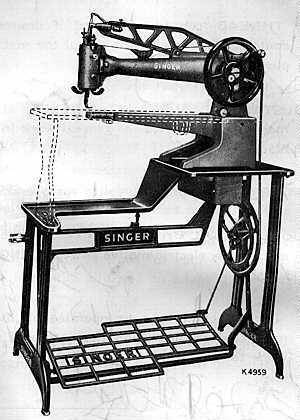

Singer 29-4 Parts Diagram Overview

The intricate world of textile craftsmanship often hinges on the seamless functionality of sewing apparatus. A deep dive into the essential elements that comprise these machines reveals not only their engineering marvel but also the artistry involved in their operation. By exploring the various components, one gains a clearer appreciation for their roles in achieving the ultimate sewing experience.

From the mechanical heart that powers the movement to the delicate attachments that ensure precision, each piece contributes significantly to the overall performance. A well-organized schematic representation aids enthusiasts and professionals alike in understanding how these elements interact harmoniously, making repairs and maintenance tasks more approachable.

As we delve into this exploration, it’s vital to recognize the historical significance and evolution of such devices. This journey not only uncovers the complexity behind their design but also highlights the craftsmanship that has allowed them to endure through generations.

Overview of Components

This section provides a comprehensive look at the essential elements that constitute a specific sewing machine model. Understanding these components is crucial for maintenance, repair, and optimal performance. Each part plays a vital role in the overall functionality, contributing to the efficiency and precision of stitching tasks.

Key Elements

The machine consists of various integral components, each serving a unique purpose. Familiarity with these parts aids users in troubleshooting and enhances their sewing experience.

| Component | Description |

|---|---|

| Needle | Critical for forming stitches; available in different sizes. |

| Bobbin | Holds the lower thread, essential for stitching continuity. |

| Presser Foot | Controls fabric movement; various types exist for different tasks. |

| Throat Plate | Supports the fabric during stitching, often marked with measurements. |

Conclusion

Grasping the function of each component enhances one’s ability to effectively utilize the machine. Proper care and understanding lead to improved outcomes and longevity of the equipment.

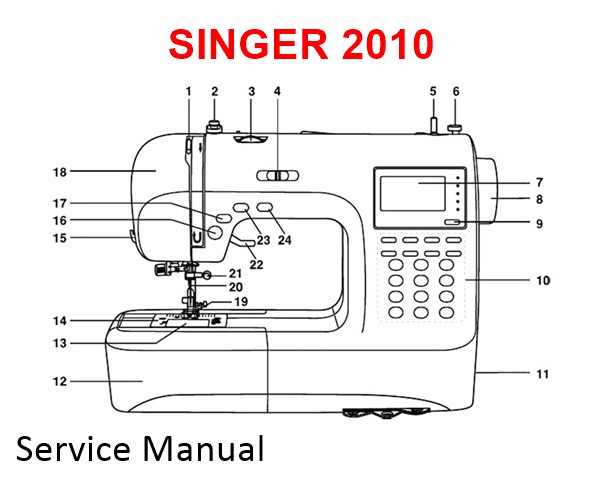

Key Components of the Sewing Machine

A sewing machine is a complex yet fascinating device, designed to facilitate the art of stitching fabric together with precision and efficiency. Understanding its main elements can enhance both the user experience and the overall effectiveness of the machine. Each component plays a crucial role in the functionality, enabling a seamless operation that transforms raw materials into finished products.

Essential Mechanisms

At the heart of any sewing device lies the motor, which provides the necessary power to perform various tasks. Coupled with the motor is the needle, an intricate part that pierces the fabric, allowing for the formation of stitches. The bobbin is another vital element, housing the lower thread that intertwines with the upper thread to create secure seams. Together, these components ensure that the stitching process is both smooth and reliable.

Support Structures

In addition to the primary mechanisms, several support structures contribute to the machine’s stability and ease of use. The frame provides the necessary support for all moving parts, while the foot pedal allows the operator to control the speed and rhythm of sewing. Furthermore, the presser foot ensures that the fabric remains in place during the stitching process, preventing any unwanted shifts that could affect the final outcome.

Understanding the Parts Diagram

This section aims to provide insight into the intricate components of a specific machine, highlighting their roles and interactions. By exploring the schematic representation, users can gain a clearer perspective on how each element contributes to the overall functionality.

Familiarizing oneself with the layout is essential for both maintenance and troubleshooting. Recognizing the different sections allows for efficient navigation and understanding of the operational principles.

| Component | Description |

|---|---|

| Motor | Powers the entire system, enabling movement and functionality. |

| Needle | Essential for stitching, its movement determines the quality of the output. |

| Bobbin | Holds the thread that is used in conjunction with the needle. |

| Presser Foot | Holds the fabric in place while stitching, ensuring even feed. |

| Tension Mechanism | Regulates the tightness of the thread, affecting stitch quality. |

Importance of Regular Maintenance

Consistent upkeep of machinery is crucial for ensuring optimal performance and longevity. Neglecting routine care can lead to various issues that compromise functionality, resulting in costly repairs and decreased efficiency. By prioritizing maintenance, users can avoid disruptions and extend the lifespan of their equipment.

Regular maintenance offers numerous benefits, including:

- Enhanced Performance: Frequent checks and adjustments can keep machinery running smoothly, preventing minor issues from escalating.

- Increased Lifespan: Proper care helps in maintaining the integrity of components, thereby extending their usability over time.

- Cost Efficiency: Addressing problems early can save significant amounts on repairs and replacements.

- Safety Assurance: Regular inspections ensure that all safety features are functioning correctly, reducing the risk of accidents.

- Improved Reliability: Well-maintained equipment is more dependable, which is essential for productivity in any operation.

Incorporating a structured maintenance schedule is vital for any user aiming to maximize the value and efficiency of their investment. This proactive approach not only safeguards the equipment but also promotes a smoother workflow and greater satisfaction in the long run.

Common Issues and Solutions

When working with sewing machines, users may encounter various challenges that can hinder performance. Understanding these problems and their resolutions is essential for maintaining optimal functionality and ensuring a smooth sewing experience.

Frequent Problems

- Thread bunching or tangling

- Skipped stitches

- Uneven tension

- Machine not feeding fabric properly

Solutions

- Check the threading: Ensure the machine is threaded correctly and the bobbin is properly inserted.

- Adjust tension settings: Experiment with different tension levels to achieve a balanced stitch.

- Use the appropriate needle: Select the correct needle type and size for the fabric being used.

- Clean the machine: Regularly remove lint and debris to prevent feeding issues.

Replacing Worn Parts Effectively

Maintaining the longevity and performance of your sewing machine is essential for achieving optimal results. Over time, certain components may wear down, leading to decreased functionality and efficiency. Addressing these issues promptly can enhance the overall performance and ensure smooth operation.

Identifying Wear and Tear

Recognizing when components need replacement is crucial. Look for the following signs:

- Unusual noises during operation

- Inconsistent stitching quality

- Frequent thread breakage

- Difficulty in maneuvering fabric

Steps for Replacement

When you identify a component that requires attention, follow these steps to ensure effective replacement:

- Gather necessary tools and replacement items.

- Consult the user manual for specific instructions related to your model.

- Carefully remove the worn item, taking note of its placement.

- Install the new component, ensuring it fits securely and aligns correctly.

- Test the machine to confirm proper functionality before regular use.

By proactively addressing worn components, you can maintain your sewing machine’s efficiency and prolong its lifespan.

Tools Needed for Repairs

When embarking on maintenance tasks for your sewing machine, having the right tools is essential for efficient and effective repairs. This section outlines the necessary instruments that will streamline the process, ensuring you can tackle any issues that arise.

Essential Instruments

- Screwdrivers (flathead and Phillips)

- Pliers (needle-nose and standard)

- Wrenches (various sizes)

- Thread snips

- Measuring tape

Additional Supplies

- Oiling tools

- Cleaning brushes

- Replacement needles

- Spools of thread

- Fabric swatches for testing

Equipping yourself with these tools will ultimately enhance your repair experience, allowing for smoother operations and quicker resolutions.

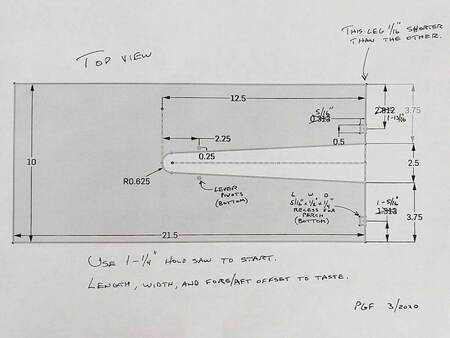

How to Access Internal Mechanisms

Understanding how to reach the inner workings of a device can greatly enhance your ability to maintain and repair it. This process often requires careful disassembly and a keen eye for detail. By following a systematic approach, you can effectively uncover the components that drive its functionality.

Preparation Steps

Before starting, ensure you have the right tools at hand. A well-lit workspace is essential for visibility. Begin by removing any external coverings gently to avoid damaging the casing. Document each step with photographs or notes to aid reassembly later.

Accessing the Core Components

Once external panels are off, locate screws or clips that secure the interior sections. Use appropriate tools to remove them, and carefully lift away any barriers. Pay attention to the arrangement of each part as you disassemble, as this knowledge is crucial for reassembly.

Adjustment Techniques for Optimal Performance

Achieving peak functionality in sewing machinery involves a careful balance of multiple components. By fine-tuning specific elements, users can enhance both efficiency and stitch quality. Understanding the various adjustment methods allows for smoother operation and prolonged machine life.

Precision Tension Management

One of the key aspects of optimal performance is the regulation of thread tension. Incorrect tension can lead to issues such as thread breakage or uneven stitching. Regularly checking and adjusting the tension settings based on the type of fabric and thread being used is crucial. Users should experiment with slight adjustments to find the ideal tension for their specific projects, ensuring flawless results.

Alignment and Positioning

Proper alignment of moving parts significantly impacts functionality. Ensuring that the needle is correctly positioned and that the feed dogs are aligned with the needle plate can prevent common operational issues. Regular maintenance checks should include examining the alignment, as even minor deviations can lead to significant performance drops. Keeping all components clean and well-lubricated further enhances efficiency and reliability.

Parts Availability and Sourcing

Accessing components for vintage sewing machines can be a challenge, yet it is essential for maintaining their functionality and longevity. Enthusiasts and professionals alike seek reliable sources to obtain the necessary items to ensure optimal performance.

- Local Craft Stores: Check for smaller retailers that specialize in sewing supplies.

- Online Marketplaces: Websites like eBay or Etsy often have listings from individual sellers.

- Specialized Suppliers: Certain companies focus exclusively on vintage machinery components.

- Forums and Community Groups: Engaging with fellow hobbyists can lead to valuable recommendations.

- Restoration Shops: Some businesses offer repair services and may have spare components available.

When sourcing, consider the condition and compatibility of the items. Researching reputable vendors can ultimately save time and ensure the quality of the components acquired.

Upgrades and Modifications for Efficiency

Enhancing the performance of your machine can significantly improve its productivity and longevity. By focusing on specific enhancements, users can streamline operations and reduce downtime. This approach not only optimizes functionality but also contributes to a smoother workflow.

One effective upgrade is the incorporation of high-quality components. Utilizing durable materials can lead to better performance and reduced wear over time. Additionally, upgrading to advanced motor systems can provide improved speed and torque, further enhancing efficiency.

Regular maintenance routines also play a crucial role in sustaining optimal performance. Keeping parts clean and well-lubricated can prevent unnecessary friction and extend the life of the machine. Furthermore, investing in precision tools ensures that all modifications are executed flawlessly, maximizing the potential of each upgrade.

Ultimately, these improvements lead to greater reliability and a more efficient operational experience, making the machine a valuable asset in any setting.

Connecting with Singer User Community

Engaging with fellow enthusiasts can significantly enhance your experience and knowledge. By joining communities dedicated to sewing machines, users can share insights, troubleshoot issues, and inspire creativity.

Benefits of Community Engagement

- Access to valuable tips and techniques

- Support for problem-solving and maintenance

- Opportunities to showcase projects and get feedback

Ways to Connect

- Join online forums and discussion boards

- Participate in social media groups

- Attend local workshops or events