Sloan Flushmate Parts Diagram Guide

In the realm of bathroom fixtures, the intricate mechanisms that ensure optimal performance are crucial for both efficiency and convenience. A well-functioning flushing system is essential for maintaining hygiene and comfort in any restroom environment. Knowledge of these systems allows users to troubleshoot issues effectively, leading to prolonged lifespan and enhanced user satisfaction.

The internal workings of these systems consist of various elements that play distinct roles in the flushing process. Understanding how each component interacts not only aids in identifying potential problems but also empowers individuals to undertake necessary repairs or replacements confidently. Clear identification of these individual parts can streamline maintenance and enhance overall functionality.

By familiarizing oneself with the layout and function of each component, users can navigate repairs with greater ease. Whether addressing leaks or ensuring optimal flushing power, an informed approach facilitates a smoother experience. This understanding ultimately transforms a potentially daunting task into a manageable one, promoting a more efficient and effective restroom environment.

Understanding Sloan Flushmate Components

This section explores the various elements that constitute a high-efficiency flushing system, designed to optimize performance and reliability. Each component plays a vital role in ensuring effective waste removal while conserving water, making these systems a popular choice in modern restroom fixtures.

To fully appreciate how these systems operate, it’s essential to familiarize oneself with the key components, their functions, and how they interact within the system. Below is a table summarizing the main elements and their respective roles:

| Component | Function |

|---|---|

| Pressure Vessel | Stores water under pressure for powerful flushing action. |

| Flush Valve | Controls the release of water from the pressure vessel to initiate the flush. |

| Fill Valve | Regulates water flow into the system, refilling the pressure vessel after each use. |

| Actuation Mechanism | Triggers the flush cycle, often activated by a handle or button. |

| Seal Components | Ensures leak-proof operation and maintains system pressure. |

Understanding these components allows for better maintenance and troubleshooting, ensuring that the system continues to operate efficiently over time.

Overview of Flushmate Systems

The innovative systems designed for efficient water management in toilets are essential for modern restroom functionality. These units provide powerful flushing capabilities, ensuring optimal performance and water conservation. Understanding the components and mechanics involved can enhance maintenance and user experience.

Key Features

- High-efficiency flushing technology

- Durability and reliability under frequent use

- Easy installation and maintenance

- Water-saving designs that promote sustainability

Components of the System

- Pressure tank for effective water storage

- Flush valve for controlled release

- Control mechanism for precise operation

- Connections for seamless integration with existing plumbing

Familiarity with these features and components can significantly aid in troubleshooting and prolonging the lifespan of these systems.

Importance of Proper Maintenance

Regular upkeep of bathroom equipment is essential to ensure optimal functionality and longevity. Neglecting routine care can lead to a range of issues, including leaks, reduced efficiency, and increased utility costs. By investing time in maintenance, homeowners can avoid costly repairs and ensure their systems operate smoothly.

Preventing Costly Repairs

One of the primary benefits of consistent maintenance is the prevention of significant breakdowns. Small issues, if left unattended, can escalate into major problems that require expensive interventions. By identifying and addressing minor faults early, homeowners can save money and extend the lifespan of their fixtures.

Enhancing Efficiency

Regular inspections and maintenance can greatly enhance the efficiency of bathroom systems. Well-maintained equipment typically consumes less water and energy, leading to lower bills and a reduced environmental footprint. This proactive approach not only benefits the homeowner financially but also contributes to sustainable living.

In conclusion, prioritizing the maintenance of bathroom fixtures is crucial for ensuring their reliability and efficiency. Taking preventive measures can safeguard against potential issues and foster a more eco-friendly household.

Common Issues with Flushmate Parts

Many users encounter a variety of challenges when dealing with the internal mechanisms of their toilet systems. Understanding these common problems can help in troubleshooting and maintaining optimal performance. This section will highlight frequent concerns that arise, along with possible solutions to enhance the efficiency of these essential components.

Leakage Problems

One of the most prevalent issues is leakage, which can occur due to worn seals or improper installation. When these components fail, water may seep from the tank, causing not only increased utility bills but also potential damage to surrounding areas. Regular inspection and timely replacement of seals can mitigate this problem.

Insufficient Flushing Power

Another common complaint is inadequate flushing strength. This can result from clogs, air in the system, or malfunctioning valves. Ensuring that all parts are free of obstructions and that the mechanism is correctly adjusted can help restore the necessary pressure for effective waste removal.

How to Identify Each Component

Understanding the various elements of a toilet system is essential for effective maintenance and troubleshooting. Recognizing each individual piece can simplify repairs and enhance performance. This section will guide you through the identification process, ensuring you can confidently distinguish between the different components.

Common Elements

Most toilet mechanisms consist of a few primary parts, each serving a unique function. The cistern lid is the top cover that protects internal workings, while the tank stores water until it’s needed. Beneath these, the flapper valve plays a crucial role in controlling water flow during flushing.

Functional Features

To further aid in identification, consider the float ball, which regulates water levels within the tank. The fill valve is responsible for refilling the tank after a flush, ensuring optimal operation. Additionally, the flush handle is the user interface, directly linked to the flushing mechanism, providing ease of use.

Replacing Worn-out Flushmate Parts

Over time, components within your toilet system may degrade, leading to inefficient flushing or leaks. Addressing these issues promptly can enhance performance and prevent further damage. Understanding the common replacements required will help maintain optimal functionality and prolong the lifespan of your fixture.

Identifying Common Issues

Typical signs of wear include weak flushes, continuous running water, or unusual noises. By regularly inspecting the mechanism, you can identify problematic elements before they result in significant inconvenience. Familiarize yourself with the various components to pinpoint which ones need attention.

Steps for Replacement

Once you’ve determined the faulty parts, the next step is the replacement process. Start by shutting off the water supply and draining the tank. Carefully remove the damaged components, ensuring not to disturb other fittings. Install the new items according to the manufacturer’s guidelines, and finally, restore the water supply to test for proper operation. This straightforward procedure can greatly enhance the performance of your toilet system.

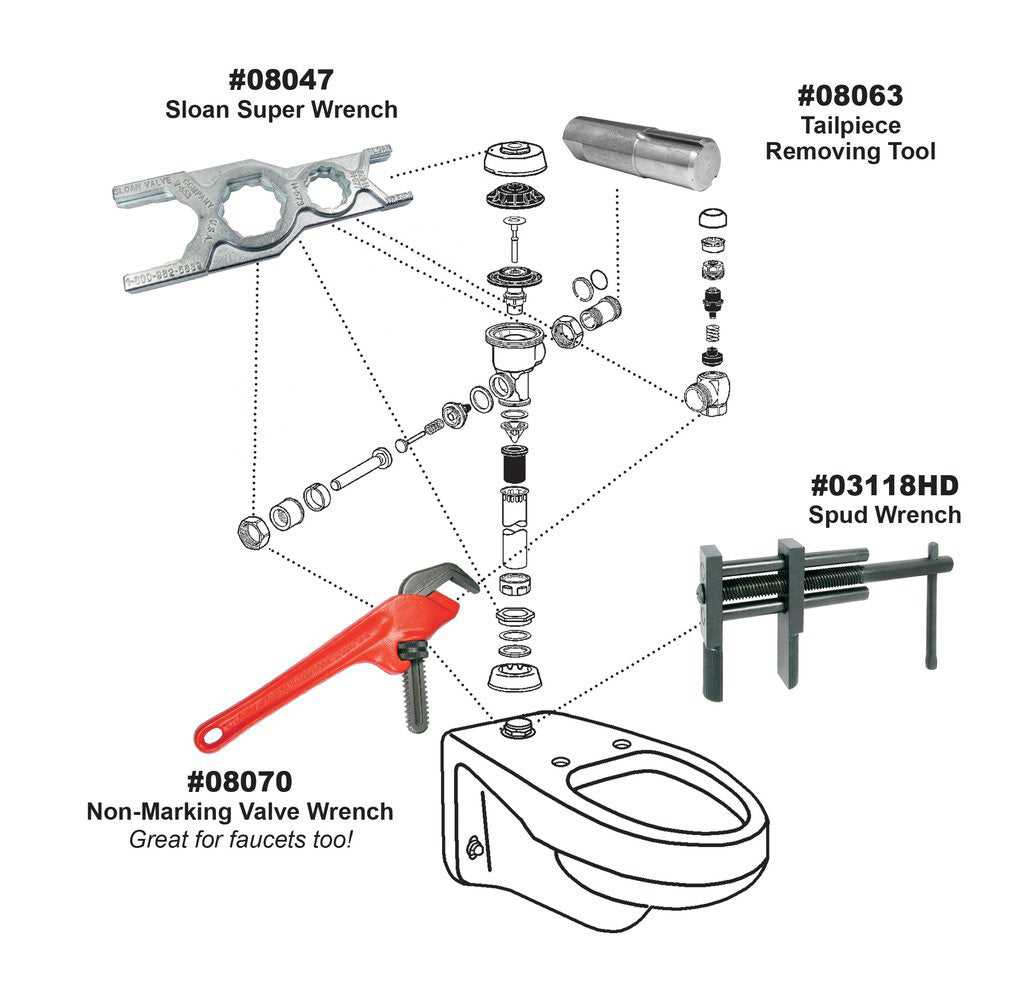

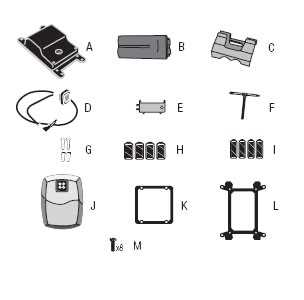

Tools Required for Repairs

When undertaking maintenance or restoration tasks, having the right instruments on hand is essential for a successful outcome. A well-equipped toolkit not only streamlines the process but also enhances safety and efficiency. Below are the key tools that are typically needed for such repairs, ensuring that you are prepared for any challenges that may arise.

Essential Hand Tools

Basic hand tools form the foundation of any repair job. These include a screwdriver set for fastening and loosening screws, wrenches for gripping and turning nuts and bolts, and pliers for holding and manipulating components. Additionally, a utility knife can be invaluable for cutting through materials or trimming excess parts. Make sure these tools are of good quality, as durability will make a noticeable difference in performance.

Specialized Equipment

In some instances, specific repair tasks may require specialized equipment. A multimeter is essential for diagnosing electrical issues, while a pipe wrench is crucial for working on plumbing fixtures. If adjustments or replacements involve pressure systems, a pressure gauge is also necessary to ensure safety and proper function. Investing in these specialized tools can lead to more effective repairs and a longer lifespan for the units being serviced.

Step-by-Step Installation Guide

This guide will walk you through the process of installing essential components for a toilet flushing system. Whether you’re replacing an old unit or setting up a new one, following these steps will ensure a smooth and effective installation.

Preparation and Tools

Before you begin, gather all necessary tools and materials. You will need a wrench, screwdriver, and possibly a utility knife. Ensure you have the new mechanism ready, as well as any seals or gaskets required for installation.

Installation Process

1. Turn Off Water Supply: Locate the water supply valve and turn it off to prevent any leaks during installation.

2. Remove Old Mechanism: Carefully detach the existing flushing unit by unscrewing the mounting bolts and disconnecting any hoses. Pay attention to the orientation for easier reinstallation.

3. Install New Components: Place the new flushing system in the same position as the old one. Secure it with bolts and ensure all connections are tight. Replace any worn seals to prevent leaks.

4. Reconnect Water Supply: Turn the water supply back on and check for leaks around the newly installed components. If everything is secure, you’re ready to test the system.

5. Test the Functionality: Flush the toilet a few times to ensure that the new mechanism operates smoothly. Make adjustments if necessary.

By following these straightforward steps, you can successfully install the flushing system and enjoy reliable performance for years to come.

Benefits of Using Genuine Parts

Opting for authentic components ensures superior performance and longevity in your plumbing system. These original items are specifically designed to meet the exact specifications of your unit, leading to a seamless fit and optimal functionality.

Quality Assurance: Genuine components undergo rigorous testing to guarantee durability and reliability. This commitment to quality minimizes the risk of malfunction and extends the lifespan of your system.

Compatibility: Authentic parts are engineered to work flawlessly with existing mechanisms, reducing the likelihood of leaks or other issues that can arise from using generic alternatives.

Warranty Protection: Utilizing original components often preserves any existing warranties, providing peace of mind. In case of a future malfunction, having authentic pieces can facilitate smoother claims processes.

Enhanced Efficiency: Original items contribute to better overall system efficiency, leading to potential savings on utility bills and reducing environmental impact through optimized performance.

Choosing genuine components is an investment in reliability, safety, and efficiency, ensuring that your plumbing system operates at its best for years to come.

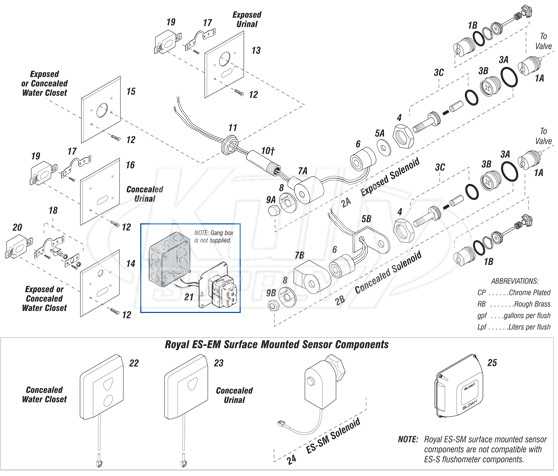

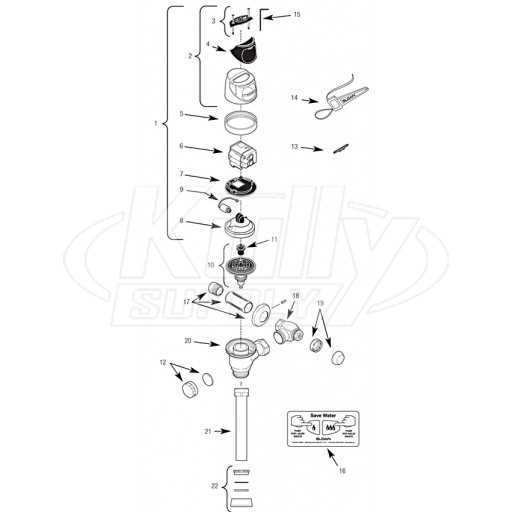

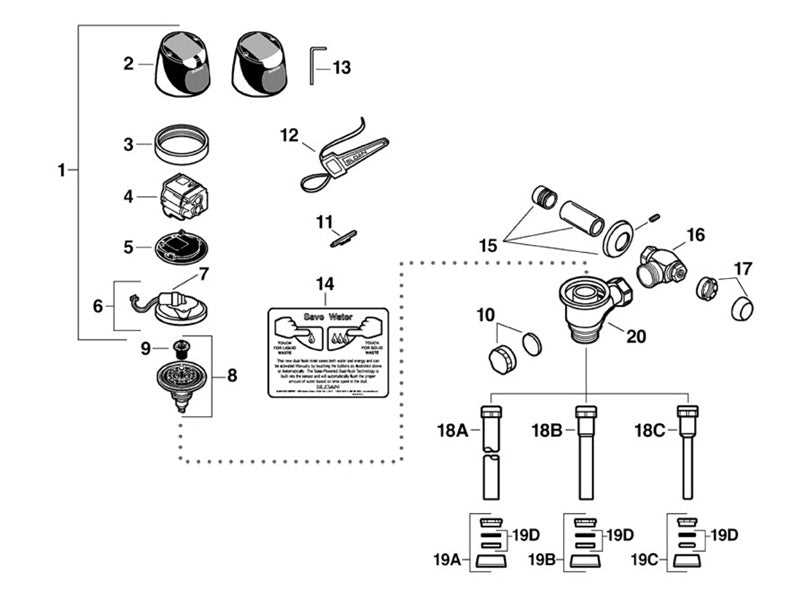

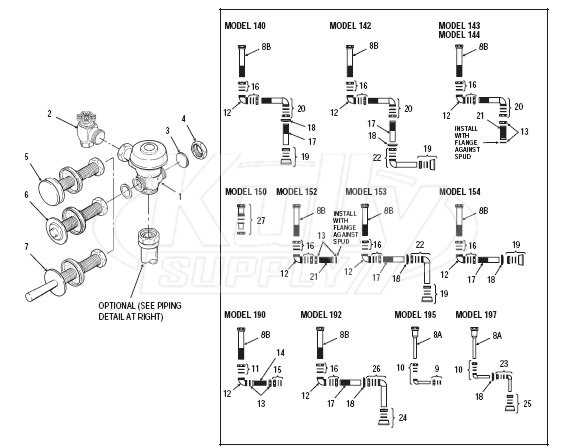

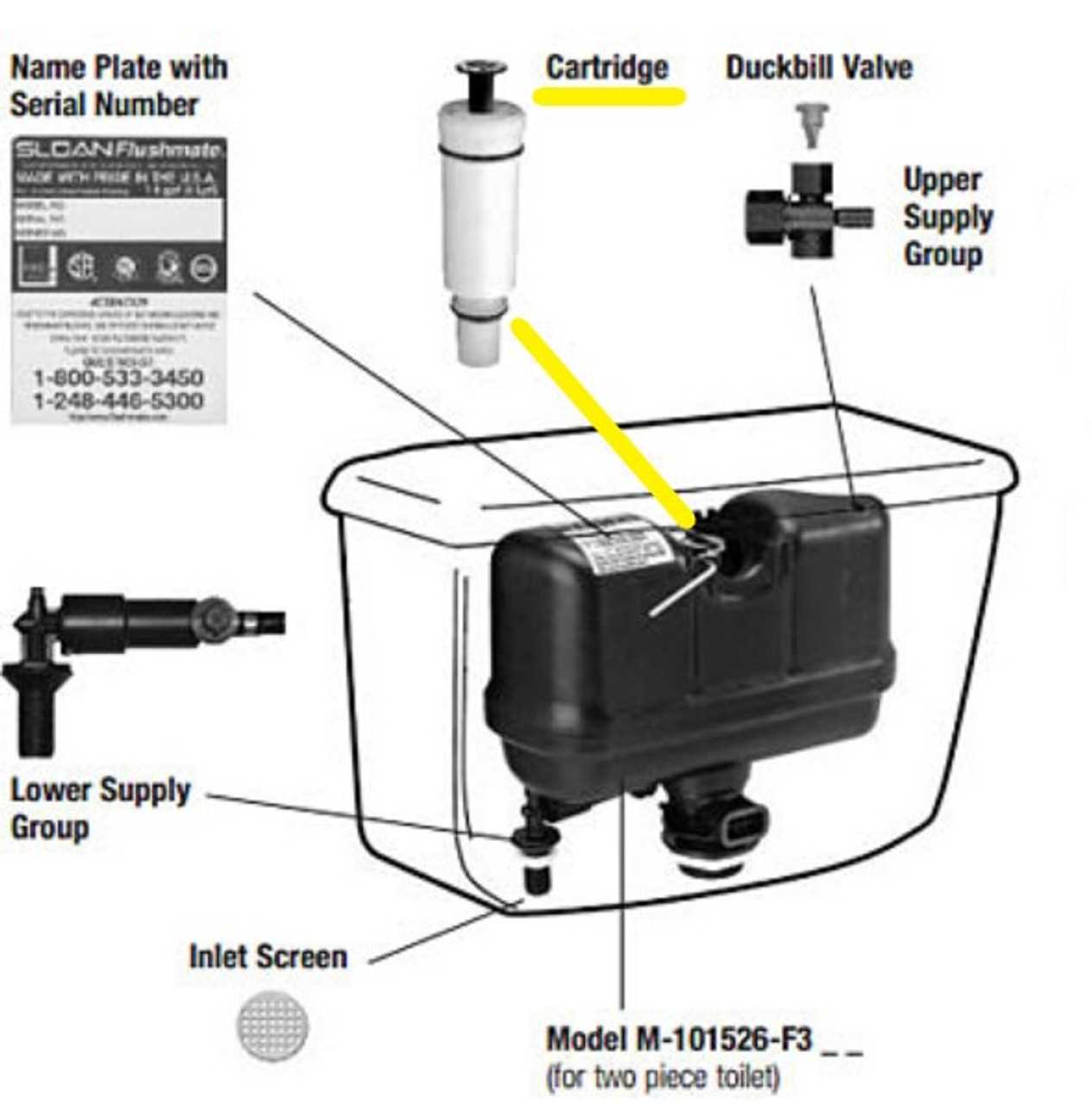

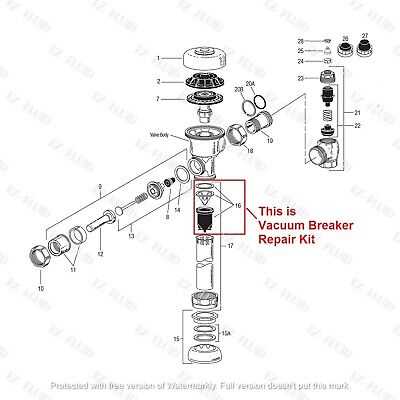

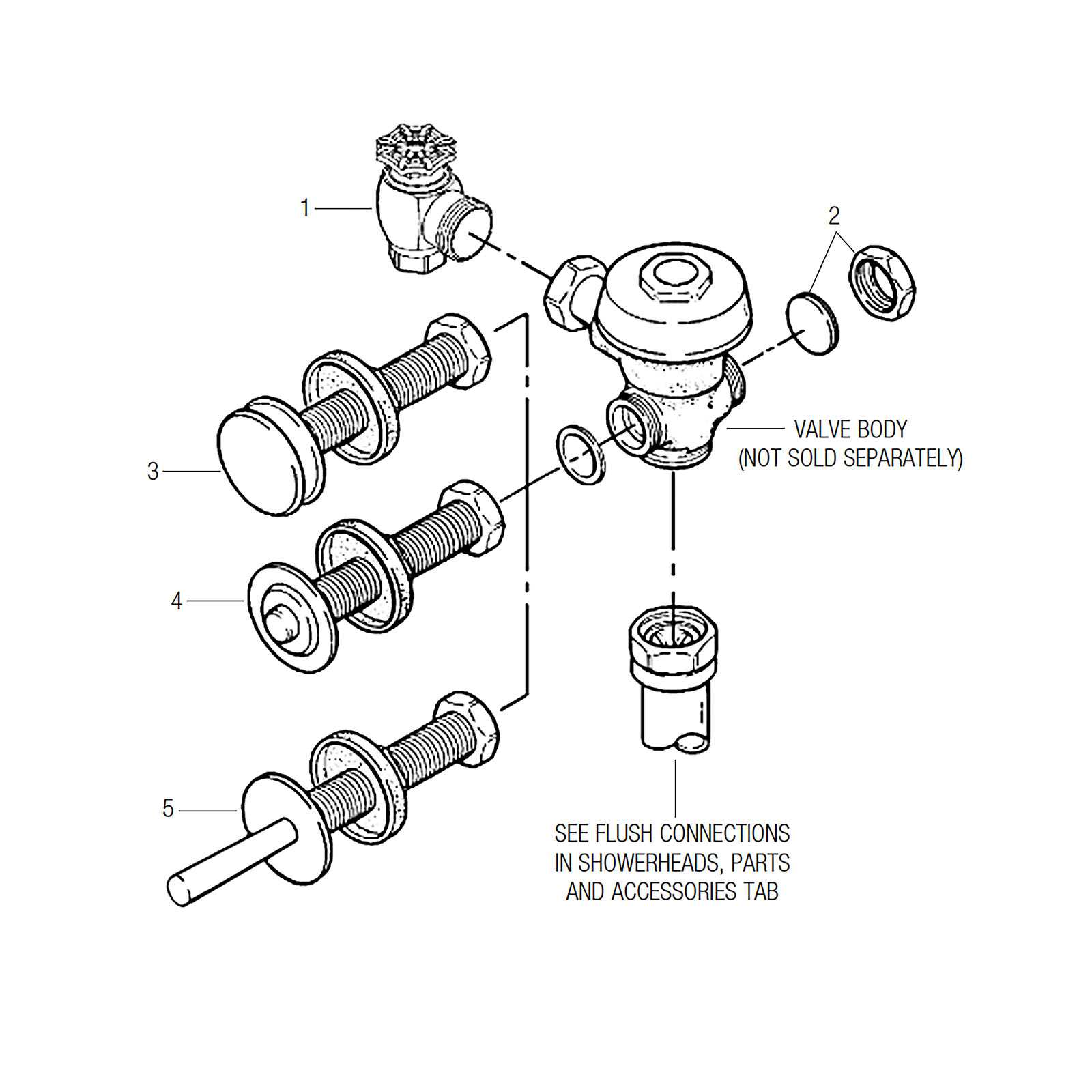

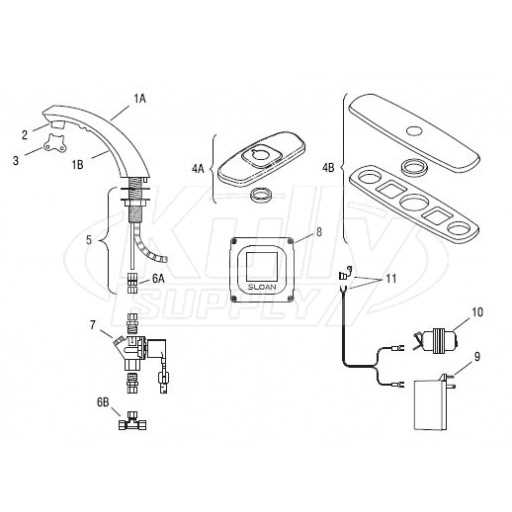

Visual Diagrams for Easy Reference

Visual aids can significantly enhance understanding and maintenance of complex systems. These illustrations serve as quick references, making it easier to identify components and their functions. Utilizing graphical representations helps streamline repairs and installations, saving time and reducing frustration.

When seeking clarity, consider the following types of visual aids:

- Schematic Drawings: Simplified representations that highlight connections and flow within the system.

- Exploded Views: Diagrams that display components separated but aligned, illustrating how parts fit together.

- Annotated Images: Pictures accompanied by labels, providing detailed explanations of each element.

These resources are invaluable for both novice and experienced users. They facilitate quicker identification of issues and ensure a comprehensive understanding of the system’s architecture.

For effective maintenance, consider the following tips:

- Always refer to visuals when disassembling or reassembling components.

- Keep a digital or printed copy accessible for quick consultation.

- Update visuals as modifications are made to the system.

By leveraging these visual tools, users can navigate complexities with confidence and efficiency.

Frequently Asked Questions About Flushmate

This section addresses common inquiries regarding a specific flushing system used in various restroom applications. It aims to provide clear and concise answers to enhance understanding and assist users in troubleshooting and maintenance.

What are the signs of a malfunctioning system?

Common indicators include weak flushing performance, persistent leaks, or unusual noises during operation. If these issues arise, further investigation may be necessary.

How can I identify the model of my system?

Most units have a label or engraving that displays the model number. Checking the manufacturer’s documentation can also provide useful information.

What maintenance is required for optimal performance?

Regular inspections for leaks, cleaning components, and replacing worn parts are essential for maintaining efficiency. Following the manufacturer’s guidelines can prolong the unit’s lifespan.

Are replacement components readily available?

Yes, most essential components can be sourced through various retailers or directly from the manufacturer. Ensure that you choose parts that are compatible with your specific model.

Can I install the system myself?

Installation is possible for those with basic plumbing skills. However, consulting a professional is recommended for complex setups to avoid potential issues.

What should I do if the unit stops working completely?

If the system ceases to function, first check the water supply and ensure all connections are secure. If problems persist, consulting a technician may be necessary to diagnose and resolve the issue.