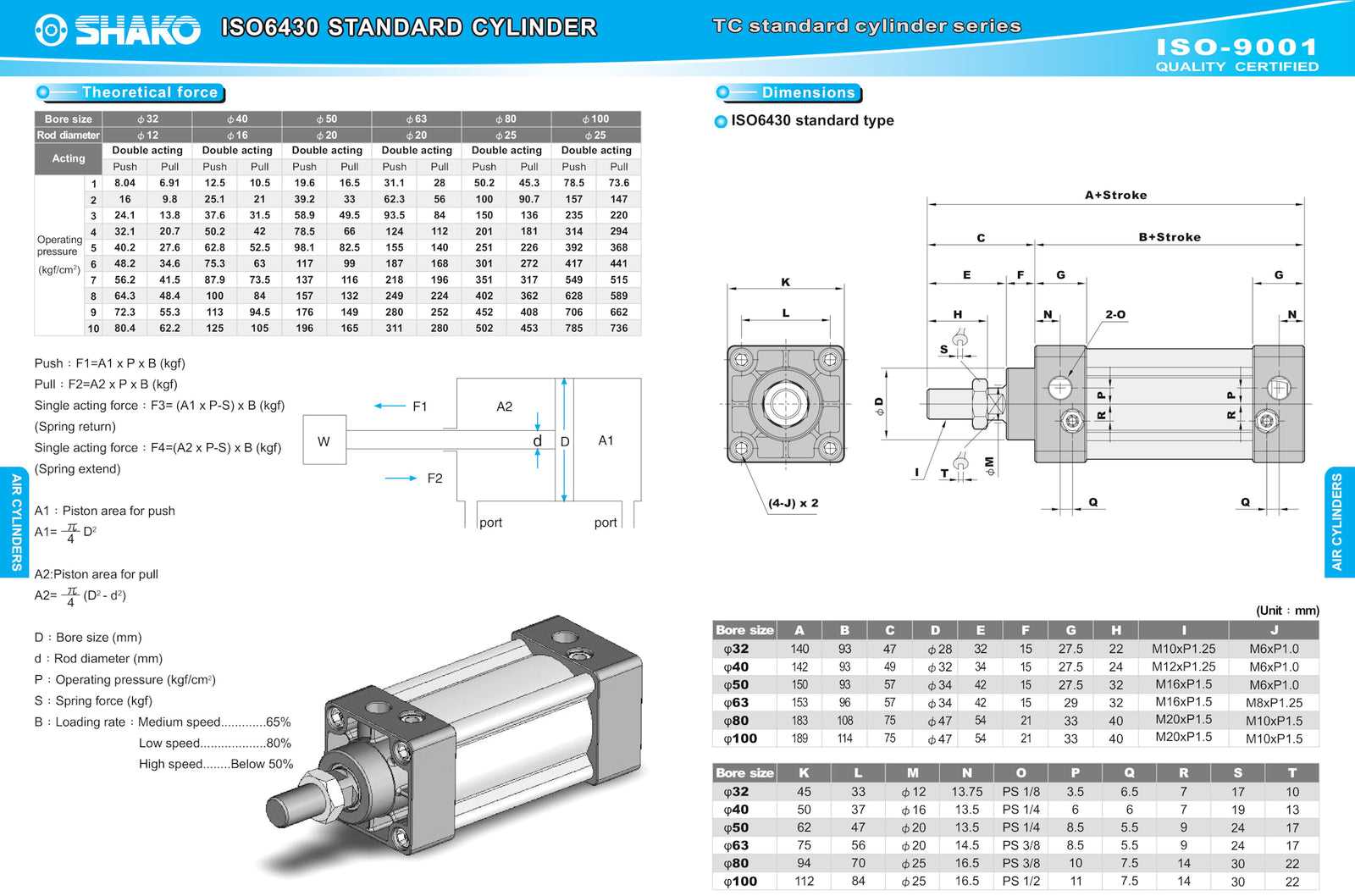

In various mechanical systems, certain devices play a crucial role in converting energy into motion. These mechanisms consist of multiple elements working in harmony to achieve precise control and efficient operation. Understanding the structure and functions of these essential components provides insight into their capabilities and potential applications across different industries.

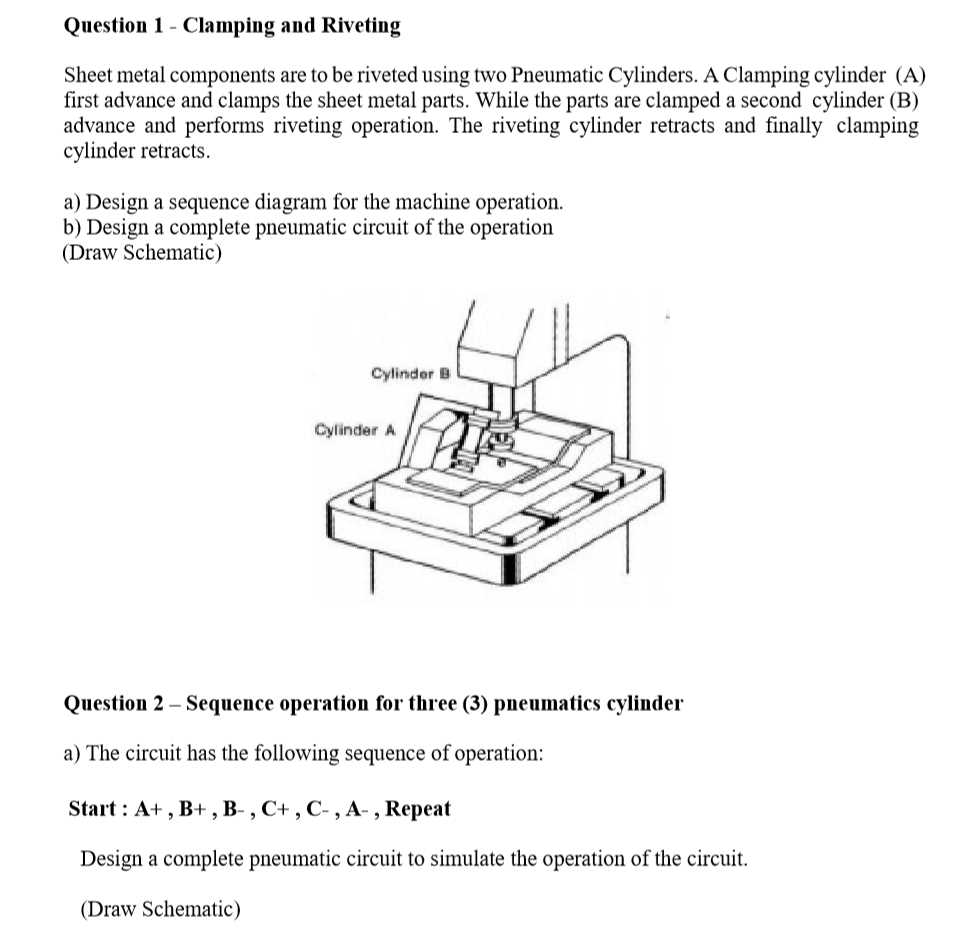

Key elements include the main body, which serves as the foundation for all other parts, and internal elements that drive motion. These internal pieces are designed to manage airflow, regulate pressure, and ensure smooth movement. Seals and fasteners are critical for maintaining durability and preventing leaks, while external connectors allow integration with other systems.

Key Functions of Cylinder Parts

Each component in a mechanical actuator plays a vital role in ensuring smooth operation and efficiency. These elements work together to create a seamless transfer of force, ensuring movement in various directions. Understanding the purpose of each part enhances overall performance and system longevity.

| Component | Function |

|---|---|

| Rod | Transfers the applied force to the external mechanism, allowing for linear movement. |

| Seal | Prevents leakage of air or fluid, maintaining internal pressure and ensuring efficient movement. |

| End Cap | Holds internal components in place and supports the structure during operation. |

| Bearing | Guides the moving parts to reduce friction and enhance durability. |

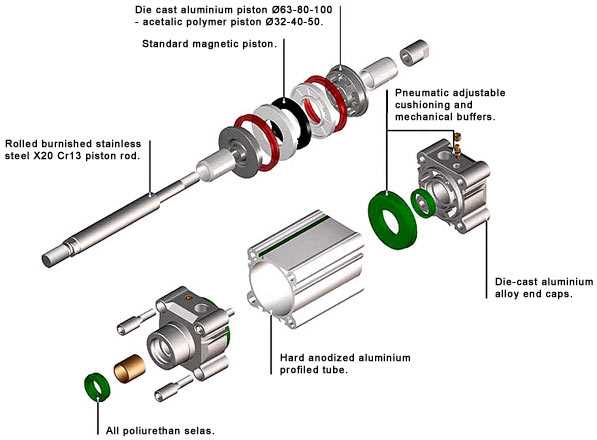

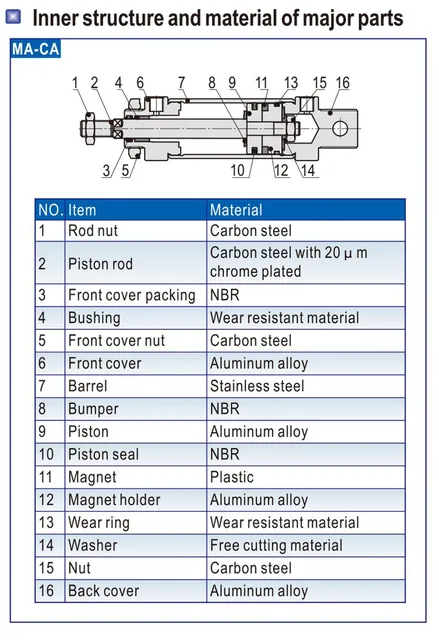

Materials Used in Pneumatic Cylinders

The components of industrial motion devices are often crafted from a variety of materials to ensure durability, performance, and resistance to wear. Different materials are selected based on the specific environment and operational demands, offering a balance between strength, corrosion resistance, and weight.

- Aluminum: Commonly used for its lightweight properties and resistance to corrosion. It is ideal for applications where mobility and weight reduction are important.

- Stainless Steel: Known for its exceptional durability and resistance to rust, this metal is often chosen for devices used in harsh or wet environments.

- Brass: This material offers excellent resistance to corrosion and is often used in fluid power systems due to its compatibility with various gases and liquids.

- Polyurethane and Rubber: Used for seals and gaskets, these flexible materials provide airtight seals and absorb shock, ensuring smooth and efficient operation.

- Composite Materials: Lightweight and strong, composites are increasingly used in modern designs, offering a good balance of strength and re

Piston Design and Operation

The core of this section revolves around the intricate structure and movement of the piston within various systems. The engineering behind it focuses on creating an efficient method of transferring energy through controlled motion. Each element plays a vital role in ensuring smooth and reliable functionality, contributing to overall system performance.

Piston Construction

The construction of a piston typically involves a combination of high-strength materials that can withstand pressure and friction. These materials ensure the component remains durable over long-term use. Precision engineering is key to achieving optimal dimensions and surface finishes that minimize wear and increase efficiency.

Functional Movement

The motion generated by the piston is critical to the operation of many devices. This movement is usually linear, facilitated by a well-sealed environment that limits energy loss. Efficient operation depends on maintaining a balance between the forces applied and the resistance encountered during motion.

Component Material Function Rod Steel Alloy Transfers force to external systems Seal Polymer Composite Prevents leakage and maintains pressure Guide Rod Sealing and Its Importance

Rod sealing plays a crucial role in the efficient functioning of mechanical systems that rely on controlled motion and force transfer. Ensuring that the moving element remains properly sealed prevents issues such as leakage, contamination, and wear, which can significantly reduce the operational lifespan of the equipment. A well-maintained sealing mechanism ensures long-term reliability and minimizes the risk of costly repairs.

Main Functions of Rod Seals

Rod seals are responsible for several essential tasks within a machine. Primarily, they retain the necessary fluids or gases, allowing the system to perform its functions smoothly. In addition, they prevent external contaminants like dust or moisture from entering sensitive areas, which could damage internal components.

Types of Rod Seals

Various seal designs are available to meet specific operational requirements, each suited for different levels of pressure, temperature, and environmental factors. Choosing the correct type of seal is essential for ensuring optimal performance and preventing system failures.

Seal Type Application Lip Seals Used for moderate pressure environments, offering good fluid retention and wear resistance. Scraper Seals Ideal for conditions with heavy contamination, preventing external particles from entering the system. V-Ring Seals Provide low-friction sealing, End Caps and Their Role

End caps are essential components in various mechanisms, serving as protective barriers and ensuring the integrity of internal mechanisms. Their design and material play a crucial role in maintaining the functionality and efficiency of the system they are part of. By enclosing the assembly, these elements prevent external contaminants from interfering with operations, thereby enhancing longevity and performance.

The significance of end caps extends beyond mere protection; they also contribute to the overall stability of the assembly. Their precise fit and secure attachment are vital for optimal functioning, influencing pressure retention and overall system efficiency.

Feature Description Material End caps are typically made from durable materials such as aluminum or plastic to withstand various environmental conditions. Design The design can vary, often incorporating grooves or seals to enhance fit and functionality. Installation Proper installation is critical to ensure they provide adequate protection and maintain system integrity. Maintenance Regular checks on end caps can prevent premature wear and failure, ensuring reliable operation over time. Cushioning Mechanism in Cylinders

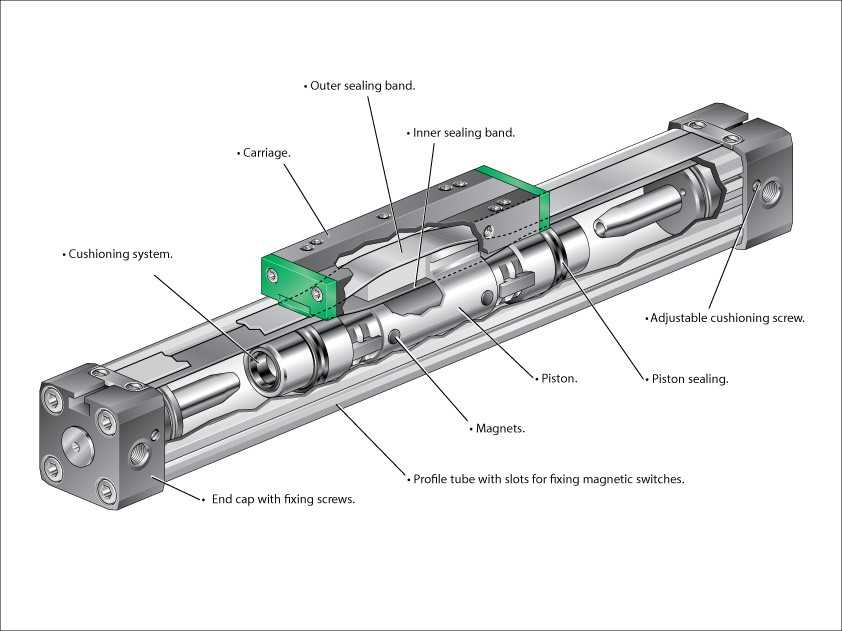

The cushioning mechanism plays a crucial role in enhancing the performance and longevity of linear actuators. By minimizing impact during the extension and retraction phases, this system ensures smooth operation, reducing wear and tear on components. Implementing effective cushioning techniques leads to increased efficiency and reliability in various industrial applications.

Functionality of Cushioning

This mechanism primarily operates by absorbing kinetic energy, which occurs when the actuator reaches the end of its stroke. The cushioning process involves the gradual deceleration of the moving element, allowing it to come to a stop without abrupt jolts. This not only protects the internal components but also enhances the overall stability of the system.

Types of Cushioning Systems

There are various types of cushioning systems utilized in linear actuators. Some common methods include adjustable cushioning, which allows users to tailor the level of damping according to specific requirements. Another popular option is the non-adjustable cushioning system, which provides a set level of damping for consistent performance. Each type offers distinct advantages, making it essential to select the appropriate system based on the application needs.

Air Supply and Control Valves

Effective management of airflow is crucial in numerous applications where motion control is required. The devices responsible for regulating this flow play a significant role in ensuring optimal operation and efficiency. Understanding the components involved in air distribution and their functions is essential for maintaining system performance.

Types of Control Valves

Control valves can be classified into various categories based on their design and functionality. Each type serves a specific purpose in managing airflow. Here are some common types:

- Manual Valves: Operated by hand, these valves allow for direct control over airflow.

- Solenoid Valves: Electrically operated, these valves automatically control the flow based on electrical signals.

- Regulating Valves: Designed to maintain a specific pressure or flow rate within a system.

Key Considerations for Selection

When choosing the right control valve, several factors should be taken into account:

- Flow Rate: Ensure the valve can handle the required flow capacity.

- Pressure Rating: Verify that the valve can withstand the system’s pressure conditions.

- Material Compatibility: Select materials that can endure the working environment without degradation.

Understanding the Barrel Structure

The barrel structure plays a crucial role in the functionality of a specific device, providing the necessary space for movement and operation. This component is designed to facilitate the effective transmission of force, ensuring that the mechanism operates smoothly and efficiently. A clear comprehension of its design and functionality can enhance overall performance and reliability.

Key Components of the Barrel

At the core of the barrel’s design are several essential elements. These include the inner surface, which is often smooth to minimize friction, and the external casing, which provides support and protection. Additionally, seals and other fittings are integrated to prevent leakage and maintain pressure, ensuring optimal operation. Understanding these components is vital for troubleshooting and maintenance.

Impact on Overall Functionality

The structure of the barrel significantly influences the device’s overall performance. A well-designed barrel can enhance efficiency, reduce wear and tear, and prolong the lifespan of the mechanism. Regular inspections and proper maintenance of this component are necessary to avoid potential issues and ensure the device functions as intended. Investing time in understanding the barrel structure can lead to improved performance and reliability in various applications.

Mounting Styles for Pneumatic Cylinders

When it comes to actuators used in various applications, the way they are secured can significantly impact their performance and versatility. Different installation techniques allow for adaptability in diverse settings, ensuring that the equipment functions efficiently and reliably.

One common approach is the tie rod style, which features rods connecting the ends of the device. This design not only provides robust support but also allows for easy maintenance and assembly. Another widely utilized method is the flange mount, which offers a stable attachment to the machinery, making it ideal for applications requiring strong lateral support.

Moreover, the foot-mounted variation is particularly beneficial for spaces with limited height, as it provides a compact installation option. Additionally, there are variations with adjustable brackets that allow for precise alignment and easy adjustments, catering to specific operational requirements.

Ultimately, choosing the right installation method can enhance functionality and extend the lifespan of the equipment, making it a crucial consideration in system design.

Maintenance Tips for Cylinder Parts

Proper upkeep of components in various mechanical systems is crucial for ensuring optimal performance and longevity. Regular maintenance can prevent malfunctions and extend the lifespan of these vital elements. Below are some essential guidelines to consider for effective care and management.

Regular Inspection

Conduct frequent assessments to identify any signs of wear, damage, or irregularities. Look for leaks, corrosion, or any unusual noise during operation. Addressing minor issues promptly can prevent major failures.

Lubrication Practices

Ensure that moving elements are adequately lubricated to reduce friction and wear. Use the manufacturer’s recommended lubricant and apply it as specified. Over-lubrication can also cause problems, so finding the right balance is essential.

Maintenance Activity Frequency Notes Visual Inspection Weekly Check for leaks and surface wear. Lubrication Monthly Use recommended lubricant; avoid over-application. Functional Testing Quarterly Ensure proper operation under load conditions. Replacement of Worn Components As Needed Replace any damaged or worn elements immediately. Common Issues and Troubleshooting

In any system utilizing compressed gas mechanisms, various complications may arise, leading to inefficiencies or failures. Understanding these common challenges and implementing effective solutions can enhance performance and longevity.

Frequent Problems

- Air Leaks: Unwanted gas escaping from connections can significantly impact efficiency.

- Slow Movement: Delays in motion may indicate blockages or low pressure.

- Inconsistent Force: Variations in output can result from internal wear or incorrect settings.

Troubleshooting Steps

- Inspect all connections and seals for signs of leakage.

- Check the pressure levels to ensure they meet operational standards.

- Examine internal components for wear or damage, replacing as necessary.

- Adjust settings to optimize output based on specific application requirements.