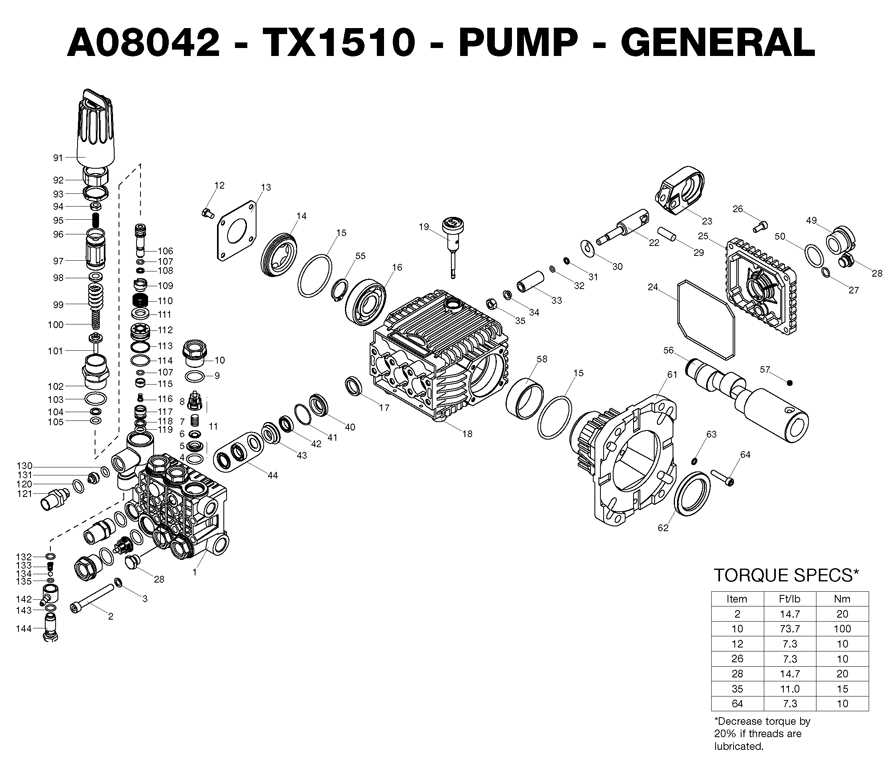

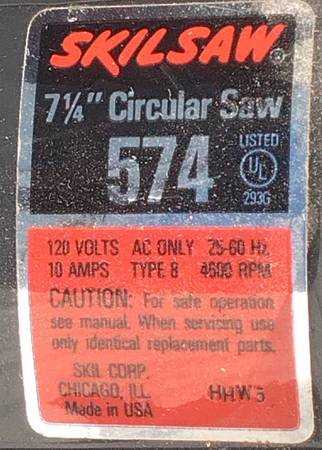

Understanding the Skilsaw 574 Parts Diagram for Easy Maintenance

When it comes to maintaining and repairing power tools, having a clear visual representation of their components is essential. A detailed illustration serves as a valuable guide, helping users identify various elements within their equipment.

By exploring the intricate layout of tool assemblies, one can gain insights into the functionality and interaction of each piece. This knowledge is crucial for effective troubleshooting and ensuring optimal performance.

Whether you are a seasoned professional or a DIY enthusiast, mastering the arrangement of these vital components will enhance your repair skills. Diving into the specifics of your tools can ultimately lead to greater efficiency and longevity in your projects.

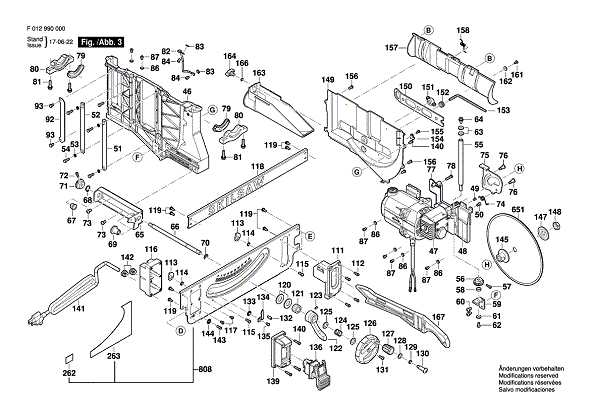

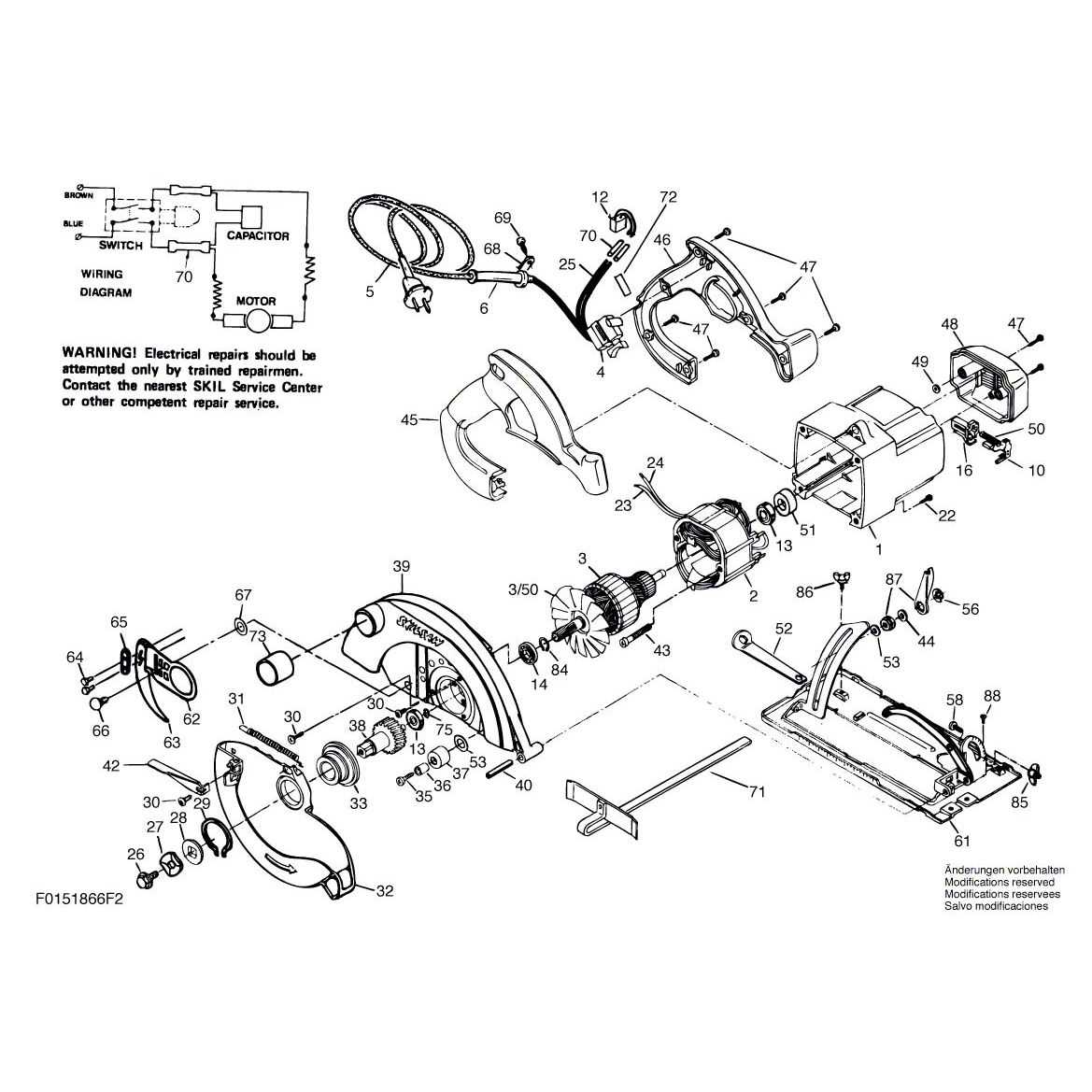

Understanding Skilsaw 574 Components

Familiarizing oneself with the elements of a circular cutting tool is essential for effective usage and maintenance. Each component plays a crucial role in the overall functionality and safety of the equipment. A comprehensive grasp of these individual parts enables users to troubleshoot issues and enhance their performance.

The motor serves as the powerhouse, driving the blade at varying speeds for different materials. Blade guards ensure safety by covering the cutting edge when not in use, while the base plate provides stability during operation. Understanding these essentials allows for a more confident approach to tasks.

Furthermore, the arbor connects the blade to the motor, ensuring a secure fit, while the depth adjustment mechanism allows for precision cutting at varying thicknesses. Recognizing the function of each piece can significantly improve both efficiency and effectiveness.

Importance of Parts Diagrams

Understanding the components of any mechanical device is crucial for effective maintenance and repair. Visual representations that illustrate the various elements and their arrangements serve as valuable resources for both professionals and hobbyists. These visuals enhance comprehension and facilitate troubleshooting, ensuring that users can efficiently address any issues that arise.

Enhancing Communication

Clear depictions of individual components promote better communication among technicians and users. When everyone refers to the same visual reference, it reduces misunderstandings and speeds up the repair process. This clarity is particularly beneficial in collaborative environments, where team members must quickly identify specific parts during discussions or hands-on work.

Facilitating Maintenance

Utilizing these illustrations aids in regular upkeep by allowing users to easily locate and recognize essential elements. By understanding the layout and function of each part, one can efficiently carry out inspections and replace worn or damaged components, ultimately prolonging the lifespan of the equipment. Proper maintenance practices are key to ensuring optimal performance and reliability.

Common Issues with Skilsaw 574

Power tools are invaluable in construction and woodworking, yet they can encounter various challenges over time. Understanding these common problems can help users troubleshoot effectively and maintain optimal performance.

1. Overheating: A frequent issue that arises is overheating, often due to prolonged use or inadequate ventilation. Users should ensure that the tool is operated within its limits and allow for cooling breaks to prevent damage.

2. Blade Dullness: Dull blades can significantly affect cutting efficiency and quality. Regular inspection and replacement of blades are essential to ensure smooth operation and clean cuts.

3. Motor Failure: Electrical failures can lead to complete tool shutdown. Users should check connections, ensure proper voltage supply, and replace worn components to extend the lifespan of the motor.

4. Alignment Issues: Misalignment of the cutting mechanism can cause inaccuracies in cuts. Regular calibration and adjustments are necessary to maintain precision and effectiveness in tasks.

5. Dust Accumulation: Excessive dust buildup can obstruct airflow and cooling, leading to overheating and mechanical failure. Regular cleaning after each use is crucial to ensure optimal functionality.

6. Handle or Switch Malfunction: Wear and tear on the handle or switch can lead to operational difficulties. Routine inspection and timely replacement of these components can prevent accidents and ensure smooth operation.

By being aware of these common issues, users can take proactive steps to maintain their tools, ensuring they remain effective and reliable for years to come.

How to Identify Parts

Understanding the components of your tool is essential for effective maintenance and repair. By recognizing individual elements, you can ensure your equipment operates optimally and address issues promptly.

Follow these steps to accurately identify the necessary components:

- Consult the manufacturer’s manual for a comprehensive overview.

- Examine the tool carefully to familiarize yourself with its layout.

- Use online resources and forums to gather insights from other users.

- Take note of any markings or numbers on the components.

By employing these strategies, you can effectively pinpoint the elements required for your maintenance needs.

Maintenance Tips for Longevity

Proper upkeep is essential for ensuring the extended life of your equipment. By following a few key practices, you can maintain optimal performance and prevent unnecessary wear and tear.

| Tip | Description |

|---|---|

| Regular Cleaning | Remove dust and debris to prevent buildup that can affect functionality. |

| Lubrication | Apply appropriate lubricants to moving parts to minimize friction and wear. |

| Inspection | Check components regularly for signs of damage or excessive wear. |

| Proper Storage | Store in a dry, protected area to avoid environmental damage. |

| Follow Guidelines | Adhere to the manufacturer’s maintenance recommendations for best results. |

Where to Find Replacement Parts

Finding suitable components for your tools can enhance their performance and longevity. There are several reliable sources to explore, ensuring you get the right pieces to maintain your equipment effectively.

Online Retailers

Numerous online platforms specialize in tool components, offering extensive inventories. Websites such as Amazon and eBay often provide a variety of options, including original and compatible alternatives. Ensure you check user reviews for quality assurance.

Local Hardware Stores

Your neighborhood hardware store can be a valuable resource. Many retailers stock essential components and can also place special orders for hard-to-find items. Building a relationship with local shop staff can lead to helpful recommendations and insights.

Assembly Instructions for Skilsaw 574

Proper assembly is crucial for ensuring optimal performance and safety when operating power tools. This section outlines the necessary steps to effectively assemble the equipment, ensuring all components fit together seamlessly and function as intended.

Required Tools

Before starting the assembly process, gather the following tools:

| Tool | Purpose |

|---|---|

| Screwdriver | For securing screws |

| Wrench | For tightening nuts and bolts |

| Measuring tape | To ensure accurate dimensions |

| Safety goggles | To protect eyes during assembly |

Assembly Steps

Follow these steps carefully to assemble your tool:

- Begin by laying out all components on a flat surface, ensuring nothing is missing.

- Attach the base to the main body, aligning the pre-drilled holes.

- Secure the base using the provided screws, making sure they are tightened adequately.

- Install the motor assembly onto the main frame, ensuring it is properly aligned.

- Connect the power cord, following the wiring diagram included in the manual.

- Attach any additional accessories or attachments as needed.

- Perform a final check to ensure all connections are secure and components are fitted correctly.

By adhering to these instructions, you will ensure your tool is assembled correctly and ready for safe operation.

Upgrading Your Skilsaw 574

Enhancing your power tool can significantly improve its performance and longevity. This section explores various upgrades that can transform your equipment into a more efficient and versatile asset in your workshop.

- Replace the blade with a high-quality option for cleaner cuts.

- Upgrade the motor for increased power and speed.

- Consider adding a laser guide for improved accuracy.

These enhancements can ultimately provide you with a smoother experience and better results in your projects.

- Evaluate your current tool’s performance.

- Research compatible upgrades.

- Install the new components carefully, following manufacturer instructions.

Investing in these improvements can make a noticeable difference in your cutting tasks and overall satisfaction with the tool.

Safety Features Explained

When operating power tools, understanding the integrated safety mechanisms is crucial for preventing accidents and ensuring user protection. These features are designed to minimize risks associated with cutting, drilling, and other activities, providing peace of mind while enhancing operational efficiency.

Blade Guard Mechanism

A prominent safety feature is the blade guard, which covers the cutting edge when not in use. This component serves as a protective barrier, significantly reducing the likelihood of accidental contact with the blade. Additionally, many designs incorporate an automatic retraction system that engages the guard as soon as the tool is lifted away from the material being worked on.

Electric Brake System

Another vital feature is the electric brake system, which quickly halts the rotation of the blade when the trigger is released. This swift response not only helps in preventing injuries but also allows for precise control over the cutting process. Users can switch from cutting to handling the tool more safely, ensuring that downtime is minimal and safety remains a priority.

Frequently Asked Questions

This section aims to address common inquiries related to tool maintenance and repair. Whether you are seeking information about components, troubleshooting issues, or general guidance, these questions cover a range of topics to enhance your understanding and experience.

What should I do if my tool is not functioning properly?

Begin by checking the power supply and ensuring all connections are secure. If the issue persists, refer to the manual for troubleshooting steps or consider consulting a professional for assistance.

How can I identify worn or damaged components?

Inspect each part visually for signs of wear, such as cracks or excessive wear patterns. Additionally, listen for unusual sounds during operation, which can indicate that a specific element needs replacement.

Where can I find replacement components?

Replacement parts can typically be found through authorized retailers or online platforms that specialize in tool accessories. Always verify that the parts are compatible with your specific model.

Is there a recommended maintenance schedule?

Regular maintenance is crucial. It is advisable to clean and inspect your tool after each use, and perform more thorough checks monthly or quarterly, depending on frequency of use.

Can I perform repairs myself?

Many users opt to handle minor repairs themselves. However, for complex issues or when in doubt, it is best to seek help from a qualified technician to avoid further damage.

Resources for Skilsaw Users

For those who frequently work with power tools, having access to reliable information and materials can greatly enhance your experience and efficiency. Whether you are a professional contractor or a DIY enthusiast, understanding how to maintain and troubleshoot your equipment is crucial. This section aims to provide valuable resources that cater to the needs of users, ensuring optimal performance and longevity of your tools.

Online Forums and Communities: Engaging with fellow users in online forums can be immensely beneficial. These platforms allow individuals to share experiences, tips, and solutions to common issues. Participating in discussions can lead to discovering new techniques and improving your overall skill set.

Instructional Videos: Visual aids are often the most effective way to learn. Numerous platforms offer a wealth of tutorial videos that cover everything from basic operation to advanced repair techniques. These resources can help users become more confident in handling their equipment.

Manufacturer Support: Many manufacturers provide extensive online resources, including user manuals and maintenance guides. These documents are essential for understanding the specific requirements of your tools and ensuring you follow recommended practices for care and upkeep.

Local Workshops: Participating in local workshops or training sessions can provide hands-on experience and direct interaction with experts. These opportunities often cover various aspects of tool usage and maintenance, allowing you to gain practical knowledge in a supportive environment.

Parts Retailers: Knowing where to find replacement components is vital for any user. Numerous online and local retailers specialize in tool parts, often providing detailed catalogs that can help you identify and order the correct items quickly.

By utilizing these resources, users can not only enhance their understanding of their tools but also ensure that they are using them safely and effectively. Empower yourself with knowledge and support to make the most of your equipment.