Comprehensive Guide to Tapco Pro 19 Parts Diagram

In the realm of mechanical engineering, grasping the intricate details of machinery is essential for both maintenance and optimal performance. This exploration focuses on the various elements that contribute to the functionality of a specific model, providing insights into how each component interacts within the larger system.

Visual aids play a crucial role in comprehending the structure and arrangement of these elements. By examining detailed illustrations, one can uncover the ultimate configuration and relationships among the individual parts, facilitating better understanding and efficient repairs.

As we delve into this topic, we aim to enhance your familiarity with these components, empowering you to tackle challenges with confidence. A clear visualization can transform the complexity of machinery into an accessible resource for enthusiasts and professionals alike.

Understanding Tapco Pro 19 Components

This section aims to explore the various elements that contribute to the functionality and efficiency of a specific tool designed for enhancing operational capabilities. By examining each component, one can gain insight into how these parts interact to achieve ultimate performance.

Key Features

Each individual element plays a crucial role, from the housing to the mechanisms that ensure precision. Understanding these features can help users appreciate the engineering behind the device.

Maintenance and Care

Regular maintenance of these components is essential for longevity. Proper care not only enhances durability but also optimizes overall effectiveness, ensuring that the equipment remains in peak condition.

Overview of Tapco Pro 19 Parts

This section provides an insight into the various components of a specific model, highlighting their significance and functionality. Understanding each element is essential for effective usage and maintenance.

Key Components

The essential elements of this model work together to ensure optimal performance. Each piece plays a vital role in the overall operation, contributing to both efficiency and reliability.

| Component | Description |

|---|---|

| Receiver | Holds and supports the main mechanism. |

| Barrel | Directs the projectile and influences accuracy. |

| Trigger | Initiates the firing process. |

| Stock | Provides stability and support for handling. |

Importance of Each Element

Every individual piece contributes to the system’s functionality. A thorough understanding aids in troubleshooting and enhances overall experience.

Importance of Accurate Diagrams

Precise illustrations play a crucial role in various fields, providing clarity and enhancing understanding. They serve as essential tools for communication, enabling individuals to interpret complex structures or systems effortlessly. By presenting information visually, these representations minimize confusion and facilitate effective learning.

In technical contexts, the accuracy of these visual aids is paramount. Incorrect or unclear visuals can lead to misunderstandings, resulting in errors during assembly or maintenance. This not only affects efficiency but can also compromise safety. Thus, reliable representations are vital for ensuring that tasks are performed correctly and safely.

Moreover, accurate visuals support training and development. They allow new users to familiarize themselves with components and processes quickly. When learners can reference detailed and precise illustrations, their confidence and competence grow, leading to better outcomes in practical applications.

In conclusion, the significance of high-quality visuals cannot be overstated. They are indispensable for effective communication, training, and the successful execution of tasks across various disciplines.

Common Issues with Tapco Pro 19

When dealing with various tools and equipment, users often encounter specific challenges that can affect performance and usability. Understanding these common problems can help in troubleshooting and maintaining optimal functionality. Below are some frequently observed issues along with their potential causes and solutions.

| Issue | Possible Causes | Suggested Solutions |

|---|---|---|

| Jamming | Debris accumulation, improper loading | Clear any obstructions and ensure correct loading techniques are used |

| Inconsistent Output | Worn components, incorrect settings | Inspect for wear and adjust settings accordingly |

| Excessive Noise | Lack of lubrication, damaged parts | Apply appropriate lubricant and check for damaged components |

| Overheating | Extended use, insufficient cooling | Allow for breaks during operation and ensure ventilation is adequate |

| Difficulty in Adjustments | Corrosion or dirt buildup | Clean adjustment mechanisms and apply a suitable lubricant |

How to Interpret Parts Diagrams

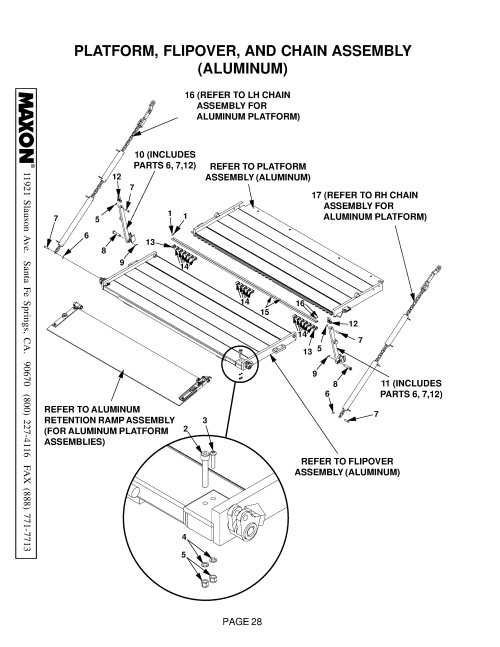

Understanding visual representations of components is essential for effective assembly, maintenance, and troubleshooting. These illustrations provide a simplified overview of individual elements and their relationships within a larger system, making it easier to identify and locate specific pieces when needed. Mastering the interpretation of these visuals can significantly enhance your efficiency and accuracy in working with mechanical systems.

Reading the Visuals

When examining a schematic, start by familiarizing yourself with the overall layout. Look for labels that indicate the names and functions of various components. Pay attention to the connections between elements, as they often reveal how parts interact and the flow of operation. Identifying different categories, such as fasteners, housings, and mechanisms, can also aid in grasping the assembly process.

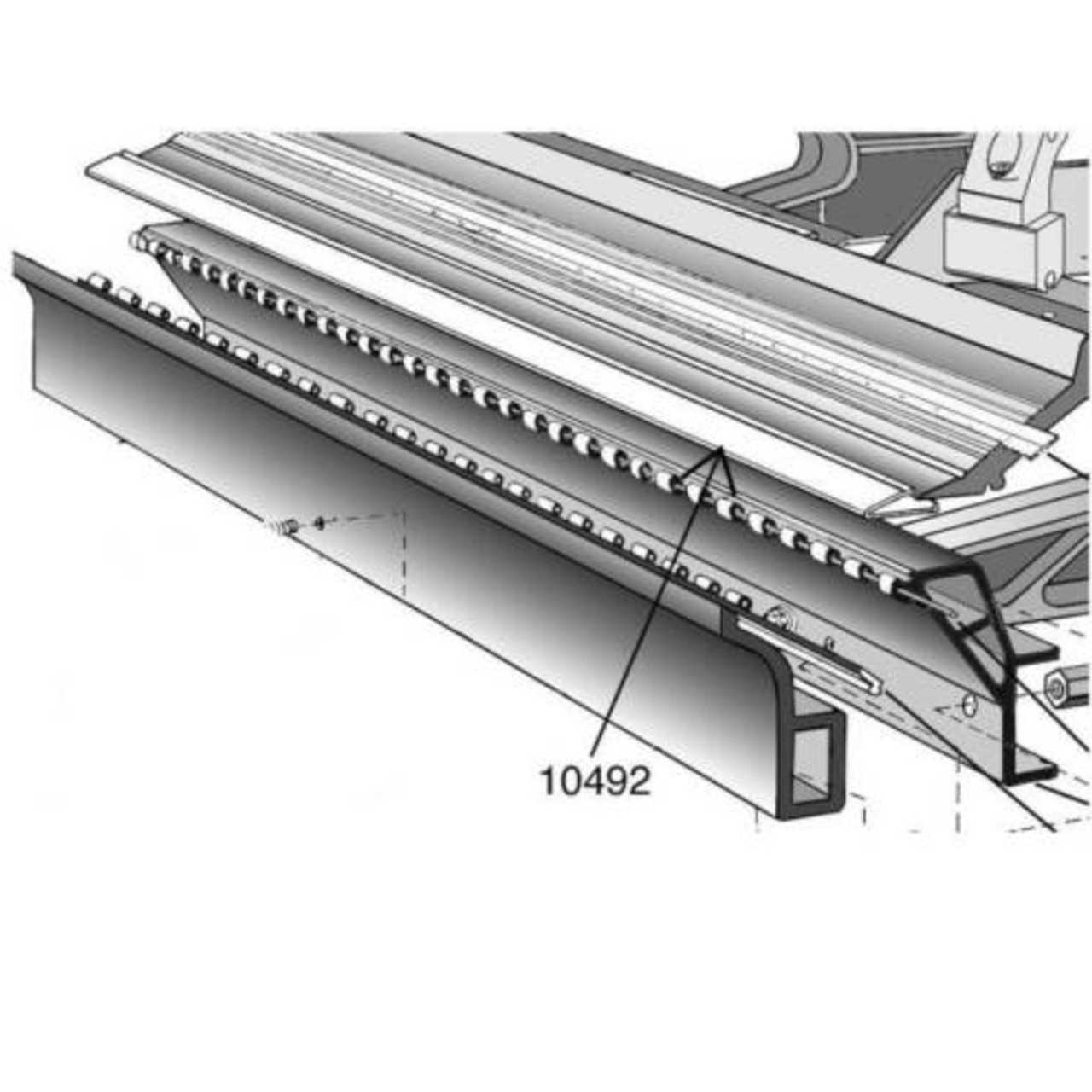

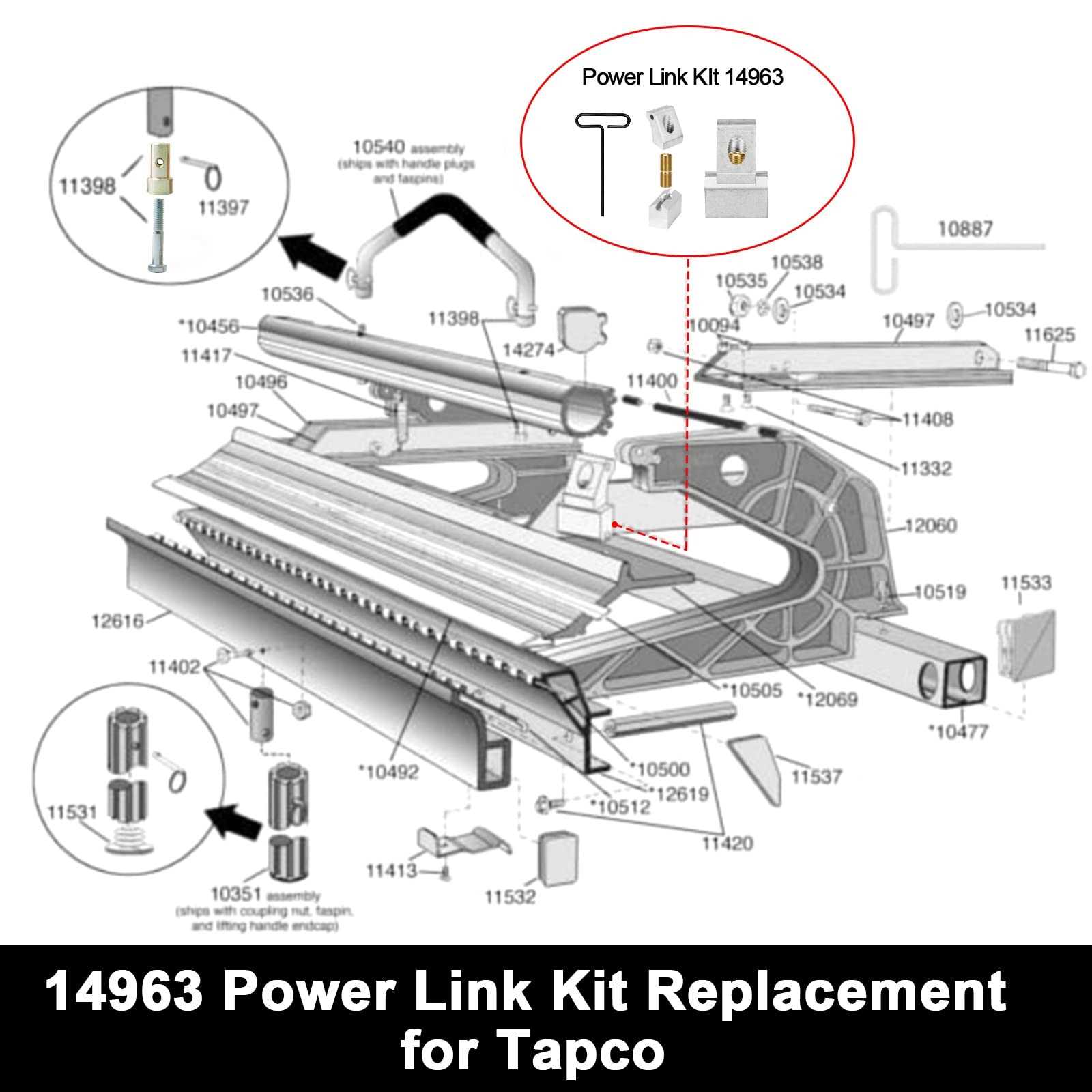

Utilizing Reference Numbers

Reference numbers typically accompany each component in these visuals, linking them to detailed descriptions in a corresponding manual. This relationship allows for quick identification and procurement of specific elements when repairs or replacements are necessary. Always cross-reference these numbers with the documentation to ensure accuracy and compatibility with your particular system.

Essential Tools for Maintenance

Proper upkeep of equipment requires a selection of vital instruments that ensure functionality and longevity. Having the right tools on hand allows for efficient repairs and adjustments, minimizing downtime and enhancing performance. This section highlights key implements necessary for effective maintenance.

Wrenches are fundamental for tightening or loosening fasteners, making them indispensable for various mechanical tasks. Ensure you have a set that includes both standard and metric sizes to accommodate different specifications.

Screwdrivers come in various types, including flathead and Phillips, and are crucial for accessing and securing components. A complete set allows for flexibility in tackling different types of screws and assemblies.

Pliers, particularly needle-nose and adjustable types, provide excellent grip and leverage for manipulating small or awkwardly positioned parts. These tools are essential for both installation and removal tasks.

Lubricants and cleaning agents help maintain smooth operation and prevent wear over time. Regular application of appropriate substances reduces friction and keeps components in optimal condition.

Lastly, measuring tools such as calipers and rulers are necessary for precision work, ensuring that adjustments meet required specifications. Maintaining accuracy is critical for the overall effectiveness of any maintenance routine.

Step-by-Step Repair Guide

This guide aims to provide a clear and concise approach to restoring equipment, ensuring optimal functionality. By following the outlined steps, even those with minimal experience can effectively address common issues and perform necessary maintenance.

Preparation

Before diving into the repair process, gather all essential tools and components. Make sure you have a clean workspace to prevent loss of small parts. Familiarize yourself with the overall assembly to enhance your understanding of the mechanism.

Repair Process

Start by disassembling the unit carefully, noting the order of components for easy reassembly. Inspect each part for wear and damage, replacing any faulty items as needed. Once repairs are completed, reassemble everything methodically, ensuring each piece is securely in place. Finally, conduct a thorough test to confirm that the unit operates correctly.

Upgrading Your Tapco Pro 19

Enhancing your firearm can significantly improve its performance and reliability. This section explores various ways to optimize your model, ensuring it meets your shooting preferences and requirements. From simple adjustments to more complex modifications, each upgrade can provide distinct advantages.

Essential Components for Enhancement

Consider upgrading crucial elements such as the trigger system, barrel, or stock. These modifications can lead to improved accuracy and comfort during use. Investing in high-quality components can make a notable difference in your shooting experience.

Maintenance and Care

Regular upkeep is vital for maximizing the longevity and efficiency of your equipment. Ensure all parts are clean and lubricated, and inspect them for wear. Implementing a maintenance routine not only enhances performance but also helps prevent potential malfunctions.

Where to Find Replacement Parts

Locating suitable components for your equipment can be a straightforward process if you know where to look. There are several reliable sources that can help you obtain the necessary items to ensure optimal performance and longevity of your device.

- Online Retailers: Numerous websites specialize in selling components for various types of machinery. Popular platforms often provide extensive catalogs, making it easy to search for specific items.

- Manufacturer’s Website: The official website of the manufacturer is a great starting point. They typically offer a complete list of available components along with detailed specifications.

- Local Hardware Stores: Visiting local shops can yield quick results. Staff members are often knowledgeable and can assist in finding the right pieces.

- Specialty Stores: Some stores focus specifically on particular brands or types of equipment. These can be invaluable for hard-to-find items.

- Online Marketplaces: Websites like eBay or Amazon can be useful for finding both new and used components at various price points.

Before making a purchase, it is advisable to compare prices and check reviews to ensure quality and compatibility. Additionally, consider reaching out to community forums or social media groups dedicated to your equipment type for recommendations and advice.

Comparing Tapco Pro Models

This section focuses on analyzing different versions of a popular series of tools, highlighting their features, specifications, and intended applications. By examining various models, users can make informed decisions based on their specific needs and preferences.

| Model | Weight | Capacity | Material | Special Features |

|---|---|---|---|---|

| Model A | 4.5 lbs | 10 rounds | Polymer | Ergonomic grip, adjustable sights |

| Model B | 5 lbs | 15 rounds | Aluminum | Quick-release mechanism, lightweight design |

| Model C | 6 lbs | 20 rounds | Steel | Enhanced durability, anti-corrosion finish |

Understanding the differences between these variations helps users choose the most suitable option for their requirements, whether for recreational use, competition, or training. Each model offers unique advantages that cater to specific user demands.

User Reviews and Experiences

This section highlights the insights and feedback from individuals who have utilized the featured equipment. By sharing their stories and evaluations, users provide a valuable perspective on performance, usability, and overall satisfaction.

General Impressions

- Many users appreciate the durability and reliability of the equipment.

- Several reviews mention ease of installation and user-friendly design.

- Overall, most experiences reflect a positive sentiment towards functionality.

Common Praise and Critiques

- Excellent performance under various conditions.

- Some users noted minor issues with specific components.

- Support and customer service received high ratings from most reviewers.

Maintaining Your Equipment Effectively

Regular upkeep is essential for ensuring the longevity and optimal performance of your machinery. By implementing systematic care practices, you can minimize breakdowns and enhance efficiency. This section will explore key strategies for effective maintenance.

Routine Inspection

Conducting frequent checks is crucial. Here are some key steps:

- Examine components for wear and tear.

- Ensure all connections are secure.

- Check for signs of corrosion or damage.

Cleaning and Lubrication

Keeping your equipment clean and properly lubricated can prevent premature failure:

- Remove dust and debris regularly.

- Apply suitable lubricants to moving parts.

- Replace filters as needed to maintain airflow.

By following these guidelines, you can achieve the ultimate performance from your machinery and extend its operational life.

Safety Tips During Repairs

Ensuring safety during maintenance tasks is crucial to prevent accidents and injuries. Adhering to proper practices can significantly enhance your protection while working on equipment.

- Always wear appropriate personal protective equipment, such as gloves and goggles.

- Keep your workspace organized to minimize hazards.

- Disconnect power sources before starting any repair work.

- Use tools correctly and maintain them in good condition.

In addition, consider the following precautions:

- Read manuals and guidelines to understand the equipment’s workings.

- Work in a well-ventilated area to avoid inhaling harmful fumes.

- Have a first aid kit readily available in case of emergencies.

- Never rush repairs; take your time to ensure everything is done safely.