Sterling 10.25 Parts Diagram Explained

The intricate workings of mechanical systems often necessitate a comprehensive understanding of their structure. By visualizing how each segment interconnects, one can better appreciate the functionality and efficiency of the entire assembly. This exploration provides insights into the design and operational characteristics that underpin performance.

Every mechanical assembly comprises various elements that play pivotal roles in ensuring smooth operation. Recognizing the specific arrangement and relationship between these elements is essential for troubleshooting, maintenance, and enhancement of overall functionality. This section aims to illuminate those connections.

Through a detailed examination of the layout, enthusiasts and professionals alike can delve into the specifics of each component. The goal is to foster a deeper understanding that not only aids in repair and upkeep but also enhances appreciation for the engineering behind these sophisticated machines.

Understanding Sterling 10.25 Parts

Gaining insight into the components of a specific vehicle system is crucial for effective maintenance and repair. By exploring these elements, one can ensure optimal performance and longevity, enhancing overall functionality.

Key Components Overview

Each segment within the system plays a vital role, contributing to the seamless operation of the vehicle. Recognizing the interplay among these individual units allows for more informed decisions regarding upgrades and replacements.

Importance of Proper Maintenance

Regular inspection and understanding of each unit’s function can prevent costly repairs and improve safety. Ensuring that all elements are in top condition is the ultimate goal for any vehicle owner.

Overview of the Sterling 10.25

This section provides an in-depth look at a specific model renowned for its durability and performance. Designed for those who demand excellence in both functionality and construction, this model stands out in various applications. Understanding its structure and components is crucial for effective maintenance and optimal usage.

The model is particularly known for its robust design, catering to various industries and environments. Its components are engineered to ensure longevity and reliability, making it a preferred choice among professionals.

| Feature | Description |

|---|---|

| Durability | Engineered to withstand harsh conditions, ensuring long-term use. |

| Performance | Delivers consistent results, even under heavy loads. |

| Maintenance | Designed for easy servicing and part replacement, minimizing downtime. |

| Versatility | Applicable in multiple sectors, making it a valuable asset. |

In summary, this model exemplifies the balance between innovation and practical design, making it an essential choice for those seeking reliable equipment. Understanding its features can enhance operational efficiency and ensure the longevity of its use.

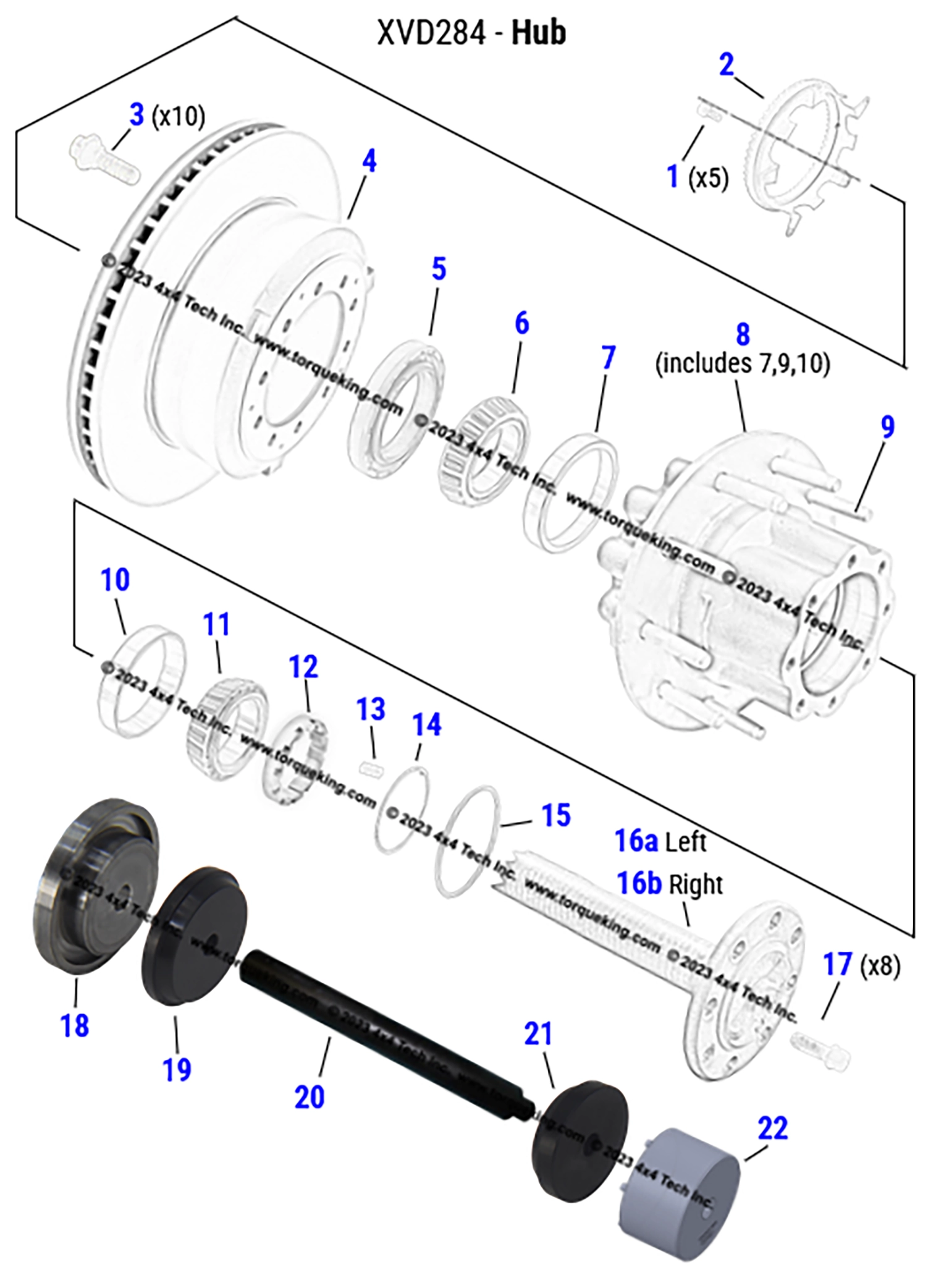

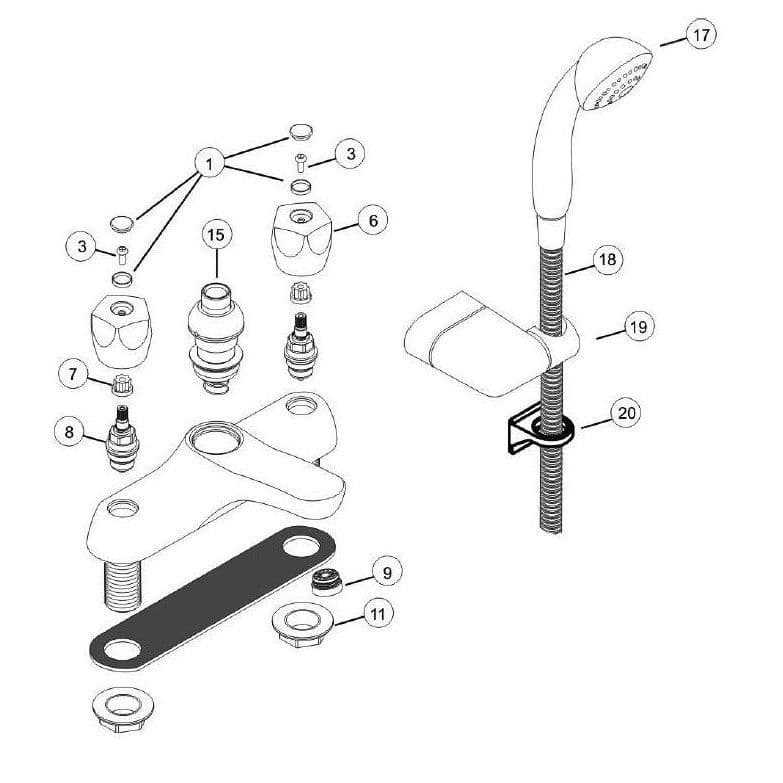

Importance of Parts Diagrams

Visual representations of components play a crucial role in understanding the intricate relationships and functions within a mechanical system. They serve as essential tools for technicians, engineers, and hobbyists alike, facilitating efficient assembly, maintenance, and troubleshooting processes. By clearly illustrating each element, these visual aids enhance comprehension and reduce the risk of errors during repairs or modifications.

Enhanced Understanding

Utilizing a visual layout enables users to grasp complex mechanisms quickly. It breaks down intricate systems into manageable sections, allowing individuals to focus on specific areas without being overwhelmed. This clarity promotes a deeper insight into how each element interacts, fostering better decision-making in maintenance and upgrades.

Efficient Troubleshooting

When issues arise, having a visual guide simplifies the diagnostic process. Users can identify faulty components swiftly, reducing downtime and improving overall productivity. Moreover, these illustrations assist in communicating problems effectively among team members, ensuring everyone is on the same page and leading to quicker resolutions.

Key Components of the Sterling 10.25

This section delves into the essential elements that contribute to the overall functionality and efficiency of a specific vehicle model. Understanding these fundamental parts is crucial for maintenance, repair, and performance enhancement.

Primary Elements

The core elements include the drivetrain, suspension system, and braking mechanisms. Each component plays a vital role in ensuring smooth operation and safety on the road. The drivetrain facilitates power transfer from the engine to the wheels, while the suspension system provides stability and comfort. Braking mechanisms are critical for controlling speed and ensuring timely stops.

Support Structures

In addition to the primary elements, various support structures enhance durability and performance. These include the chassis, which provides the framework for the vehicle, and electrical systems that power essential features. Together, these components create a harmonious balance, allowing for a reliable and efficient driving experience.

How to Read a Parts Diagram

Understanding a visual representation of components is crucial for effective assembly and maintenance. Such illustrations provide a clear overview of various elements, making it easier to identify each piece’s role and relation to others.

To navigate these illustrations successfully, follow these essential steps:

- Familiarize Yourself with the Legend: Most visuals include a legend or key. This section explains symbols and color codes used, helping you decipher the meanings.

- Identify Major Components: Start by locating the primary elements. These often serve as the foundation for understanding how smaller parts connect and function.

- Trace Connections: Pay attention to lines or arrows indicating how components interact. This can reveal the flow of operation or assembly sequence.

- Note Any Annotations: Look for notes or labels that provide additional information. These can include part numbers, specifications, or installation tips.

- Review Related Sections: If available, check adjoining areas that might reference complementary components. This can broaden your understanding of the entire system.

By following these guidelines, you can effectively interpret visual representations of components, enhancing your ability to work with complex assemblies or systems.

Common Issues with Sterling 10.25

Understanding the frequent challenges associated with this particular axle model can help users maintain performance and extend longevity. Here are some typical problems encountered:

- Leaking Seals: Often, users report fluid leaks, primarily due to worn or damaged seals.

- Noise Issues: Unusual sounds can indicate underlying wear in components, requiring immediate attention.

- Brake Performance: Decreased braking efficiency may stem from uneven wear or malfunctioning parts.

- Alignment Problems: Improper alignment can lead to uneven tire wear and handling difficulties.

Addressing these issues promptly can prevent further complications and ensure optimal functionality.

Maintenance Tips for Longevity

Ensuring the durability of your equipment requires regular attention and care. By following a few simple practices, you can significantly extend the lifespan of your machinery and keep it operating smoothly. Proactive maintenance not only prevents unexpected failures but also enhances overall efficiency.

Regular Inspections

Conducting frequent checks on your equipment helps identify wear and tear early. Look for any signs of damage or irregularities that could lead to larger issues. Pay special attention to areas prone to friction or heat buildup, as these are often the first to show signs of stress.

Proper Lubrication

Using the right lubricants and applying them regularly is crucial for minimizing friction between moving components. Ensure that you follow the manufacturer’s recommendations regarding the type and frequency of lubrication. Keeping all parts well-lubricated reduces wear and maintains efficiency, leading to a longer operational life.

Finding Replacement Parts Easily

Locating suitable components for your machinery can often feel like a daunting task. However, with the right approach and resources, you can streamline the process significantly. This section offers insights into effective strategies to ensure you acquire the necessary items without unnecessary hassle.

Utilize Online Resources: The internet is a treasure trove of information. Websites dedicated to machinery supply, forums, and community groups can provide invaluable support. These platforms often have detailed specifications and reviews that can help you identify the right component.

Consult with Experts: Engaging with professionals who have extensive knowledge in your specific field can save you time and effort. Mechanics, engineers, or specialists often have recommendations for reliable suppliers and can guide you on compatibility and quality.

Make Use of Catalogs: Many manufacturers provide comprehensive catalogs that include detailed information about their offerings. These resources often feature diagrams and specifications that make it easier to pinpoint the exact item you need.

Networking: Connecting with other enthusiasts or professionals in your area can lead to valuable recommendations. Networking often opens doors to discovering lesser-known suppliers or even second-hand options that might suit your requirements.

By leveraging these methods, you can enhance your chances of finding the correct items efficiently, ensuring that your machinery remains in optimal condition.

Benefits of Using Official Diagrams

Utilizing authorized illustrations offers numerous advantages, ensuring accuracy and reliability in technical contexts. These resources are designed to provide clarity and enhance understanding, making complex systems more accessible for users.

| Advantage | Description |

|---|---|

| Accuracy | Official resources are meticulously created to reflect the precise specifications of components. |

| Reliability | Using sanctioned illustrations reduces the risk of errors associated with unofficial sources. |

| Consistency | Authorized visuals maintain uniformity across documentation, facilitating easier comprehension. |

| Time-saving | Accessing well-organized information expedites troubleshooting and maintenance processes. |

| Enhanced Learning | These illustrations aid in the education of users, allowing for a deeper grasp of systems. |

Comparing with Other Models

When examining various designs within the same category, it becomes evident that differences in functionality, efficiency, and structural composition can greatly impact user experience. Each model brings unique features that cater to different preferences and requirements, making the comparison essential for informed decision-making.

Key Differences

- Design Complexity: Some models feature intricate configurations, offering advanced capabilities, while others focus on simplicity and ease of use.

- Material Quality: Variations in construction materials can influence durability and maintenance needs.

- Performance Metrics: Speed, load capacity, and energy efficiency are critical factors that distinguish these systems.

Market Positioning

- Target Audience: Different models are tailored for specific user groups, ranging from casual users to professionals.

- Price Range: Pricing strategies vary widely, impacting accessibility and perceived value.

- Brand Reputation: Established brands may offer reliability and customer support, while newer entrants might emphasize innovation and cost-effectiveness.

By analyzing these aspects, potential users can better navigate their options, ensuring they choose a system that aligns with their needs and expectations.

Resources for Further Information

For those seeking to expand their knowledge on specific components and assembly details, numerous resources are available to provide comprehensive insights. Whether you are a professional technician or an enthusiastic hobbyist, these references can enhance your understanding and facilitate effective maintenance.

- Manufacturer Manuals: Official guides often contain in-depth information about the assembly, operation, and maintenance of equipment.

- Online Forums: Community platforms allow users to exchange experiences, troubleshooting tips, and advice related to various models.

- Technical Websites: Dedicated sites may offer extensive articles, tutorials, and video guides for visual learners.

- Trade Publications: Journals and magazines focusing on automotive technology frequently include reviews, comparisons, and expert insights.

- Workshops and Webinars: Participating in educational sessions can provide practical knowledge and networking opportunities with industry experts.

By utilizing these resources, individuals can gain valuable expertise, ensuring they are well-equipped to handle any challenges related to their equipment.