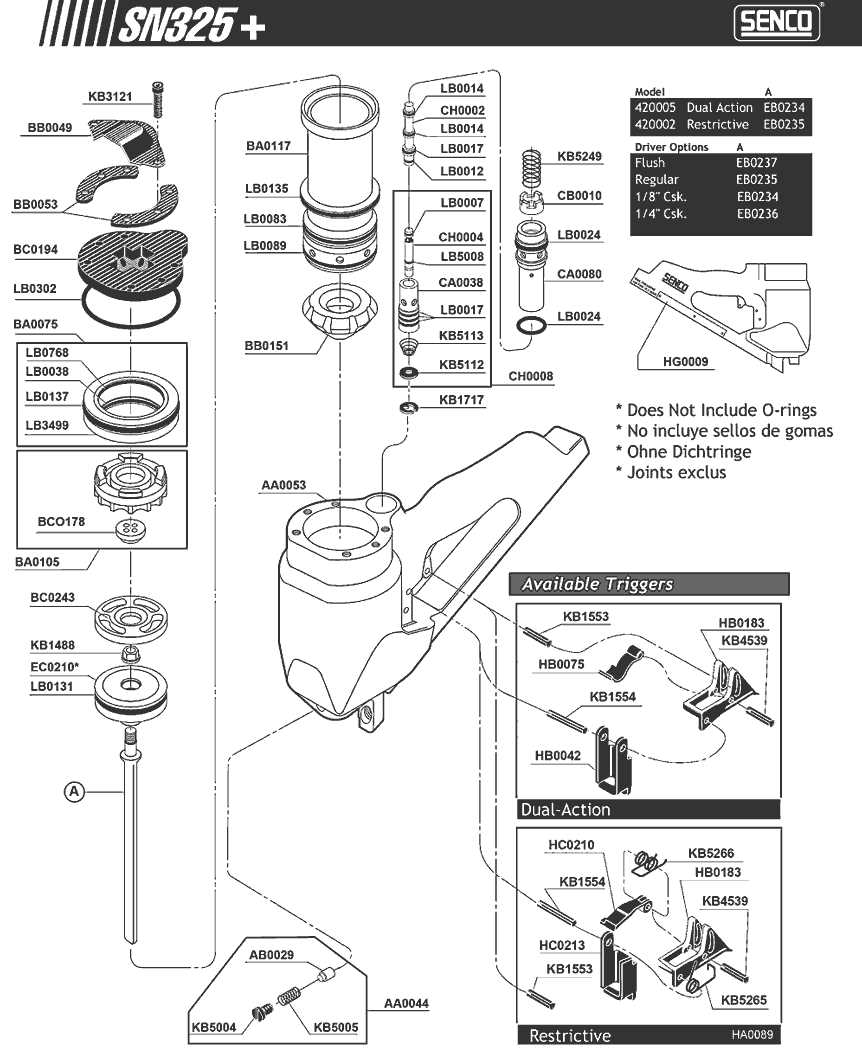

Comprehensive Guide to the Sn325 Parts Diagram

In the realm of technology and engineering, comprehending the arrangement of elements is essential for effective design and maintenance. The intricate relationships between various components can significantly impact functionality and performance. By exploring these configurations, we can enhance our understanding of how systems operate and interact.

Visual representations serve as valuable tools in this exploration, allowing engineers and enthusiasts alike to grasp complex structures with ease. These illustrations offer insights into connections, placements, and the overall architecture of the system. Delving into these visual aids not only clarifies individual roles but also reveals the ultimate synergy within the assembly.

By examining such layouts, one can better appreciate the meticulous design that goes into modern technology. Whether for troubleshooting, optimization, or educational purposes, these guides provide a foundation for deeper knowledge and practical application in various fields.

Understanding the SN325 Parts Diagram

Comprehending the layout of components within a particular system is essential for effective troubleshooting and maintenance. A visual representation can greatly enhance one’s ability to identify individual elements and their interconnections, ultimately leading to better operational understanding.

Key aspects to consider when analyzing such illustrations include:

- Identification: Recognizing each element is crucial for diagnosing issues or upgrading components.

- Relationships: Understanding how each piece interacts with others helps in grasping the overall functionality.

- Orientation: Properly interpreting the orientation of each part can prevent errors during assembly or disassembly.

To effectively utilize these visual guides, one should follow these steps:

- Start with a thorough examination of the layout, noting the positions of major components.

- Cross-reference with documentation to clarify any uncertainties regarding specific parts.

- Practice by tracing connections to reinforce memory and familiarity with the setup.

By mastering the interpretation of these illustrations, individuals can enhance their skills in both diagnostics and repairs, ensuring more efficient operations in the long run.

Components Overview in SN325

This section provides an in-depth examination of the various elements that contribute to the functionality and performance of the system. Each component plays a crucial role in ensuring the overall efficiency and reliability, making it essential to understand their individual characteristics and interactions.

Key Elements

The principal constituents are designed to work harmoniously, with each fulfilling specific tasks. From power management to signal processing, these components are engineered to meet rigorous standards, thereby enhancing the operational capabilities of the entire setup. Understanding their roles can aid in troubleshooting and optimization.

Functionality and Interaction

Each part interacts with others in a well-coordinated manner, leading to seamless performance. Understanding these interactions is vital, as it allows for better diagnostics and potential upgrades. The integration of advanced technologies further amplifies the effectiveness of these elements, resulting in a robust system architecture.

Importance of Accurate Diagrams

Precision in visual representations is crucial for effective communication and understanding within any technical field. Accurate visuals not only aid in the identification of components but also facilitate smoother collaboration among professionals.

Enhancing Understanding

Clear illustrations can significantly improve comprehension by:

- Providing a visual reference that simplifies complex ideas.

- Helping individuals grasp relationships and functions of various elements.

- Reducing the likelihood of misinterpretations and errors.

Streamlining Processes

When visuals are meticulously detailed, they contribute to efficiency in various ways:

- Minimizing the time spent on troubleshooting and repairs.

- Enabling quicker onboarding for new team members.

- Supporting effective training and education initiatives.

Common Issues in SN325 Assemblies

When assembling complex systems, various challenges can arise that affect performance and reliability. Understanding these common complications is essential for maintaining efficiency and ensuring long-term functionality.

Electrical Failures

One prevalent issue involves electrical failures, which can stem from poor connections or inadequate insulation. These failures often lead to short circuits or inconsistent power supply, ultimately compromising the overall operation of the assembly.

Mechanical Misalignments

Another significant concern is mechanical misalignments that may occur during assembly. Such misalignments can result in increased wear on components, leading to premature failure and necessitating costly repairs or replacements.

How to Read the Diagram Effectively

Understanding a visual representation of components is essential for successful navigation and interpretation. This knowledge allows users to identify key elements and their interrelations, facilitating better comprehension of the entire system.

1. Familiarize Yourself with Symbols

Begin by learning the common symbols and notations used in the illustration. Each symbol often carries specific meaning, and recognizing these will aid in deciphering the layout more quickly.

2. Identify Key Sections

Break the image down into manageable parts. Focus on major segments before diving into the details. This method provides a clearer overview and helps to avoid becoming overwhelmed by intricate specifics.

3. Utilize a Legend

If available, refer to a legend or key that explains the symbols and markings. This tool can significantly enhance your understanding, ensuring that you grasp the context of each element represented.

4. Take Notes

As you analyze the visual, jot down important points or observations. This active engagement reinforces your understanding and creates a useful reference for future consultations.

5. Cross-Reference with Documentation

Whenever possible, cross-reference the visual with accompanying materials or manuals. This practice can provide additional clarity and context, making complex ideas more accessible.

By following these strategies, you can enhance your ability to interpret and utilize the visual effectively, leading to more informed decisions and actions in your projects.

Tools Needed for Assembly

Assembling complex devices requires a specific set of instruments to ensure precision and efficiency. Having the right tools on hand not only streamlines the process but also enhances the overall outcome, allowing for a seamless integration of components.

Essential Instruments

Key instruments include screwdrivers, wrenches, and pliers. These basic tools are vital for manipulating various elements, ensuring a secure fit and function.

Additional Equipment

Beyond the essentials, items such as torque wrenches and calipers may be necessary for achieving the ultimate accuracy. Using these tools effectively can significantly impact the assembly quality.

Maintenance Tips for SN325 Parts

Regular upkeep is essential for ensuring optimal performance and longevity of your equipment. Proper attention to components can significantly reduce the risk of malfunctions and enhance overall efficiency.

1. Regular Inspections: Conduct frequent checks to identify wear and tear early. Look for signs of damage or corrosion that may indicate a need for replacement.

2. Cleaning: Keep all elements clean from dust and debris. Use appropriate cleaning agents to avoid any chemical damage to surfaces.

3. Lubrication: Ensure that moving parts are adequately lubricated. This minimizes friction and helps maintain smooth operation.

4. Follow Manufacturer Guidelines: Always adhere to the recommended maintenance schedules provided by the manufacturer. This will help you avoid unnecessary issues.

5. Document Maintenance: Keep a log of all maintenance activities. This documentation can assist in tracking performance trends and anticipating future needs.

6. Training: Ensure that all personnel are properly trained in maintenance procedures. Knowledgeable staff can identify problems more efficiently and handle repairs appropriately.

By implementing these practices, you can prolong the life of your equipment and ensure it operates at its ultimate potential.

Comparative Analysis with Similar Models

This section explores the similarities and differences between various models within the same category, providing insights into their functionalities, specifications, and overall performance. By examining these alternatives, we can better understand the nuances that may influence a buyer’s decision.

| Model | Specifications | Performance | Price |

|---|---|---|---|

| Model A | 4GB RAM, 256GB Storage | High efficiency | $300 |

| Model B | 6GB RAM, 512GB Storage | Superior speed | $400 |

| Model C | 8GB RAM, 1TB Storage | Outstanding performance | $600 |

By analyzing these models, potential buyers can weigh their options based on desired features, budget constraints, and specific needs, ultimately guiding them towards the most suitable choice.

Best Practices for Troubleshooting

Effective problem resolution requires a systematic approach to identify and rectify issues. By following established methodologies, you can streamline the process and enhance your chances of success. This section outlines key strategies that can be applied universally across various scenarios to ensure a thorough and efficient investigation.

1. Define the Problem Clearly

Start by articulating the issue in specific terms. Gather as much information as possible regarding the symptoms and any related occurrences. A precise understanding of the problem is crucial for effective diagnosis.

2. Gather Relevant Data

Collect data related to the situation, including error messages, operational logs, and performance metrics. This information can provide valuable insights and help in pinpointing the root cause of the malfunction.

3. Develop a Hypothesis

Based on the collected data, formulate a hypothesis regarding potential causes. Consider multiple angles and avoid jumping to conclusions. A well-reasoned theory will guide your troubleshooting efforts.

4. Test Systematically

Implement tests one at a time to evaluate your hypothesis. This methodical approach will help you determine whether a specific change resolves the issue without introducing new variables.

5. Document Your Findings

Keep a record of your observations, tests conducted, and outcomes. Documentation not only aids in tracking progress but also serves as a reference for future troubleshooting endeavors.

6. Seek Assistance When Necessary

If the issue persists despite your efforts, don’t hesitate to reach out for help. Collaborating with colleagues or consulting experts can bring fresh perspectives and solutions that you may not have considered.

By adhering to these practices, you can enhance your troubleshooting skills and improve your ability to resolve issues efficiently and effectively.

Resources for Further Learning

Expanding your understanding of complex systems requires access to diverse materials. Whether you’re a novice or an expert, leveraging a variety of resources can enhance your knowledge and skills.

Books and Publications

- Technical manuals and reference guides

- Scholarly articles on related technologies

- Industry reports and case studies

Online Platforms

- Educational websites and tutorials

- Forums and discussion groups for collaborative learning

- Webinars and online courses for in-depth study

Future Developments in SN325 Technology

The ongoing evolution of this technology promises significant advancements that will enhance performance and efficiency. As industries seek to optimize their processes, innovations in design and functionality are anticipated, paving the way for more robust applications.

Potential Innovations

Future improvements may focus on integrating cutting-edge materials and smarter algorithms, which could lead to increased reliability and reduced energy consumption. These enhancements are expected to make systems more adaptable to various environments and demands.

Market Trends

Current trends indicate a growing interest in sustainable solutions and smart technologies. As the market shifts, developers will likely prioritize eco-friendly options that align with consumer expectations and regulatory standards.

| Innovation | Impact |

|---|---|

| Smart Integration | Enhanced adaptability and efficiency |

| Eco-friendly Materials | Reduced environmental footprint |

| Advanced Algorithms | Improved reliability and performance |