Comprehensive Guide to Predator 212 Parts Diagram

Exploring the intricate details of small engine assemblies can enhance maintenance and repair capabilities. A comprehensive understanding of these mechanical systems empowers users to effectively troubleshoot and optimize performance.

Every engine comprises various elements, each playing a crucial role in overall functionality. Familiarity with these components aids in identifying issues and ensures smooth operation.

In this section, we will delve into the essential elements that make up these machines, providing a clear visual representation to assist in comprehension. This guide serves as the ultimate resource for enthusiasts and professionals alike, facilitating informed decisions and efficient repairs.

Understanding Predator 212 Engine Components

Exploring the various elements of a small engine is essential for both enthusiasts and those in need of maintenance. Each component plays a crucial role in ensuring efficient operation and longevity. By grasping the function and interrelation of these parts, one can better diagnose issues and perform effective repairs.

The heart of the engine is the combustion chamber, where fuel and air mix to create the power needed for operation. Surrounding this chamber are critical components such as the piston, connecting rod, and crankshaft, all of which work together to convert fuel energy into mechanical energy. Understanding how these parts interact is vital for optimizing performance.

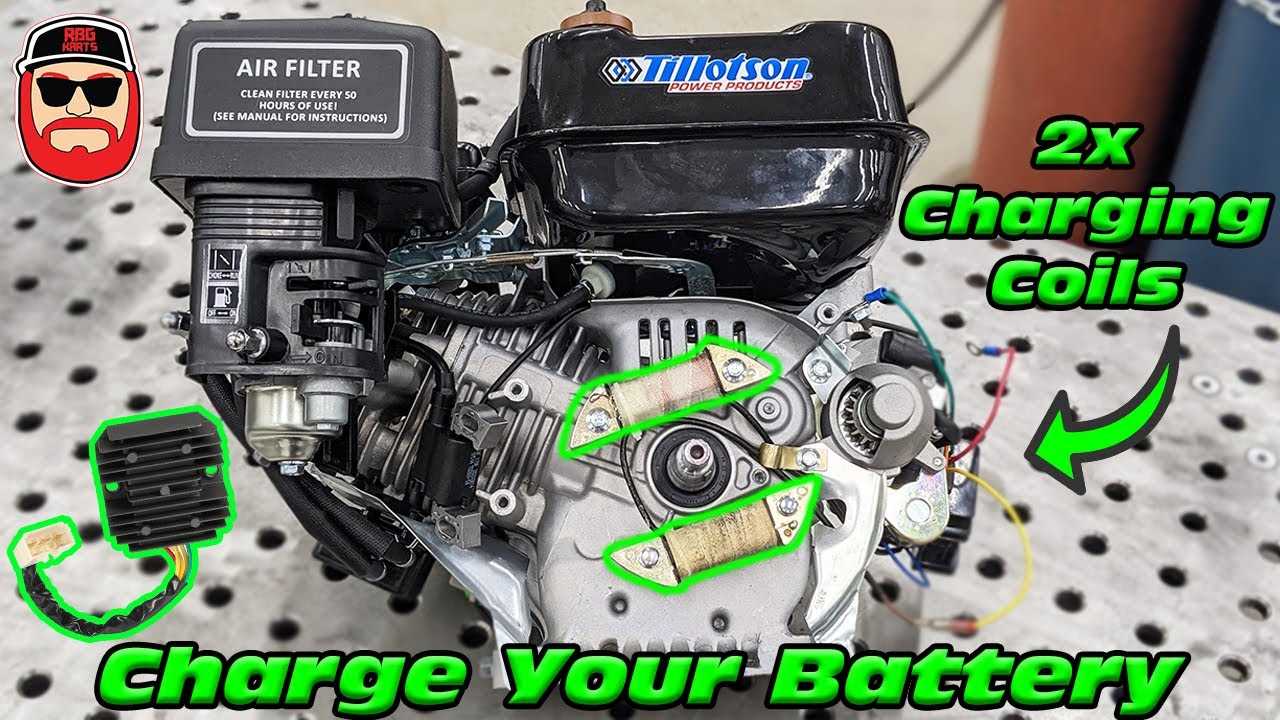

Additionally, the ignition system is integral to the engine’s operation. It includes the spark plug and coil, which generate the necessary spark to ignite the air-fuel mixture. A malfunction in this system can lead to starting difficulties or performance issues, highlighting the importance of regular checks.

Cooling and lubrication systems are also key to maintaining engine health. The cooling system prevents overheating, while the lubrication system ensures all moving parts operate smoothly. Familiarity with these systems can help prevent costly repairs and extend the lifespan of the engine.

Finally, recognizing the various accessories, such as air filters and exhaust systems, contributes to a comprehensive understanding of the engine’s overall functionality. By studying these components, one can gain valuable insights into effective maintenance and troubleshooting practices.

Overview of Predator 212 Parts

This section provides a comprehensive look at the essential components of a popular small engine model. Understanding the various elements involved is crucial for maintenance, upgrades, or repairs. Each element plays a vital role in ensuring optimal performance and longevity.

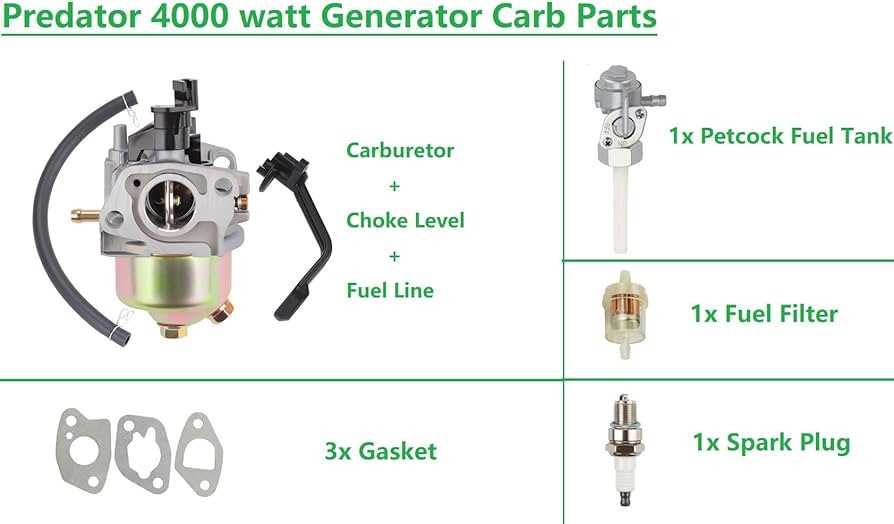

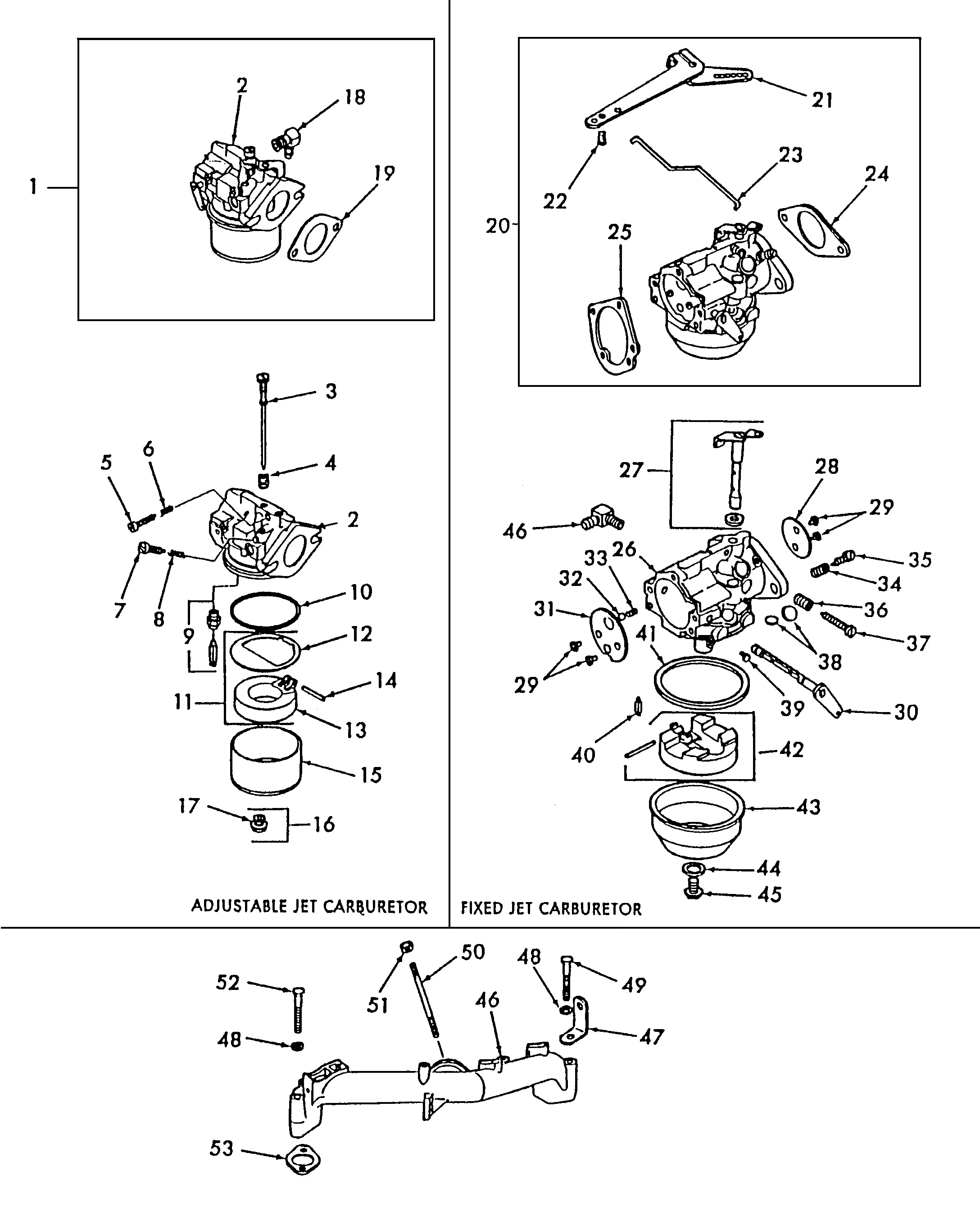

Core Components: The engine consists of several key units, including the crankshaft, cylinder head, and carburetor. These components work in harmony to convert fuel into mechanical energy.

Supporting Elements: Additional features, such as the ignition system and exhaust manifold, contribute to efficiency and emission control. Each piece must be compatible to achieve the ultimate functionality.

Maintenance and Upgrades: Regular inspection of these components can enhance performance. Upgrading specific units may provide increased power and efficiency, allowing enthusiasts to delve deeper into engine modifications.

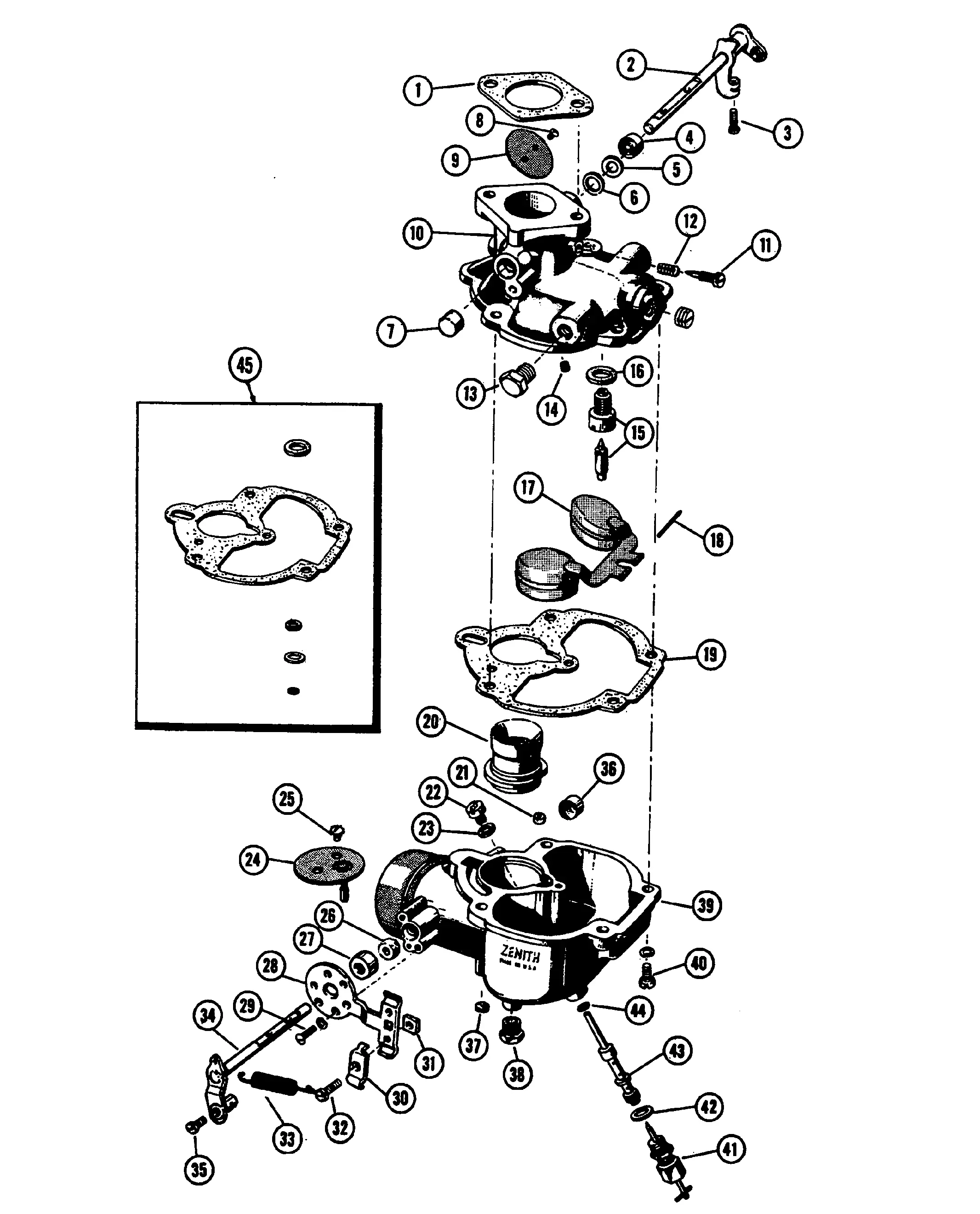

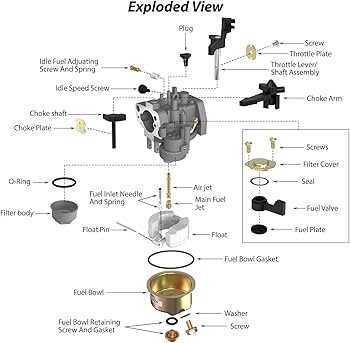

Importance of Engine Diagrams

Visual representations of mechanical assemblies play a crucial role in understanding the intricacies of machinery. They serve as essential tools for both novice and experienced users, simplifying complex concepts and ensuring efficient maintenance and repair processes.

| Benefits | Description |

|---|---|

| Clarity | Provides a clear overview of component relationships and functions. |

| Efficiency | Facilitates quicker repairs by allowing users to identify parts easily. |

| Education | Acts as a learning tool for those new to engine mechanics. |

| Problem Solving | Assists in diagnosing issues by illustrating potential failure points. |

Common Issues with Predator 212

When it comes to small engines, several typical challenges may arise that can affect performance and reliability. Understanding these common problems can help in maintaining optimal functionality and prolonging the lifespan of the machinery.

Starting Difficulties

One of the most frequent complaints is trouble with ignition. This can stem from fuel quality, spark plug issues, or carburetor blockages. Regularly checking these components can often resolve starting issues and improve engine reliability.

Overheating Problems

Overheating is another prevalent issue that can lead to severe damage if not addressed promptly. Causes may include inadequate cooling, low oil levels, or debris clogging air intake. Ensuring proper maintenance and airflow can mitigate these risks and enhance overall performance.

How to Read Parts Diagrams

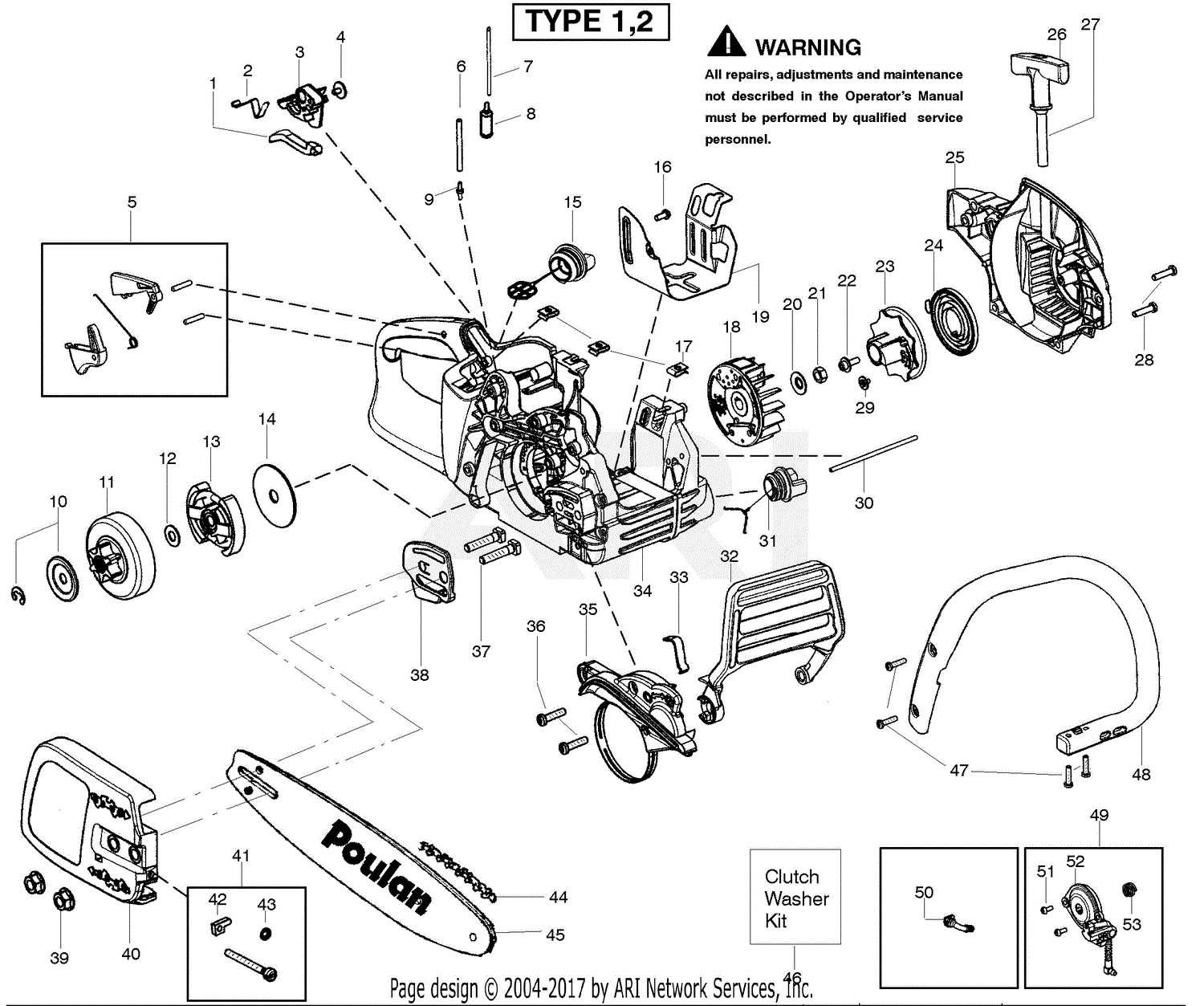

Understanding technical illustrations is essential for anyone looking to maintain or repair machinery. These visual representations provide critical insights into the assembly and functionality of various components, making it easier to identify and source replacements. By familiarizing yourself with the layout and symbols used, you can streamline your maintenance process and enhance your troubleshooting skills.

Identifying Components

Begin by examining the key elements of the illustration. Each part is typically labeled with a number or letter, corresponding to a list that details specifications. Take your time to match these labels with their descriptions to gain clarity on the function of each element. This foundational step will aid in recognizing any discrepancies during maintenance.

Understanding the Layout

The arrangement of parts in the illustration often reflects their physical configuration within the machine. Pay attention to how components are grouped together, as this can indicate their relationship and interaction. Familiarity with common layouts will improve your ability to visualize the assembly, allowing for more efficient repairs. Additionally, note any special symbols or notations that may highlight specific installation procedures or warnings.

Essential Tools for Maintenance

Proper upkeep of machinery requires a selection of crucial instruments to ensure optimal performance and longevity. These tools facilitate efficient servicing, allowing users to address issues promptly and maintain functionality.

Basic Toolkit

- Wrenches

- Screwdrivers

- Pliers

- Socket set

Specialized Equipment

- Oil filter wrench

- Compression tester

- Multimeter

- Cleaning brushes

Having these essential tools on hand can significantly enhance the maintenance process, ensuring that your equipment operates smoothly and efficiently.

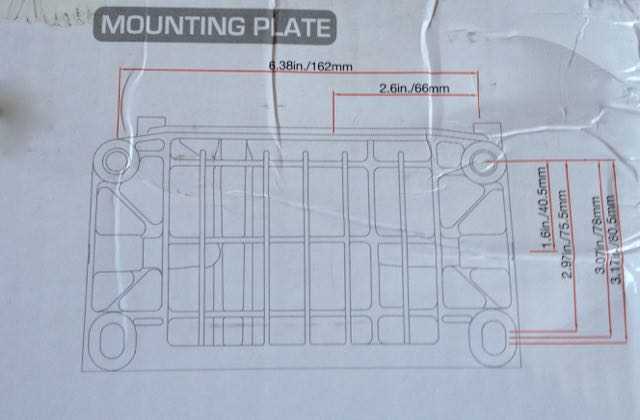

Identifying Replacement Parts

Understanding the components of your equipment is crucial for effective maintenance and repairs. Knowing how to accurately identify each element can significantly enhance performance and longevity. This section will guide you through the process of recognizing the various elements and finding suitable substitutes when necessary.

Common Components and Their Functions

Each component plays a vital role in the overall functionality of the machine. Here’s a brief overview of some essential parts and their purposes:

| Component | Function |

|---|---|

| Cylinder | Houses the combustion chamber, crucial for power generation. |

| Piston | Converts fuel energy into mechanical motion. |

| Crankshaft | Transfers power from the piston to the output shaft. |

| Ignition Coil | Generates the spark necessary for combustion. |

| Air Filter | Prevents debris from entering the engine, ensuring clean airflow. |

Tips for Finding Suitable Replacements

When searching for replacements, consider the following tips to ensure compatibility:

- Consult the user manual for specific specifications.

- Take measurements of the existing components for accuracy.

- Research reputable suppliers to find high-quality alternatives.

- Look for online resources and forums where enthusiasts share recommendations.

Where to Find Quality Diagrams

Locating high-quality illustrations for mechanical components is essential for effective repairs and maintenance. These resources provide detailed visuals that help in understanding assembly and functionality, making it easier to troubleshoot issues.

Here are some reliable sources:

| Source | Description |

|---|---|

| Manufacturer Websites | Official sites often have downloadable manuals and detailed visuals for their products. |

| Online Forums | Community-driven platforms can offer shared resources and personal experiences related to specific models. |

| Repair Shops | Local or online repair services may provide guides or diagrams based on their expertise. |

| Parts Retailers | Some retailers offer detailed breakdowns to assist customers in identifying the correct components. |

Assembly Process of Predator 212

Assembling a small engine requires precision and attention to detail. The following steps provide a structured approach to ensure that every component fits together seamlessly, resulting in a functional and efficient machine.

- Preparation

- Gather all necessary tools and components.

- Ensure the workspace is clean and organized.

- Base Assembly

- Begin with the crankcase and install the crankshaft.

- Secure the flywheel onto the crankshaft using the appropriate fasteners.

- Installing the Cylinder

- Position the cylinder head over the base and align the bolt holes.

- Tighten the bolts in a crisscross pattern for even pressure.

- Fuel System Setup

- Attach the carburetor, ensuring all gaskets are in place.

- Connect the fuel lines securely to prevent leaks.

- Cooling System Integration

- Install the cooling fins, if applicable, to enhance airflow.

- Ensure that the engine is positioned for optimal heat dissipation.

- Final Assembly and Testing

- Double-check all connections and fasteners.

- Fill the engine with the appropriate oil and fuel mix.

- Start the engine and monitor for any irregular sounds or leaks.

By following these detailed steps, one can successfully assemble a small engine that operates smoothly and reliably.

Upgrading Components for Performance

Enhancing the efficiency and output of small engines involves a thoughtful approach to component modifications. By strategically replacing certain elements, enthusiasts can achieve significant improvements in power and responsiveness. Each upgrade should be tailored to the specific requirements of the application, ensuring compatibility and optimal performance.

Air Intake Systems play a crucial role in maximizing airflow, which directly influences engine efficiency. Upgrading to a high-flow air filter or an aftermarket intake can facilitate better breathing, resulting in improved throttle response and overall power gains.

Exhaust Modifications are equally important. A less restrictive exhaust system can reduce back pressure, allowing exhaust gases to exit more freely. This enhancement not only boosts power but can also contribute to a more aggressive sound, appealing to many users.

Cylinder Head and Valvetrain upgrades are another area worth exploring. High-performance valves, springs, and camshafts can increase airflow and improve timing, further optimizing combustion efficiency. These modifications, however, should be approached with an understanding of the overall balance required for reliable operation.

Fuel Delivery systems may also need attention. Upgrading the carburetor or fuel injectors can ensure that the engine receives the optimal fuel-air mixture, supporting better performance. It’s vital to consider how these components interact with other modifications for seamless integration.

Finally, don’t overlook ignition systems. A high-output ignition coil or advanced spark plugs can enhance spark intensity, leading to more complete combustion and increased power output. These upgrades can significantly elevate the overall performance of your engine.

Preventive Maintenance Tips

Regular upkeep is essential for ensuring optimal performance and longevity of your machinery. Implementing a proactive approach helps identify potential issues before they escalate, thereby reducing downtime and costly repairs.

Routine Checks

- Inspect fluid levels regularly.

- Examine belts and hoses for signs of wear.

- Clean air filters to ensure proper airflow.

Scheduled Servicing

- Follow the manufacturer’s recommended service intervals.

- Replace worn or damaged components promptly.

- Lubricate moving parts to reduce friction and wear.

Frequently Asked Questions About Parts

This section aims to address common inquiries regarding components and their functionality in various applications. Understanding these elements can enhance your knowledge and assist in making informed decisions for repairs or upgrades.

| Question | Answer |

|---|---|

| What are the essential components I need for maintenance? | Key elements include filters, spark plugs, and gaskets, which help ensure optimal performance. |

| How can I identify a malfunctioning component? | Signs may include unusual noises, leaks, or decreased efficiency. Regular inspections are crucial. |

| Where can I find replacement components? | Authorized dealers, online retailers, and local hardware stores are reliable sources for quality items. |

| Are there aftermarket options available? | Yes, many manufacturers offer compatible alternatives that can be more affordable. |

| How do I ensure compatibility with my system? | Always refer to the specifications or consult a professional to match the correct components. |