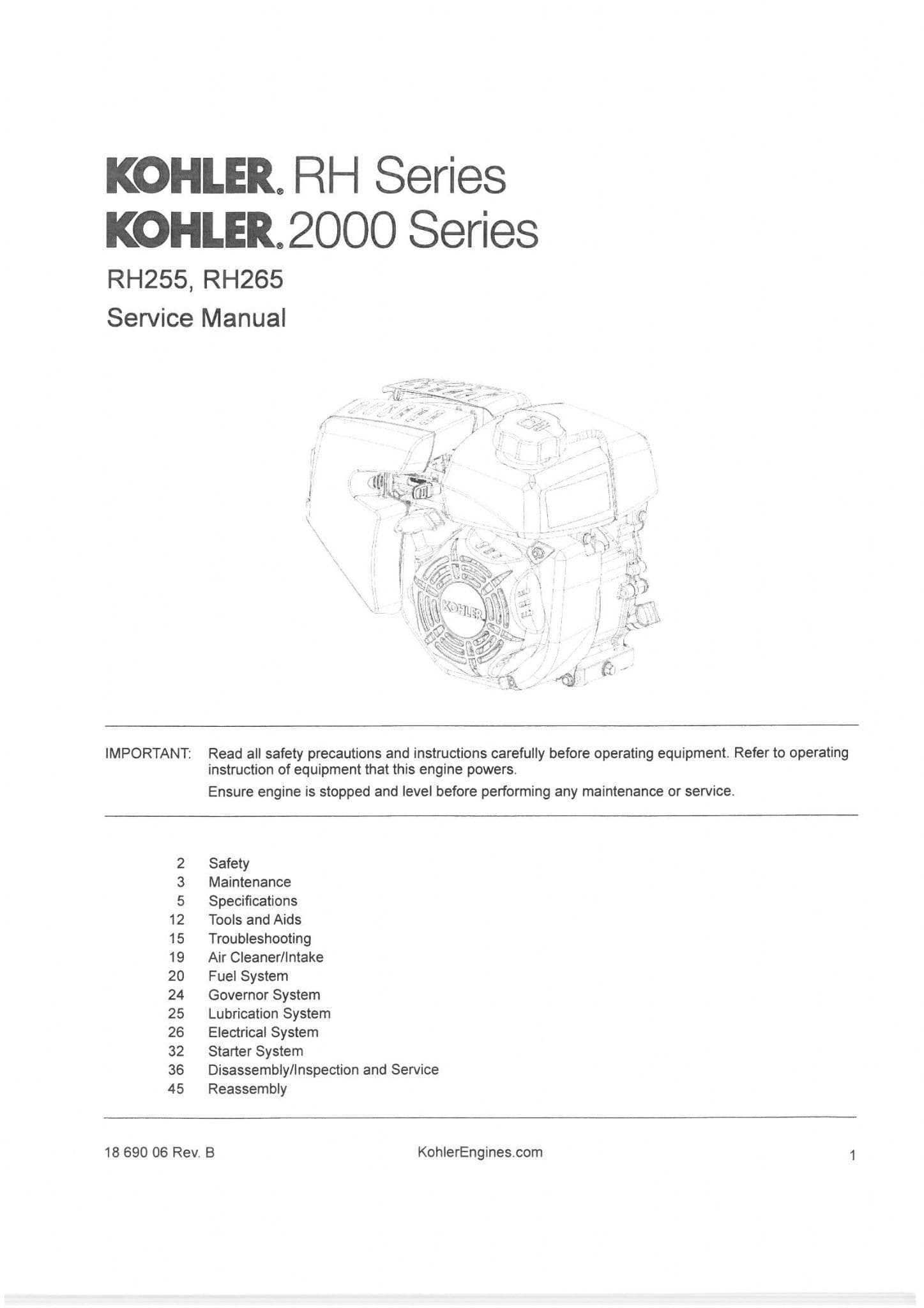

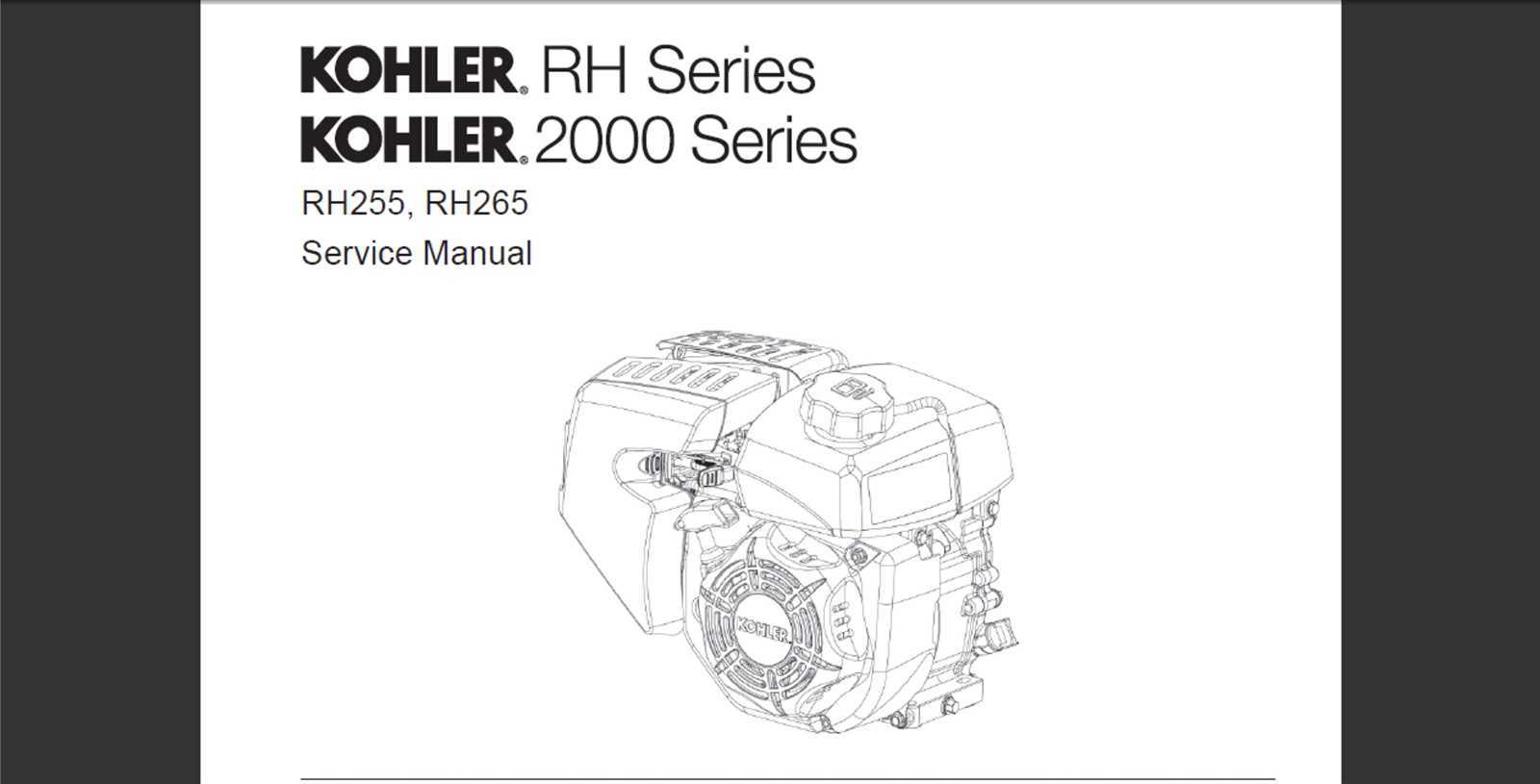

Understanding the Components of Rh265

The intricate world of machinery often relies on well-structured layouts to ensure optimal performance and functionality. Each section plays a pivotal role, contributing to the overall efficiency of the system. Understanding these configurations allows for better maintenance, troubleshooting, and enhancement of operations.

To fully appreciate how various elements interconnect, one must delve into the specifics of their arrangement. This knowledge not only aids in recognizing potential issues but also fosters a more profound comprehension of the machinery’s overall design philosophy. By exploring the relationships between different components, users can make informed decisions that enhance the longevity and reliability of their equipment.

Furthermore, having access to a detailed representation of these structures can simplify the learning curve for operators and technicians alike. It serves as a valuable reference, guiding individuals through complex interactions while facilitating a clearer understanding of each unit’s purpose. Emphasizing the significance of this knowledge underscores its role in achieving optimal operational standards.

This section aims to provide a comprehensive framework for exploring the intricate components of the specified model. By examining the various elements involved, readers will gain a clearer understanding of how these parts interact and contribute to overall functionality.

- Overview of the Model’s Design

- Key Functional Features

- Component Identification Techniques

- Maintenance Best Practices

- Common Issues and Troubleshooting

- Replacement and Upgrade Options

- Assembly and Disassembly Guidelines

- Tools Required for Maintenance

- Safety Precautions during Repairs

- Resource References for Further Reading

- Frequently Asked Questions

- Conclusion and Summary

Key Components Overview

This section provides an essential insight into the primary elements that contribute to the functionality and efficiency of the equipment. Understanding these components is crucial for proper maintenance and operation, ensuring optimal performance and longevity.

Core Elements

The core elements include the crucial mechanisms that enable the overall system to operate seamlessly. Each component plays a distinct role, from powering the unit to facilitating communication between various sections. Grasping the purpose of these elements aids in troubleshooting and enhances the ability to perform necessary repairs.

Supportive Features

Supportive features enhance the performance of the main components. These may encompass safety devices, control interfaces, and other auxiliary systems designed to improve user experience and operational safety. Recognizing these features allows for a more comprehensive understanding of the overall assembly.

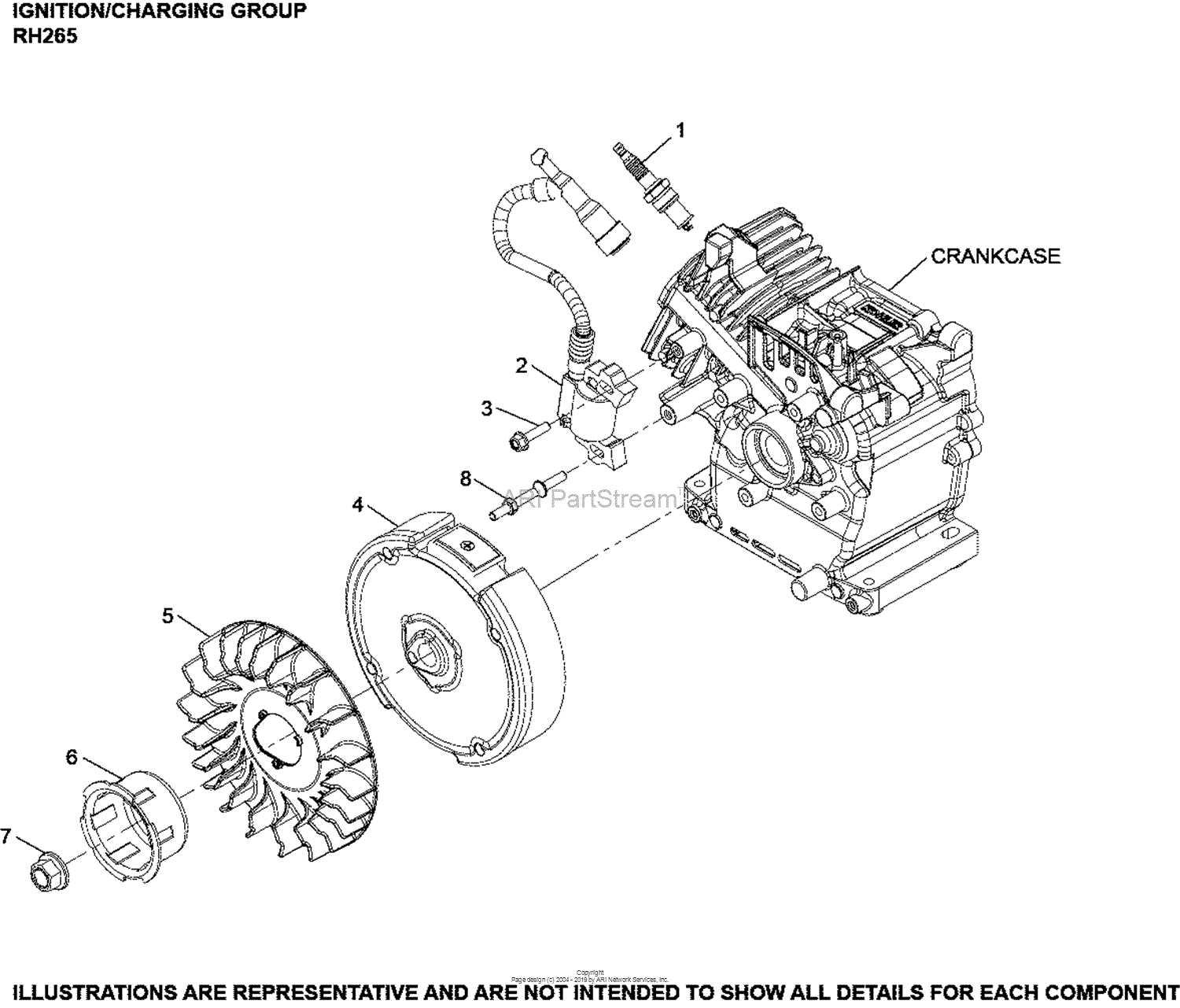

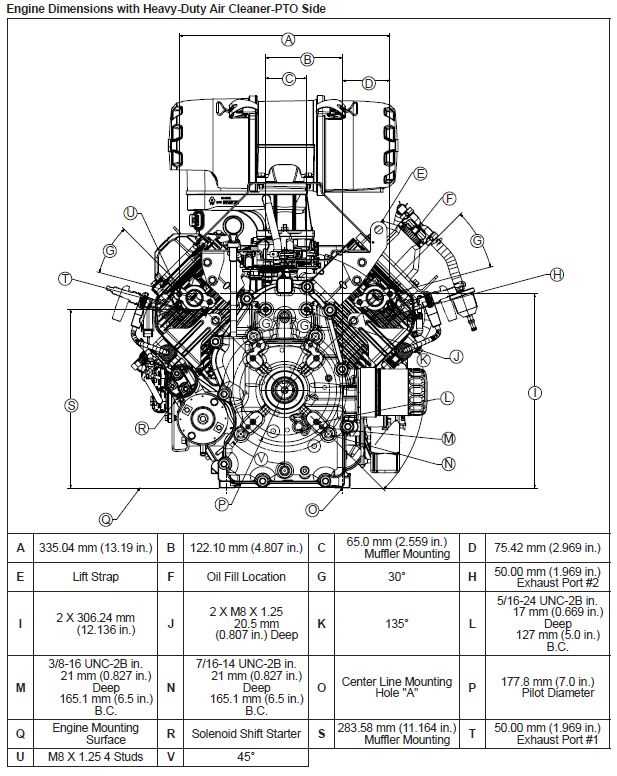

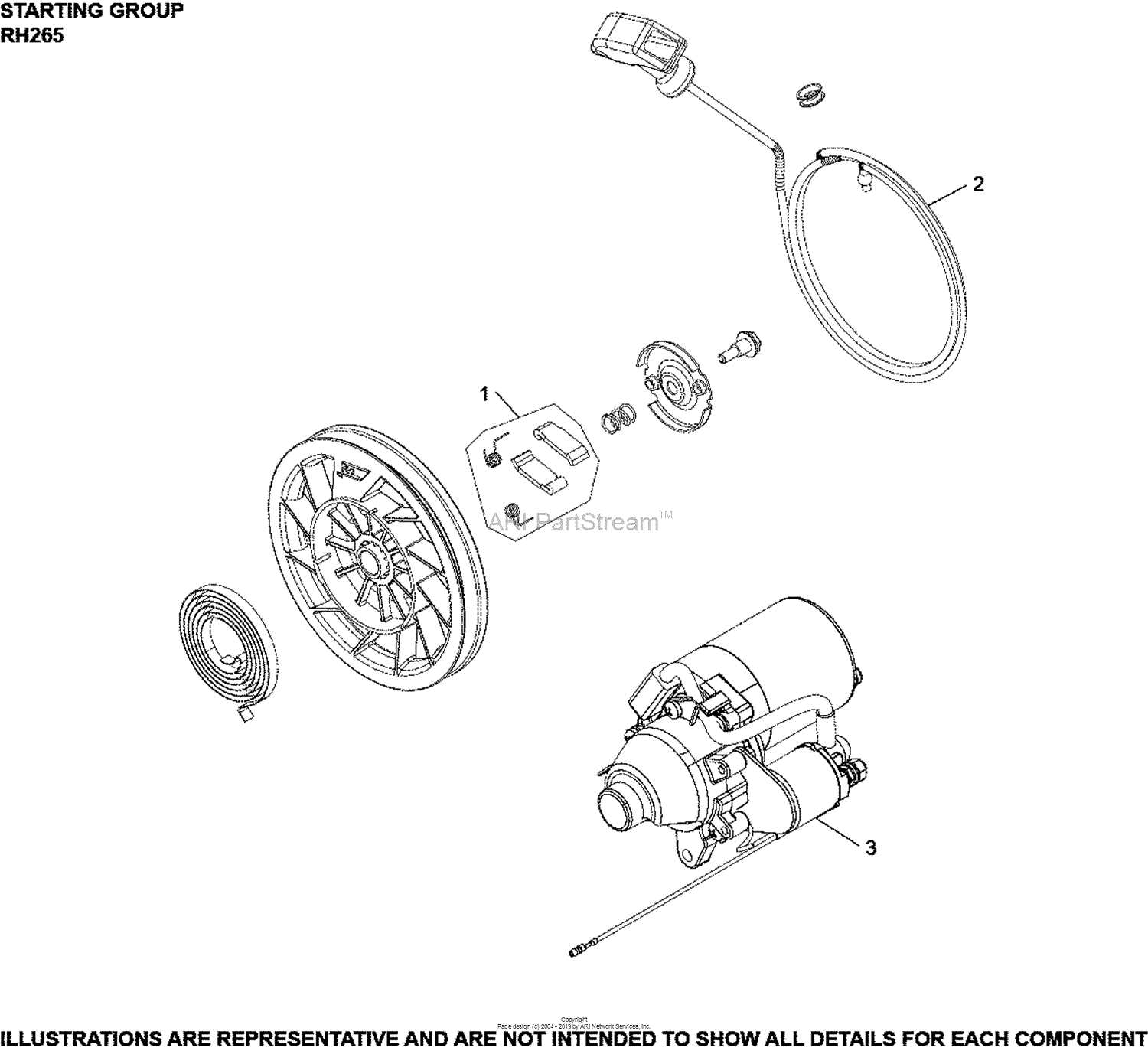

Exploring the Parts Layout

The arrangement of components within a machinery system plays a crucial role in its overall functionality and efficiency. Understanding how these elements interact allows for better maintenance and optimization. This section delves into the configuration of various sections, highlighting their specific roles and interconnections.

| Component Name | Description | Functionality |

|---|---|---|

| Element A | Main unit responsible for energy conversion. | Converts input energy into mechanical motion. |

| Element B | Support structure providing stability. | Ensures secure placement of the main unit. |

| Element C | Control module for operation management. | Regulates the performance of the entire system. |

| Element D | Connecting rods for transmission of motion. | Transfers energy from one part to another. |

Functionality of Major Elements

This section explores the essential roles of key components within a specific system. Understanding how each part contributes to overall performance provides valuable insights into the efficiency and effectiveness of the entire assembly.

The primary element serves as the core, facilitating various operations and ensuring the smooth interaction of other components. It is responsible for managing processes, directing energy flow, and maintaining stability during operation.

Secondary units are crucial for supporting the main element. They enhance functionality by providing necessary adjustments and modifications, optimizing performance based on varying conditions. These units work in tandem to refine the overall output, ensuring the system operates at peak efficiency.

Additionally, auxiliary components contribute to the reliability of the system. They may include safety features that prevent failures or malfunctions, as well as systems for monitoring and feedback. Their integration allows for proactive management and troubleshooting, minimizing downtime and maintaining operational integrity.

In conclusion, each element plays a vital role in the system’s architecture. By comprehending their functionalities, one can appreciate the complexity and sophistication involved in the design and implementation of such assemblies.

Importance of Accurate Diagrams

Detailed illustrations play a crucial role in understanding the composition and functionality of complex systems. These visual representations serve as essential tools for professionals and enthusiasts alike, enabling them to grasp intricate details quickly and efficiently. By providing a clear overview of components and their interrelations, accurate visuals enhance comprehension and facilitate effective troubleshooting.

Enhancing Clarity and Communication

Clear visuals foster improved communication among team members and stakeholders. They offer a common reference point, ensuring everyone is aligned in their understanding of the system. This clarity can lead to:

- Reduced misunderstandings during discussions.

- More effective collaboration on projects.

- Quicker identification of potential issues.

Facilitating Maintenance and Repair

When it comes to upkeep and repairs, precise representations are invaluable. They assist technicians in locating specific components and understanding their functions, which leads to:

- Increased efficiency in repair processes.

- Lower chances of errors during maintenance.

- Extended lifespan of equipment through proper care.

Common Issues with Parts Identification

Identifying components within complex machinery can often present significant challenges. Various factors can complicate this process, leading to miscommunication and potential errors in maintenance or repair efforts. Understanding these common pitfalls is essential for effective troubleshooting and ensuring optimal performance.

Ambiguities in Terminology

One prevalent issue arises from the inconsistent use of terminology. Different manufacturers or regions may employ varied names for similar components, creating confusion. This inconsistency can lead to mistakes in procurement and assembly.

- Varying descriptions for identical items

- Region-specific jargon

- Inconsistent labeling practices

Lack of Comprehensive Documentation

Another significant hurdle is the absence of detailed and clear documentation. When manuals or guides are incomplete or poorly organized, it becomes challenging to identify components accurately. This lack of clarity can result in inefficient repairs and increased downtime.

- Missing part numbers

- Poorly illustrated guides

- Outdated or inaccurate information

Comparing Similar Models

When evaluating different machinery configurations, it is essential to analyze various models that share comparable features and specifications. This comparative approach allows users to identify distinct advantages and disadvantages, ensuring that the selected model aligns with specific operational requirements.

Several configurations on the market boast similar capabilities, making it crucial to examine key aspects such as performance metrics, durability, and user interface. By conducting a thorough comparison, potential buyers can make informed decisions that cater to their individual needs, whether for industrial applications or smaller-scale tasks.

Furthermore, assessing customer feedback and expert reviews can provide invaluable insights into the reliability and efficiency of each model. Such evaluations help to paint a clearer picture of how these machines perform in real-world scenarios, guiding users towards the best choice for their intended use.

Maintenance Tips for Longevity

Ensuring the durability and efficiency of equipment requires consistent care and attention. Adopting effective maintenance practices can significantly extend the lifespan of machinery and reduce the likelihood of unexpected failures.

Here are some essential tips for preserving functionality:

- Regular Inspections: Schedule periodic evaluations to identify potential issues before they escalate.

- Proper Lubrication: Ensure all moving components are adequately lubricated to minimize friction and wear.

- Keep Clean: Maintain cleanliness around the equipment to prevent dust and debris buildup, which can hinder performance.

- Follow Manufacturer Guidelines: Adhere to the recommended maintenance schedule and procedures outlined by the manufacturer.

- Monitor Performance: Track operational metrics to detect any deviations from normal performance early on.

By implementing these strategies, operators can significantly enhance the reliability and longevity of their machinery.

Tools for Effective Repairs

Successful repairs require the right tools to ensure efficiency and precision. Selecting appropriate instruments not only simplifies the process but also enhances the overall quality of the work. A well-equipped workspace is essential for tackling various tasks effectively, reducing time spent on troubleshooting and improving outcomes.

Essential Instrumentation

Understanding which tools are indispensable for various repair tasks can greatly impact performance. Below is a list of vital instruments commonly utilized:

| Tool | Purpose |

|---|---|

| Screwdriver Set | For tightening or loosening screws in various components. |

| Wrench Set | Used for gripping and turning fasteners. |

| Pliers | Essential for gripping, twisting, and cutting wires. |

| Multimeter | For measuring voltage, current, and resistance in circuits. |

| Heat Gun | Used for softening materials or removing components. |

Maintaining Your Toolkit

Proper maintenance of tools is crucial for ensuring longevity and reliability. Regular cleaning, calibration, and storage can prevent wear and tear, leading to a more effective repair experience. Always inspect tools before use to ensure they are in optimal condition, as damaged equipment can hinder progress and compromise safety.

Resources for Further Study

For those seeking to deepen their understanding of intricate machinery and components, a variety of materials are available. These resources encompass technical manuals, online platforms, and communities that provide valuable insights and knowledge.

Recommended Books

Books remain a fundamental resource for learning about complex systems. Here are some noteworthy titles:

| Title | Author | Publication Year |

|---|---|---|

| Mechanical Systems Design | John Smith | 2018 |

| Advanced Engineering Mechanics | Jane Doe | 2020 |

Online Platforms

Utilizing digital resources can enhance your learning experience. Below are some useful websites:

- Engineering Toolbox – Offers a wealth of information on various engineering concepts.

- Academic Journals – Access to the latest research articles and studies in the field.

- Online Forums – Platforms like Reddit and Stack Exchange where experts and enthusiasts share knowledge.

Expert Recommendations on Upgrades

Enhancing the efficiency and performance of machinery often involves strategic modifications and improvements. By focusing on key components and adopting high-quality alternatives, users can achieve significant gains in functionality and longevity. Below are several expert suggestions that can assist in optimizing equipment performance through thoughtful enhancements.

| Upgrade Component | Description | Benefits |

|---|---|---|

| Enhanced Motor | Consider upgrading to a more efficient motor designed for higher torque and speed. | Improved power consumption and increased productivity. |

| Advanced Control System | Implement a modern control interface with advanced automation features. | Greater precision and easier operation management. |

| Quality Bearings | Replace standard bearings with high-performance variants that reduce friction. | Extended lifespan and reduced maintenance frequency. |

| Upgraded Cooling System | Integrate a more efficient cooling mechanism to manage heat effectively. | Enhanced performance stability and lower risk of overheating. |

Frequently Asked Questions

This section addresses common inquiries related to the assembly and components of specific machinery. Here, we aim to clarify various aspects, offering insights into installation, maintenance, and troubleshooting processes to enhance user understanding.

Below are some of the most frequently posed questions along with their answers:

| Question | Answer |

|---|---|

| What are the key elements of this machinery? | The essential components include the engine, transmission, and control systems, all working together to ensure optimal performance. |

| How can I identify issues with the system? | Common signs of malfunction include unusual noises, decreased efficiency, and warning lights on the control panel. Regular inspections can help detect problems early. |

| What maintenance is recommended for longevity? | Routine checks on fluid levels, filters, and belts, along with periodic servicing, can significantly extend the lifespan of the equipment. |

| Are there specific tools needed for repairs? | Basic hand tools, such as wrenches and screwdrivers, along with specialized equipment like diagnostic scanners, are often required for effective repairs. |

| Where can I find replacement components? | Replacement parts are typically available through authorized dealers, online retailers, or specialized suppliers dedicated to this type of machinery. |