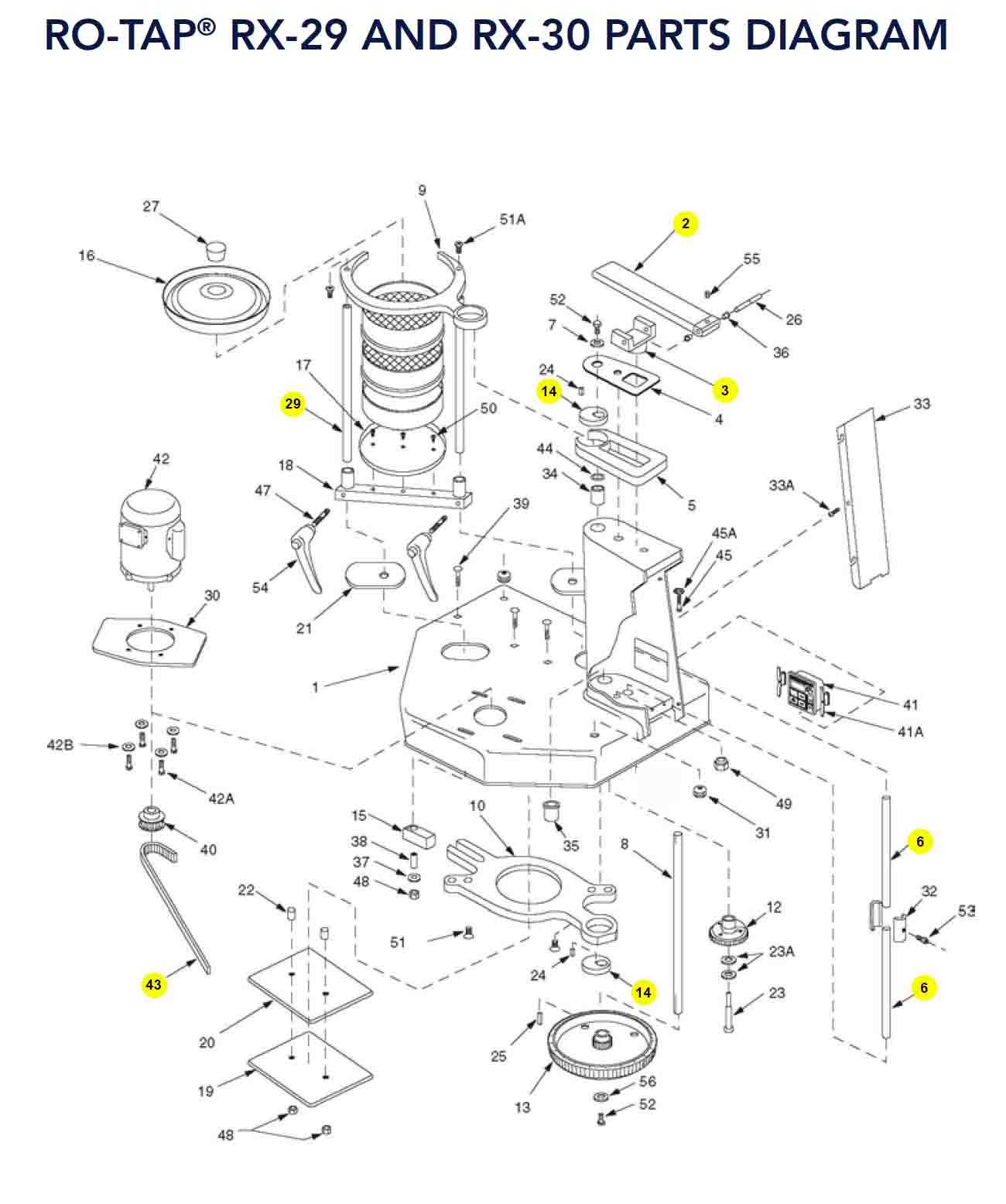

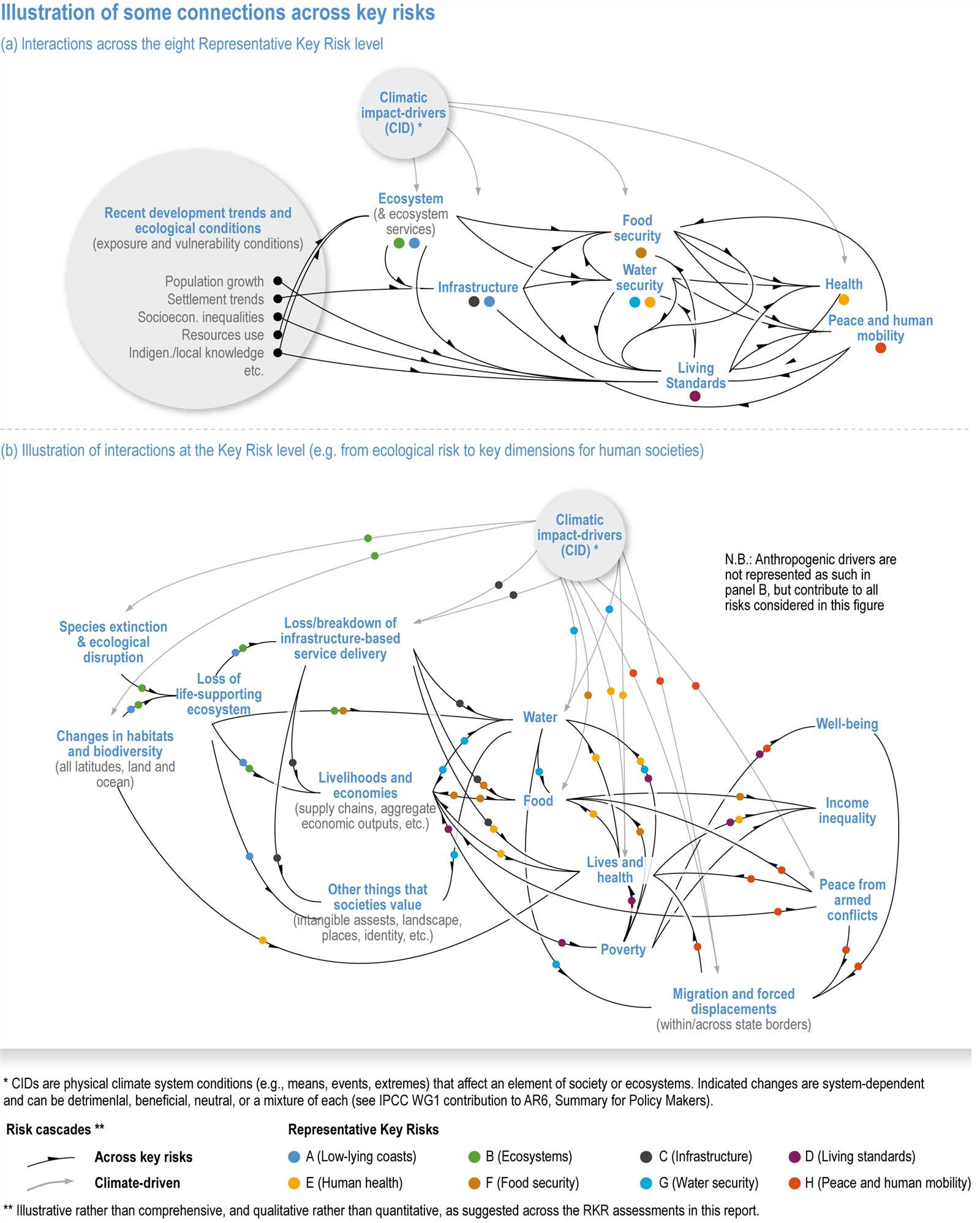

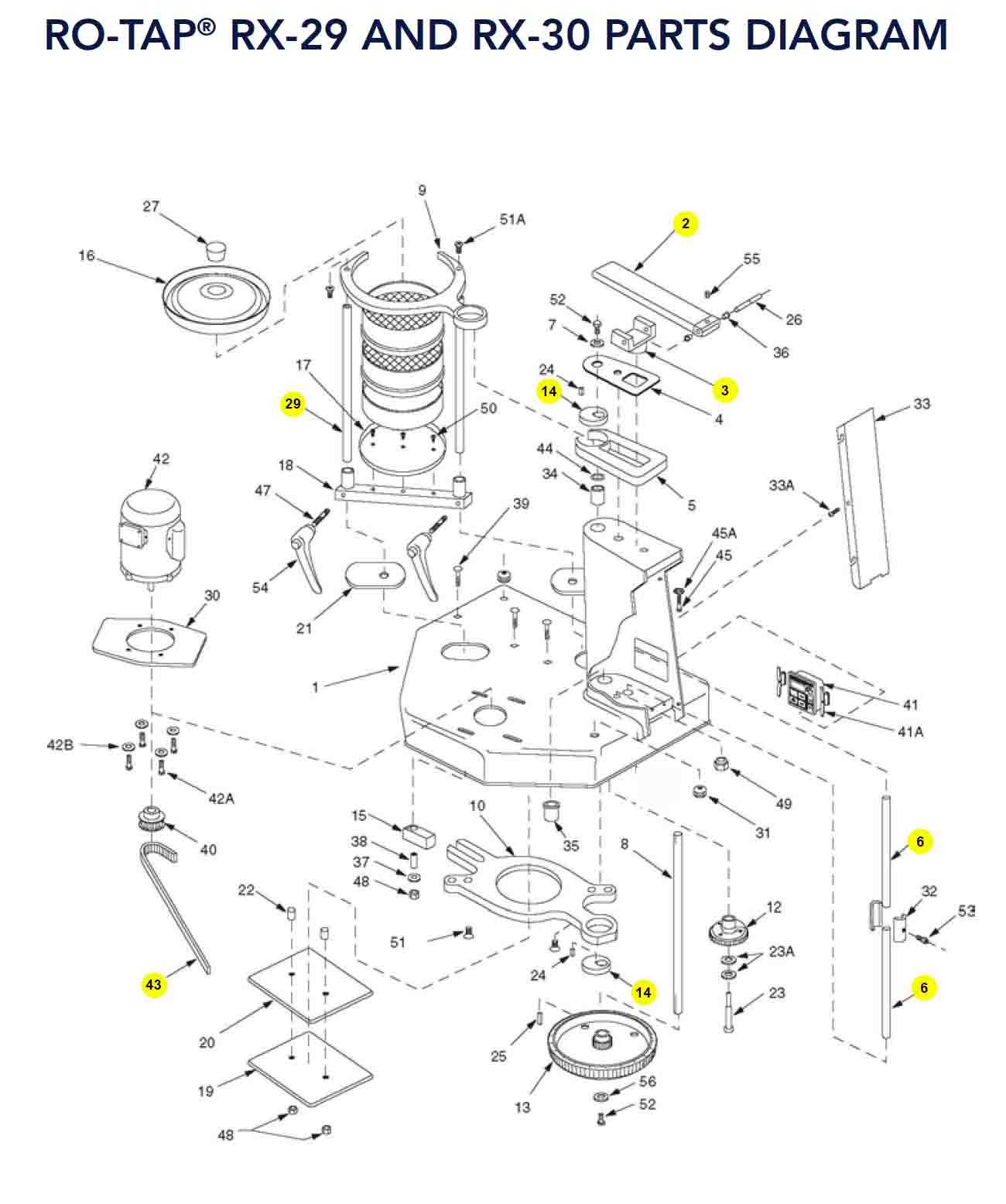

Understanding the internal layout of a sophisticated refrigeration unit is essential for both efficient maintenance and repair. Each element within such a system plays a specific role, ensuring the appliance operates smoothly and effectively over time. Whether you are looking to enhance performance or resolve a technical issue, knowing how different components interact is critical to achieving the best results.

When evaluating the individual sections of the cooling equipment, it’s important to recognize how various assemblies come together to create a seamless refrigeration experience. From cooling mechanisms to intricate electronic controls, every part works in unison to provide optimal functionality. Familiarity with the arrangement and purpose of these components can significantly improve troubleshooting and overall system performance.

Overview of Sub Zero 561 Components

The appliance in question features a variety of essential elements that contribute to its efficient cooling and preservation functions. Each of these components plays a key role in ensuring the overall performance, maintaining temperature stability, and enhancing the user experience. Understanding how these pieces interact is crucial for both proper maintenance and any future upgrades.

Cooling system elements include the mechanisms responsible for temperature regulation, ensuring consistent operation and preventing spoilage. These components work together to provide a balanced internal environment, supporting long-term food preservation.

Control mechanisms allow users to adjust settings and monitor the appliance’s status. They include intuitive panels and sensors, providing precise control over various functions.

Structural elements, including shelves, drawers, and gaskets, are designed to maximize space utilization and ensure a reliable seal, minimizing energy loss. These features contribute to the appliance’s efficiency and ease of use.

Main Functions of Key Parts

The system relies on various essential elements that work together to ensure optimal performance. Each component plays a specific role in maintaining efficiency and reliability. Understanding how these critical elements function can help diagnose issues and improve overall operation.

Compressor: The compressor is responsible for circulating refrigerant throughout the system. It compresses the gas, increasing its pressure and temperature, which allows the cooling cycle to function effectively.

Evaporator: This component absorbs heat from the surrounding environment, allowing the system to remove warmth and maintain a cool environment. The refrigerant evaporates here, which lowers the temperature inside.

Condenser: The condenser releases the heat absorbed by the refrigerant. As the refrigerant passes through, it condenses back into liquid form, which facilitates further cooling.

Thermostat: The thermostat controls and regulates the system’s temperature. By monitoring the conditions, it activates or deactivates the cooling mechanism to maintain the

Identifying Electrical Connections

Understanding how various wiring and connectors work is essential for ensuring that everything functions correctly. Knowing the purpose of each wire and how they link together can help in maintenance or when replacing components. A solid grasp of the setup allows users to confidently manage repairs or upgrades.

Common Wiring Types

There are typically different types of cables and connections, such as power lines and signal wires. Each one plays a unique role in ensuring that energy or data is transmitted effectively. These wires usually differ in color and size, which assists in quickly identifying them during troubleshooting or installation.

Key Connector Points

Connectors allow for secure and organized attachment between the various electrical elements. Below is an example of how different connector points might be laid out, with corresponding descriptions for easy reference.

| Connector |

Description |

Wire Type |

Compressor and Cooling System Details

The heart of any efficient cooling device lies in its ability to manage temperature consistently and reliably. At the core of this process is the compressor, which plays a critical role in regulating the flow of refrigerant throughout the entire system. Its performance is essential for maintaining optimal cooling conditions, ensuring that the environment inside the unit remains at the desired temperature. Additionally, the surrounding cooling components work in tandem with the compressor to circulate air and dissipate heat, maximizing the efficiency of the refrigeration cycle.

One of the primary functions of the system is to compress the refrigerant gas, raising its pressure and temperature. This heated gas is then passed through a condenser, where it cools and transforms into a liquid. The liquid refrigerant flows through the evaporator, absorbing heat from the internal environment, which effectively cools the space. Finally, the refrigerant returns to its

Door Assembly and Seals Explained

The construction of a refrigerator’s door is crucial for maintaining the internal temperature and ensuring energy efficiency. A well-structured door assembly, combined with high-quality sealing, helps prevent the escape of cold air, improving the overall performance of the unit. This section will outline the key elements involved in the door assembly and the role of seals in maintaining proper insulation.

Main Components of the Door

The door includes several key parts that ensure its functionality and efficiency. These include the outer panel, which provides durability and aesthetics, the inner liner, responsible for insulation, and various hinges and handles that allow smooth opening and closing. Proper alignment and materials used in these components ensure the door functions optimally over time.

Importance of Seals

The seal, also known as the gasket,

Understanding the Defrost Mechanism

The defrost mechanism is a critical component in maintaining optimal performance in refrigeration systems. This process is designed to eliminate frost buildup, which can impede efficiency and reduce cooling capabilities. By periodically melting ice that accumulates on cooling surfaces, the system ensures that the internal temperature remains stable and that airflow is unobstructed.

This mechanism typically operates automatically, relying on sensors and timers to detect when defrosting is necessary. When frost reaches a certain thickness, the system activates the heating elements to warm the evaporator coils, facilitating the melting of ice. The resulting water is then drained away, preventing any overflow or pooling inside the unit.

Understanding the various elements involved in the defrost cycle can help users troubleshoot issues effectively. For instance, if the defrost function is not activating as expected, it may be due to a faulty sensor or timer. Regular maintenance and monitoring can prevent such problems, ensuring that the cooling unit operates efficiently and prolonging its lifespan.

Control Panel and Sensor Locations

The control interface and sensor placements are crucial elements in maintaining optimal performance and functionality of the refrigeration unit. Understanding the layout of these components can significantly enhance user experience and troubleshooting efficiency.

Typically, the control panel is situated on the front of the appliance, allowing for easy access to adjust settings and monitor the internal environment. This panel usually features a series of buttons and a display that provides real-time feedback on temperature settings and operational status.

In addition to the control panel, various sensors are strategically positioned within the unit to ensure accurate temperature regulation. Temperature sensors are often located in the interior space, allowing for precise readings of the compartment’s conditions. Meanwhile, door sensors play a vital role in monitoring whether the doors are securely closed, contributing to energy efficiency.

Proper understanding of these locations not only aids in the effective management of the appliance but also assists in diagnosing any potential issues. Familiarity with the control interface and sensor placement can lead to improved maintenance practices and longevity of the refrigeration unit.

Water and Ice Dispenser Components

The efficiency and functionality of a refrigeration unit greatly depend on the various elements involved in the delivery of chilled water and frozen cubes. Understanding these essential components is vital for troubleshooting and maintenance, ensuring smooth operation and consistent performance over time.

Main Components

- Water Reservoir: This is the storage area where water is held before being dispensed. It plays a crucial role in maintaining a steady supply.

- Ice Maker: This assembly is responsible for producing ice cubes, utilizing a refrigeration cycle to freeze water efficiently.

- Dispensing Mechanism: A system that allows users to easily access water or ice. This may include levers or buttons to activate the dispensing process.

- Water Filter: A vital component that ensures the water being dispensed is clean and free from impurities, enhancing taste and safety.

Supporting Elements

- Hoses and Tubing: These connect the water supply to the reservoir and the ice maker, facilitating smooth water flow.

- Control Board: This electronic component regulates the operation of the ice and water dispenser, responding to user commands.

- Cooling System: This includes compressors and evaporators that maintain the necessary temperatures for both water and ice production.

- Thermostats: Devices that monitor and regulate temperatures within the system, ensuring optimal conditions for ice formation and water storage.

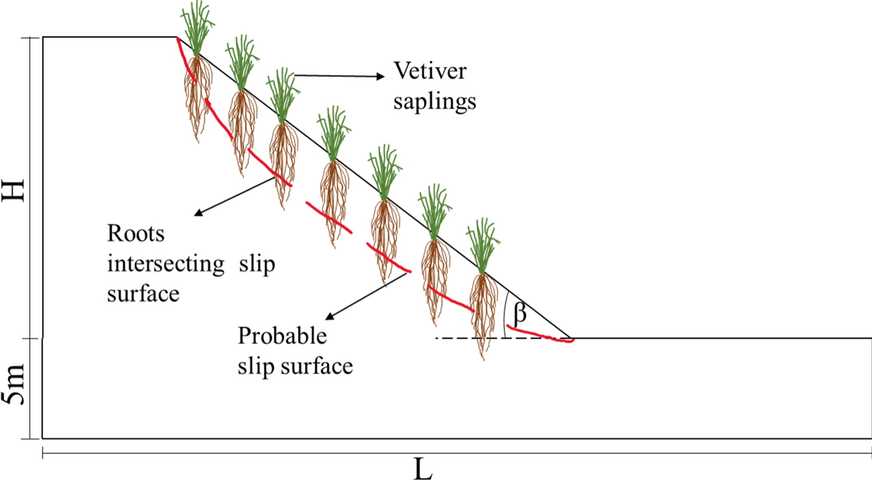

Air Flow and Ventilation Pathways

The effective circulation of air within refrigeration systems is crucial for optimal performance and energy efficiency. Proper airflow ensures that temperature regulation occurs uniformly, preventing cold spots and ensuring that all areas are adequately cooled. Understanding how air moves through the system can lead to better maintenance practices and enhanced longevity of the equipment.

Key components that influence air movement include:

- Fans: These devices are responsible for pushing air through the various compartments, promoting even distribution.

- Vents: Openings designed to facilitate airflow between different sections of the unit, allowing for the exchange of air.

- Insulation: Proper insulation helps maintain the desired temperature by minimizing heat exchange with the environment.

Several factors affect airflow and ventilation pathways:

- Design: The layout of the refrigeration system plays a significant role in how air travels through it.

- Obstructions: Items placed too close to vents can restrict airflow, leading to inefficient operation.

- Filters: Clogged filters can impede air movement, necessitating regular cleaning or replacement.

Regular maintenance and monitoring of these elements can significantly enhance air circulation efficiency, contributing to the overall performance and effectiveness of refrigeration systems.

Maintenance Tips for Longevity

Ensuring the long-lasting performance of your refrigeration unit requires consistent care and attention. Regular maintenance not only enhances efficiency but also extends the lifespan of your appliance. Below are several effective strategies to keep your cooling device in optimal condition.

Routine Cleaning

- Keep the exterior clean to prevent dust accumulation.

- Regularly clean the condenser coils to improve airflow and efficiency.

- Wipe down the interior surfaces with a mild detergent to avoid odors and mold growth.

Regular Inspections

- Check door seals for any signs of wear or damage.

- Inspect the drainage system for clogs or blockages.

- Monitor the temperature settings to ensure they are within the recommended range.

By following these maintenance tips, you can significantly enhance the reliability and longevity of your refrigeration appliance, ensuring it serves you well for years to come.

Ordering Genuine Replacement Parts

When it comes to maintaining your appliance, acquiring authentic components is crucial for ensuring optimal performance and longevity. Choosing the right replacements not only enhances functionality but also protects your investment over time.

Here are some key considerations to keep in mind when ordering genuine components:

- Identify the Model: Always verify the model number of your appliance before placing an order. This ensures that you receive the correct item tailored for your specific unit.

- Check Authorized Dealers: Purchase from certified retailers or directly from the manufacturer to guarantee the authenticity of the components.

- Review Warranty Information: Genuine components typically come with a warranty, providing additional peace of mind regarding their quality and performance.

Following these guidelines can help you secure the right replacements, enhancing the efficiency and durability of your appliance.