Thermo King APU Parts Diagram Explained

In the realm of vehicular mechanisms, understanding the intricate composition and functionality breakdown of essential elements is crucial. These components, crucial to the operational framework, serve as the fundamental building blocks, ensuring seamless integration and optimized performance in dynamic environments.

Examining the Anatomy

The anatomy of these critical elements reveals a sophisticated network of interconnections and interdependencies. Each constituent part plays a pivotal role in sustaining operational efficiency, characterized by its unique structure and specialized function.

Unveiling Functional Integration

The integration of these elements culminates in a cohesive system that harmonizes diverse functionalities, catering to the multifaceted demands of modern applications. This systematic approach not only enhances reliability but also underscores the precision engineering required for sustained performance.

Comprehensive Guide to Components Representation: APU

In this section, we delve into a detailed breakdown of the various elements that constitute the functional components of an Auxiliary Power Unit (APU). The APU system comprises essential units that collectively ensure optimal performance and efficiency in auxiliary power supply. Understanding these constituent parts aids in the comprehensive comprehension of the APU’s operational dynamics.

| Component | Function | Description |

|---|---|---|

| Generator | Power Generation | The unit responsible for producing electrical power to support various onboard systems and appliances. |

| Engine | Power Generation | Primary source of mechanical power that drives the APU, typically fuel-powered for sustained operation. |

| Cooling System | Temperature Regulation | Ensures optimal operating temperatures within the APU, critical for long-term reliability and efficiency. |

| Exhaust System | Gas Disposal | Manages the discharge of combustion gases from the APU engine, maintaining environmental compliance and safety. |

| Control Panel | Operational Management | Facilitates user interaction and monitoring of APU performance, providing vital feedback and control functionalities. |

Each of these components plays a crucial role in the seamless operation of the APU, contributing to its reliability and efficiency in providing auxiliary power. The interconnectedness and synergy among these parts ensure optimal functionality and performance under various operational conditions.

Understanding Thermo King APU Components

When it comes to the auxiliary power units utilized in transportation, a comprehensive grasp of their individual elements is crucial for effective operation and maintenance. Each component plays a vital role in ensuring optimal performance, efficiency, and reliability, thereby contributing to the overall functionality of the system. A detailed examination of these components allows users to appreciate their significance and interconnectivity.

Key Elements and Their Functions

Among the various elements, the engine serves as the powerhouse, generating energy that drives other components. Coupled with this is the control unit, which regulates the operational parameters, ensuring that the system operates within safe and efficient limits. Additionally, the cooling system is essential for dissipating heat, preventing overheating, and maintaining performance standards.

Importance of Regular Maintenance

Regular inspection and upkeep of these individual components are imperative for longevity and efficiency. Over time, wear and tear can affect performance, making it necessary to replace or repair specific elements. Understanding the role each part plays aids in identifying potential issues early, thus enhancing the overall reliability of the auxiliary power system. Proactive maintenance not only extends the lifespan of the unit but also optimizes fuel efficiency and operational readiness.

Exploring the Functionality of Auxiliary Power Unit Components

Delving into the inner workings and operations of these crucial components, we uncover their intricate roles within the system. Understanding their functionality goes beyond mere identification; it involves comprehending their essential contributions to the overall performance and efficiency.

The Core Operations of Key System Elements

These integral parts execute pivotal tasks that sustain operational integrity and optimize energy utilization. Their functions are pivotal in ensuring seamless integration and reliable performance across diverse environmental conditions.

Exploring the intricacies of their mechanisms provides insight into the sophisticated interplay of engineering and design principles, underscoring their criticality in enhancing operational resilience.

Identifying Key Components in Thermo King APU Systems

Understanding the critical elements of a mobile cooling system is essential for efficient operation and maintenance. These systems incorporate various components that work synergistically to provide optimal performance. Recognizing each part and its function can lead to better diagnostics and enhanced longevity of the equipment.

Key components in such systems typically include:

- Compressor: This component is vital for refrigerant circulation, ensuring efficient heat exchange.

- Condenser: Responsible for dissipating heat absorbed from the interior, allowing the refrigerant to condense back into a liquid.

- Evaporator: Facilitates the cooling process by evaporating the refrigerant, absorbing heat from the surrounding area.

- Expansion Valve: Regulates the flow of refrigerant into the evaporator, controlling the cooling effect.

- Control Unit: Manages the operation of the entire system, adjusting parameters based on user settings and environmental conditions.

Proper knowledge of these components not only aids in troubleshooting but also helps in planning maintenance schedules. Understanding the interplay among these elements can significantly improve the overall efficiency and reliability of mobile cooling solutions.

Analyzing the Structural Layout of Thermo King APU Parts

Understanding the configuration of components within a mobile climate control system is essential for effective maintenance and optimization. A well-structured arrangement not only facilitates efficient operation but also enhances the longevity of the equipment. This analysis focuses on the intricate relationships and positioning of various elements, highlighting how each contributes to overall functionality.

Component Interrelationships

Each element within the system plays a critical role, often interconnected to maximize efficiency. For instance, the alignment of the compressor with the evaporator and condenser ensures optimal thermal exchange. By examining these interrelations, one can better comprehend how energy flows through the system and identify potential areas for improvement or troubleshooting.

Importance of Design Efficiency

A well-thought-out design minimizes wasted space and reduces the risk of overheating or mechanical failure. Ergonomic placement of components, along with streamlined connections, can significantly impact the ease of access for repairs. Furthermore, thoughtful engineering can lead to enhanced performance, ensuring the system operates at peak efficiency even under demanding conditions.

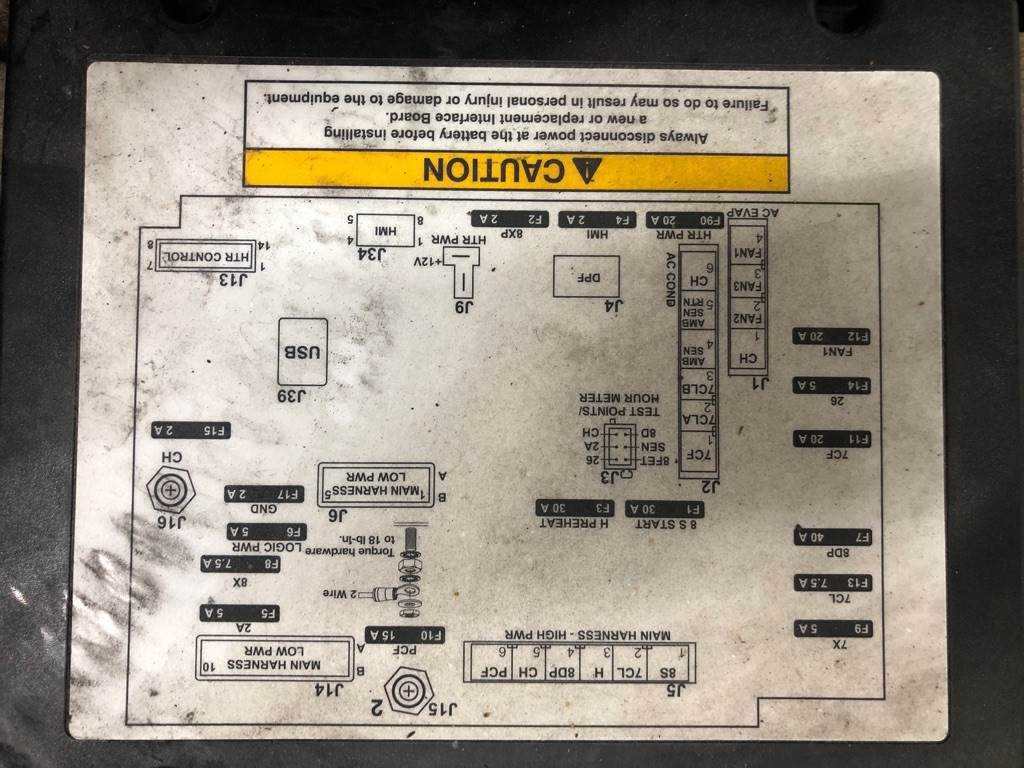

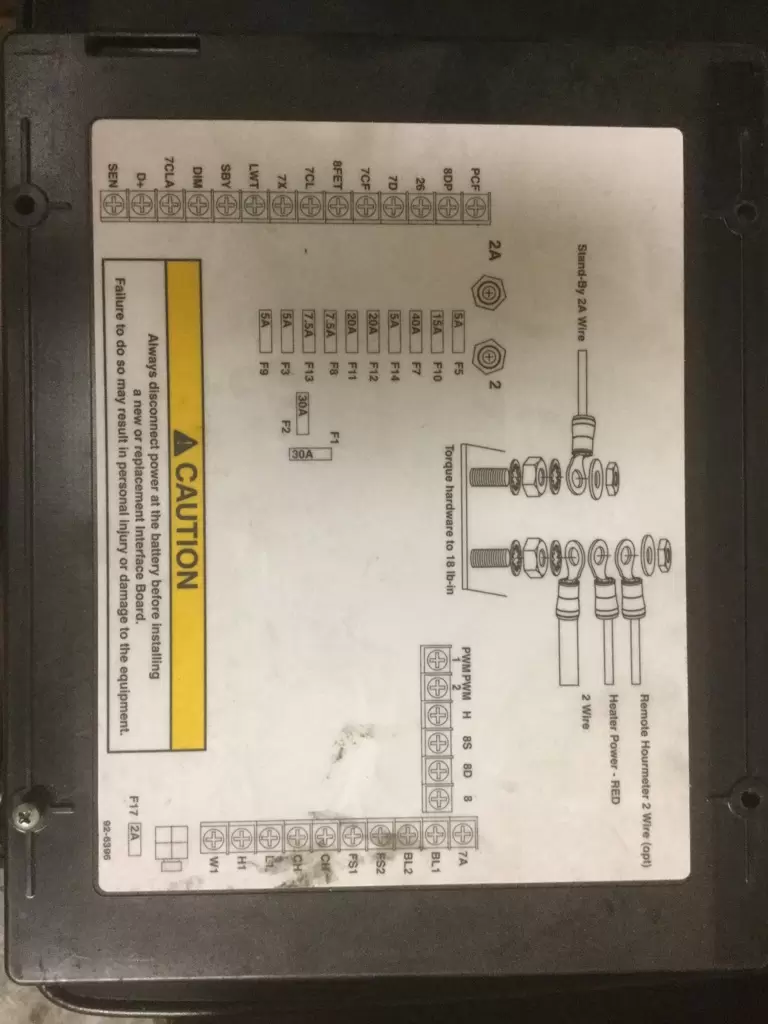

Visual Representation: Thermo King APU Parts Diagram Overview

This section provides a comprehensive overview of the visual representations commonly used to illustrate the components of a mobile refrigeration unit. Understanding these schematics is crucial for efficient maintenance, repair, and overall functionality. Such visuals serve not only as a guide but also as a means to facilitate better understanding of the intricate systems at play.

Key Components Illustrated

- Power Unit

- Compressor Assembly

- Cooling System

- Control Module

- Air Flow System

Each of these elements plays a vital role in ensuring optimal performance and efficiency. By familiarizing oneself with their locations and functions, operators can troubleshoot issues more effectively.

Benefits of Visual Representations

- Enhances understanding of complex systems.

- Facilitates quicker repairs and maintenance.

- Improves training for new technicians.

- Reduces errors during troubleshooting.

Utilizing these graphical depictions not only streamlines the repair process but also contributes to extending the lifespan of the equipment. Engaging with visual aids allows users to become more adept in identifying and resolving issues proactively.

Importance of Thermo King APU Parts in Cooling Systems

In the realm of mobile refrigeration, the components that ensure optimal performance are crucial for maintaining the desired temperature levels. These elements play a vital role in enhancing efficiency, reducing operational costs, and extending the lifespan of the entire cooling system. Understanding the significance of these components helps in ensuring that the equipment functions effectively, especially in demanding environments.

Effective temperature management relies on the seamless interaction of various mechanisms. Each element contributes to the overall functionality, making it essential to prioritize their maintenance and timely replacement. Neglecting any of these components can lead to decreased performance and potential system failures.

| Component | Function | Impact on Cooling System |

|---|---|---|

| Compressor | Circulates refrigerant | Critical for heat exchange efficiency |

| Condenser | Removes heat from refrigerant | Essential for maintaining low temperatures |

| Evaporator | Absorbs heat from the environment | Determines cooling capacity |

| Expansion Valve | Regulates refrigerant flow | Ensures optimal pressure and temperature |

Prioritizing the upkeep of these essential components not only ensures smooth operation but also enhances the overall reliability of the cooling apparatus. Investing in quality replacements and conducting regular maintenance can lead to significant long-term benefits for any refrigeration system.

Diagnostic Significance: Troubleshooting Thermo King APU Parts

Understanding the intricacies of cooling unit components is essential for effective maintenance and repair. Identifying issues promptly can enhance performance and prolong the lifespan of the equipment. This section delves into the diagnostic processes that aid in troubleshooting, ensuring that operators can efficiently address any malfunctions.

Key aspects of diagnosing these systems include:

- Visual Inspection: Regular checks can reveal signs of wear, damage, or loose connections.

- Error Codes: Utilizing onboard diagnostics to interpret fault messages can pinpoint specific issues.

- Performance Monitoring: Analyzing operational efficiency helps detect deviations from normal performance.

Common troubleshooting techniques include:

- Checking electrical connections and wiring for integrity.

- Examining fluid levels and leaks that could impact operation.

- Testing the functionality of key components, such as compressors and fans.

By systematically addressing these areas, technicians can effectively resolve issues and ensure optimal functionality of the equipment.

Thermo King APU Parts Maintenance and Replacement Guidelines

Regular upkeep and timely substitution of components are essential for ensuring optimal performance and longevity of your cooling system. Adhering to a structured maintenance regimen not only minimizes downtime but also enhances overall efficiency, resulting in cost savings and improved reliability.

To facilitate effective management, it is crucial to follow systematic procedures for inspection, cleaning, and replacement of various elements. Below is a table that outlines key components, recommended maintenance practices, and replacement intervals.

| Component | Maintenance Practice | Replacement Interval |

|---|---|---|

| Compressor | Check refrigerant levels and listen for unusual noises. | Every 3 years |

| Condenser Coil | Clean with a soft brush and inspect for damage. | Annually |

| Evaporator Coil | Inspect for frost build-up and clean to maintain airflow. | Every 6 months |

| Filters | Replace or clean to ensure proper airflow and efficiency. | Every 1-2 months |

| Batteries | Check connections and charge levels regularly. | Every 2 years |

By following these guidelines, operators can significantly extend the lifespan of their systems while ensuring they operate at peak efficiency. Regular monitoring and proactive care are the keys to a successful maintenance strategy.

Enhancing Efficiency: Upgrades for Thermo King APU Parts

Improving the performance of auxiliary power units is essential for optimizing fuel consumption and enhancing overall functionality. Upgrades can lead to significant advancements in efficiency, allowing operators to enjoy a more reliable and cost-effective experience. Implementing the right enhancements not only extends the lifespan of the equipment but also contributes to sustainability efforts.

Key Enhancements to Consider

Among the various modifications available, high-efficiency generators stand out as a vital upgrade. These generators minimize energy loss, ensuring that every drop of fuel is utilized effectively. Additionally, advanced control systems offer better management of energy use, allowing for real-time adjustments based on demand. Such innovations lead to smoother operations and reduced wear and tear on the unit.

Regular Maintenance and Upgrades

Incorporating upgraded filtration systems can also yield substantial benefits. Improved air and fuel filtration enhances engine performance and reliability. Moreover, regular maintenance schedules should be paired with these enhancements to guarantee optimal operation. Staying proactive in upgrading and maintaining the unit ensures that efficiency remains at the forefront of your operational strategy.

Economic Considerations: Cost Analysis of Thermo King APU Parts

When evaluating the financial implications of maintenance and repairs for specialized cooling systems, it is essential to understand the various factors that contribute to overall expenses. Analyzing the costs associated with components can provide valuable insights for fleet operators, ensuring informed decisions that balance quality and affordability.

Cost Components

The total expense of maintaining these systems encompasses several elements, including initial acquisition costs, ongoing maintenance, and potential replacement of components. Each of these factors plays a critical role in the total cost of ownership. Initial investments typically vary based on the specifications and technological features of the equipment, while ongoing upkeep can include routine servicing and emergency repairs that may arise over time.

Long-term Financial Impact

Understanding the long-term financial impact is crucial for effective budgeting. Investing in high-quality components may lead to reduced frequency of failures and lower overall maintenance costs. On the other hand, opting for cheaper alternatives could result in increased downtime and more frequent replacements, ultimately affecting productivity and profitability. Thus, a thorough cost-benefit analysis is recommended to ensure sustainable financial planning.

Compatibility Factors: Using Thermo King APU Parts with Different Models

When considering the integration of various components within engine cooling systems, it’s essential to understand the nuances of compatibility across different vehicle models. Each system’s design may vary, impacting performance and efficiency. Ensuring that the elements in question work harmoniously can significantly influence overall functionality.

Understanding Model Variations

Different vehicle models often come with unique specifications and configurations. Compatibility hinges on factors like size, mounting points, and power requirements. Adapting components from one model to another requires careful assessment of these attributes to avoid potential issues.

Key Considerations for Successful Integration

It’s crucial to consider manufacturer guidelines and industry standards when selecting components. Pay attention to part numbers and design features that may impact fitment and operation. Ultimately, thorough research and consultation with experts can lead to optimal performance and longevity of the system.

Future Trends: Innovations in Thermo King APU Parts Design

The landscape of auxiliary power units is evolving rapidly, driven by advancements in technology and the increasing demand for efficiency. Innovations are paving the way for enhanced performance, sustainability, and user-friendliness, ultimately transforming the design and functionality of these crucial components. As manufacturers embrace new materials and smart technologies, the future looks promising for both operators and the environment.

Smart Technology Integration

One of the most significant trends is the integration of smart technology into the components. This includes the use of IoT devices that monitor performance metrics in real-time. Such features enable proactive maintenance, reducing downtime and extending the lifespan of units. Additionally, the ability to connect to mobile applications allows users to track and manage their systems remotely, enhancing convenience and operational efficiency.

Sustainable Materials and Design

Another vital area of innovation is the shift towards sustainable materials. Manufacturers are increasingly focusing on eco-friendly alternatives that not only minimize environmental impact but also improve durability and performance. This approach not only meets regulatory requirements but also appeals to environmentally conscious consumers. Lightweight designs are becoming the norm, contributing to overall energy efficiency while maintaining structural integrity.

| Innovation | Description |

|---|---|

| Smart Monitoring | Real-time performance tracking using IoT technology for predictive maintenance. |

| Sustainable Materials | Use of eco-friendly alternatives to enhance durability and reduce environmental impact. |

| Lightweight Design | Optimized structural components for improved energy efficiency and performance. |

| Remote Management | Mobile applications allowing users to control and monitor systems from anywhere. |