Understanding the Parts Diagram of Porter Cable FC350A

When it comes to maintaining and repairing machinery, having a clear understanding of its components is essential. A comprehensive visual representation can significantly enhance one’s ability to identify and source the necessary elements for efficient operation. This section aims to shed light on the intricate design and functionality of a widely used tool.

Exploring the specific arrangements of individual components allows users to effectively troubleshoot issues and streamline repairs. This knowledge empowers enthusiasts and professionals alike, ensuring that their equipment remains in peak condition. Familiarity with these layouts can lead to improved performance and longevity of the tool.

Additionally, knowing where to find replacement items is crucial for those who rely on their equipment for both personal and commercial use. By delving into the details of this assembly, one can uncover the ultimate guide to maintaining a trusted companion in any workshop.

Understanding the Porter Cable FC350A

This section explores the intricacies of a popular tool, highlighting its design, functionality, and essential components. Gaining insight into this equipment can enhance user experience and ensure optimal performance during projects.

Key Features

The tool boasts a robust construction, designed to withstand heavy use while delivering consistent results. Its ergonomic design not only improves handling but also reduces user fatigue, making it ideal for prolonged tasks.

Maintenance Tips

Regular upkeep is crucial for longevity. Users should ensure cleanliness and lubrication of moving parts. Additionally, checking for wear and tear on critical components will contribute to maintaining the ultimate efficiency of the tool.

Importance of Parts Diagrams

Understanding the intricate components of machinery is essential for effective maintenance and repair. Visual representations of these elements serve as invaluable tools for both technicians and hobbyists alike. They facilitate a deeper comprehension of how individual pieces interact within a system, thereby streamlining the process of troubleshooting and assembly.

Enhanced Clarity

Detailed illustrations provide a clear view of each component’s location and function. This clarity minimizes the likelihood of errors during reassembly or replacement, ensuring that users can follow the correct procedures without confusion. Visual aids can also reveal the complexity of a device, helping users to appreciate its design and engineering.

Efficiency in Repairs

Access to comprehensive visuals accelerates repair times by allowing technicians to quickly identify needed components. Timely identification means less downtime, which is particularly crucial in professional settings. Moreover, understanding the arrangement of parts enables users to perform preventative maintenance, potentially extending the lifespan of the equipment.

Common Issues with FC350A Parts

When dealing with tools of this nature, users often encounter a range of frequent problems that can hinder performance and efficiency. Understanding these common challenges can facilitate better maintenance and repair strategies.

| Issue | Description | Solution |

|---|---|---|

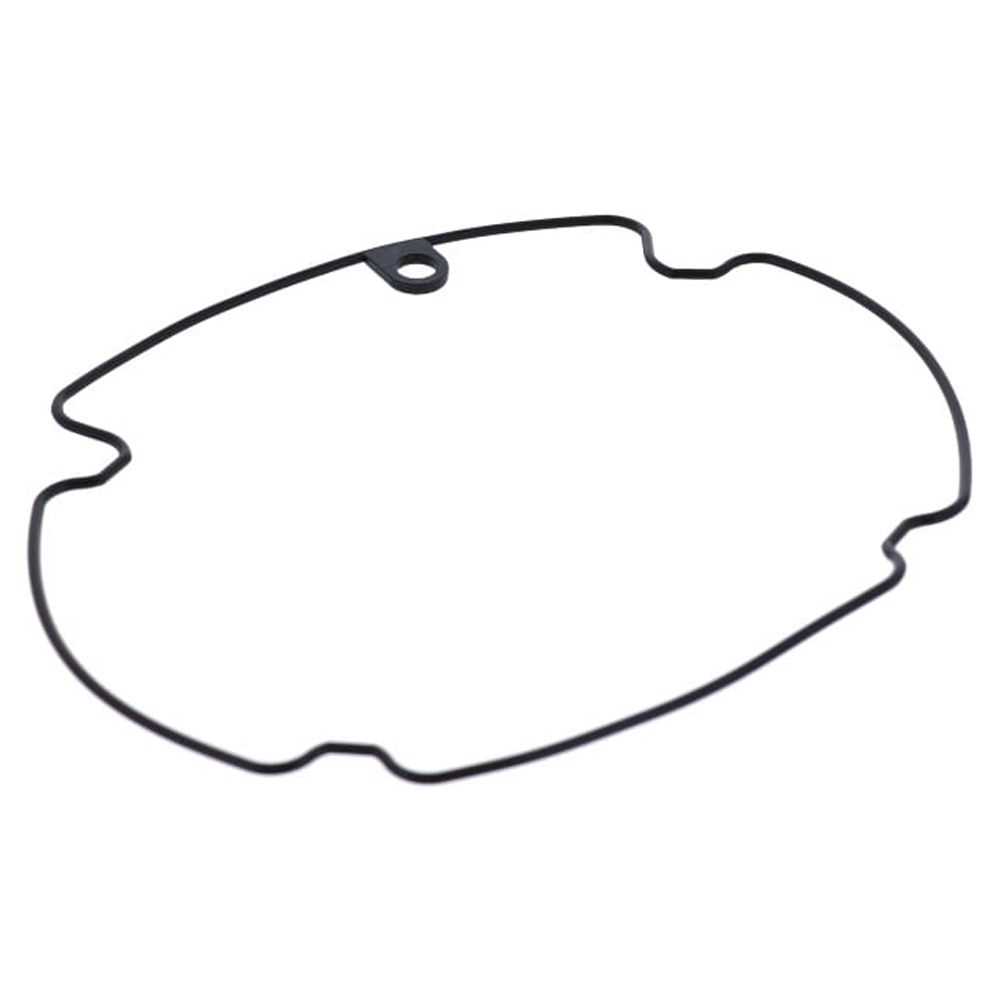

| Leakage | Fluid leaks can occur, affecting the tool’s functionality. | Inspect seals and gaskets; replace if damaged. |

| Power Loss | Inconsistent power output can lead to operational difficulties. | Check connections and replace any worn wires. |

| Jamming | Material may get stuck, causing interruptions during use. | Clear debris and ensure proper alignment of components. |

| Noisy Operation | Excessive noise can indicate internal wear or damage. | Lubricate moving parts and replace worn bearings. |

Where to Find Replacement Parts

Locating suitable components for your tools can enhance their longevity and performance. Many reliable sources offer a variety of options, ensuring you can restore your equipment to optimal functionality.

Online Retailers

Numerous online platforms specialize in tool accessories. Websites like Amazon or eBay often provide a wide selection of items at competitive prices, making it easy to compare and purchase what you need.

Local Hardware Stores

Visiting nearby hardware stores can yield immediate results. Staff members are usually knowledgeable and can help you find the necessary components, ensuring you get the right fit for your equipment.

How to Read Parts Diagrams

Understanding visual representations of components is essential for efficient assembly and maintenance. These illustrations serve as a guide, showcasing various elements and their interconnections. Learning to interpret these visuals can simplify repair processes and enhance your overall comprehension of the equipment.

Identifying Key Elements

Most illustrations feature labeled components, which may include numbers or letters corresponding to a legend. Familiarizing yourself with these identifiers is crucial for effective navigation. Pay attention to the following:

| Element | Description |

|---|---|

| Labels | Usually numeric or alphanumeric references indicating specific parts. |

| Connections | Lines or arrows that illustrate how components fit together. |

| Groupings | Clusters of elements that indicate a subassembly or a specific function. |

Following the Assembly Process

Once you’ve identified the elements, refer to accompanying documentation for guidance on assembly or disassembly. This often includes step-by-step instructions paired with the visual representation. Pay close attention to the orientation and placement of each component, as improper installation can lead to malfunction.

Maintenance Tips for the FC350A

Proper upkeep of your tool is essential to ensure its longevity and optimal performance. Regular maintenance not only prevents unexpected breakdowns but also enhances efficiency during usage. By following a few simple guidelines, you can keep your equipment in top shape, ready for any task.

Regular Cleaning

Dust and debris can accumulate quickly, affecting the functionality of your device. After each use, take a moment to wipe down the exterior and clean out any residue from the internal components. Use a soft brush or compressed air to remove particles that may hinder operation.

Routine Inspections

Performing frequent inspections helps identify potential issues before they become serious problems. Check for any signs of wear or damage, particularly in moving parts. Replace worn components promptly to avoid further complications. Additionally, lubricate necessary parts as specified in the manufacturer’s guidelines to maintain smooth operation.

By incorporating these practices into your routine, you will significantly enhance the reliability and efficiency of your equipment, ensuring it serves you well for years to come.

Identifying Faulty Components

Recognizing malfunctioning elements in a device is crucial for efficient repair and maintenance. When components fail, they can lead to suboptimal performance or complete breakdowns. This section focuses on common indicators that suggest specific parts may need attention or replacement.

Common Signs of Malfunction

Users should look for unusual noises, vibrations, or overheating. These symptoms often signal that internal mechanisms are not functioning correctly. Visual inspections can also reveal signs of wear, such as cracks or frayed wires.

Testing and Troubleshooting Techniques

Employing basic testing methods can help pinpoint issues. Multimeters can measure electrical continuity, while specific tools can check the performance of individual parts. This proactive approach aids in effectively addressing the ultimate cause of the problem.

Tools Required for Repairs

When undertaking maintenance or repairs on equipment, having the right tools is essential for achieving efficient and effective results. A well-equipped toolkit not only simplifies the process but also enhances safety and precision during the task. Understanding the necessary instruments can save time and prevent damage to the device.

Essential tools typically include screwdrivers of various sizes, pliers for gripping and bending, and wrenches for tightening or loosening bolts. Additionally, a multimeter can be invaluable for diagnosing electrical issues, while a set of replacement components may be necessary to ensure optimal functionality. Having a reliable work surface and proper safety gear, such as gloves and goggles, is also crucial for a successful repair experience.

Upgrading Your FC350A Parts

Enhancing the components of your tool can significantly improve its performance and longevity. By selecting high-quality upgrades, you can ensure smoother operation and greater efficiency, ultimately leading to more successful projects. This section will explore various options for improving the key elements of your device.

Choosing Quality Components

When it comes to enhancing your tool, the quality of replacement elements is crucial. Opt for well-reviewed and durable options that are designed to withstand regular use. Investing in superior materials not only boosts functionality but also reduces the likelihood of future breakdowns.

Installation Tips

Proper installation is essential for any upgrades to be effective. Make sure to follow the manufacturer’s guidelines closely. Taking the time to ensure a secure fit will help maintain performance and prevent unnecessary wear. Additionally, consider seeking assistance from a professional if you are unsure about the installation process.

Warranty Considerations for Parts

When it comes to replacement components, understanding warranty terms is crucial for consumers. Many manufacturers offer guarantees that can protect buyers from defects and ensure proper functionality. Being informed about these terms can help you make better decisions regarding repairs and replacements.

Types of Warranties

Warranties can vary widely, encompassing full coverage for defects or limited terms that only cover specific issues. It’s important to carefully review the details to know what is included and excluded.

Claim Process

To successfully claim a warranty, documentation such as receipts and original packaging may be required. Familiarize yourself with the steps involved to avoid potential setbacks.

| Warranty Type | Description |

|---|---|

| Limited Warranty | Covers specific defects for a defined period. |

| Full Warranty | Offers complete coverage for defects without limitations. |

| Lifetime Warranty | Provides coverage for the entire lifespan of the item. |

User Experiences with FC350A Repairs

When it comes to repairing tools, many users share their journeys and challenges. From seeking replacement components to understanding the assembly process, these experiences often highlight common issues and solutions. The insights gained from various individuals can serve as a valuable resource for both novice and seasoned repair enthusiasts.

Many users have noted the importance of having clear guidelines while attempting fixes. Detailed manuals and community forums frequently become lifesavers, offering tips that make the process smoother. A few have even created instructional videos that illustrate complex steps, enriching the repair experience.

Frustration can arise when parts are difficult to find or when discrepancies in the product’s design lead to unexpected complications. However, this challenge often drives users to delve deeper, fostering a community spirit where individuals support one another with shared knowledge and troubleshooting techniques.

Overall, the stories of those who have undertaken repairs reveal a mix of satisfaction and learning. Each experience contributes to a collective understanding, ultimately enhancing the repair process for future users.