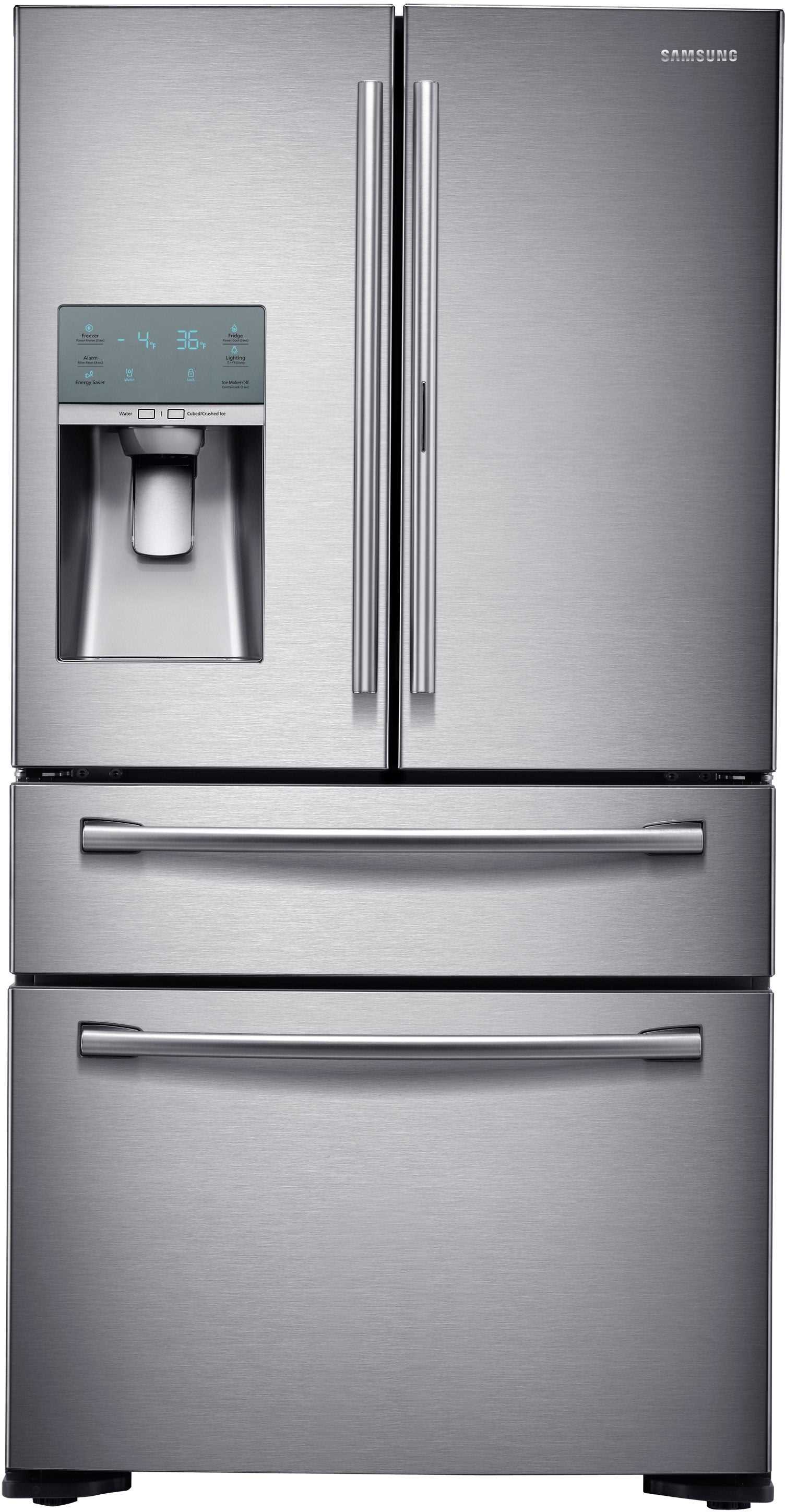

Understanding the Rf31fmesbsr Parts Diagram

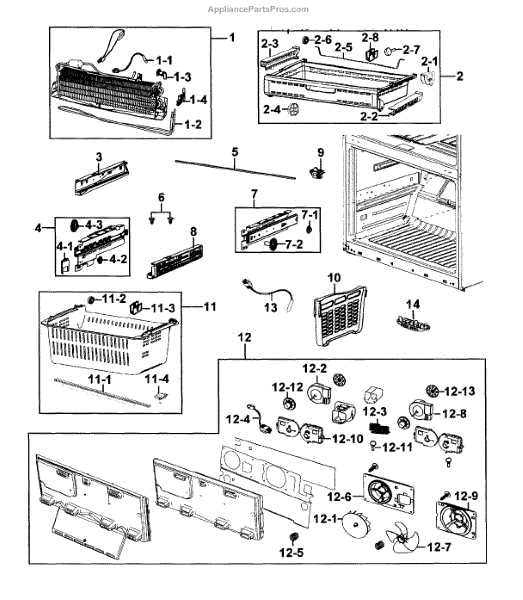

In the realm of engineering, comprehending the intricate relationships among components is crucial for effective design and maintenance. A well-structured representation of these relationships not only enhances clarity but also facilitates troubleshooting and repairs. By exploring the various elements and their connections, one can gain valuable insights into the overall functionality of a system.

Visual representations serve as essential tools for anyone involved in assembly and repair tasks. They provide a clear overview of how individual parts fit together and interact within a larger framework. This understanding empowers technicians and engineers to pinpoint issues quickly and implement effective solutions.

Ultimately, mastering the layout of these mechanical systems allows for greater efficiency and precision. As we delve deeper into this topic, we will uncover the essential features that contribute to a seamless operational experience.

Understanding Rf31fmesbsr Components

In the realm of intricate machinery, comprehending the various elements that contribute to its functionality is essential. Each component plays a crucial role, ensuring that the system operates smoothly and efficiently. A thorough understanding of these individual parts enhances maintenance practices and informs users about their significance in the overall structure.

Key Elements of the System

Every assembly consists of numerous key elements that interact to produce desired outcomes. These include structural components that provide stability, functional pieces that perform specific tasks, and connectors that facilitate seamless operation. Identifying these elements helps in troubleshooting issues and optimizing performance.

Importance of Component Knowledge

Knowledge of each element’s characteristics and functions is vital for effective operation. It empowers users to make informed decisions during repairs and upgrades, ensuring longevity and reliability. Additionally, understanding how these components work together can lead to better innovations and improvements in design.

Importance of Parts Diagrams

Visual representations of components are crucial in various fields, providing clarity and enhancing understanding of complex systems. They serve as essential tools for technicians and engineers, enabling them to identify and locate specific elements quickly and efficiently.

These illustrations not only facilitate maintenance and repairs but also aid in the design and assembly processes. By breaking down intricate assemblies into manageable visuals, users can delve into details that might otherwise be overlooked.

Ultimately, such visual aids foster better communication among team members, ensuring everyone is on the same page. This leads to increased efficiency, reduced errors, and a smoother workflow in any technical environment.

Common Issues with Rf31fmesbsr Parts

When dealing with complex machinery, certain challenges frequently arise that can impact functionality and longevity. Identifying these problems early can save time and resources, ensuring optimal performance and reducing downtime.

Frequent Mechanical Failures

Mechanical components are susceptible to wear and tear, leading to unexpected failures. Regular maintenance and inspection are crucial to mitigating these issues.

Electrical Malfunctions

Electrical systems can experience issues ranging from short circuits to connectivity problems, which can disrupt operations. Proper troubleshooting techniques can help address these concerns effectively.

| Issue Type | Description | Possible Solutions |

|---|---|---|

| Wear and Tear | Gradual degradation of moving components | Regular lubrication and timely replacement |

| Electrical Issues | Faulty wiring or short circuits | Routine checks and circuit repairs |

| Component Misalignment | Improper positioning leading to inefficiency | Realignment and calibration |

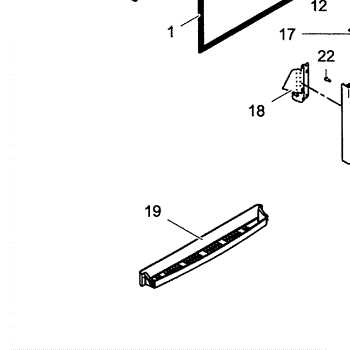

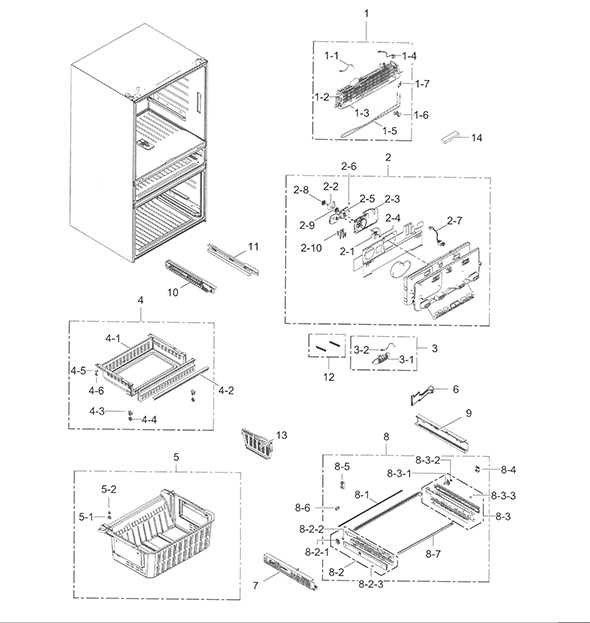

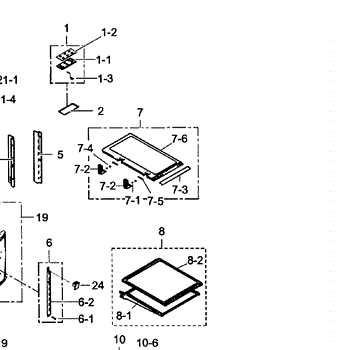

How to Read Parts Diagrams

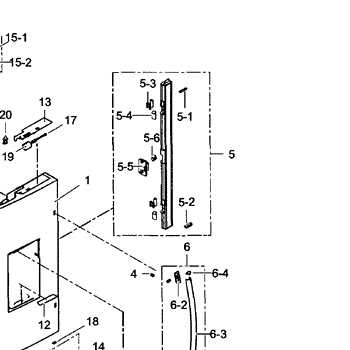

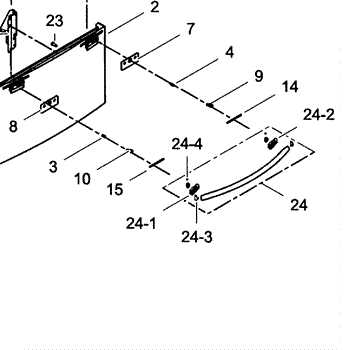

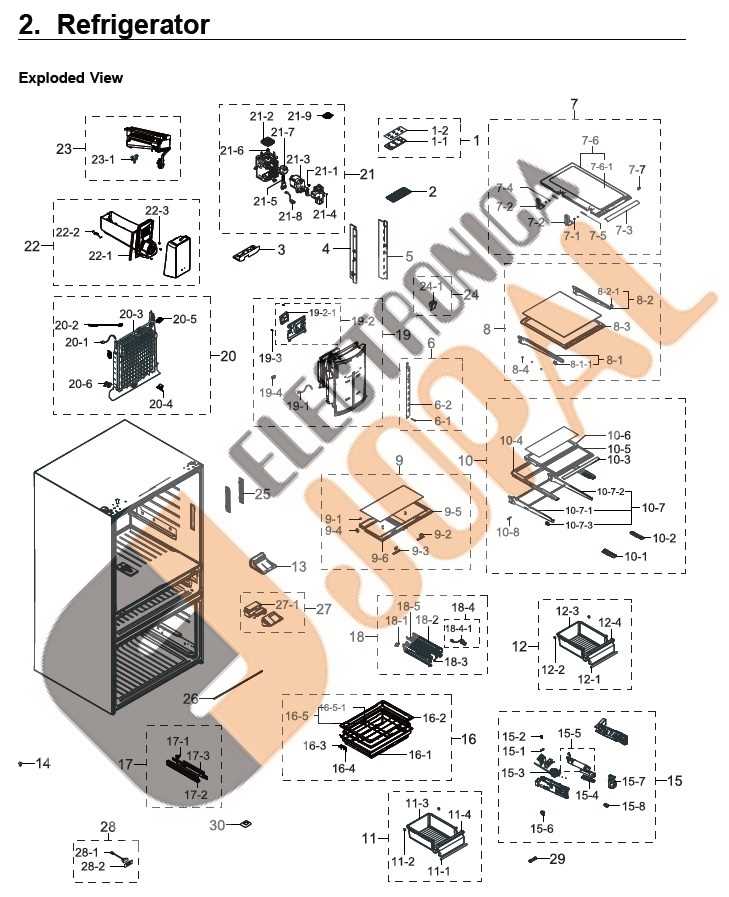

Understanding visual representations of components can greatly enhance your ability to assemble or repair machinery. These illustrations provide a clear view of how each element fits together, ensuring that you can effectively identify and locate specific items within a complex system.

Begin by familiarizing yourself with the overall layout of the image. Take note of the key sections, as they often categorize various elements based on their function or placement. Look for labels, numbers, or symbols that correspond to individual pieces, as these will guide you in identifying the right components during your tasks.

Next, pay attention to the connecting lines or arrows, which often indicate how different parts interact or relate to one another. Understanding these connections is crucial for ensuring that everything is assembled correctly. Additionally, review any accompanying legends or notes that provide further clarification on the components shown.

Finally, practice makes perfect. The more you work with these illustrations, the more intuitive they will become. Over time, you will develop a keen eye for quickly navigating through complex visual guides, ultimately streamlining your maintenance or assembly processes.

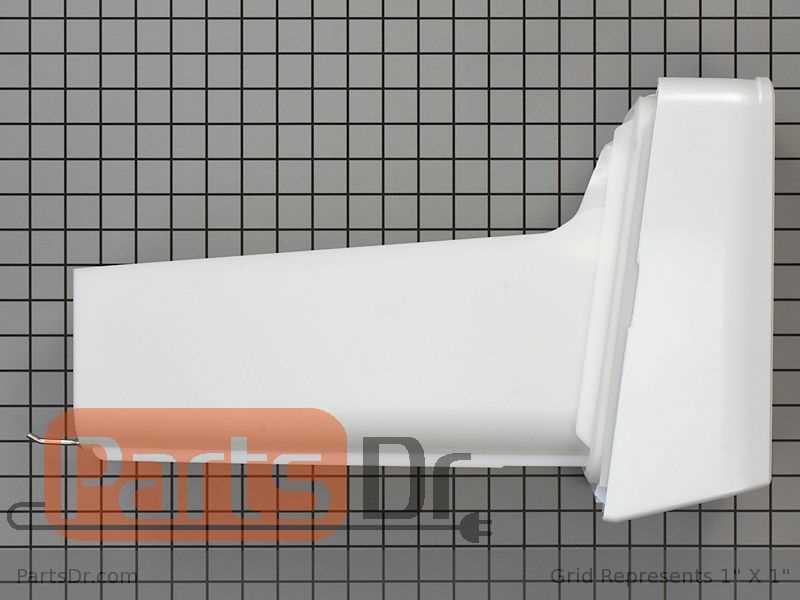

Finding Replacement Parts Easily

Locating suitable components for machinery or equipment can often feel like a daunting task. However, with the right approach and resources, the process can be streamlined significantly. Understanding where to search and how to evaluate options is essential for efficient replacement and maintenance.

Utilizing Online Resources

The internet is an invaluable tool for finding necessary components. Here are some effective strategies:

- Manufacturer Websites: Start with official sites that provide detailed catalogs and specifications.

- Retail Platforms: Explore e-commerce sites known for hardware and components to compare prices and availability.

- Forums and Community Groups: Engage with online communities for recommendations and shared experiences regarding sourcing.

Tips for Successful Searching

To enhance your search efficiency, consider the following tips:

- Identify the specific requirements of the item you need.

- Make use of specific keywords related to the component.

- Cross-reference multiple sources to ensure accuracy and reliability.

- Keep track of vendors and their reputations for quality and service.

By employing these strategies and tips, finding the right replacements becomes a more manageable and straightforward endeavor.

Manufacturer Recommendations for Maintenance

To ensure optimal performance and longevity of equipment, manufacturers provide essential guidance on regular upkeep and care. Adhering to these suggestions not only enhances reliability but also minimizes the risk of unexpected failures.

Regular inspections and timely replacements of critical components are fundamental. It is advisable to follow the specific intervals outlined by the manufacturer, as these are based on extensive testing and real-world usage data.

Utilizing recommended lubricants and cleaning agents is crucial for maintaining the efficiency of moving parts. Additionally, keeping the equipment clean and free from debris can significantly improve its operational effectiveness.

Incorporating routine checks for wear and tear will help identify potential issues before they escalate. Documentation of maintenance activities is also beneficial for tracking performance and ensuring compliance with warranty requirements.

Visualizing the Assembly Process

Understanding the assembly procedure is crucial for ensuring efficiency and accuracy in any mechanical project. By creating a visual representation of each step involved, one can simplify complex tasks and facilitate better comprehension. This approach not only aids in identifying necessary components but also highlights the sequence of actions required for successful completion.

Benefits of Visual Representation

Utilizing visuals enhances clarity and reduces the risk of errors. When individuals can see how various elements fit together, they are more likely to grasp the relationships between different pieces. This method also allows for quicker identification of missing or misplaced elements, ultimately saving time and resources.

Techniques for Effective Visualization

Several methods can be employed to create effective visual aids. Flowcharts and exploded views are popular options that provide a clear depiction of the assembly flow. Additionally, using color coding can further distinguish different components and their functions, making the overall process more intuitive. Incorporating these techniques into your planning can greatly improve the assembly experience and outcomes.

Comparing Diagrams Across Models

When evaluating different configurations of machinery, understanding the variations in their layouts can provide valuable insights. Each model may feature distinct arrangements, influencing functionality and efficiency. Analyzing these variations helps in identifying strengths and weaknesses, leading to informed decisions in maintenance and upgrades.

In order to facilitate a comprehensive comparison, we can categorize several key aspects of these layouts. The following table illustrates the primary components and their corresponding characteristics across multiple models.

| Model | Component Type | Configuration Features | Notable Differences |

|---|---|---|---|

| Model A | Assembly | Standard layout with compact design | Higher efficiency in space utilization |

| Model B | Assembly | Extended layout for enhanced performance | Greater output capacity but requires more maintenance |

| Model C | Assembly | Modular design allowing customization | Flexibility in upgrades, but initial setup complexity |

By scrutinizing these differences, users can better grasp how each model aligns with their specific requirements and operational contexts. This comparative approach ultimately fosters improved performance and operational longevity.

Tools for Rf31fmesbsr Repairs

When tackling repairs on complex machinery, having the right equipment is essential for success. The appropriate tools not only facilitate efficient work but also ensure precision and safety during the process. Investing in high-quality instruments can make a significant difference in the outcome of your maintenance tasks.

Essential Tools: Among the most vital tools for these repairs are wrenches, screwdrivers, and pliers, each serving a unique purpose. A comprehensive toolkit also includes diagnostic devices, allowing for accurate assessments of any issues.

Safety Equipment: Don’t overlook the importance of safety gear. Gloves, goggles, and protective clothing should always be worn to safeguard against potential hazards during repairs.

By selecting the right tools and ensuring proper safety measures, you can delve deeper into the intricacies of maintenance, leading to ultimate efficiency and effectiveness in your repair endeavors.

Expert Tips for Troubleshooting

Tackling issues with complex machinery can often be daunting. However, with the right approach and mindset, you can effectively diagnose and resolve problems. This section provides practical advice to streamline your troubleshooting process and enhance your efficiency.

- Understand the Symptoms: Begin by carefully observing the signs of the malfunction. Take note of any unusual noises, performance drops, or error messages.

- Consult Documentation: Reference manuals and guides specific to your equipment. They often contain valuable insights and troubleshooting steps tailored to common issues.

- Check Connections: Loose or corroded connections can lead to significant problems. Ensure all cables and components are securely attached and free from damage.

- Isolate the Problem: Systematically test each part of the system. This methodical approach helps in pinpointing the source of the malfunction.

- Utilize Diagnostic Tools: Leverage any built-in diagnostic features or external tools. They can provide crucial information that aids in identifying faults.

By following these strategies, you can not only resolve existing issues but also prevent future occurrences, ensuring your equipment operates smoothly and efficiently.