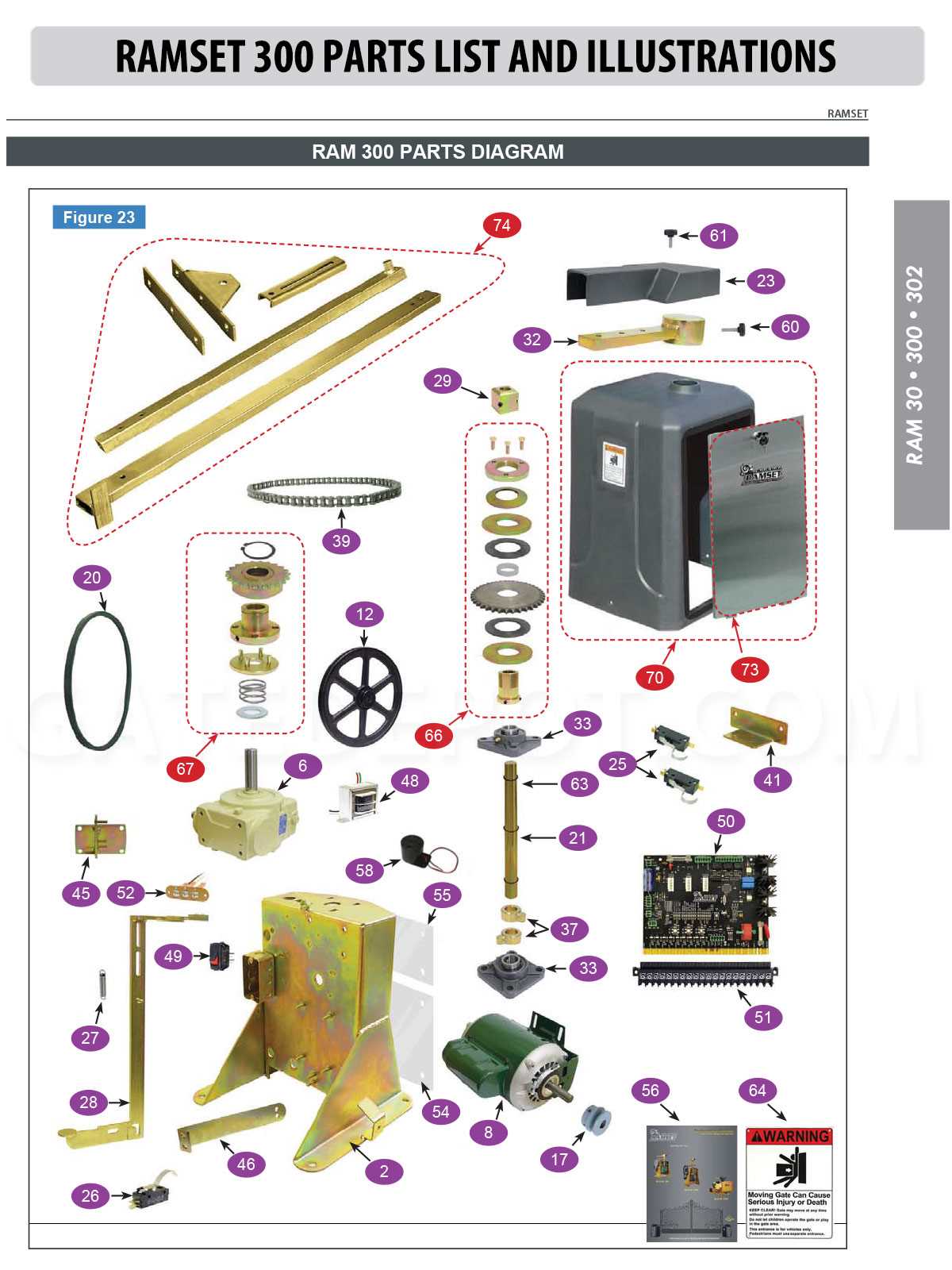

Understanding the Ramset Parts Diagram for Optimal Usage

When it comes to efficient fastening solutions, grasping the intricacies of the various elements involved is crucial. Each component plays a pivotal role in ensuring functionality and reliability, making it essential for users to familiarize themselves with the inner workings of these mechanisms.

This exploration aims to uncover the relationships and arrangements that contribute to the overall performance of fastening devices. By examining the structure and design of these tools, one can gain valuable insights that enhance both usage and maintenance.

Furthermore, a detailed overview of the system’s configuration empowers individuals to troubleshoot issues effectively. Understanding how each piece interacts ultimately leads to a more informed approach to selection and application.

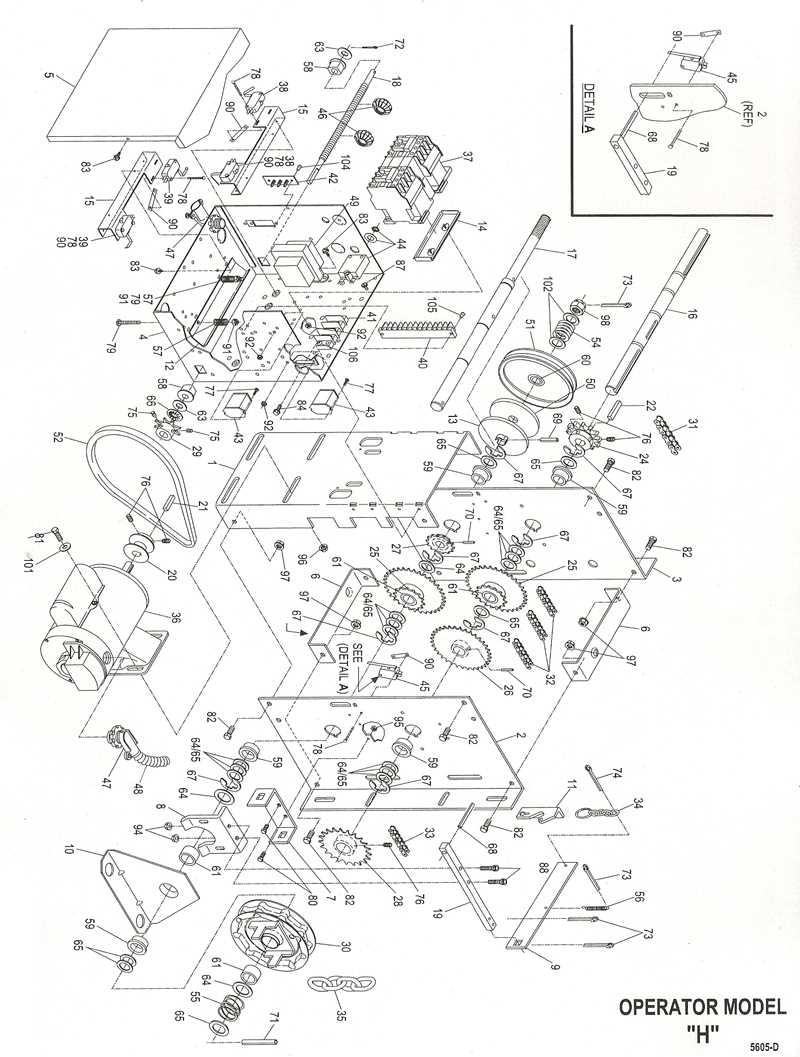

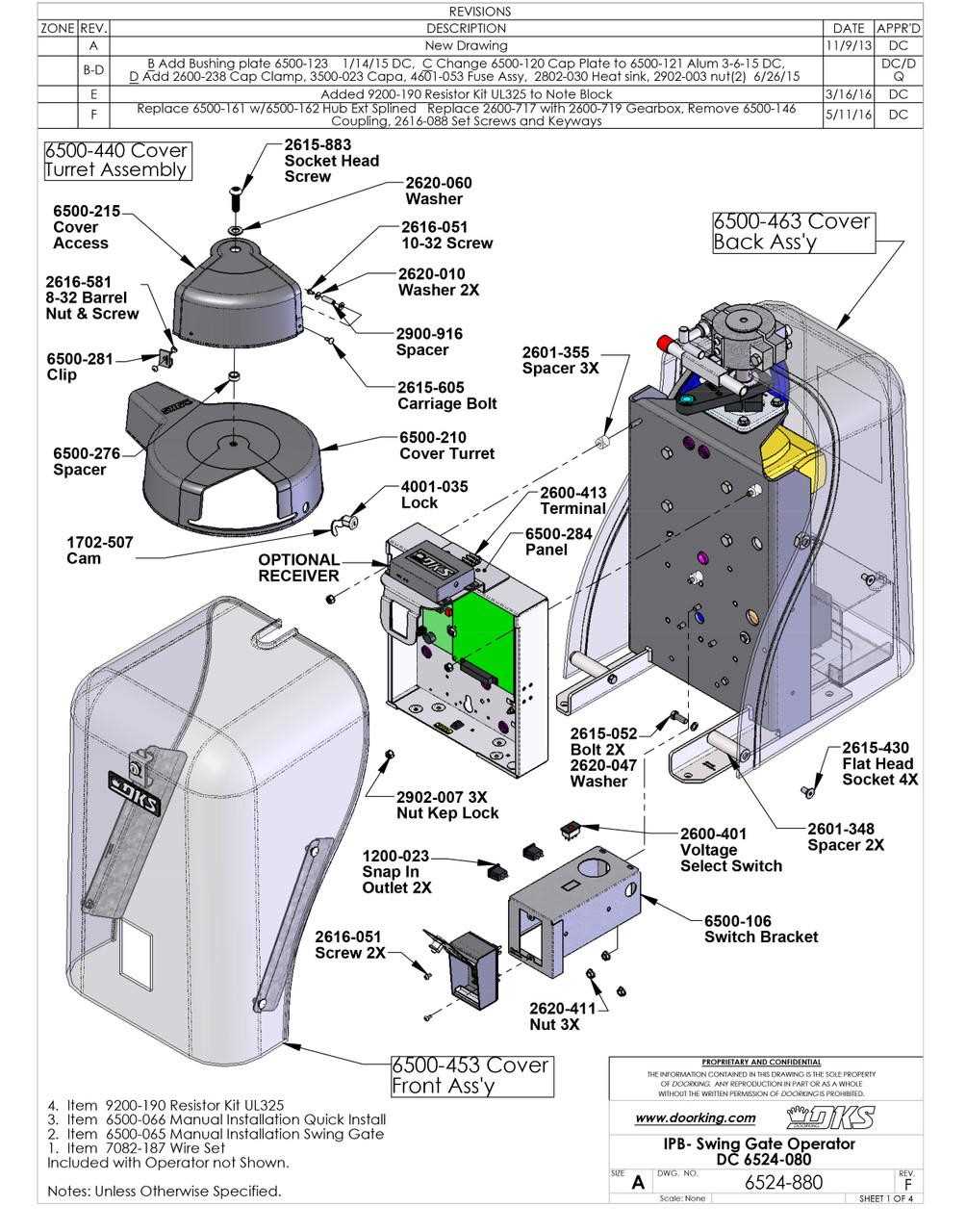

Understanding Ramset Components

In the realm of construction and fastening tools, a deep familiarity with individual elements is essential for achieving optimal performance and safety. Recognizing how these components interact can greatly enhance efficiency and effectiveness on job sites. Each piece plays a vital role in ensuring that tasks are completed smoothly and accurately.

Key Elements and Their Functions

The essential elements of fastening equipment include the housing, trigger mechanisms, and power sources. The housing provides structural integrity, while the trigger initiates the fastening process. Power sources, whether pneumatic, electric, or chemical, drive the tool’s functionality. Understanding these roles helps users select the right tool for specific applications.

Importance of Maintenance and Care

Proper maintenance of these individual elements is crucial for longevity and reliability. Regular inspection and cleaning ensure that components function optimally, preventing malfunctions and enhancing user safety. Familiarity with maintenance practices allows operators to keep their tools in peak condition, ultimately leading to more successful projects.

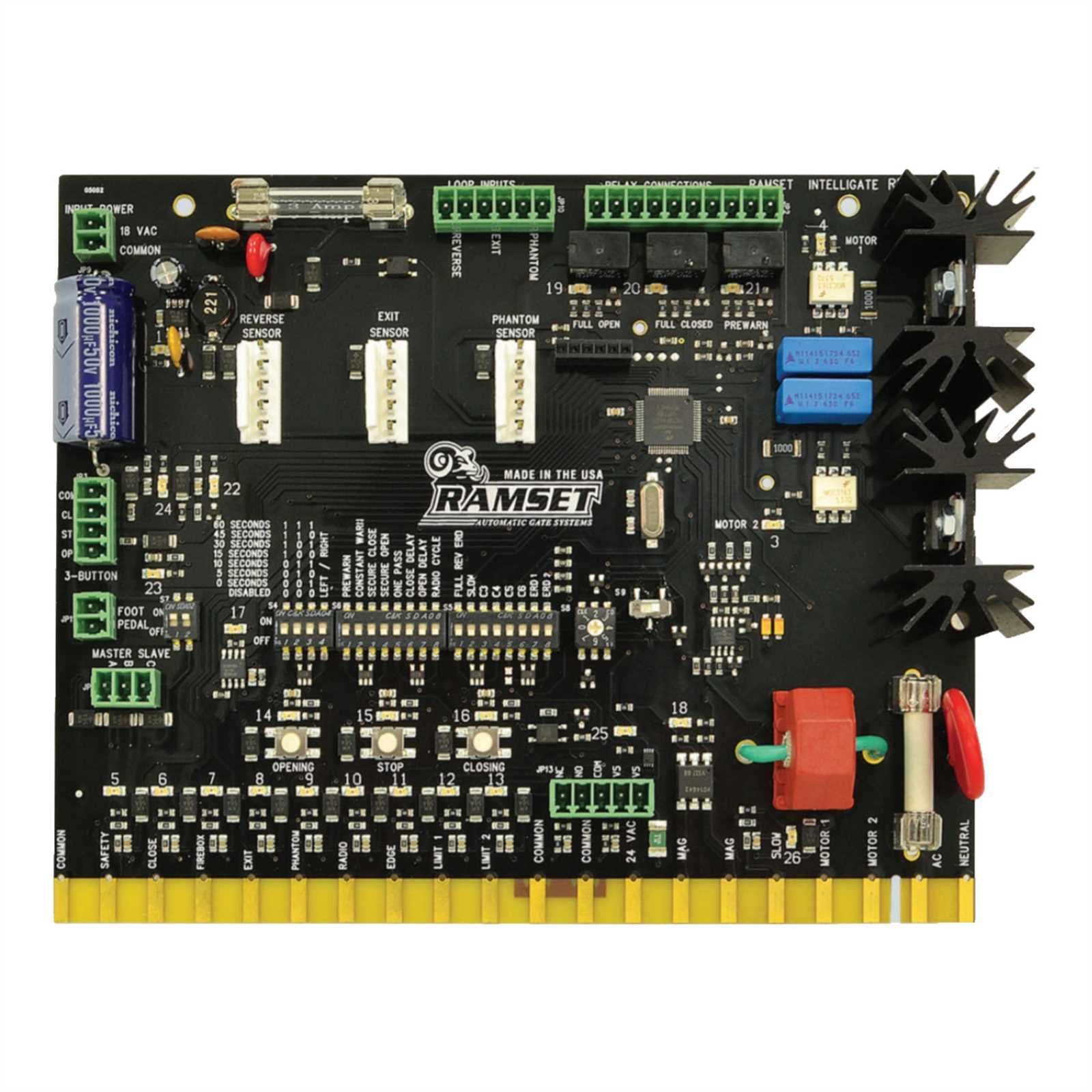

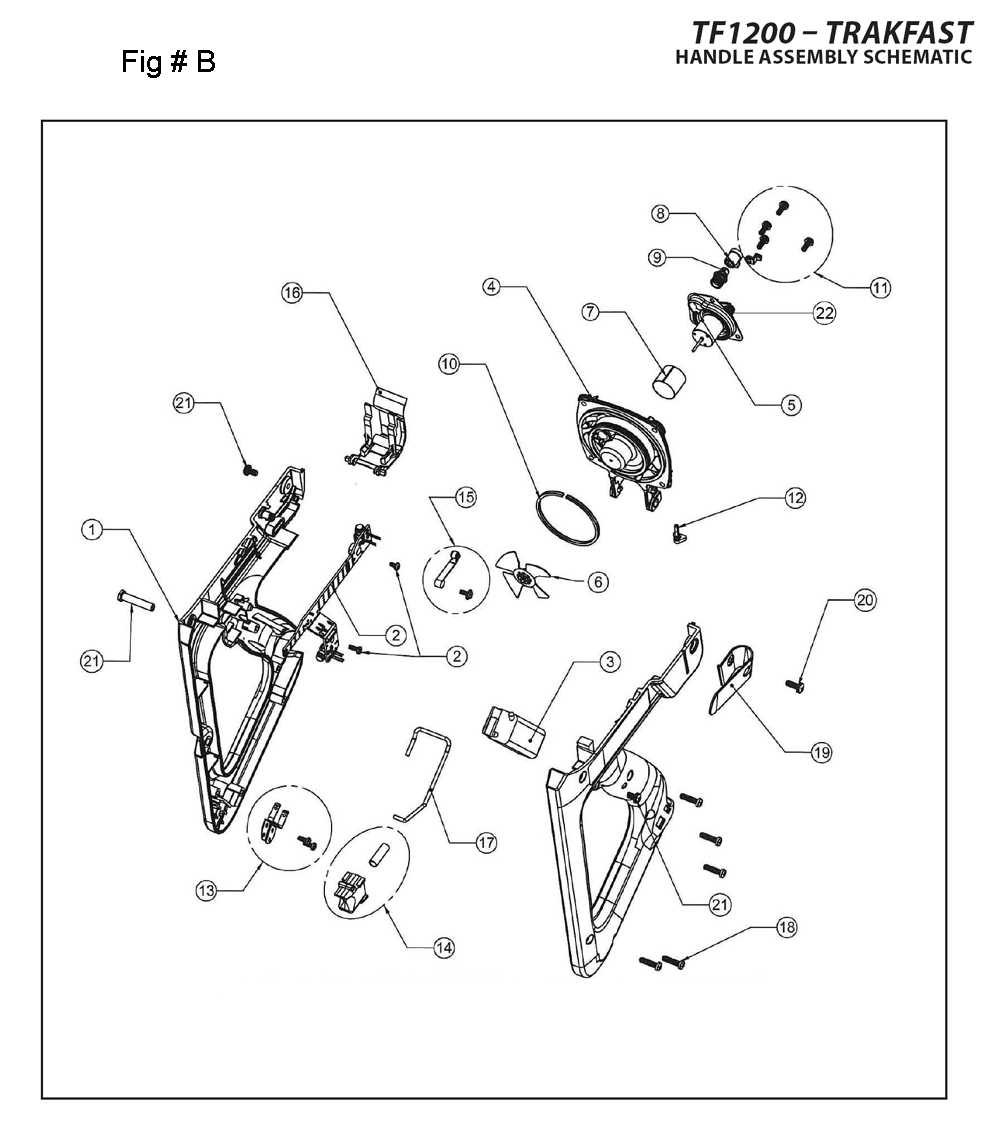

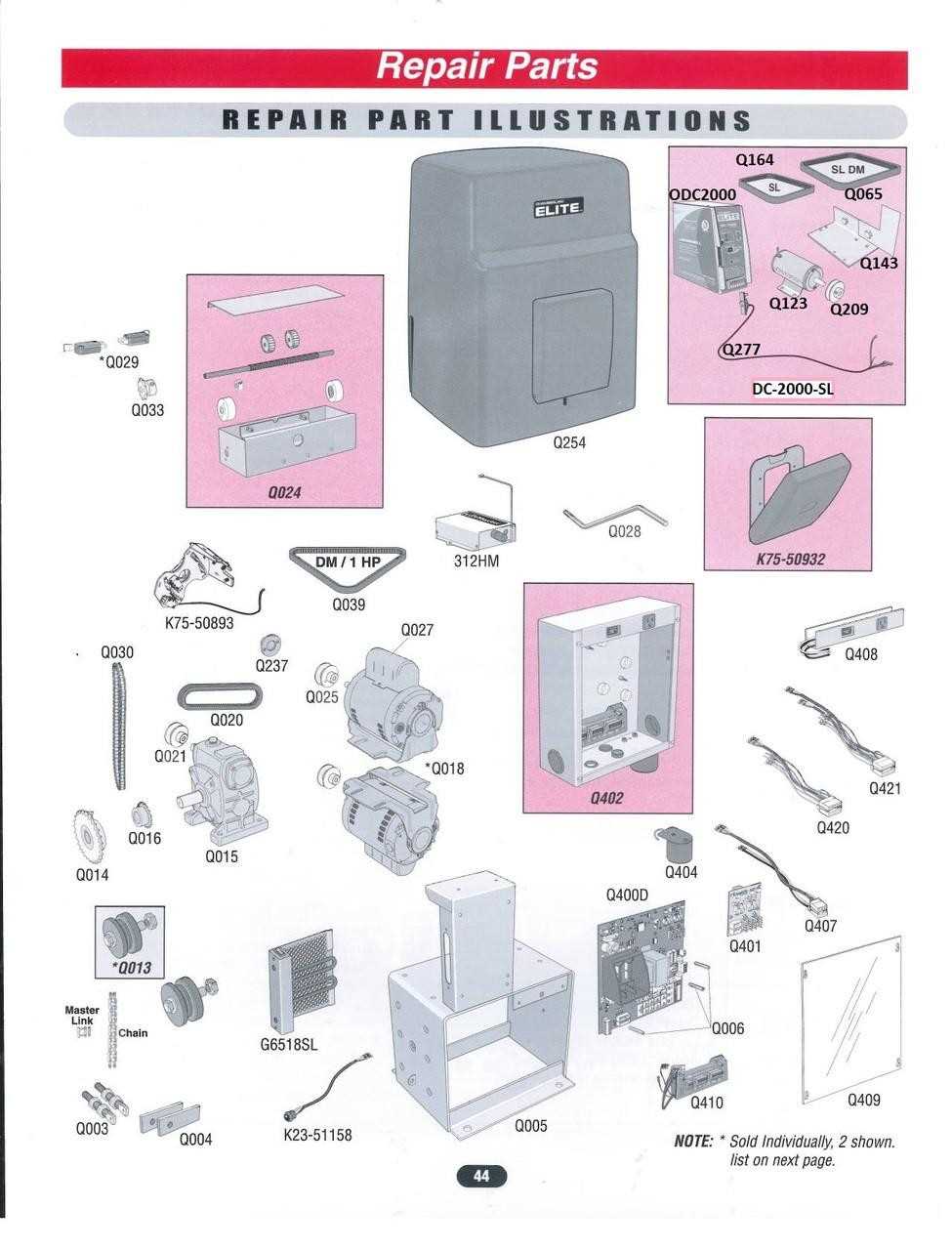

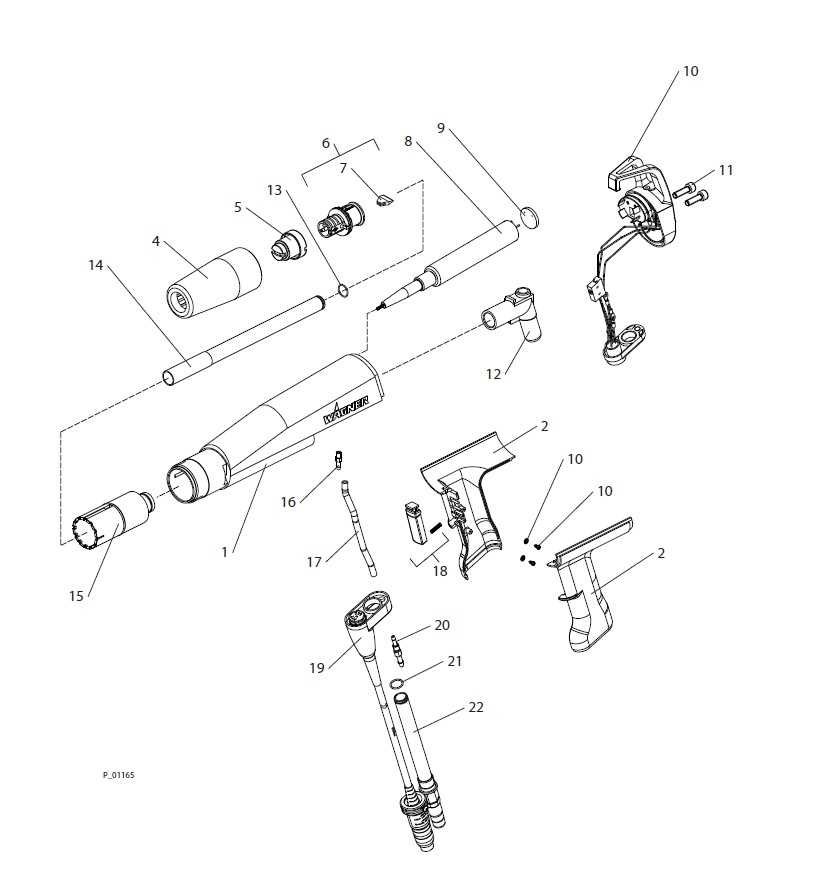

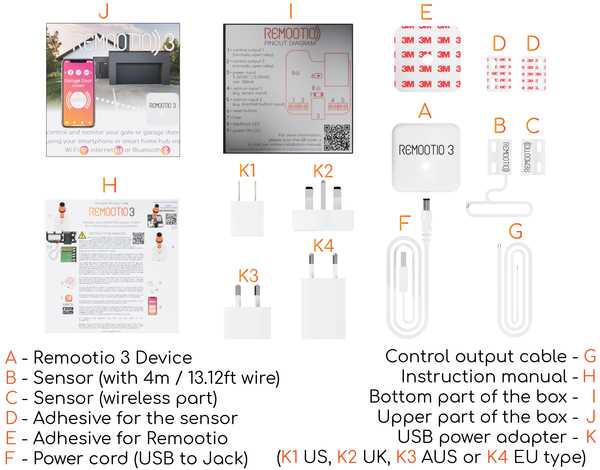

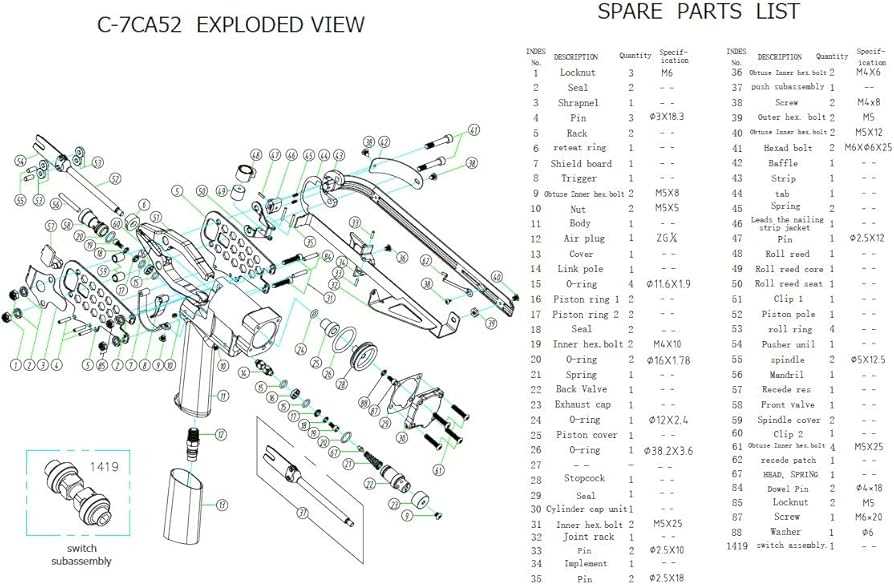

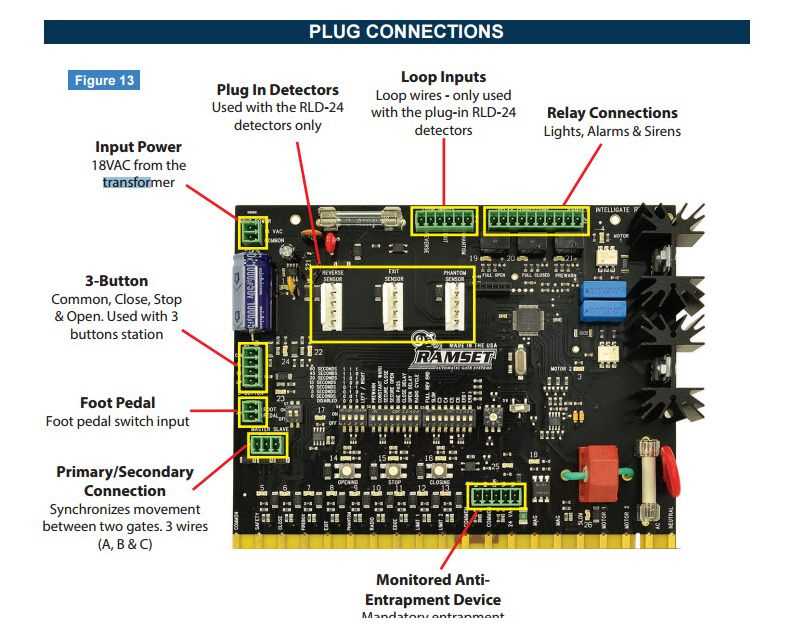

Importance of Parts Diagram

Understanding the components of any mechanical system is crucial for efficient maintenance and repair. Visual representations of these elements not only aid in identifying individual pieces but also enhance overall comprehension of how they function together. This clarity is essential for both novice users and experienced technicians, ensuring seamless operations and minimizing downtime.

Facilitating Troubleshooting

Having a visual reference simplifies the diagnostic process. Technicians can quickly locate and assess the status of each element, enabling faster identification of issues. This leads to more efficient repairs and reduces the likelihood of errors during the maintenance process.

Enhancing Assembly and Disassembly

Clear visual guides make it easier to assemble and disassemble systems. Technicians can follow step-by-step instructions, ensuring that each component is correctly placed, thereby improving overall safety and functionality.

| Benefit | Description |

|---|---|

| Efficiency | Reduces time spent on repairs and maintenance. |

| Clarity | Aids in understanding complex systems. |

| Accuracy | Minimizes errors during assembly and disassembly. |

Common Ramset Tools Overview

This section provides an insight into essential tools used for fastening applications, emphasizing their significance in construction and renovation projects. Understanding these instruments can enhance efficiency and accuracy in various tasks.

Fastening Devices

Fastening devices are crucial for securely attaching materials to surfaces. They come in various forms, each designed for specific applications, ensuring strong and reliable connections. Their design often prioritizes user-friendliness and safety, making them accessible for both professionals and DIY enthusiasts.

Power Sources

Power sources play a vital role in the operation of fastening tools, providing the necessary energy to drive fasteners effectively. Options range from pneumatic systems to combustion engines, each offering distinct advantages depending on the project requirements. Choosing the right power source can significantly impact performance and productivity.

How to Read Diagrams Effectively

Understanding visual representations of mechanical assemblies or components is crucial for effective communication and problem-solving. Mastering the ability to interpret these illustrations can greatly enhance your efficiency in maintenance, assembly, and troubleshooting tasks.

Here are some key strategies to improve your interpretation skills:

- Familiarize Yourself with Symbols: Each illustration typically employs a set of standardized icons. Learning these symbols will allow you to quickly grasp the overall structure.

- Follow the Flow: Look for directional arrows and lines that indicate the sequence of assembly or operation. This helps in visualizing how different elements interact.

- Pay Attention to Labels: Descriptive tags provide essential information about each component, including specifications and part numbers.

- Identify Key Components: Start by recognizing the major elements before diving into the details. This will give you a clearer context.

Practice these techniques regularly to become proficient in reading and interpreting these complex illustrations. The more you engage with them, the more intuitive your understanding will become.

Maintenance Tips for Ramset Parts

Regular upkeep is essential for ensuring the longevity and efficiency of your tools. By following a few straightforward practices, you can enhance performance and reduce the risk of malfunction.

- Inspect components regularly for signs of wear or damage.

- Clean tools after each use to prevent debris buildup.

- Lubricate moving parts as recommended to ensure smooth operation.

In addition to basic cleaning and inspection, consider the following:

- Store equipment in a dry, secure place to avoid corrosion.

- Replace worn or damaged components immediately to maintain safety.

- Follow the manufacturer’s guidelines for maintenance schedules.

By incorporating these tips into your routine, you can help ensure that your tools remain reliable and effective for all your projects.

Identifying Wear and Tear

Recognizing the signs of deterioration is crucial for maintaining optimal performance and ensuring safety. Regular inspections can help you spot potential issues before they escalate.

- Visual Inspection: Look for cracks, rust, or discoloration.

- Functionality Checks: Test each component for smooth operation.

- Sound Audits: Listen for unusual noises during use.

- Measuring Dimensions: Check for any deviations from standard sizes.

By systematically assessing these factors, you can prolong the lifespan of your equipment and maintain its effectiveness.

Replacing Damaged Components

When equipment experiences wear or damage, it’s crucial to address the issue promptly to maintain functionality and safety. Understanding the components involved and their roles can significantly ease the replacement process. This section focuses on how to effectively swap out compromised elements, ensuring optimal performance and reliability.

Identifying Damaged Parts

The first step in the replacement process is accurately identifying the damaged components. Look for the following signs:

- Visible cracks or breaks

- Unusual noises during operation

- Decreased efficiency or performance

- Leaking fluids or gases

Steps for Replacement

Once you have identified the faulty elements, follow these steps to ensure a successful replacement:

- Turn off the equipment and disconnect from power sources.

- Carefully remove the damaged components using the appropriate tools.

- Clean the surrounding area to prevent debris from interfering with the new parts.

- Install the new components, ensuring they are secure and properly aligned.

- Reconnect power and perform a test run to verify functionality.

By following these guidelines, you can restore your equipment to its optimal condition, ensuring longevity and reliability in its operation.

Upgrades for Enhanced Performance

Improving efficiency and effectiveness in any mechanical system can significantly enhance overall functionality. By focusing on advanced components and innovative technologies, users can unlock the ultimate potential of their equipment, leading to increased reliability and productivity.

Key Enhancements

Several upgrades can be implemented to achieve superior performance. These modifications not only boost operational capabilities but also extend the lifespan of the machinery.

| Upgrade Type | Description | Benefits |

|---|---|---|

| High-Quality Fasteners | Utilizing robust fastening solutions for secure connections. | Increased stability and durability. |

| Advanced Lubrication Systems | Incorporating modern lubricants for improved motion. | Reduced friction and wear, enhancing efficiency. |

| Performance-Optimized Components | Replacing standard parts with high-performance alternatives. | Greater power output and efficiency. |

Conclusion

Investing in these enhancements not only maximizes performance but also ensures long-term sustainability of the machinery. Embracing innovation can lead to significant advancements in operational success.

Safety Precautions During Repairs

When undertaking maintenance tasks, ensuring a secure environment is paramount. This involves not only personal safety but also the protection of the equipment being serviced. Following specific guidelines can significantly reduce the risk of accidents and enhance the overall efficiency of the repair process.

Personal Protective Equipment

Utilizing appropriate safety gear is essential. Items such as gloves, goggles, and hard hats can safeguard against potential hazards. Always assess the specific risks associated with the task at hand and choose the necessary protective equipment accordingly.

Workspace Organization

A well-organized workspace minimizes the likelihood of accidents. Ensure that tools are easily accessible and that the area is free from clutter. Proper lighting also plays a crucial role in maintaining focus and preventing mishaps during repairs.

FAQs About Ramset Parts

This section aims to address common inquiries related to components and their functionalities in a specific tool system. Understanding the intricacies of these elements can enhance the user experience and improve overall efficiency.

What are the most common issues encountered with these components?

Users often face challenges such as wear and tear, misalignment, or compatibility problems with different tools. Regular maintenance can help mitigate these issues.

How can I identify a malfunctioning component?

Signs of malfunction may include unusual noises, decreased performance, or visible damage. Conducting regular inspections can aid in early detection.

Are replacement items easy to find?

Yes, most suppliers offer a wide range of replacement options that are readily available both online and in physical stores.

How do I ensure proper installation of new components?

Consult the manufacturer’s guidelines for installation procedures. Following these instructions will ensure optimal performance and longevity.

What maintenance practices should I follow?

Regular cleaning, lubrication, and inspection can prolong the life of components and maintain their efficiency in operation.

Resources for Further Learning

Expanding your knowledge in this area can significantly enhance your understanding and application of tools and components. There are various materials available that cater to different learning preferences, whether through reading, visual aids, or hands-on experiences.

| Resource Type | Details |

|---|---|

| Books | Look for comprehensive guides that cover tools, techniques, and best practices in detail. |

| Online Courses | Explore platforms offering courses that provide interactive learning experiences and expert insights. |

| Video Tutorials | Check out channels that specialize in demonstrations and practical applications, enhancing visual learning. |

| Forums and Communities | Engage with online communities where enthusiasts share knowledge, tips, and troubleshooting advice. |