Comprehensive Diagram of Steam Train Parts Explained

The intricate design of historic locomotives showcases a remarkable synergy of engineering and creativity. Each element plays a crucial role in the overall function, ensuring that these majestic machines operate seamlessly. This section aims to explore the various elements that contribute to the movement and efficiency of these powerful vehicles.

Through a detailed exploration of the key mechanisms involved, we will uncover the significance of each component in maintaining performance and safety. From the driving force to the support structures, every segment is meticulously crafted to endure the demands of travel over diverse terrains.

Additionally, visual representations will enhance our understanding of how these components interconnect. By breaking down the complexities of these mechanical wonders, we can gain a deeper appreciation for the innovation that powers them and the craftsmanship involved in their construction.

Understanding Steam Train Components

The intricate machinery of locomotives is a marvel of engineering, comprising various elements that work harmoniously to facilitate movement. Each component plays a critical role in ensuring efficient operation, contributing to the overall functionality of these impressive vehicles.

| Component | Function |

|---|---|

| Boiler | Generates steam by heating water. |

| Cylinders | Convert steam pressure into mechanical energy. |

| Valves | Regulate the flow of steam and exhaust. |

| Chassis | Supports the entire structure and components. |

| Drive Wheels | Transmit power to the track for movement. |

Each element is vital, forming a cohesive system that showcases the ultimate ingenuity of locomotive design.

Historical Significance of Steam Trains

The advent of powered locomotion marked a transformative era in transportation, reshaping economies and societies. These remarkable machines not only facilitated the movement of goods and people but also served as a catalyst for industrial growth and urbanization.

Economic Impact

The introduction of these powerful vehicles enabled faster trade routes, reducing travel time significantly. This efficiency allowed industries to flourish, creating jobs and stimulating local economies.

Cultural Influence

Beyond economics, these locomotives became symbols of progress and innovation, inspiring literature, art, and music. They connected distant communities, fostering cultural exchanges that enriched societies.

| Aspect | Significance |

|---|---|

| Economic Growth | Boosted trade and industry |

| Urbanization | Facilitated city expansion |

| Cultural Exchange | Enhanced connectivity between regions |

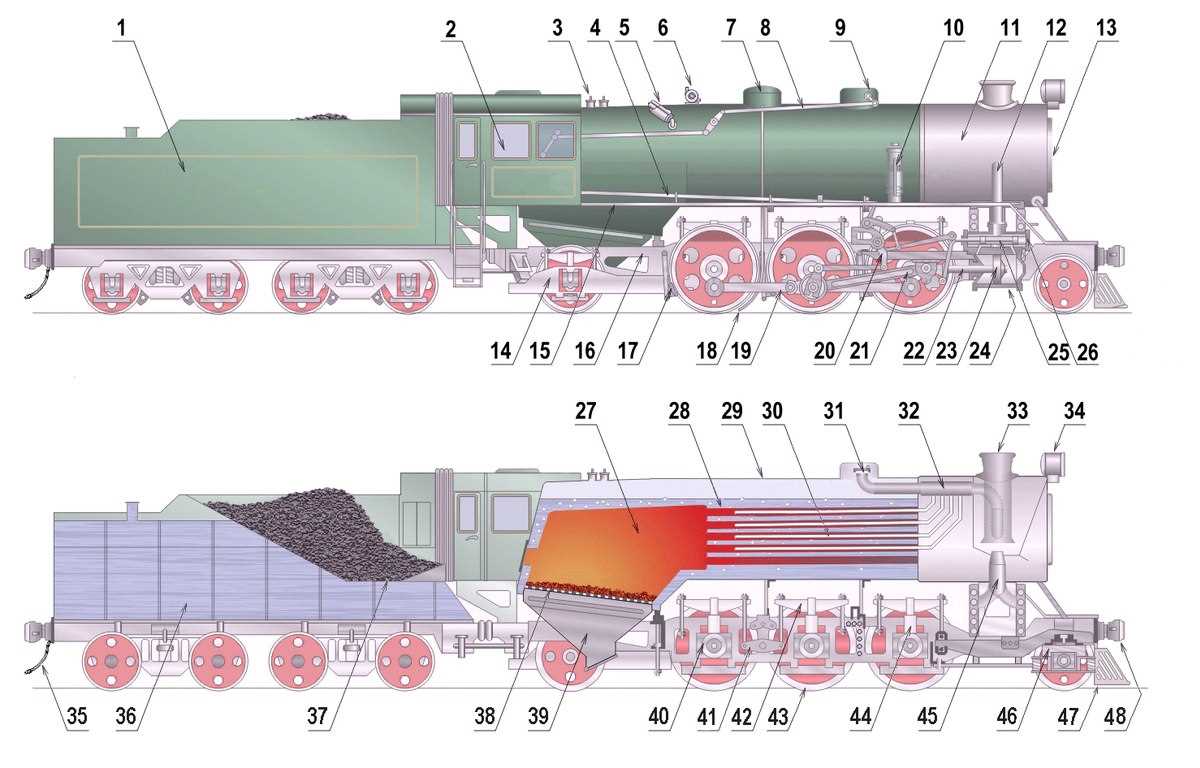

Main Parts of a Steam Engine

The operation of a locomotive relies on several essential components, each contributing to its overall functionality and efficiency. Understanding these key elements provides insight into how this powerful machine harnesses energy to produce movement.

Key Components

- Boiler

- Piston

- Cylinder

- Connecting Rod

- Crankshaft

Supporting Mechanisms

- Fuel Supply System

- Water Tank

- Safety Valve

- Exhaust System

Each of these elements plays a crucial role in the overall performance and efficiency of the machine, showcasing the intricate design and engineering behind its operation.

How Steam Locomotives Function

This section explores the intricate workings of a powerful machine that revolutionized transportation. Understanding its operation involves examining various components that work together harmoniously to create movement and efficiency.

Basic Principles of Operation

The core principle behind this mechanism lies in the conversion of thermal energy into mechanical energy. Here’s how it typically functions:

- Heat is generated by burning fuel.

- This heat converts water into high-pressure vapor.

- The vapor expands and pushes against movable surfaces, causing them to shift.

Key Components

Several crucial elements contribute to the overall functionality:

- Boiler: Generates the required vapor.

- Piston: Converts vapor pressure into linear motion.

- Connecting Rod: Transmits motion to wheels.

- Firebox: Where the fuel combustion occurs.

By delving into these fundamental aspects, one can appreciate the ultimate engineering marvel that facilitated advancements in travel and commerce.

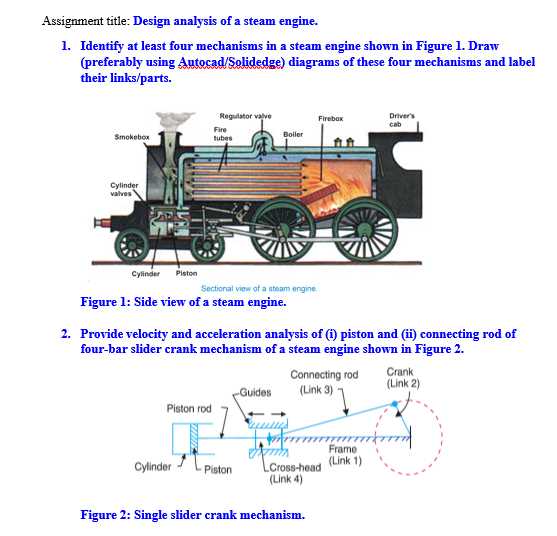

Diagrams: Visualizing Train Mechanics

Illustrative representations play a crucial role in understanding complex mechanical systems. They provide clarity and insight into the intricate workings of various components, making it easier for enthusiasts and professionals alike to grasp their functions and interrelations.

Importance of Visual Aids

Visual tools enhance comprehension and retention. Here are some benefits:

- Simplification of complex structures

- Identification of key elements

- Facilitation of learning and teaching

Types of Illustrative Representations

Different styles of visuals can be utilized to convey information:

- Technical drawings: Detailed representations showing precise dimensions.

- Schematic diagrams: Simplified outlines focusing on relationships and functions.

- Exploded views: Illustrations displaying components separated for clarity.

Boiler: The Heart of Steam Power

The boiler serves as a fundamental component in the generation of thermal energy, acting as a critical source of power for various machinery. Its ability to transform water into vapor under pressure allows for the efficient harnessing of energy, essential for propulsion and operation.

Key Functions

- Converts water into high-pressure vapor.

- Maintains optimal temperature and pressure levels.

- Distributes heat energy to other systems.

Components of a Boiler

- Shell: The outer casing that contains the water and vapor.

- Furnace: The area where fuel combustion occurs.

- Heat Exchanger: Transfers heat from combustion gases to water.

- Safety Valve: Prevents excessive pressure build-up.

Driving Wheels and Their Role

Driving wheels are crucial components in the mechanism of locomotion, providing the necessary traction and support for movement. Their design and functionality significantly impact performance and efficiency.

These wheels are typically larger and more robust than other wheels, enabling the vehicle to generate the required force for acceleration and maintaining speed. The interaction between the driving wheels and the track is fundamental in achieving optimal movement.

| Feature | Importance |

|---|---|

| Size | Influences traction and speed capabilities. |

| Material | Affects durability and weight distribution. |

| Configuration | Determines stability and handling characteristics. |

Understanding the role of these wheels allows for a deeper appreciation of their significance in mechanical design and functionality.

Understanding the Firebox System

The firebox is a crucial component in the operation of locomotives, playing a vital role in the generation of heat necessary for propulsion. It serves as the core area where fuel is combusted, allowing for the efficient transfer of energy to the surrounding water. This process is essential for creating steam, which ultimately powers the machinery.

Construction and Design

Typically made from robust materials, the firebox is designed to withstand extreme temperatures and pressures. Its structure must facilitate optimal airflow to enhance combustion efficiency. Additionally, the configuration of the firebox can significantly influence the overall performance of the engine.

Heat Transfer Mechanism

Within the firebox, heat is generated through the burning of various fuels, such as coal or wood. This intense heat warms the water in the adjacent boiler, producing steam that drives the pistons. The effectiveness of this heat transfer is crucial for maintaining operational efficiency.

Maintenance and Operation

Proper maintenance of the firebox is essential to ensure safe and effective operation. Regular inspections are necessary to check for any wear or damage that could affect its performance. Operators must also monitor fuel levels and combustion rates to optimize the heat generation process.

In summary, the firebox system is integral to the functionality of locomotives, requiring careful attention to design, operation, and maintenance to ensure optimal performance.

Connecting Rods and Motion Transfer

The efficiency of mechanical systems relies heavily on the effective transfer of motion between various components. One of the crucial elements in achieving this is a specific connecting mechanism that facilitates the conversion of linear movement into rotational force, enabling machinery to function smoothly and effectively.

Functionality and Design

The design of these connecting elements plays a significant role in their functionality. Key aspects include:

- Material selection for strength and durability

- Dimensions that match the requirements of the system

- Geometry that optimizes the transfer of energy

Types of Motion Transfer

In mechanical systems, different types of motion are often utilized. The primary methods include:

- Reciprocating motion: This involves back-and-forth movement, essential in various applications.

- Rotational motion: This is the circular movement that drives components such as gears and wheels.

Understanding how these mechanisms interact allows for better design and efficiency in any mechanical setup, ensuring that energy is transmitted with minimal loss.

Importance of the Cylinder Assembly

The cylinder assembly plays a pivotal role in the operation of a locomotive, serving as the heart of the propulsion system. This component transforms thermal energy into mechanical energy, making it essential for efficient performance. Its design and functionality directly impact the overall efficiency and reliability of the vehicle.

Functionality and Design

The assembly consists of several key elements working in harmony to ensure smooth operation. Each component is meticulously engineered to withstand high pressures and temperatures, contributing to the locomotive’s durability.

Impact on Performance

A well-maintained cylinder assembly significantly enhances the power output and fuel efficiency of the locomotive. Regular inspections and proper upkeep are crucial to maintaining its optimal functionality.

| Component | Function |

|---|---|

| Cylinder | Houses the piston and facilitates movement |

| Piston | Converts steam pressure into mechanical force |

| Rings | Ensure a tight seal to maintain pressure |

| Valves | Control the flow of steam into the cylinder |

Safety Features in Steam Trains

The journey of innovation in transportation has led to the implementation of various safety mechanisms designed to ensure the well-being of passengers and crew. These essential systems play a crucial role in minimizing risks and enhancing operational reliability, ultimately creating a secure environment during travel.

Fire Prevention and Detection

One of the primary concerns in this mode of transportation is the risk of fire. Fireboxes are equipped with advanced insulation materials to prevent heat escape, while smoke detectors and automatic extinguishing systems are integrated to swiftly manage any potential threats, ensuring safety at all times.

Braking Systems

Reliable stopping mechanisms are vital for safe operation. Air brakes and mechanical brakes are meticulously designed to provide responsive stopping power, while safety valves ensure optimal pressure management, allowing for seamless control and increased security throughout the journey.

Modern Applications of Steam Technology

In today’s world, the principles of thermal power generation have evolved, finding numerous applications across various industries. This approach harnesses heat to produce energy, enabling advancements in efficiency and innovation.

| Industry | Application | Benefits |

|---|---|---|

| Energy Production | Power plants | High efficiency, reduced emissions |

| Manufacturing | Process heating | Consistent temperature control |

| Food Processing | Cooking and sterilization | Improved safety and quality |

| Healthcare | Autoclaving | Effective sterilization |

These innovations illustrate the versatility and ongoing relevance of thermal technologies, shaping a sustainable future.