Understanding the Rack and Pinion Parts Diagram

In the realm of mechanical systems, the interaction between linear and rotational motion plays a crucial role in various applications. These systems facilitate efficient movement and control, allowing for smooth transitions between different types of motion. By examining the intricate components involved, one can gain valuable insights into their functionality and design.

Mechanisms that convert rotational force into linear displacement are widely utilized in industries ranging from automotive to robotics. Their versatility is evident in numerous devices, where precision and reliability are paramount. A detailed exploration of these elements reveals their importance in achieving desired outcomes.

To grasp the underlying principles of these systems, it is essential to analyze the configuration and relationships among the individual components. Each element contributes to the overall efficiency, making it imperative to understand their arrangement and interaction. Such knowledge not only enhances design capabilities but also improves troubleshooting and maintenance practices.

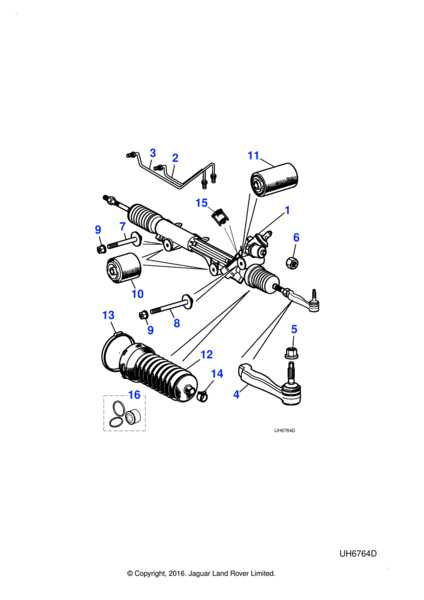

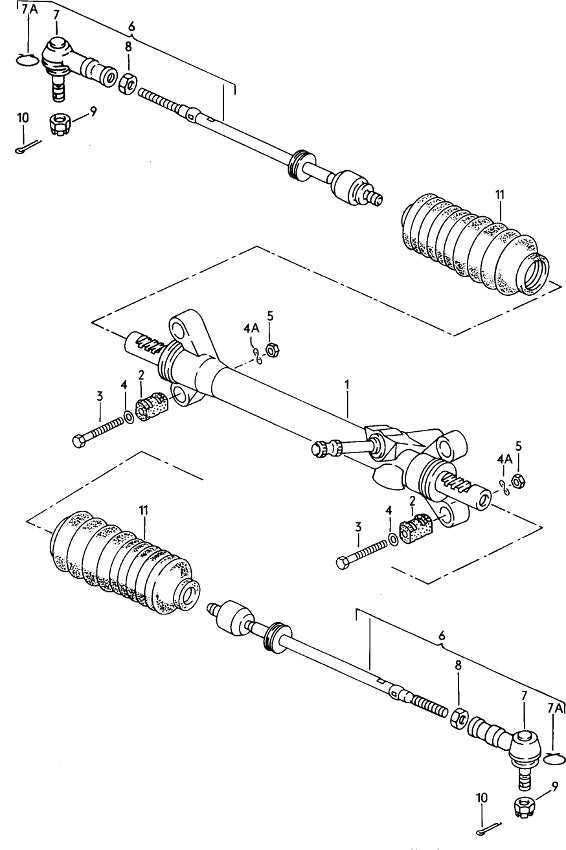

Guide to Components in Rack and Pinion Mechanism

In this comprehensive section, we delve into the intricate components that comprise the essential gear assembly of the rack and pinion system. This guide provides an insightful exploration of the fundamental elements involved, offering a detailed examination of each constituent part. From the primary driving component to the smaller, yet equally significant, elements that facilitate smooth operation, each piece plays a crucial role in the overall functionality.

- Principal Gear Element

- Supportive Linkages

- Connecting Joints

- Motion Transfer Mechanisms

- Enhancing Bearings

- Stabilizing Fixtures

By dissecting these essential constituents, we aim to provide a comprehensive understanding of how each element contributes to the overall effectiveness of the rack and pinion system. This section aims to serve as an invaluable resource for those seeking to grasp the intricacies of gear mechanics without relying on overly technical jargon.

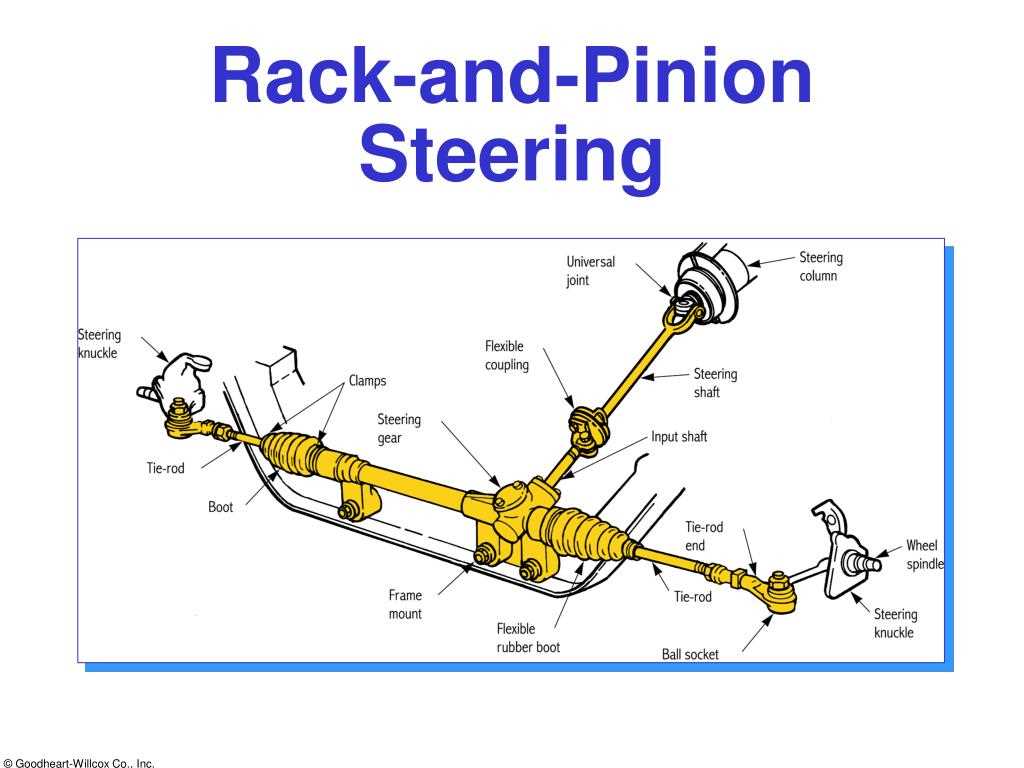

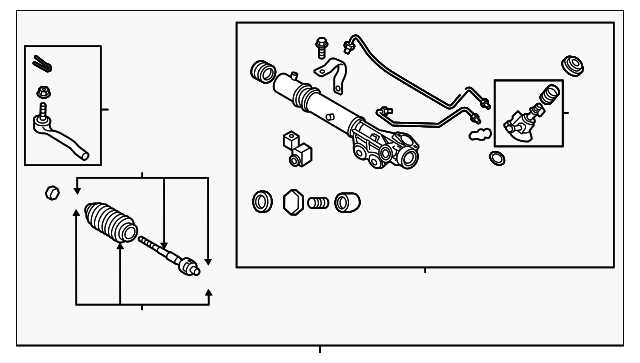

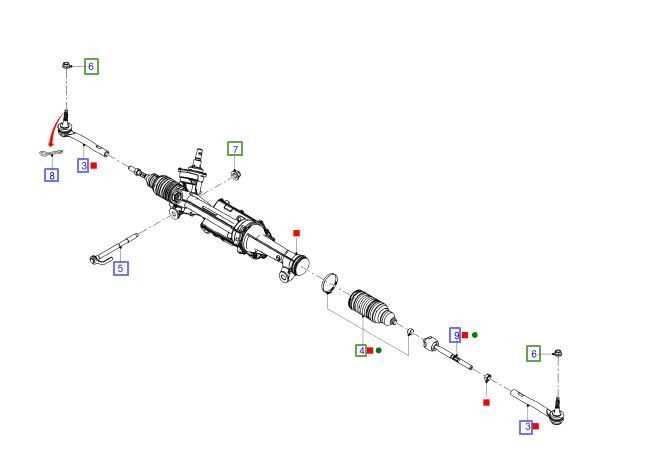

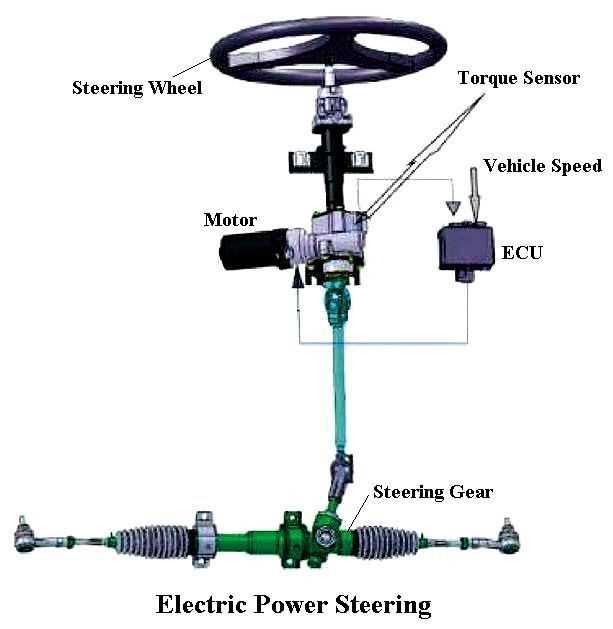

Understanding Rack and Pinion Steering Systems

This section explores the mechanics behind a widely used steering mechanism in vehicles. Its design allows for efficient control and responsiveness, ensuring a smooth driving experience. By translating rotational movement into linear motion, this system enhances maneuverability and stability, crucial for safe navigation on the road.

Key Components

- Central rod: The main element that facilitates movement.

- Teeth: Engaged elements that allow for precise steering adjustments.

- Gear assembly: Converts rotational force from the steering wheel into linear motion.

- Support system: Provides stability and alignment for optimal performance.

Benefits of This Steering Mechanism

- Improved steering precision: Enhances driver control.

- Compact design: Saves space under the hood.

- Reduced maintenance: Fewer moving parts lead to lower wear and tear.

- Responsive handling: Provides quick feedback to the driver.

Understanding these elements helps in appreciating the sophistication and effectiveness of this steering system, contributing significantly to modern automotive engineering.

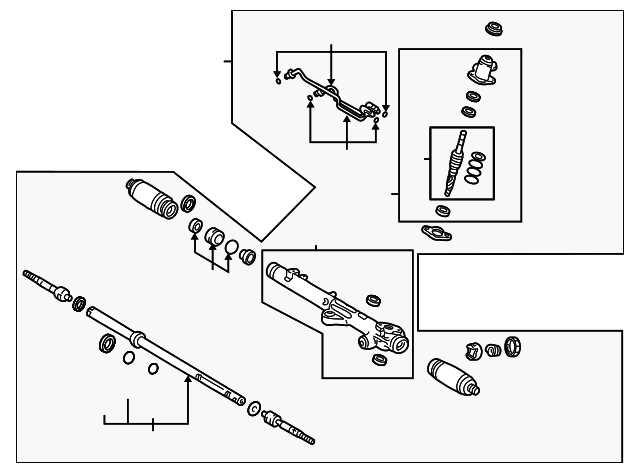

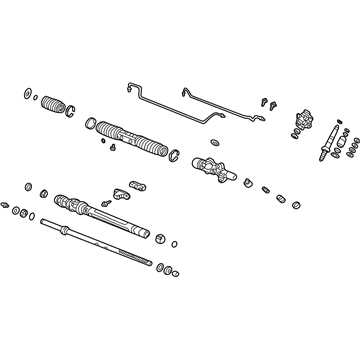

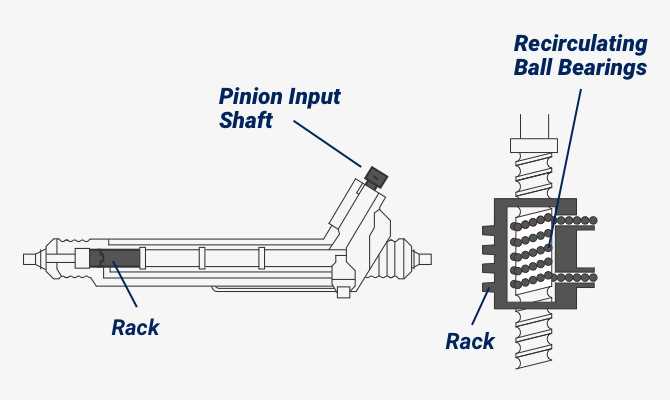

Exploring the Function of the Sliding Gear Component

The essential role of this mechanical element lies in its pivotal contribution to the smooth and controlled movement within a mechanical system. Operating silently and efficiently, it facilitates the translation of rotational motion into linear motion, ensuring precise engagement and movement along a defined path. This integral part of the mechanism enables the seamless transmission of force, crucial for the effective functioning of various machinery.

The Principle of Linear Motion Conversion

At its core, this component exemplifies the conversion of rotary force into a directed linear movement, embodying mechanical simplicity yet engineering sophistication. Its design optimizes the distribution of force, minimizing energy loss while maintaining stability and reliability in operation. This functionality underscores its versatility in applications ranging from automotive steering systems to industrial machinery, where precise control and responsiveness are paramount.

Anatomy of a Pinion Gear

Understanding the structure of a small gear component is essential for comprehending its role in various mechanical systems. This element functions as a crucial interface that facilitates movement and force transmission in conjunction with other gears or linear components.

The fundamental elements of this gear include:

- Teeth: These are the projecting parts that engage with another gear or linear mechanism, enabling rotational movement.

- Pitch Circle: This imaginary circle represents the point where the teeth effectively engage with a corresponding element, dictating the gear’s operational efficiency.

- Base Circle: This is the circle from which the tooth profile is generated, essential for understanding the gear’s shape and functionality.

- Face: The surface of the gear tooth that is in contact during operation, influencing wear and performance.

- Root: The lowest point of the tooth profile, crucial for determining the strength and durability of the gear.

In addition to these key features, several characteristics contribute to the performance and application of the gear:

- Material: The choice of material affects the gear’s strength, weight, and resistance to wear.

- Module: This defines the size of the teeth and directly impacts how well the gear meshes with others.

- Pressure Angle: The angle at which the teeth meet influences the efficiency and load capacity.

A comprehensive understanding of this small but vital component reveals its significant role in ensuring smooth operation across various machinery and vehicles.

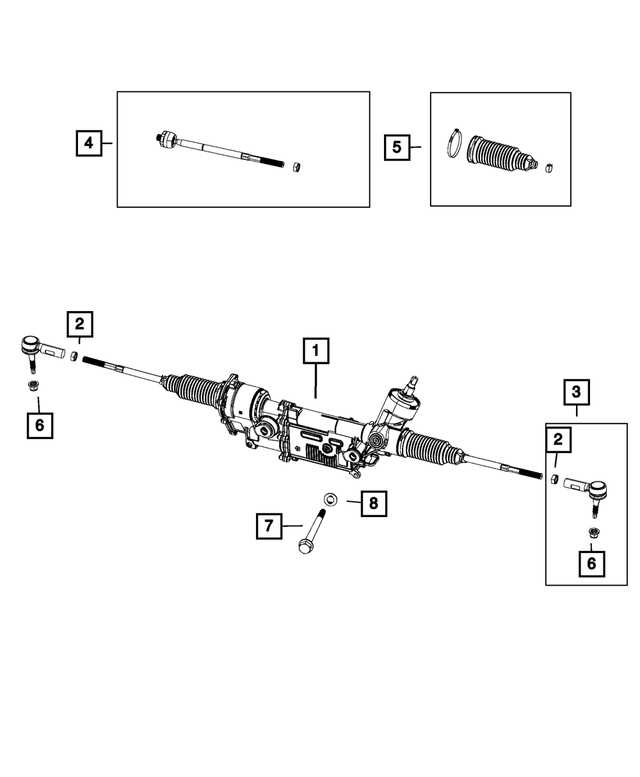

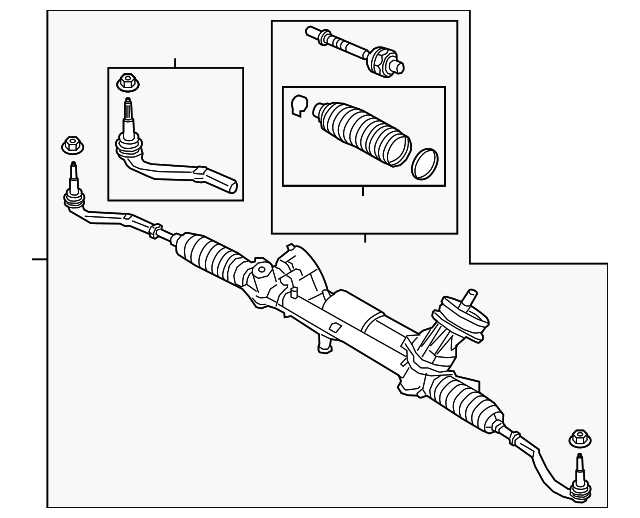

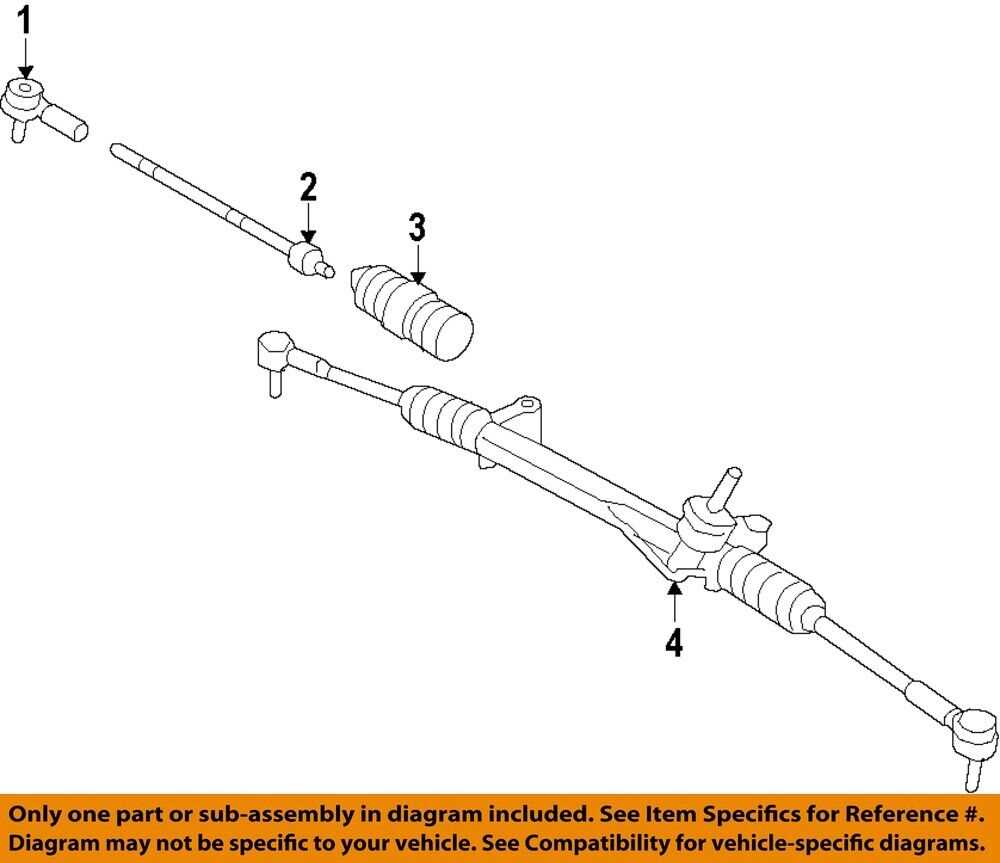

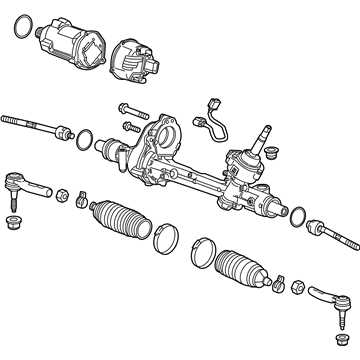

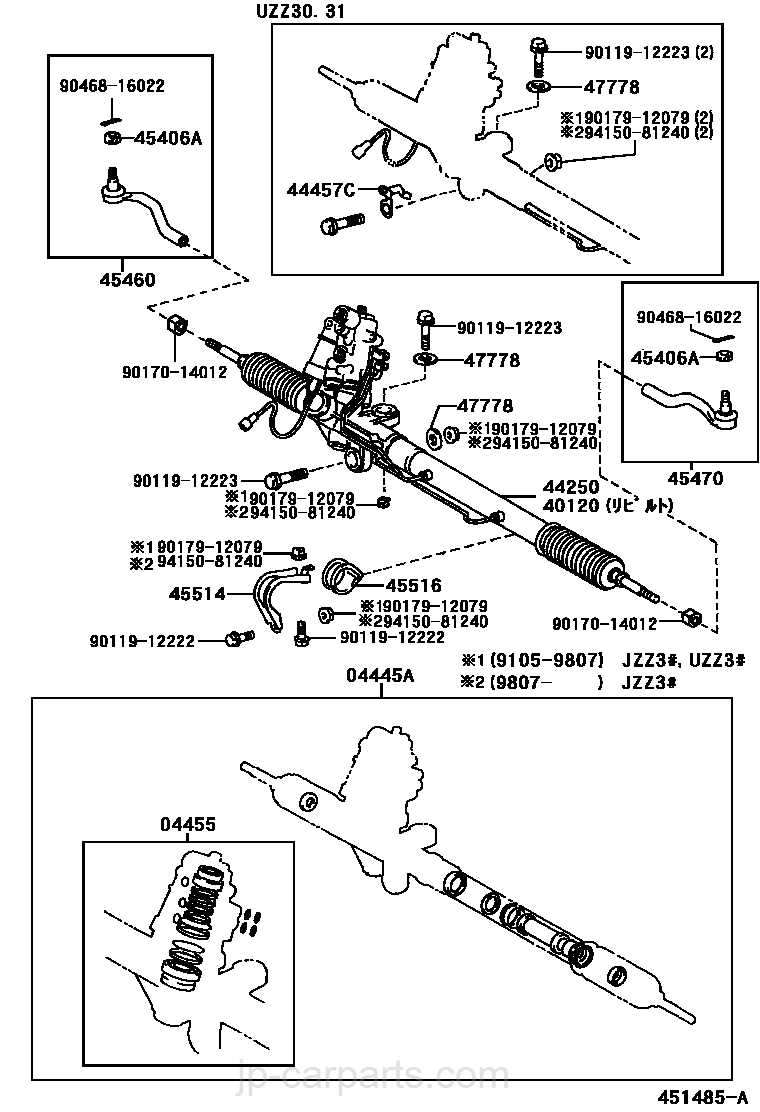

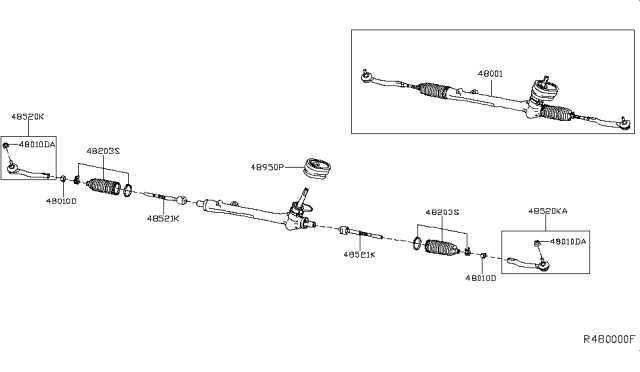

Key Components of a Rack and Pinion Assembly

The mechanism in question is a fundamental element in various engineering applications, converting rotational motion into linear movement. Understanding its essential components is crucial for anyone interested in mechanics or design, as each part plays a vital role in its overall functionality and efficiency.

Driving Gear

The driving gear serves as the heart of this system, responsible for initiating movement. Typically circular in shape, it engages with another component to transform rotational energy into directed force. Its precision in construction directly influences the effectiveness and responsiveness of the entire setup.

Linear Bar

The linear bar complements the driving gear by providing a stable track for movement. It features teeth that interlock with the driving gear, allowing for smooth translation. The quality of this component affects durability and wear over time, making its material selection essential for longevity and performance.

In summary, each component within this assembly contributes to the seamless operation of the mechanism, highlighting the importance of meticulous design and engineering. Emphasizing the right materials and manufacturing processes can significantly enhance efficiency and reliability.

Common Materials Used in Rack and Pinion Parts

In various mechanical systems, the selection of materials for essential components plays a crucial role in performance, durability, and efficiency. Different substances provide unique properties that cater to specific applications, influencing factors like strength, wear resistance, and friction characteristics. Understanding these materials is vital for optimizing design and ensuring longevity.

Metal Alloys

Metal alloys, such as steel and aluminum, are frequently chosen for their remarkable strength and resilience. Steel, often used in heavy-duty applications, offers excellent load-bearing capabilities, while aluminum provides a lighter alternative with good corrosion resistance. The choice of alloy often depends on the required balance between weight and strength.

Plastics and Composites

Plastics, including nylon and acetal, are popular due to their low friction and self-lubricating properties, which reduce wear and noise. Composites can also be employed, combining the benefits of different materials to achieve a tailored performance. These substances are ideal for lighter mechanisms where weight savings are essential without compromising functionality.

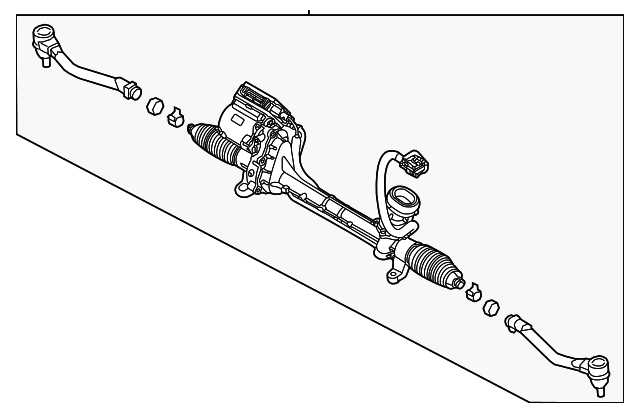

How Rack and Pinion Systems Improve Steering Precision

In modern automotive engineering, enhancing the accuracy of vehicle direction is crucial for both safety and performance. A specific mechanism plays a vital role in achieving this goal, providing smooth and responsive handling. This system transforms rotational motion into linear movement, allowing for precise control of the vehicle’s front wheels.

One of the primary advantages of this mechanism lies in its design, which facilitates a direct connection between the steering wheel and the wheels. This results in several key benefits:

- Immediate Response: The direct link ensures that any movement of the steering wheel is transmitted quickly to the wheels, minimizing delay.

- Enhanced Feedback: Drivers receive better sensory input from the road, allowing for more informed decision-making during driving.

- Compact Design: The mechanism occupies less space, enabling more flexible vehicle layouts without compromising performance.

- Reduced Wear: Fewer components mean less friction and wear, contributing to longevity and reliability.

Furthermore, precision engineering allows for adjustments in gear ratios, enabling manufacturers to tailor the feel of the steering based on vehicle type and intended use. This adaptability enhances the driving experience, ensuring that the system meets diverse demands.

Overall, this innovative mechanism not only improves steering accuracy but also elevates driver confidence, making it an essential element in contemporary vehicle design.

Comparing Rack and Pinion vs. Other Steering Mechanisms

When evaluating various steering systems, it’s essential to consider their operational efficiency, responsiveness, and overall design. Each mechanism brings unique characteristics to the table, impacting handling, precision, and maintenance requirements. Understanding these differences can help in selecting the most suitable option for specific applications.

The conventional method relies on a set of gears to convert rotational movement into linear motion. This design typically offers greater simplicity and reduced component wear. In contrast, alternative systems may provide enhanced feedback to the driver but often at the cost of increased complexity and maintenance challenges.

Another notable system employs a series of hydraulic components, allowing for smoother operation and easier maneuvering. While this mechanism can enhance comfort during driving, it often requires more frequent servicing due to the additional parts involved. Furthermore, these systems may introduce delays in response time compared to more direct methods.

When comparing systems, the weight and space considerations also play a vital role. Some designs are compact and lightweight, contributing to better fuel efficiency and overall performance. Conversely, others might be bulkier but offer enhanced durability, making them suitable for heavier vehicles or off-road applications.

Ultimately, the choice between various steering systems depends on specific needs, such as driving conditions, vehicle type, and personal preferences. Each option has its strengths and weaknesses, making it crucial to weigh these factors carefully before making a decision.

Maintenance Tips for Rack and Pinion Systems

Proper upkeep of mechanical systems is crucial for their longevity and efficient operation. Regular maintenance helps to prevent wear and tear, ensuring smooth functionality over time. By following a few essential practices, you can enhance performance and extend the life of your equipment.

Regular Inspection

Frequent assessments are vital for identifying potential issues before they escalate. Look for signs of wear, misalignment, or damage. Early detection allows for timely repairs, reducing the risk of system failure.

Lubrication Practices

Consistent lubrication minimizes friction and prevents corrosion. Use appropriate lubricants that meet the specifications of your system. Apply grease or oil at regular intervals, following manufacturer guidelines.

| Maintenance Task | Frequency | Notes |

|---|---|---|

| Visual Inspection | Monthly | Check for alignment and wear. |

| Lubrication | Every 500 hours of operation | Use recommended lubricants. |

| Component Tightening | Quarterly | Ensure all fasteners are secure. |

| Cleaning | Every 6 months | Remove debris and contaminants. |

Diagnosing Common Issues with Rack and Pinion Assemblies

When dealing with the steering mechanism that translates rotational movement into linear motion, it’s essential to identify potential problems that can affect performance. Various symptoms may indicate underlying faults, impacting both safety and drivability.

Uneven Steering Response can be a primary sign of trouble. If the steering feels sluggish or requires more effort to turn, it might suggest wear in the components or insufficient lubrication. Inspecting the assembly for any obstructions or damage is crucial to ensure smooth operation.

Unusual Noises often accompany mechanical issues. Sounds such as grinding, popping, or clunking can indicate a lack of lubrication, damaged gears, or misalignment. Paying attention to these auditory clues can guide you toward the source of the problem.

Vibration During Use is another common concern. Excessive shaking while steering can result from imbalanced elements or worn-out joints. Regular checks can help prevent further damage and ensure a stable driving experience.

Finally, Fluid Leaks should not be overlooked. If you notice any fluid pooling under the vehicle, it may signal a breach in the seals or hoses, leading to reduced efficiency. Addressing leaks promptly is vital to maintaining optimal functionality.

Future Trends in Rack and Pinion Technology

The future of linear motion mechanisms is poised for significant advancements as technology continues to evolve. Innovations in design, materials, and manufacturing processes are set to enhance performance, efficiency, and versatility across various industries. This section explores emerging trends that will shape the future landscape of these mechanical systems.

Innovative Materials

- Lightweight composites are gaining traction, reducing overall system weight.

- Advanced alloys promise increased strength and durability.

- Smart materials will allow for adaptive responses to environmental changes.

Integration with Automation

- Seamless connectivity with IoT devices will enable real-time monitoring and control.

- Increased automation in manufacturing processes will streamline production and reduce costs.

- Robotics applications will demand more precise and responsive mechanisms for improved functionality.

As these trends unfold, industries will benefit from enhanced capabilities, paving the way for more efficient and innovative solutions in motion control systems.