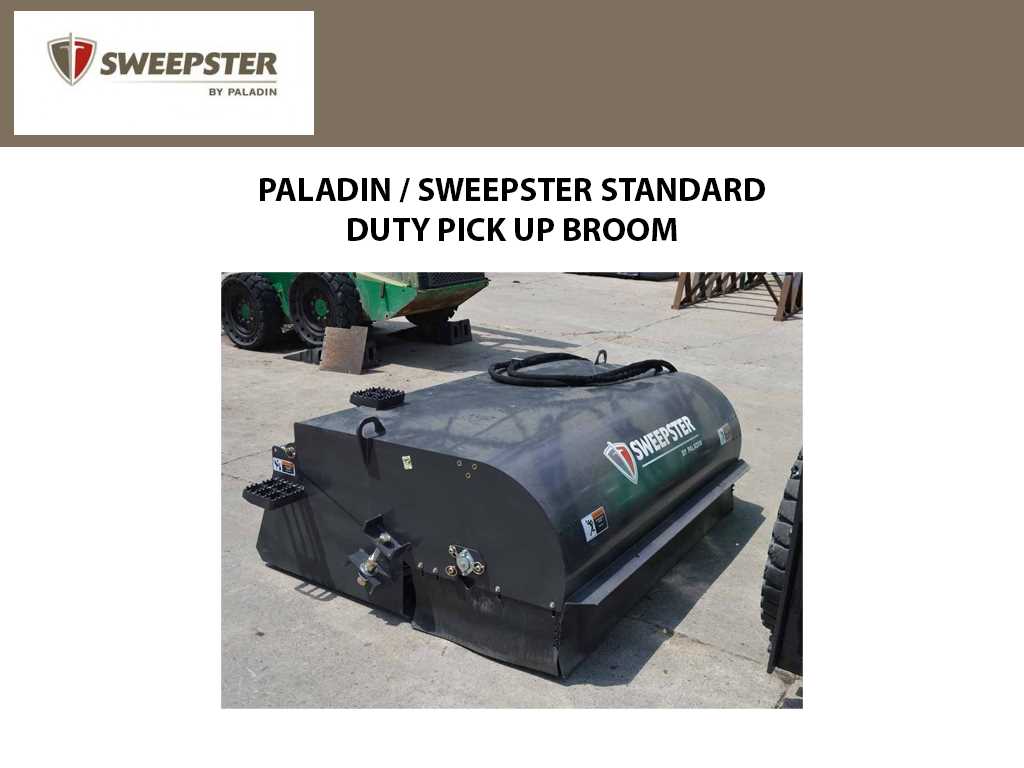

Sweepster Parts Diagram for Easy Reference

In the world of outdoor machinery, comprehending the intricate assembly of components is essential for optimal performance. Each element plays a pivotal role in ensuring smooth operation, and familiarity with these parts can greatly enhance maintenance and troubleshooting efforts. This knowledge empowers users to make informed decisions regarding repairs and upgrades, ultimately leading to a more efficient experience.

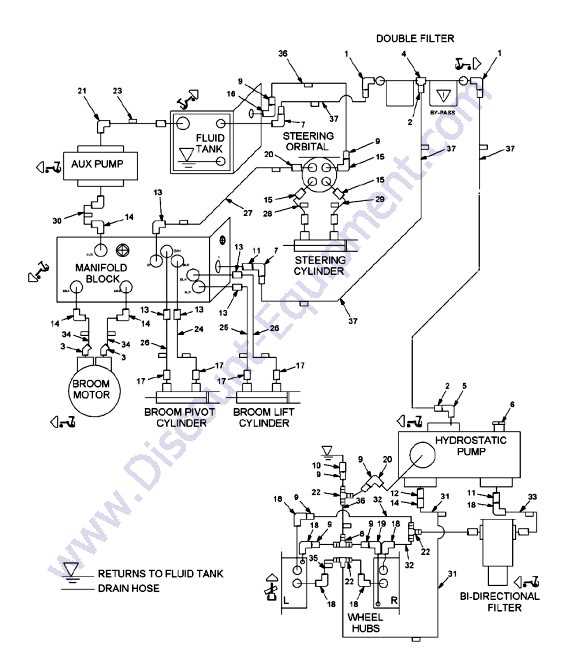

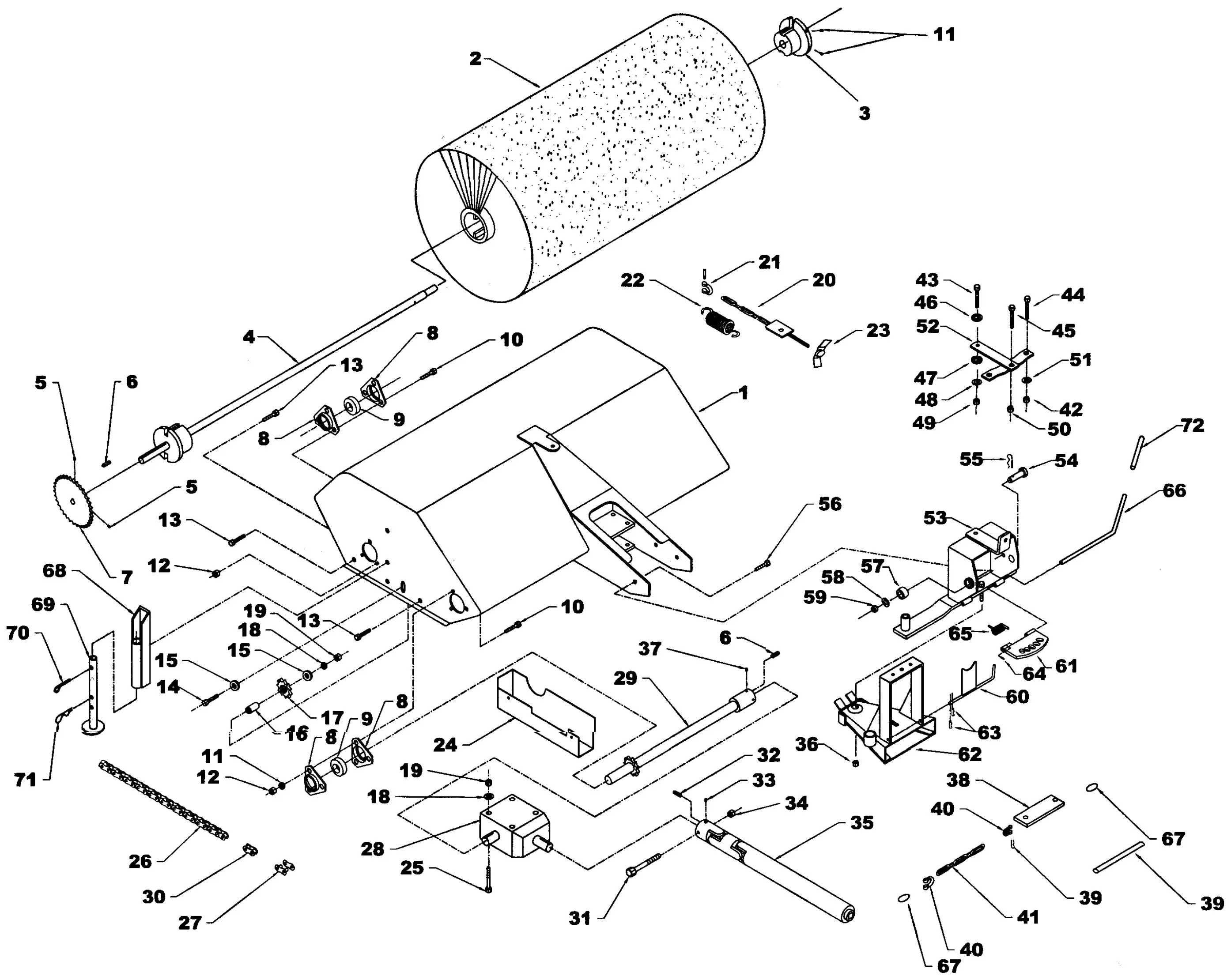

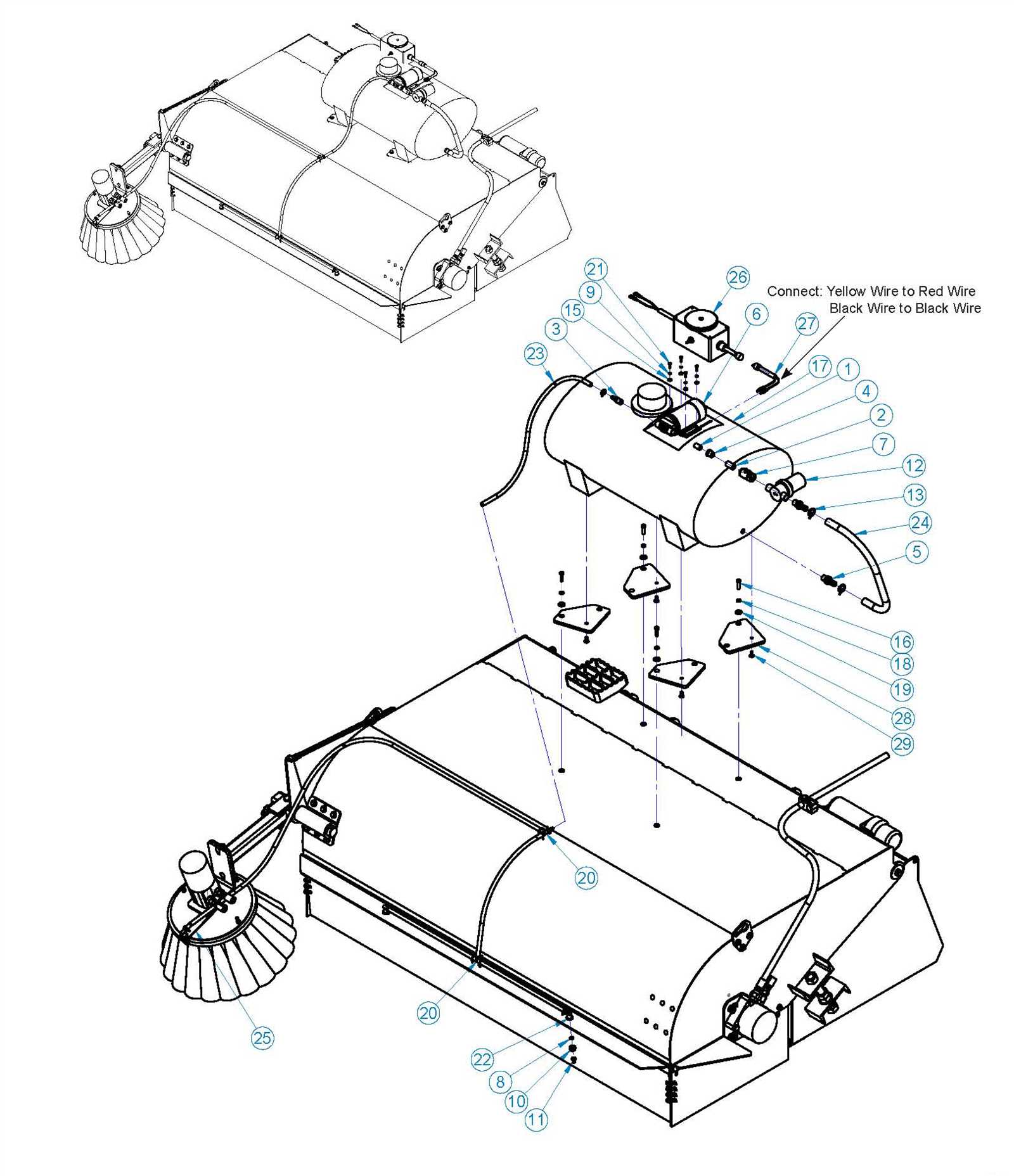

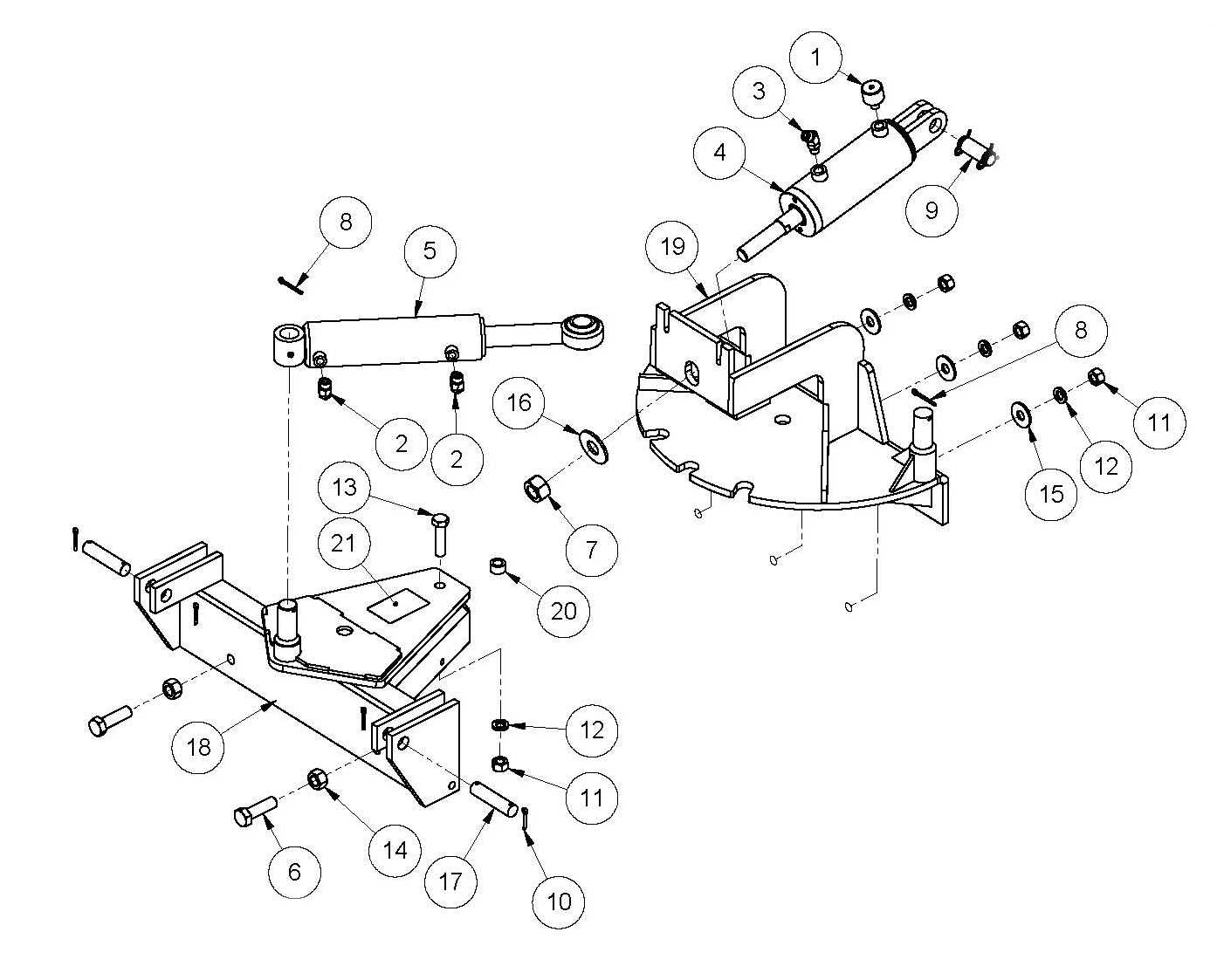

Visual representations of machinery layouts serve as invaluable tools for both novices and seasoned operators. By illustrating the relationships and functions of each piece, these visuals facilitate a deeper understanding of how everything fits together. Recognizing how different elements interact can demystify the complexities of maintenance and enhance one’s ability to tackle issues effectively.

Additionally, having a clear overview of the various sections within the equipment allows for easier identification of potential wear and tear. Knowing where to look for signs of trouble can save time and resources, ensuring that operations remain uninterrupted. This awareness not only contributes to better upkeep but also fosters a sense of confidence in handling the machinery.

Sweepster Parts Overview

This section provides a comprehensive examination of the various components essential for the efficient operation of the equipment. Understanding these elements is crucial for maintenance, repairs, and optimal performance, ensuring that everything runs smoothly.

Key Components

- Brushing System

- Drive Mechanism

- Chassis Frame

- Collection Bins

- Mounting Brackets

Maintenance Considerations

- Regular inspection of the brushing system for wear and tear.

- Checking the drive mechanism for proper functionality.

- Ensuring the chassis frame is free from rust and damage.

- Monitoring collection bins for capacity and cleanliness.

- Tightening mounting brackets to prevent loosening over time.

Importance of Understanding Diagrams

Comprehending visual representations is crucial for effective problem-solving and communication in various fields. These illustrative guides provide clarity, enabling individuals to grasp complex information quickly and efficiently. By breaking down intricate systems into understandable components, they serve as essential tools for both learning and application.

Enhancing Communication

Visual aids facilitate clearer communication among team members and stakeholders. They allow for the sharing of ideas in a universally understandable format, minimizing the chances of misinterpretation. This is particularly beneficial in collaborative environments where diverse expertise converges.

Facilitating Problem-Solving

Understanding visual schematics empowers individuals to identify issues more effectively. By visualizing relationships and functions, one can pinpoint malfunctioning elements and devise appropriate solutions. This proactive approach not only saves time but also enhances overall efficiency.

Key Components of Sweepster Equipment

Understanding the fundamental elements of this specialized machinery is essential for optimal performance and maintenance. Each component plays a vital role in ensuring efficiency and durability, contributing to the overall functionality of the equipment.

- Motor: The powerhouse of the machine, providing the necessary energy for operation.

- Brush Assembly: This part is crucial for effective debris collection, featuring rotating bristles designed to sweep various surfaces.

- Chassis: The framework that supports all components, designed for stability and durability in various working conditions.

- Hopper: A collection container that gathers the debris, allowing for easy disposal and maintaining a clean workspace.

- Drive System: This includes belts and gears that transmit power from the motor to the brushes and wheels, facilitating movement and operation.

By familiarizing oneself with these essential elements, users can ensure that their equipment remains in peak condition, enhancing its lifespan and reliability.

Common Issues with Sweepster Parts

When utilizing outdoor cleaning equipment, users often encounter several recurring challenges that can affect performance and efficiency. Understanding these common problems is crucial for effective maintenance and optimal operation. By recognizing the typical issues, operators can take proactive measures to ensure their machinery functions smoothly.

One frequent concern involves wear and tear on rotating components. Over time, brushes and belts may degrade, leading to diminished cleaning effectiveness. Regular inspection and timely replacement of these elements are essential to maintain peak performance.

Another prevalent issue is the buildup of debris and clogs in various mechanisms. Accumulated materials can hinder movement and reduce the machine’s ability to clean effectively. Routine cleaning and maintenance are vital to prevent these obstructions from causing operational delays.

Additionally, users may face challenges related to the alignment of various moving parts. Misalignment can lead to increased strain on the machinery, resulting in premature failure. Ensuring that components are properly adjusted can significantly extend the lifespan of the equipment.

Lastly, issues with electrical connections can arise, particularly in models that rely on electronic controls. Loose wires or faulty connections can disrupt operation and cause unexpected shutdowns. Regular checks of the electrical system are necessary to identify and rectify potential problems before they escalate.

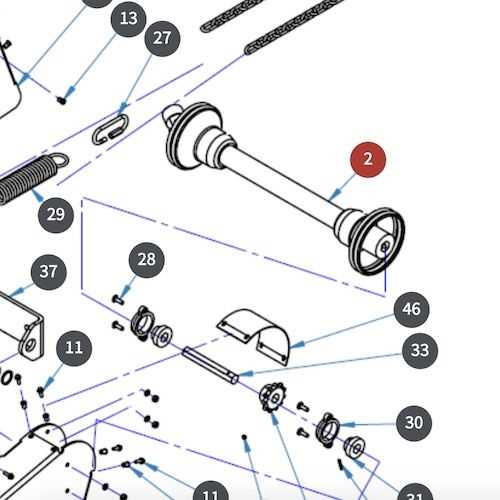

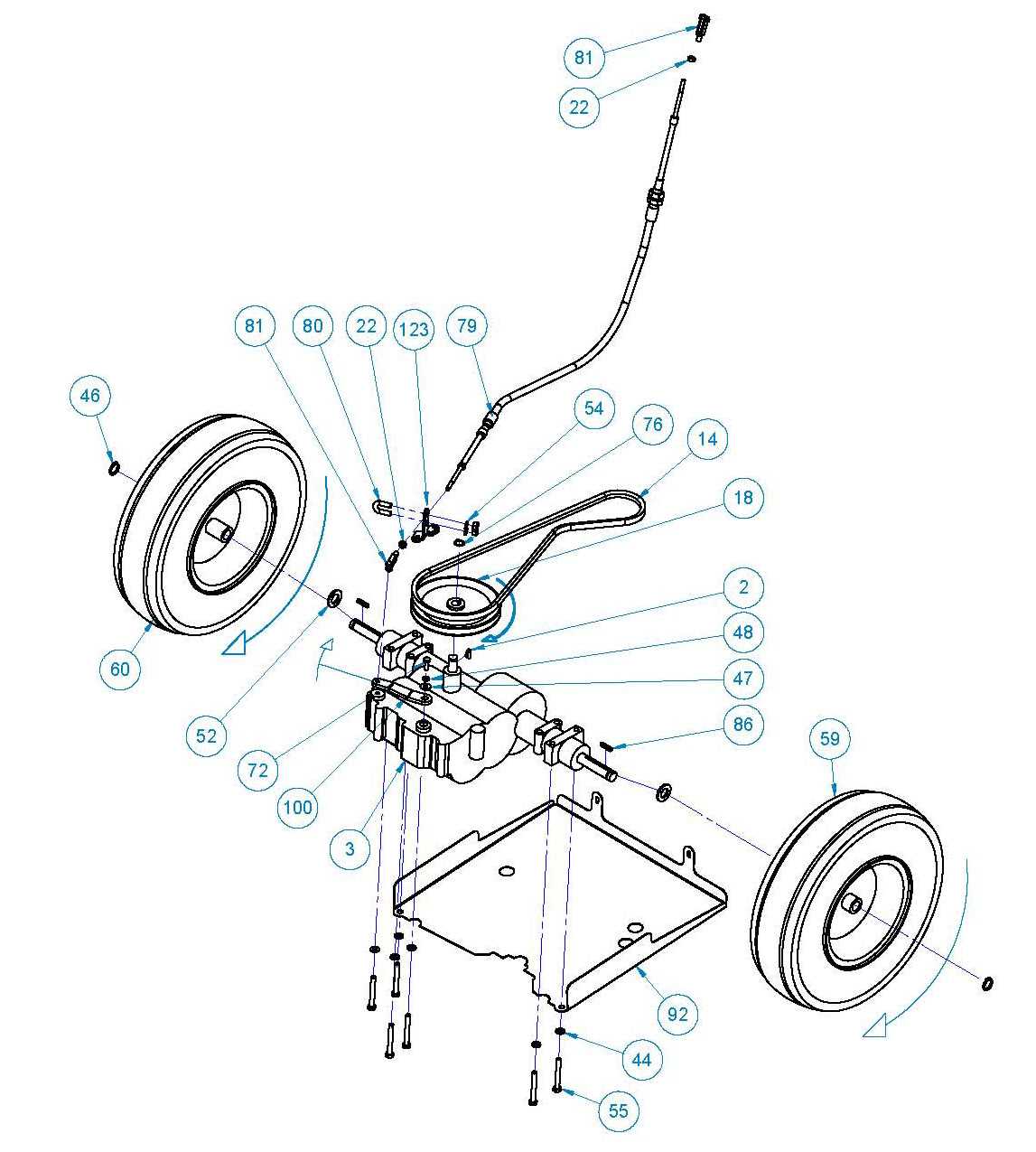

How to Read a Parts Diagram

Understanding a visual representation of components is essential for effective assembly and maintenance. These illustrations serve as a guide, helping users identify and locate each element within a mechanical system. By familiarizing yourself with the layout and symbols used, you can enhance your troubleshooting skills and streamline the repair process.

To begin, examine the overall structure. Typically, these visuals provide an exploded view, showcasing how various pieces fit together. Look for labels and annotations that indicate specific components. Pay attention to the numbering or lettering system, as it usually corresponds to a list that details each item’s specifications.

Next, observe the connections between the elements. Arrows or lines often represent how parts interact, guiding you in understanding their relationships. Recognizing these connections is crucial for proper assembly or disassembly.

Lastly, consult the accompanying documentation for further details. These references often include additional information, such as part numbers or maintenance tips. By combining the visual with textual information, you will gain a comprehensive understanding of the entire system.

Maintenance Tips for Sweepster Models

Ensuring optimal performance and longevity of your equipment requires regular attention and care. Implementing a consistent maintenance routine can prevent costly repairs and enhance efficiency. Here are some essential strategies to keep your machinery in excellent condition.

Regular Inspection

Frequent evaluations of your equipment can help identify potential issues before they escalate. Consider the following:

- Check for any signs of wear and tear on moving parts.

- Inspect belts and chains for proper tension and alignment.

- Examine electrical connections for signs of corrosion or damage.

Cleaning and Lubrication

Proper cleaning and lubrication are vital for smooth operation. Follow these guidelines:

- Clean debris from surfaces after each use to prevent buildup.

- Apply lubricant to hinges, bearings, and other moving components regularly.

- Ensure that air filters are clean to promote efficient airflow.

By adhering to these maintenance practices, you can enhance the reliability and performance of your equipment over time.

Where to Find Official Diagrams

For those seeking detailed visual references for machinery components, there are several reliable sources available. Accessing these resources ensures you have accurate information to assist in maintenance, repair, or upgrades.

One of the best places to start is the manufacturer’s official website. Here, you can often find downloadable resources that include detailed illustrations and descriptions of various elements. These documents are typically updated regularly, ensuring you have the most current information.

In addition, authorized dealers often provide access to comprehensive guides and manuals. These sources can be particularly useful, as they often include insights and tips from experienced professionals.

Online forums and communities dedicated to machinery enthusiasts can also be valuable. Members often share their own findings and links to official documentation, making it easier to locate the specific visual references you need.

Lastly, reaching out to customer support can yield quick access to the necessary materials. They can direct you to the most relevant documents tailored to your specific needs.

Identifying Parts by Model Type

When working with various equipment, understanding how to recognize components based on specific model classifications is essential. This knowledge not only streamlines maintenance but also enhances the efficiency of repairs and replacements. Each model often comes with unique identifiers that can assist users in pinpointing the exact elements needed for optimal functionality.

Model identification serves as the first step in this process. By examining the unique features and specifications associated with a particular version, users can navigate through a plethora of options more effectively. Key characteristics may include dimensions, shapes, and attachment methods, which can all aid in distinguishing one model from another.

Additionally, manufacturer documentation plays a crucial role. Technical manuals and reference guides typically provide detailed insights into the various components relevant to each model type. These resources can be invaluable when trying to determine compatibility and specific requirements for replacements.

Furthermore, engaging with community forums and expert resources can enhance understanding. Fellow users often share their experiences and solutions regarding specific models, offering practical advice that can simplify the identification process. This collaborative approach not only fosters a deeper understanding but also builds a network of support for those navigating similar challenges.

DIY Repairs: What You Need

Embarking on home repair projects can be both rewarding and cost-effective. With the right tools and resources, you can tackle a variety of maintenance tasks yourself. Understanding what you need before starting can make the process smoother and more efficient.

Essential Tools: A well-equipped toolkit is fundamental for any DIY enthusiast. Common tools include a reliable screwdriver set, pliers, wrenches, and a sturdy hammer. Additionally, having a measuring tape and a level will ensure accuracy in your work.

Safety Gear: Prioritizing safety is crucial. Invest in protective eyewear, gloves, and, if necessary, a dust mask. This will help you avoid injuries and ensure a safe working environment.

Repair Materials: Depending on the task at hand, you may require specific materials. Stock up on items like adhesives, fasteners, and replacement components relevant to the projects you plan to undertake. Researching beforehand can help you identify what is necessary.

Reference Guides: Having access to instructional materials can significantly aid your efforts. Online tutorials, manuals, and videos provide step-by-step guidance and troubleshooting tips, making it easier to navigate challenges that arise during repairs.

By preparing adequately and gathering the right equipment, you can enhance your DIY experience and achieve satisfying results in your home repair endeavors.

Tools Required for Part Replacement

When undertaking the task of replacing components in your equipment, having the right instruments on hand is essential for a smooth and efficient process. Proper tools not only facilitate the removal and installation of various elements but also ensure safety and precision throughout the procedure.

Below is a list of necessary implements that you may need to complete the replacement task effectively:

| Tool | Purpose |

|---|---|

| Screwdriver Set | For loosening and tightening screws of various sizes. |

| Socket Wrench | Used for removing and securing nuts and bolts. |

| Pliers | Helpful for gripping, twisting, and cutting wires or small components. |

| Torque Wrench | Ensures that bolts are tightened to the manufacturer’s specifications. |

| Utility Knife | For cutting through materials or insulation when necessary. |

| Flashlight | Illuminates dark areas for better visibility during work. |

| Work Gloves | Provides protection to hands from sharp edges and debris. |

By equipping yourself with these tools, you can ensure that the replacement process is handled with care and efficiency, minimizing the risk of errors or damage. Proper preparation and the right equipment are key to achieving satisfactory results.

Supplier Recommendations for Spare Parts

When maintaining equipment, finding reliable sources for components is crucial. A well-informed choice can enhance performance and longevity, ensuring that machinery operates efficiently. This section aims to provide insights into selecting trustworthy suppliers for essential replacements, focusing on quality, availability, and support.

Key Factors to Consider

Choosing the right supplier involves evaluating several important aspects. These include the reputation of the vendor, the quality of the products offered, and the level of customer service provided. Below is a table summarizing critical criteria to help guide your decision-making process.

| Criterion | Description |

|---|---|

| Quality Assurance | Ensure that components meet industry standards and have undergone rigorous testing. |

| Availability | Look for suppliers with a wide range of items in stock for quick access. |

| Customer Support | Choose vendors who offer responsive and knowledgeable assistance. |

| Pricing | Compare costs among different sources to find competitive rates. |

| Warranty | Opt for suppliers that provide warranties on their products, ensuring peace of mind. |

Recommended Suppliers

To facilitate your search, here are a few recommended vendors known for their reliability and quality:

- Supplier A: Renowned for its extensive inventory and competitive pricing.

- Supplier B: Offers exceptional customer service and expert advice.

- Supplier C: Specializes in high-quality components with excellent warranties.

Upgrading vs. Replacing Components

When it comes to enhancing the efficiency and longevity of machinery, the decision between upgrading existing elements and replacing them entirely can be pivotal. Both approaches offer distinct advantages and potential drawbacks that can influence overall performance and cost-effectiveness.

Upgrading involves enhancing specific features or capabilities of current components, often resulting in improved functionality without the need for a complete overhaul. This method can be more economical and less time-consuming, allowing for a quicker return to operation while retaining some familiar elements.

On the other hand, replacing components entails removing outdated or malfunctioning parts and substituting them with new ones. This option may provide a more significant boost in performance, especially if the original components are severely worn or no longer meet operational standards. However, it often comes with higher initial costs and longer downtimes.

Ultimately, the choice between upgrading and replacing will depend on various factors, including budget constraints, the specific goals of the operation, and the condition of the existing machinery. Evaluating these elements thoroughly can lead to a more informed decision, optimizing both performance and resource allocation.

Resources for Further Learning

Expanding your knowledge on machinery components and their functionalities can greatly enhance your understanding and maintenance skills. Numerous resources are available to help you delve deeper into the intricacies of these systems. Whether you’re looking for technical manuals, online courses, or community forums, there is a wealth of information that can support your learning journey.

Online Courses and Tutorials

Platforms like Coursera and Udemy offer a range of courses focusing on mechanical systems and equipment maintenance. These structured programs often include video tutorials, quizzes, and hands-on projects to facilitate practical learning. Exploring these can provide you with foundational knowledge as well as advanced techniques.

Community Forums and Discussion Groups

Engaging with online communities can be an invaluable resource for gaining insights from experienced professionals. Forums such as Reddit and specialized Facebook groups allow users to share experiences, ask questions, and exchange tips. Participating in these discussions can help you troubleshoot issues and learn from real-world scenarios.