Comprehensive Guide to Stiga P901 Parts Diagram

When it comes to maintaining and optimizing your machinery, having a clear understanding of its individual elements is crucial. Each component plays a significant role in ensuring the overall functionality and efficiency of the system. By familiarizing yourself with these parts, you can enhance performance, troubleshoot issues, and extend the lifespan of your equipment.

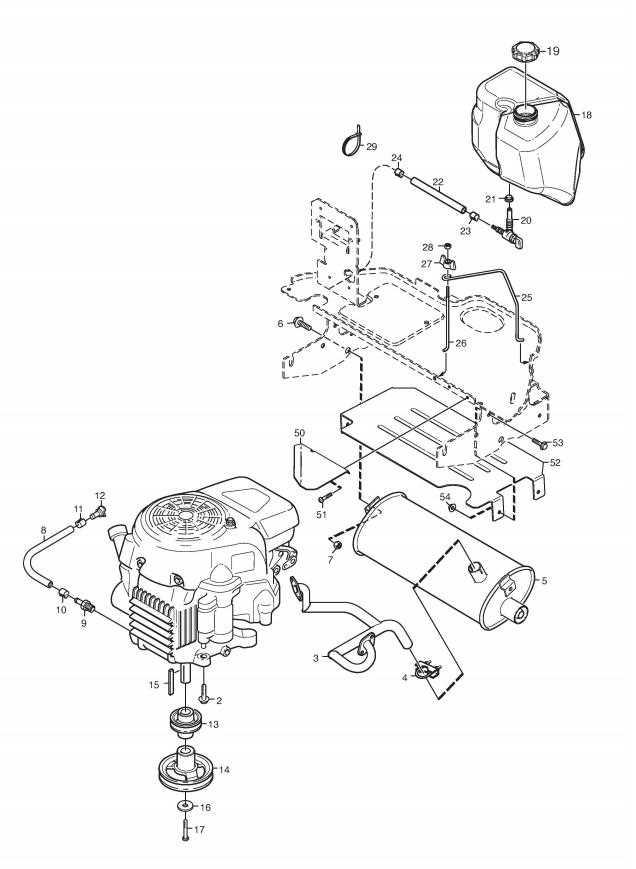

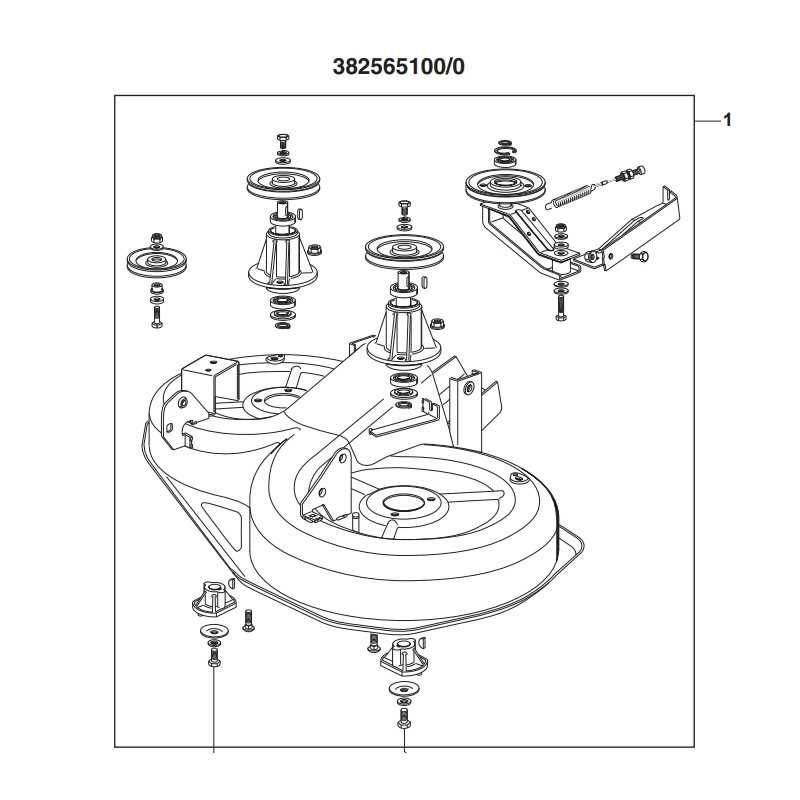

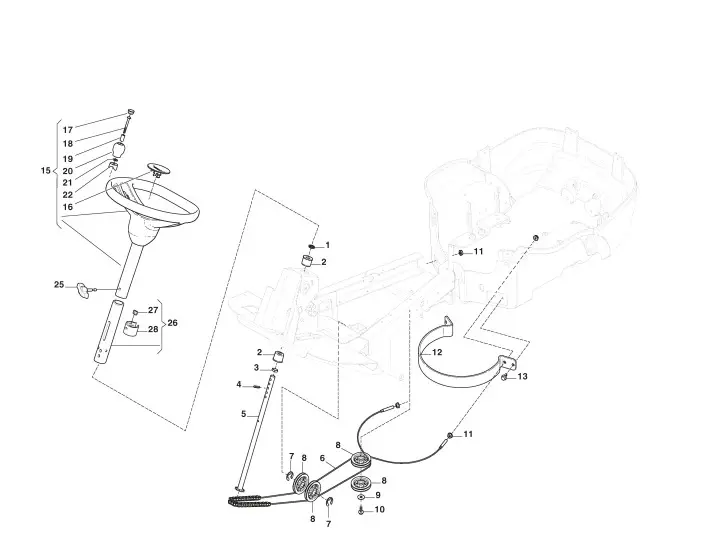

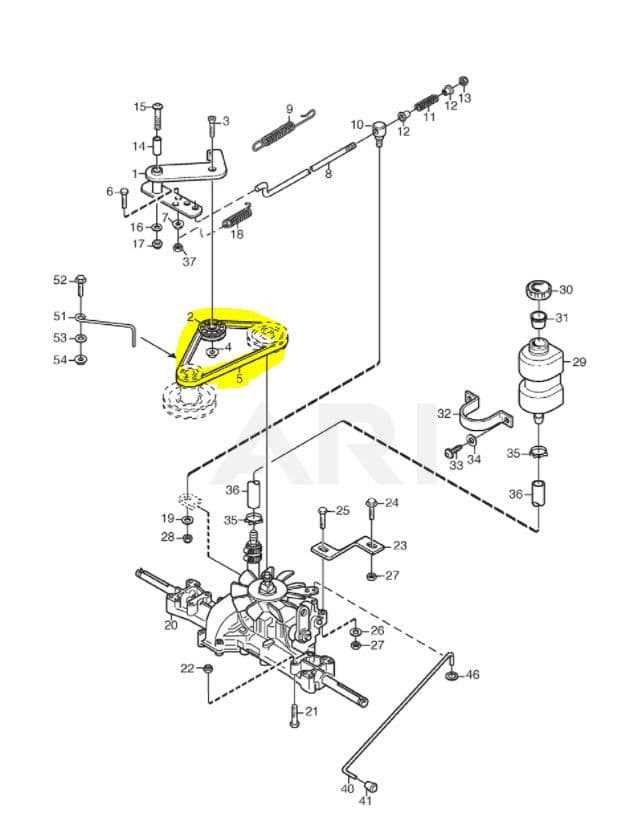

Exploring the intricate layout of these elements not only aids in effective repairs but also empowers users to make informed decisions regarding upgrades or replacements. Visual representations of the assembly provide valuable insights, allowing for a deeper comprehension of how each section interrelates within the complete structure. Such knowledge is essential for anyone looking to maximize the potential of their devices.

In this article, we will delve into the specific arrangements of these components, highlighting their functions and interactions. Whether you are a seasoned technician or a novice user, understanding this assembly will enhance your ability to work efficiently and confidently with your equipment.

Understanding Stiga P901 Components

Exploring the intricacies of a machine’s elements is essential for optimal performance and maintenance. Familiarity with individual components enhances functionality and ensures longevity. This section delves into the various elements, their roles, and the importance of understanding them for effective operation.

Key components of such machinery typically include:

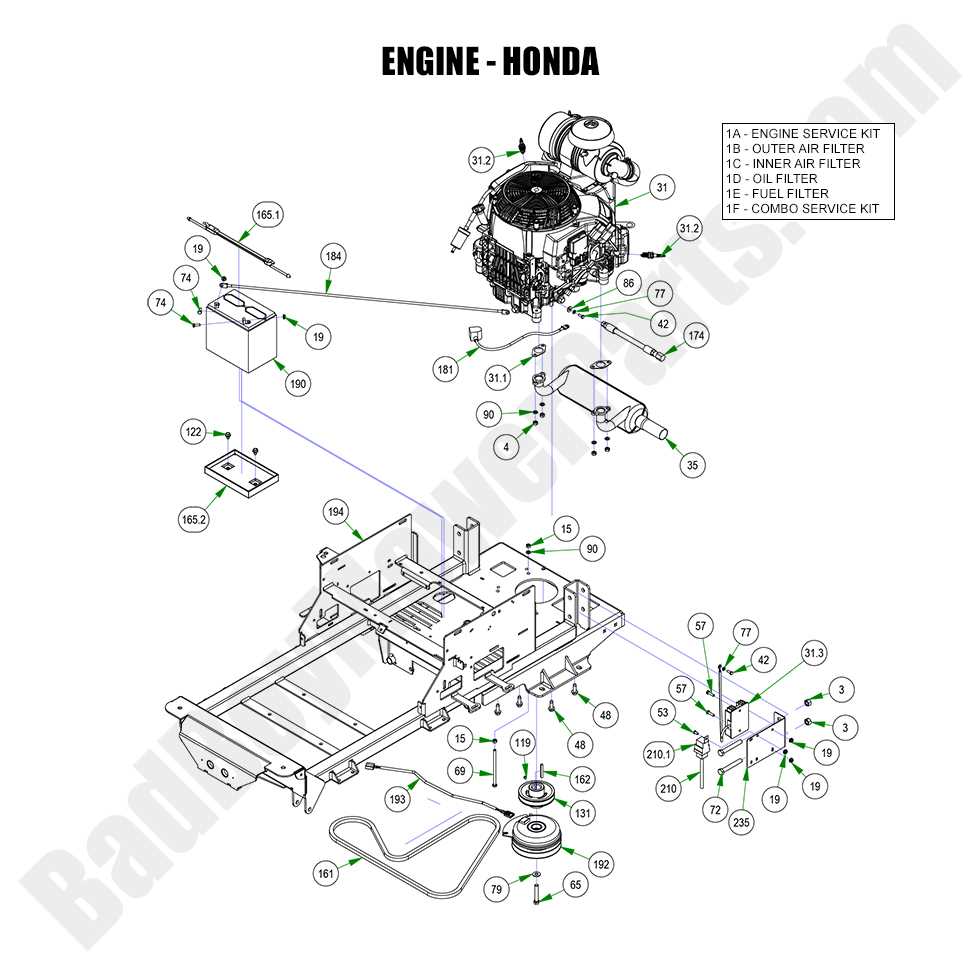

- Engine: The powerhouse that drives all functions, providing the necessary energy for operation.

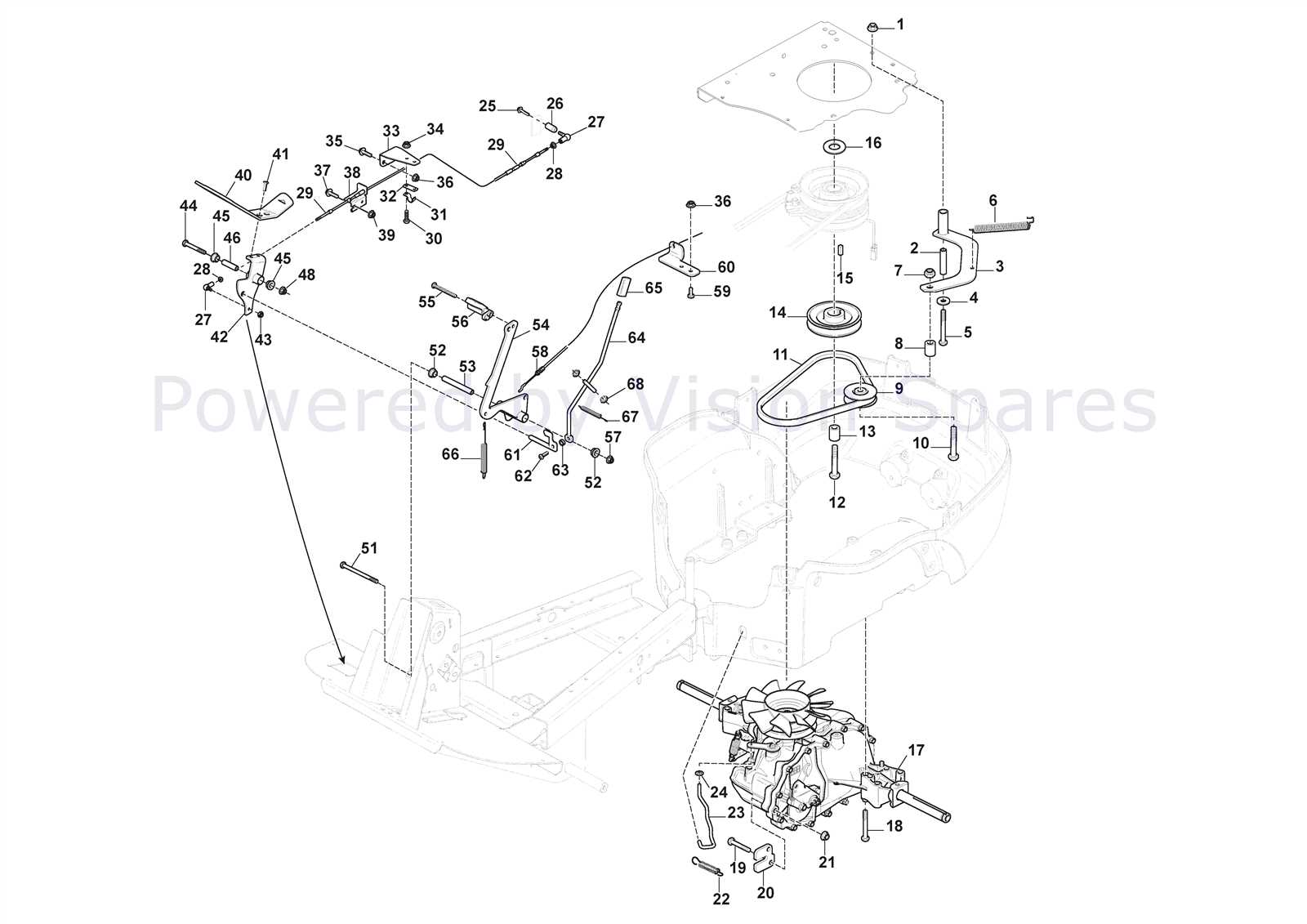

- Transmission: Responsible for transferring power from the engine to the wheels, affecting speed and maneuverability.

- Chassis: The framework that supports the entire structure, ensuring stability and durability.

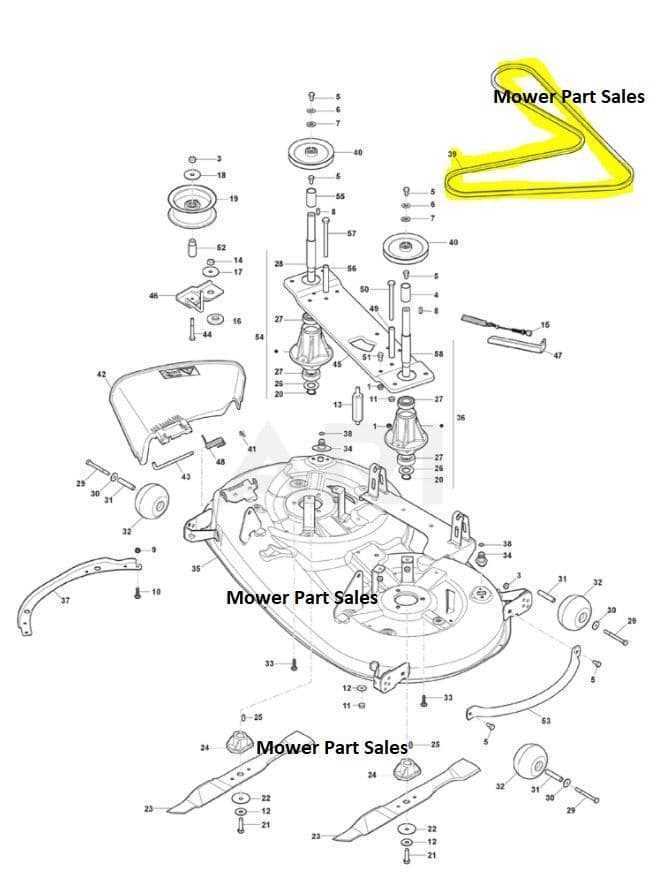

- Cutting System: Essential for achieving desired results in maintenance tasks, this system includes blades and adjustments for height and angle.

- Wheels and Tires: Crucial for traction and movement across various terrains, impacting overall performance.

Understanding the function of each element allows operators to make informed decisions regarding maintenance and repairs. Proper care can prevent breakdowns and enhance the efficiency of the machine. Regular inspections of these components help identify potential issues before they escalate, ensuring seamless operation.

In summary, a comprehensive grasp of the various elements involved is fundamental for anyone looking to optimize their machine’s performance and extend its lifespan. Familiarity with the key components allows for better troubleshooting and maintenance practices.

Importance of Parts Diagrams

Understanding the intricacies of mechanical systems is crucial for effective maintenance and repair. Visual representations that illustrate the various components and their relationships play a vital role in this process. They provide clarity and enhance comprehension, making troubleshooting more straightforward.

These illustrations serve several key purposes:

- Enhances Understanding: Clear visuals help users grasp the structure and function of each component.

- Facilitates Repair: Knowing how parts fit together simplifies the disassembly and reassembly process.

- Promotes Accuracy: Accurate identification of components minimizes the risk of errors during repairs.

- Streamlines Maintenance: Regular upkeep becomes more efficient when users can easily reference the layout of the system.

In summary, these visual aids are essential tools for anyone involved in the upkeep or repair of machinery, ensuring that tasks are completed efficiently and correctly.

Common Issues with Stiga P901

When it comes to maintaining outdoor equipment, users often encounter a variety of challenges that can hinder performance. Understanding these common problems can help in troubleshooting and ensuring longevity.

Frequent Problems

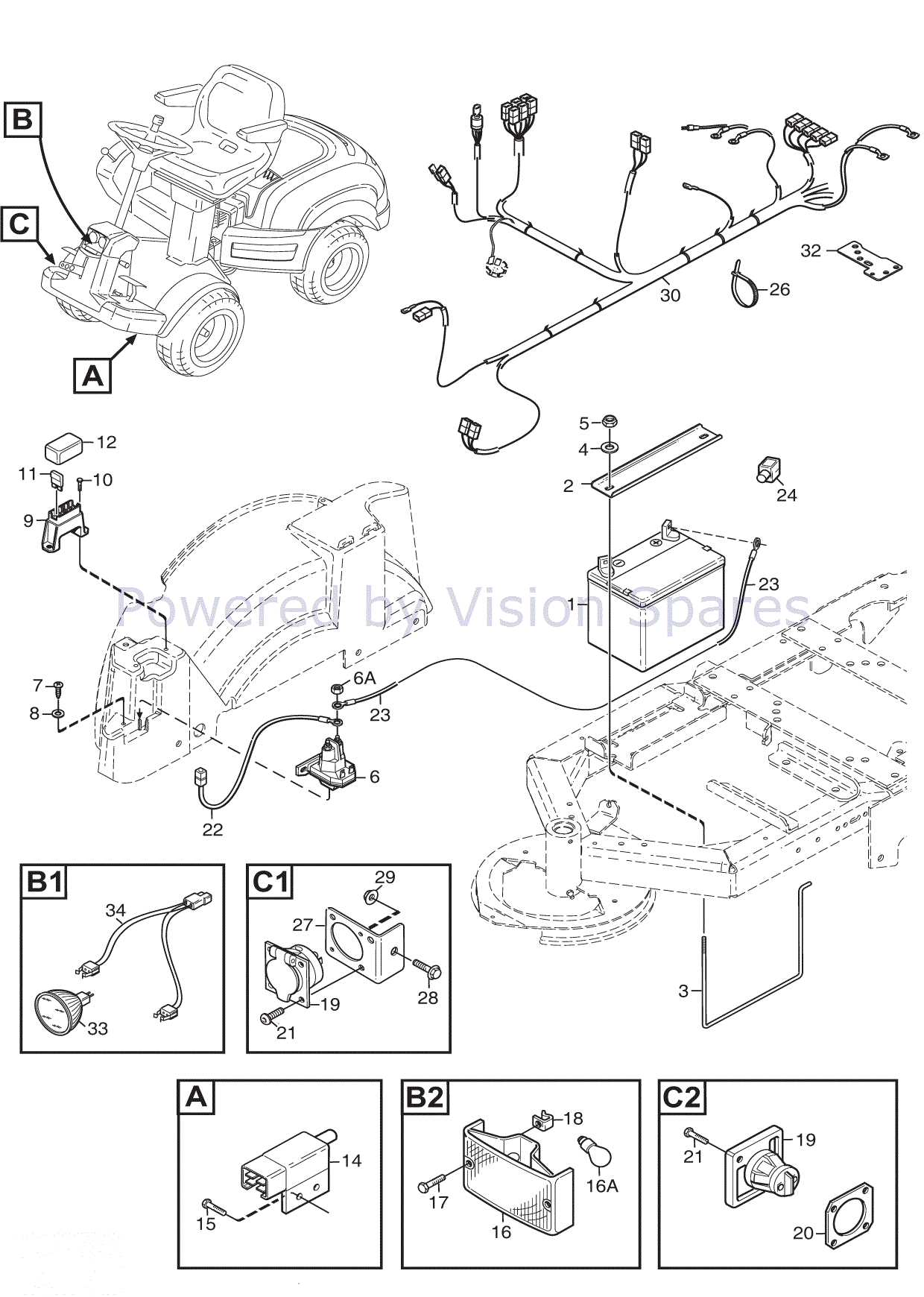

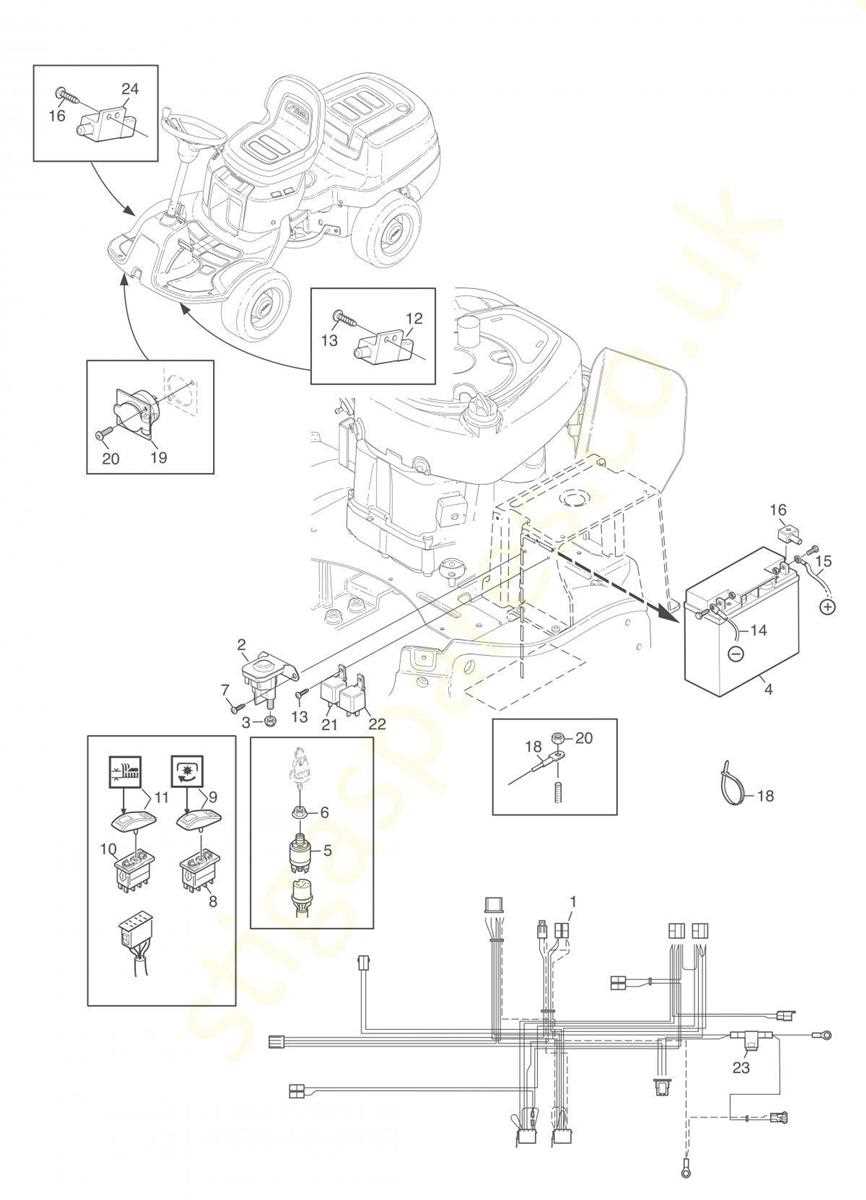

- Engine Starting Difficulties: Users may find that the engine fails to start, which can be due to fuel issues or ignition system failures.

- Overheating: Overheating can occur from insufficient cooling or clogged air filters, impacting overall efficiency.

- Uneven Cutting: This issue is often linked to dull blades or improper height adjustment, resulting in an unsatisfactory finish.

Troubleshooting Tips

- Check Fuel Levels: Ensure that the fuel is fresh and properly mixed, as stale fuel can cause starting issues.

- Inspect Air Filters: Regularly clean or replace air filters to prevent overheating and maintain optimal airflow.

- Sharpen or Replace Blades: Keeping blades sharp is essential for effective cutting; consider sharpening or replacing them as needed.

Where to Find Diagrams Online

Locating detailed schematics for various equipment has become increasingly convenient thanks to the vast resources available on the internet. Whether you are looking to repair, assemble, or understand your machinery better, numerous websites offer comprehensive visual guides that cater to different needs. These resources can help you identify components and their arrangement, making maintenance tasks simpler and more efficient.

Manufacturer Websites: The official sites of equipment manufacturers often host a wealth of information, including manuals and illustrations. These resources are typically the most reliable, as they come directly from the source.

Online Forums and Communities: Engaging with user forums can provide valuable insights. Enthusiasts and professionals alike often share diagrams, tips, and modifications that can enhance your understanding of specific models.

Third-Party Retailers: Many retailers specializing in machinery parts and accessories maintain extensive libraries of schematics on their platforms. These illustrations are often accompanied by part numbers, making it easier to order replacements.

DIY and Repair Websites: Numerous websites dedicated to home improvement and repair feature sections specifically for machinery. Here, you can find user-generated content, including diagrams, repair guides, and instructional videos that can aid in troubleshooting.

Social Media and Video Platforms: Platforms like YouTube and Instagram are rich with visual content. Many creators post detailed walkthroughs, showcasing parts and their functions, which can serve as a valuable supplementary resource.

By exploring these avenues, you can access a wide array of visual aids that enhance your ability to work with your equipment confidently and effectively.

How to Read a Parts Diagram

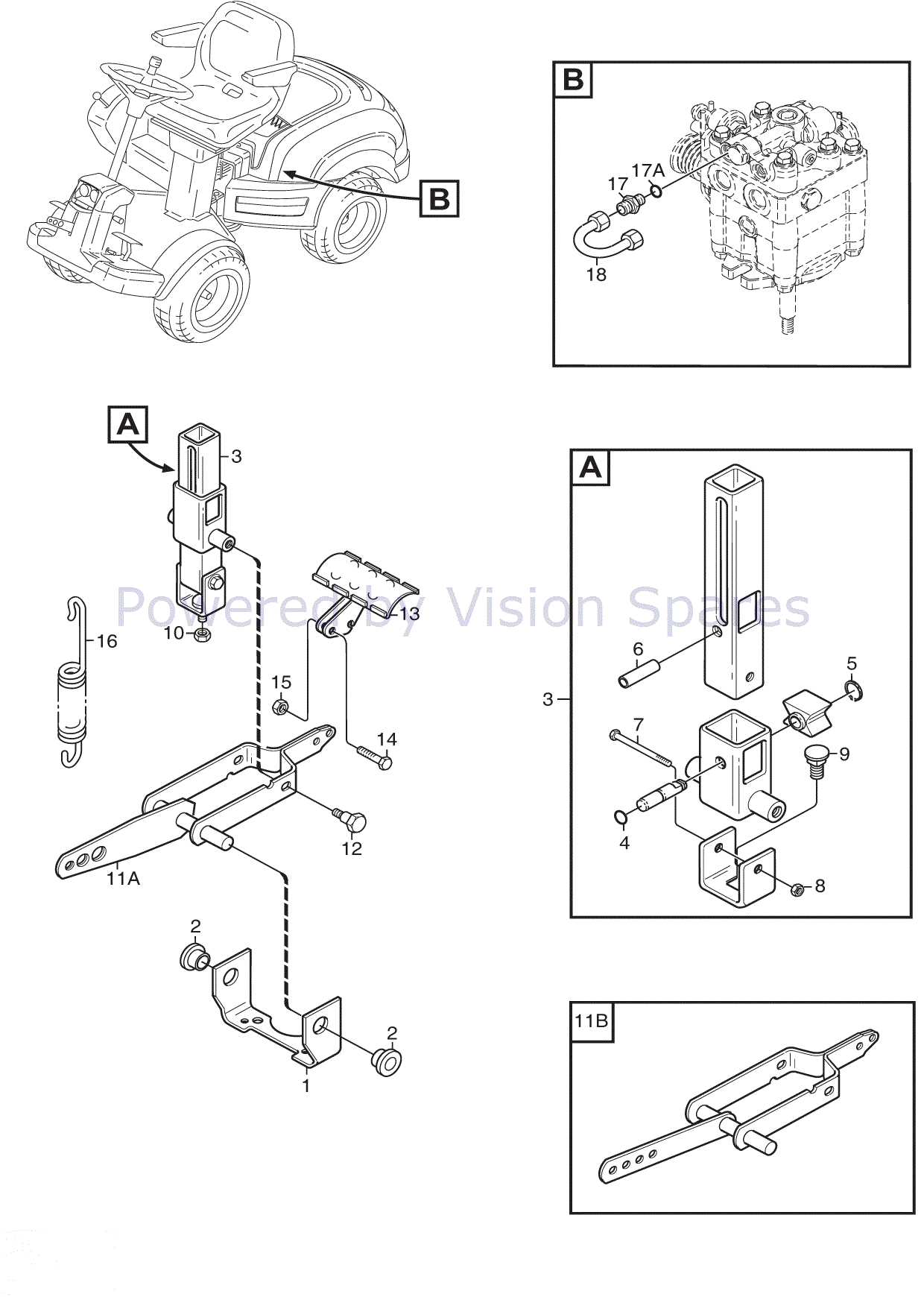

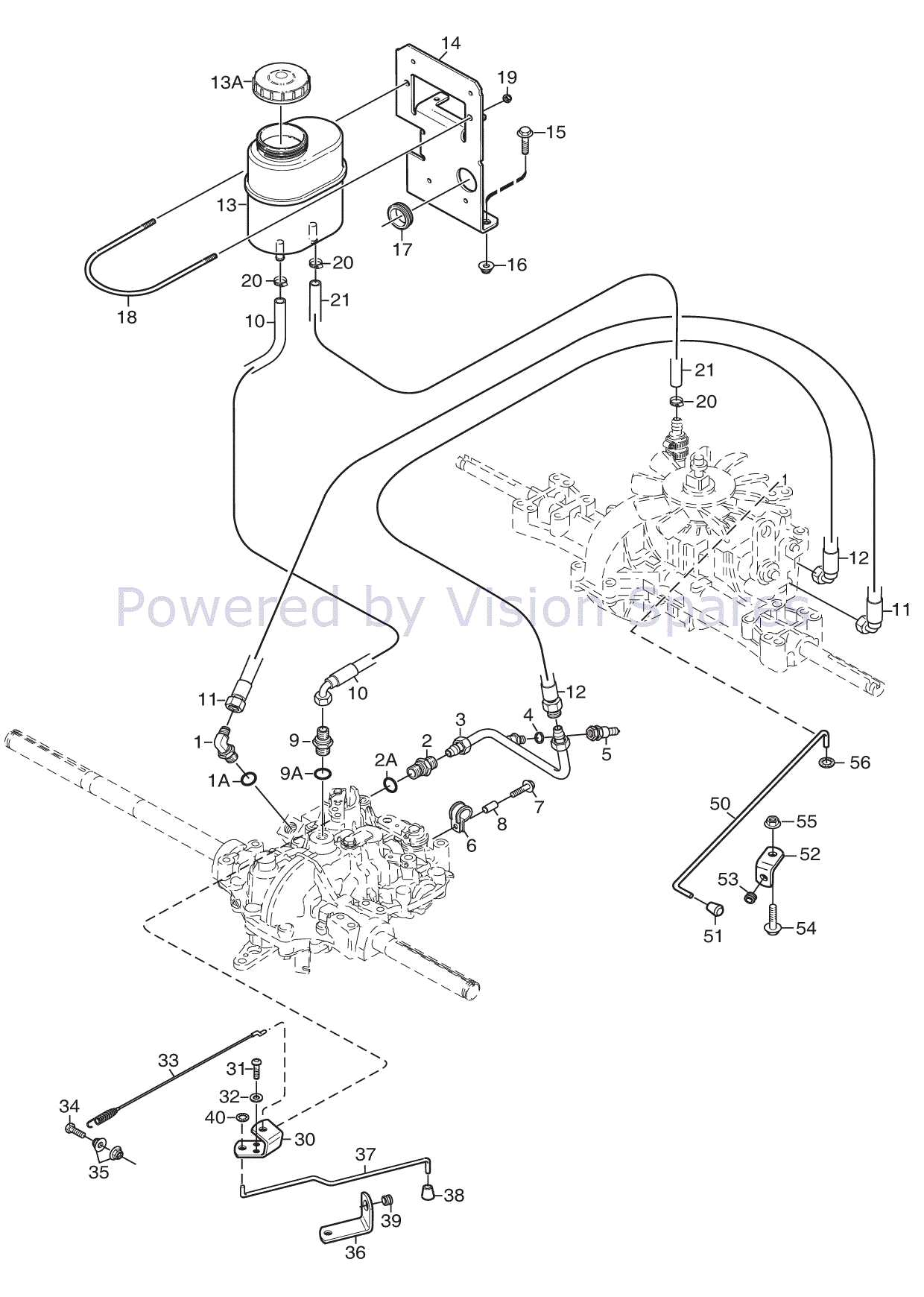

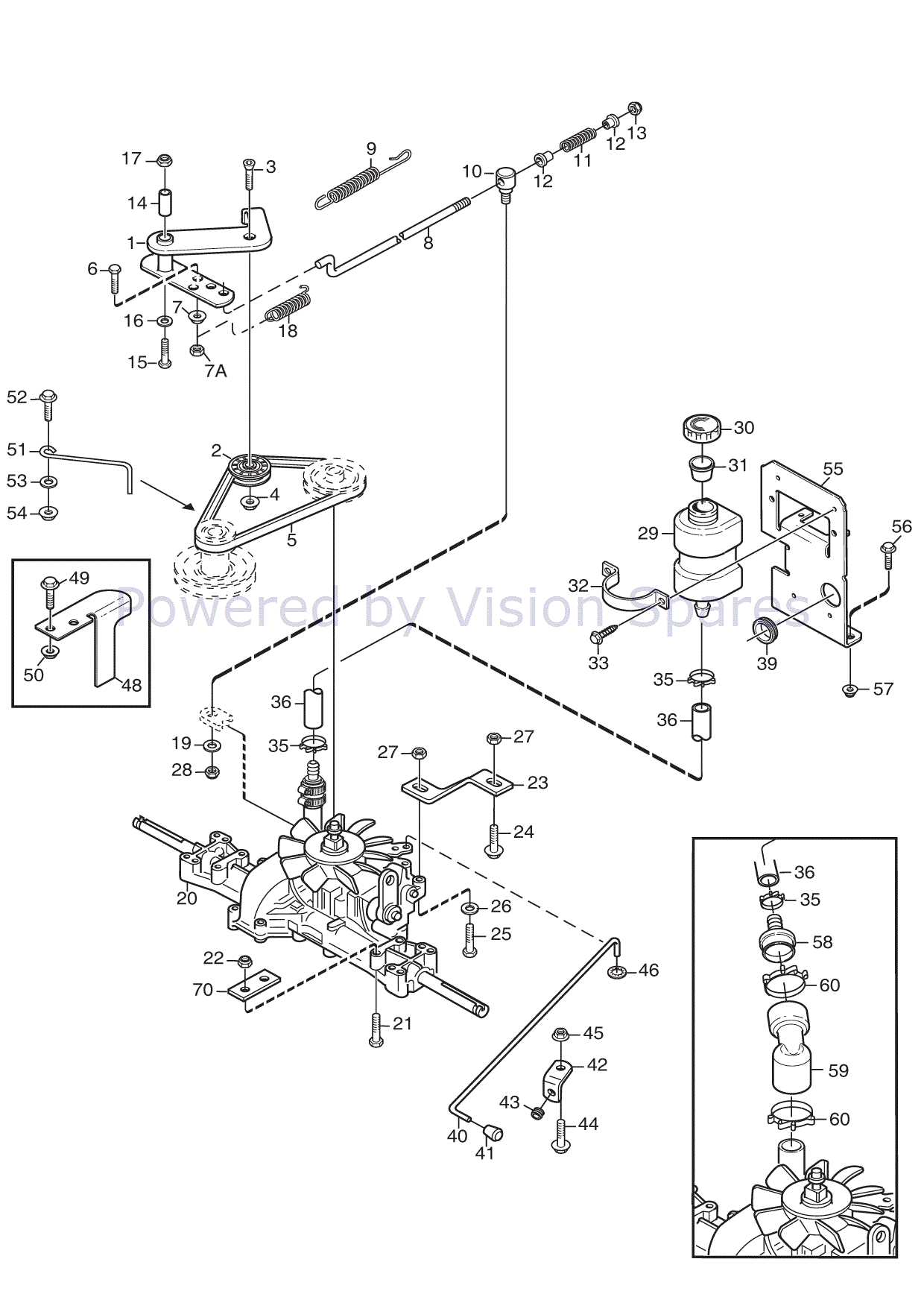

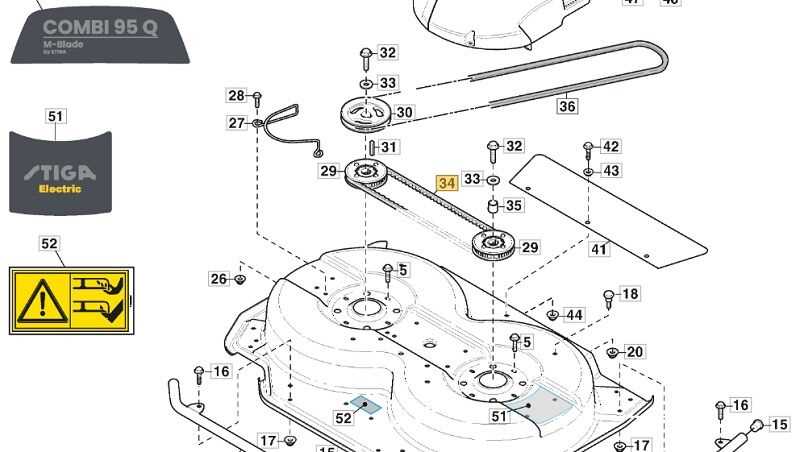

Understanding an assembly illustration can greatly enhance your ability to identify components and their functions within a system. These visual representations serve as a crucial guide, allowing you to navigate the intricate relationships between different elements.

First, familiarize yourself with the legend or key that often accompanies such visuals. This section usually explains symbols, numbers, and color codes that are essential for accurate interpretation. Pay close attention to these details, as they provide context and clarity.

Next, analyze the layout of the illustration. Components are typically arranged in a logical sequence, which can help you trace the assembly process. Look for lines connecting parts, indicating relationships or assembly order. Noting these connections can assist in understanding how each piece interacts within the overall mechanism.

Additionally, take note of any annotations or labels included in the visual. These often provide valuable information regarding specifications, such as size or material, and can guide you in sourcing replacements. Highlighting these details in your notes can streamline your repair or maintenance tasks.

Finally, practice makes perfect. The more you engage with these visuals, the easier it becomes to interpret them. Regular exposure will help you develop an intuitive understanding, allowing you to tackle repairs and modifications with confidence.

Essential Tools for Repairs

When it comes to maintaining and restoring equipment, having the right instruments at your disposal is crucial. These tools not only facilitate efficient repairs but also ensure safety and precision throughout the process. Understanding which implements are necessary can make all the difference in achieving a successful outcome.

First and foremost, a quality screwdriver set is indispensable. Various types and sizes of screwdrivers allow for the removal and installation of screws in different applications. Additionally, a reliable wrench set is essential for loosening and tightening nuts and bolts. The versatility of both tools makes them fundamental for any repair task.

Another important category includes cutting tools. Utility knives and wire cutters can help in modifying components as needed. Furthermore, a multimeter is invaluable for diagnosing electrical issues, providing readings that guide the repair process.

To ensure that all parts fit together smoothly, having a measuring tape and a level is advisable. These tools help in achieving precise alignments and measurements, contributing to the overall effectiveness of the repair.

Lastly, a good workbench equipped with proper lighting and organization can enhance efficiency. This dedicated workspace allows for focus and minimizes the risk of losing essential items during repairs.

Identifying Replacement Parts

When it comes to maintaining outdoor equipment, understanding how to find the right components is crucial. Ensuring that each element functions correctly not only enhances performance but also extends the lifespan of the machinery. This section focuses on effective strategies for recognizing and sourcing the necessary elements for your devices.

Steps to Identify Components

- Examine the Equipment

- Look for model numbers or identification labels.

- Check for any unique characteristics that may distinguish your item.

- Consult the manual for a detailed list of components.

- Use diagrams provided in the manual to visualize the assembly.

- Visit manufacturer websites for additional documentation.

- Explore forums or community groups for advice from fellow users.

Where to Find Replacement Elements

- Authorized Dealers

- Online Retailers

- Local Repair Shops

- Second-Hand Marketplaces

By following these steps and utilizing available resources, you can efficiently identify and acquire the components needed for optimal functionality of your equipment.

Maintenance Tips for Longevity

Regular upkeep is essential for ensuring the extended life of any equipment. By adopting a systematic approach to care, users can enhance performance and prevent premature wear and tear. This section outlines key practices that contribute to the durability and reliability of your machinery.

1. Clean After Use: Always remove dirt, debris, and residues after every use. Keeping the exterior and moving parts clean reduces the risk of damage and corrosion.

2. Regular Inspections: Schedule frequent checks to identify any signs of wear or potential issues early. Look for loose connections, frayed wires, or any unusual noises during operation.

3. Lubrication: Apply appropriate lubricants to moving parts as recommended in the user manual. Proper lubrication minimizes friction and helps components operate smoothly.

4. Follow Manufacturer Guidelines: Adhere strictly to the maintenance schedule outlined in the user manual. This ensures all necessary services are performed on time, maximizing lifespan.

5. Store Properly: When not in use, store the equipment in a dry, sheltered area to protect it from harsh weather conditions. Covering it can also prevent dust accumulation.

6. Use Quality Fuel and Oils: Utilize recommended fuels and oils that meet quality standards. Poor quality products can lead to decreased performance and potential damage.

7. Keep It Dry: Moisture can lead to rust and other forms of corrosion. Always ensure that components are dry before storing or using the equipment.

By implementing these straightforward maintenance strategies, users can significantly enhance the longevity of their machinery, ensuring reliable performance for years to come.

Comparison with Similar Models

In the realm of outdoor equipment, understanding the nuances between various models can significantly impact user experience and performance. By evaluating similarities and differences, consumers can make informed decisions tailored to their specific needs. This section delves into how comparable devices stack up against each other, highlighting key features and functionalities.

Design and Build Quality

Many alternatives exhibit robust construction, often utilizing high-grade materials that ensure durability. However, certain models may prioritize weight reduction, making them easier to maneuver but potentially sacrificing sturdiness. Evaluating the balance between these aspects is crucial for users seeking longevity versus ease of use.

Performance and Efficiency

When assessing operational capabilities, some devices may offer superior power output, translating to quicker results and increased efficiency. Conversely, others might focus on fuel economy or lower emissions, appealing to environmentally conscious users. A thorough comparison of performance metrics can help identify the best option for various applications.

Ordering Parts from Official Sources

When it comes to maintaining or repairing your equipment, sourcing components directly from authorized providers ensures quality and compatibility. This approach not only guarantees that the items you receive meet the necessary standards but also supports the longevity and performance of your machinery.

Identifying Authorized Dealers is the first step in the process. Visit the official website of the manufacturer to find a list of licensed distributors. These dealers are equipped with the most accurate and up-to-date inventory, allowing you to find exactly what you need without hassle.

Another important factor is considering warranty implications. Purchasing from certified sources often safeguards your warranty rights, protecting your investment in the long run. Always check the terms and conditions related to your warranty before making any purchases.

Online platforms have become increasingly popular for ordering components, providing convenience and a wide range of options. Many manufacturers offer e-commerce solutions where you can easily navigate through categories and specifications to find the necessary items.

Lastly, customer support is an invaluable resource. Official channels usually provide assistance in identifying the correct components, ensuring that you have the right specifications for your needs. Don’t hesitate to reach out to them for guidance; their expertise can save you time and prevent errors.

DIY Repair vs. Professional Help

When faced with a malfunctioning device, individuals often grapple with the decision of whether to tackle the repairs themselves or seek assistance from a professional. Both options come with their own set of advantages and disadvantages that can influence the outcome of the repair process.

Choosing the DIY route can be appealing for several reasons:

- Cost savings: Handling repairs independently often reduces labor costs.

- Flexibility: DIY repairs can be scheduled at the owner’s convenience.

- Satisfaction: Successfully fixing an issue can provide a sense of accomplishment.

However, there are also challenges associated with self-repair:

- Knowledge gap: Lack of expertise may lead to improper fixes.

- Time-consuming: Finding solutions and completing repairs can take considerable time.

- Risk of further damage: Incorrect handling might exacerbate the original problem.

On the other hand, seeking professional help presents its own benefits:

- Expertise: Professionals possess specialized knowledge and experience.

- Efficiency: Repairs are typically completed faster by skilled technicians.

- Warranty protection: Many services offer guarantees on their work, providing peace of mind.

Yet, relying on experts also comes with downsides:

- Higher costs: Professional services can be significantly more expensive than DIY options.

- Dependency: Owners may feel less empowered to understand their own devices.

- Scheduling issues: Finding a suitable time for a technician can be inconvenient.

Ultimately, the choice between self-repair and hiring a professional depends on individual circumstances, including skill level, budget, and the complexity of the issue at hand.

FAQs About Stiga P901 Parts

This section addresses common inquiries regarding components and accessories for a specific model of outdoor equipment. Understanding these elements can enhance maintenance and performance, ensuring optimal use.

- What components are essential for optimal functioning?

Key elements typically include the engine, blade assembly, and drive belts. Each plays a vital role in overall performance.

- Where can I find replacement items?

Replacement components can usually be sourced from authorized dealers, online marketplaces, and specialized repair shops.

- How do I know if a part needs replacing?

Signs include unusual noises, decreased efficiency, and visible wear. Regular inspections can help identify these issues early.

- Are there specific tools required for maintenance?

Commonly needed tools may include wrenches, screwdrivers, and lubricants. Having the right tools simplifies the maintenance process.

- Can I upgrade any components for better performance?

Yes, certain parts can be upgraded. It’s advisable to consult with a professional to ensure compatibility and safety.

- Is there a warranty for replacement items?

Many manufacturers offer warranties on their products. Check the details when purchasing to understand coverage options.