Understanding the Flush Valve in Toilet Parts Diagram

In every household, efficient management of water flow is crucial for both functionality and conservation. This intricate system consists of various components working together seamlessly to regulate the usage of water during sanitation processes. A closer examination of these elements reveals their essential roles in ensuring optimal performance and durability.

One of the key elements in this assembly is responsible for initiating and halting the water flow, allowing for precise control during operation. This mechanism is designed to handle fluctuations in pressure and ensure a consistent supply, contributing to the overall effectiveness of the system. By understanding its configuration and operation, homeowners can better appreciate how to maintain and troubleshoot these vital functions.

As we delve deeper into the specifics of this water management system, it becomes clear that familiarity with its components can lead to improved efficiency and longevity. Knowledge of how each element interacts not only empowers users to make informed decisions regarding repairs and upgrades but also promotes a greater awareness of water conservation practices.

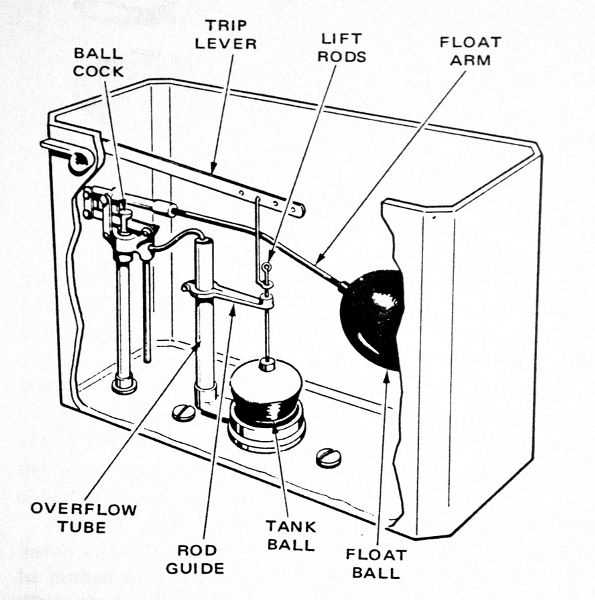

Understanding Flush Valve Components

Effective operation of a restroom facility relies on various mechanisms that work in harmony. Among these, a specific assembly plays a crucial role in controlling the flow of water, ensuring both functionality and efficiency. This section delves into the fundamental elements that comprise this essential system, highlighting their individual roles and interconnections.

Key Elements of the Mechanism

- Water Supply Connection: This is where the water enters the assembly, providing the necessary flow for operation.

- Sealing Mechanism: A critical component that ensures water does not leak when not in use, maintaining efficiency.

- Actuation Device: This element triggers the release of water, often activated by user input.

- Overflow Tube: A safety feature designed to prevent excess water from spilling, directing it back to the tank.

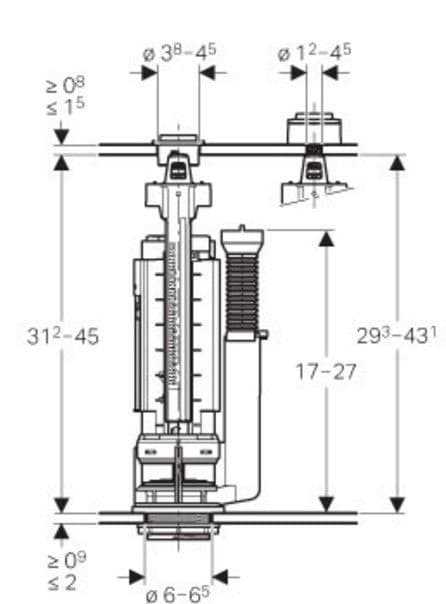

- Adjustable Height Mechanism: Allows for customization of water levels, accommodating various preferences and needs.

Functionality and Interaction

Each component works together to create a seamless experience. When the actuation device is engaged, the sealing mechanism releases water, while the overflow tube safeguards against potential overflow. The adjustable height feature enhances versatility, adapting to different requirements. Understanding these elements not only aids in maintenance but also empowers users to optimize performance.

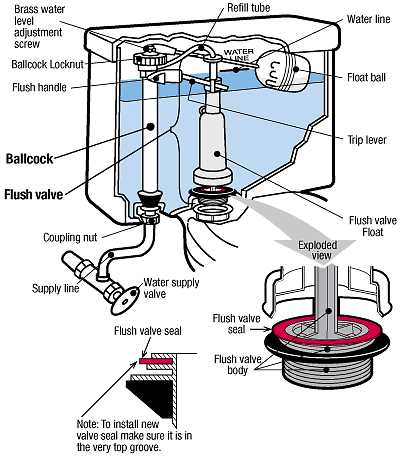

Function of the Flush Valve

The mechanism in question plays a crucial role in the efficient disposal of waste. Its primary task is to manage the flow of water, ensuring that the process occurs smoothly and effectively.

- Controls the release of water from the reservoir.

- Initiates the cleaning process after activation.

- Maintains proper water levels for optimal function.

- Prevents leaks and ensures reliability during use.

Understanding its operation is essential for maintaining overall functionality and addressing any potential issues that may arise.

Common Types of Flush Valves

Understanding the various mechanisms responsible for water release in sanitation systems is essential for maintenance and efficient operation. These systems can vary significantly in design, functionality, and installation, each serving a specific purpose to ensure optimal performance.

Cylinder Mechanisms

Cylinder-based mechanisms are widely recognized for their reliability and ease of use. They typically consist of a cylindrical body that controls water flow, allowing for smooth operation during each cycle.

Piston Mechanisms

Piston systems operate with a sealed cylinder and a moving piston, which generates pressure to release water. These are often praised for their durability and effectiveness in controlling flow rates.

| Type | Characteristics |

|---|---|

| Cylinder | Reliable, easy to operate, common in residential settings. |

| Piston | Durable, effective in flow control, used in high-demand environments. |

How Flush Valves Operate

The mechanism responsible for the rapid release of water is a vital component in the overall functionality of sanitation systems. Understanding how this system works is essential for efficient maintenance and effective operation.

Typically, the process involves several key steps:

- Activation: A lever or button initiates the release process.

- Water Release: A seal is lifted, allowing water to flow from the reservoir.

- Clearing Cycle: The released water forces waste away through the drainage system.

- Refill: The reservoir replenishes to prepare for the next cycle.

Key features that enhance functionality include:

- Durability: Materials withstand constant use and pressure.

- Efficiency: Design minimizes water waste during operation.

- Adjustability: Settings can be modified to suit specific needs.

Ultimately, understanding this mechanism aids in troubleshooting and enhances the user experience.

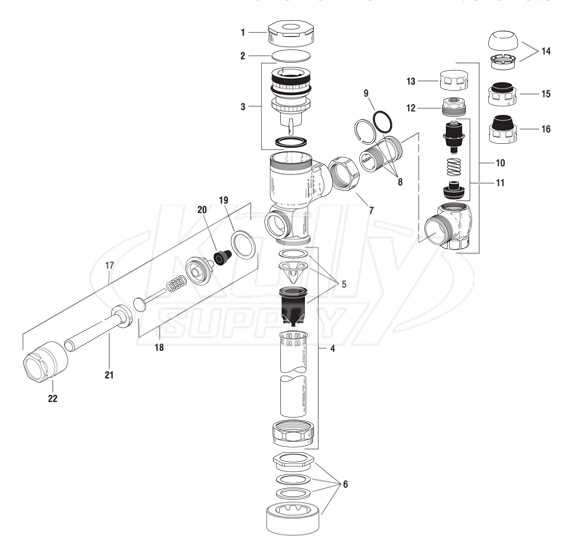

Identifying Flush Valve Parts

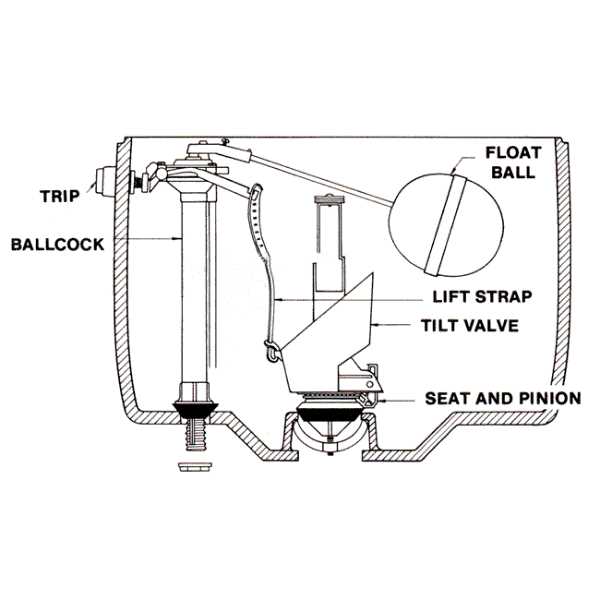

Understanding the components of a water control mechanism is essential for effective maintenance and troubleshooting. Each element plays a crucial role in ensuring proper function and efficiency, and recognizing these components can simplify repairs and replacements.

Water Storage Chamber: This is the main reservoir where liquid is held until it is released. It is essential for managing the flow during operation.

Release Mechanism: Often operated by a lever or button, this part initiates the flow of water, allowing the stored liquid to exit when needed.

Sealing Element: This crucial component prevents leakage when the system is not in use. A well-functioning seal ensures that the chamber retains water until the next operation.

Float Assembly: This device regulates the water level within the chamber, ensuring it fills to an appropriate level before operation commences.

Adjustable Overflow Tube: This feature prevents overfilling by directing excess water away from the storage area, maintaining safety and efficiency.

By familiarizing yourself with these elements, you can confidently address any issues that may arise and maintain optimal performance of your water management system.

Maintenance Tips for Flush Valves

Regular upkeep of your restroom’s flushing mechanism is crucial for optimal performance and longevity. Implementing simple maintenance practices can prevent leaks and ensure smooth operation, ultimately saving water and reducing costs.

Routine Checks

- Inspect for leaks: Regularly check the area for any signs of water accumulation.

- Listen for noises: Unusual sounds can indicate malfunctioning components.

- Monitor water levels: Ensure that the water reaches the appropriate height for effective functioning.

Cleaning and Replacement

- Clean components: Remove debris and mineral buildup from internal parts periodically.

- Replace worn seals: Inspect rubber components for wear and replace as needed.

- Test operation: After cleaning or replacements, flush multiple times to confirm proper performance.

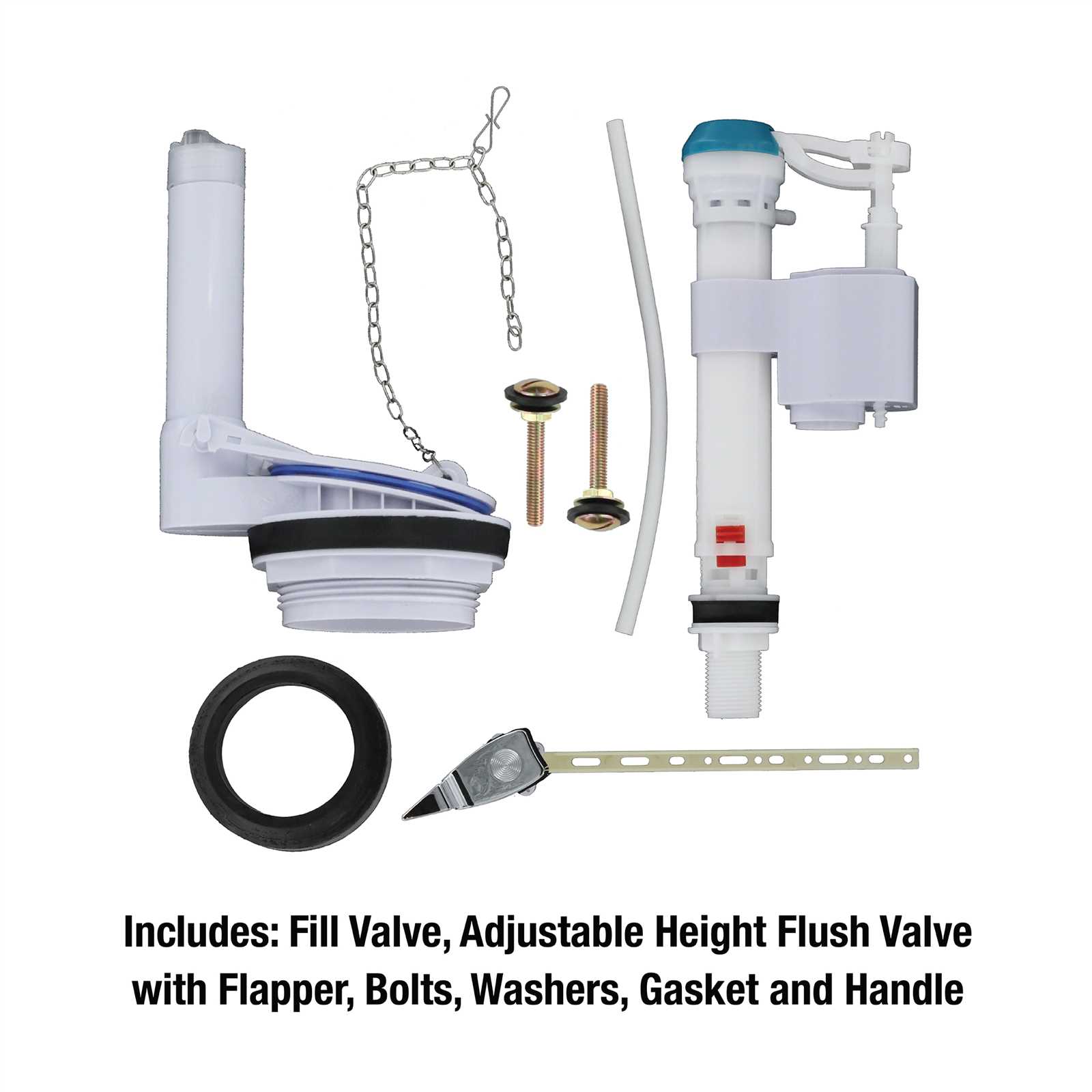

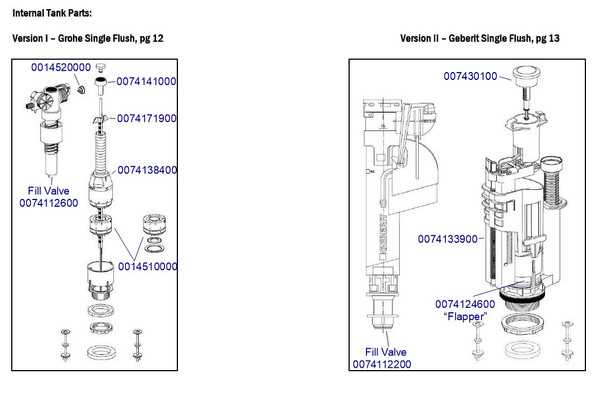

Flush Valve Installation Guide

This section provides a comprehensive overview of how to properly install a crucial component of your sanitation system. Understanding the correct procedures will ensure optimal functionality and longevity of the mechanism, making your experience more efficient.

Preparation Steps

Before starting the installation process, gather all necessary tools and materials. It is advisable to turn off the water supply to avoid any spills. Clear the area around the fixture to create a safe working environment. A clean workspace minimizes the risk of losing small components during installation.

Installation Process

Begin by removing the existing mechanism carefully, ensuring not to damage surrounding fixtures. Follow the manufacturer’s instructions closely when placing the new unit. Secure all connections firmly but avoid overtightening, which could lead to leaks. After installation, restore the water supply and check for any leaks or irregularities in performance. Allow the system to fill completely before testing functionality.

Note: Regular maintenance will prolong the life of your new component. Always refer to the user manual for specific care instructions.

Common Issues with Flush Valves

Understanding the frequent problems associated with the mechanism responsible for waste removal is essential for maintaining efficiency and functionality. Many users encounter issues that can disrupt proper operation, leading to inconvenience and potential damage if not addressed promptly.

One of the most prevalent concerns is leaking, which often results from worn or damaged seals. This can lead to water wastage and increased utility bills. Additionally, improper alignment of components can cause intermittent functioning, where the mechanism may not activate consistently.

Another common problem is the accumulation of debris, which can hinder performance and lead to blockages. Regular maintenance can help mitigate this issue, ensuring smooth operation. Furthermore, users may experience noise during the operation, typically indicative of air bubbles or pressure imbalances within the system.

Addressing these challenges promptly can prolong the lifespan of the mechanism and enhance overall performance, making it crucial for users to stay informed about potential issues.

Flush Valve Repair Techniques

Repairing components related to water management in sanitary systems can be a straightforward process if approached methodically. Understanding the common issues and employing the right methods can lead to effective solutions, ensuring optimal performance and longevity of the system.

Identify the Issue: The first step involves diagnosing the problem, whether it’s leaks, inadequate performance, or noises. Observing the symptoms will help in pinpointing the malfunctioning element.

Gather Necessary Tools: Ensure you have all required tools at hand, such as wrenches, screwdrivers, and replacement elements. Having the right equipment will facilitate a smoother repair experience.

Disassemble with Care: Carefully dismantle the system, taking note of the arrangement of components. This will assist in reassembly and prevent confusion during the process.

Replace or Repair: Depending on the condition of the components, either replace worn-out items or repair them using appropriate sealants or adhesives. Ensure that any new pieces are compatible with the existing setup.

Reassemble and Test: After making necessary repairs, reassemble the components methodically. Once everything is in place, conduct tests to confirm functionality and check for any leaks.

Regular maintenance and timely repairs can significantly enhance the efficiency of your system, leading to fewer issues and a better overall experience.

Tools Needed for Repair

When tackling repairs in plumbing systems, having the right equipment is essential for a successful outcome. A well-prepared toolkit ensures efficiency and minimizes frustration during the process. Understanding the specific tools required can make the task more manageable and effective.

For basic maintenance, a pair of adjustable pliers and a screwdriver set are crucial for loosening and tightening fittings. A bucket is useful for catching any residual water, while a sponge or cloth helps with clean-up. Additionally, a utility knife can assist in cutting materials as needed. For more intricate repairs, specialized tools such as a pipe wrench or a basin wrench may be required. Having these instruments on hand will enable you to address any issues with confidence and ease.

When to Replace a Flush Valve

Understanding when to change this crucial component can save you time, money, and frustration. Certain signs indicate that it’s time for a replacement, ensuring optimal functionality and efficiency.

Signs of Wear and Tear

- Frequent leaks or drips

- Unusual noises during operation

- Inconsistent water levels

- Visible cracks or damage

Maintenance Considerations

- Regular inspections are essential.

- Replace if repairs become too frequent.

- Consider upgrading to improve efficiency.

Choosing the Right Flush Valve

Selecting the appropriate mechanism for your restroom’s waste disposal system is crucial for ensuring efficient performance and longevity. A variety of options exist, each designed to cater to specific requirements and preferences. Understanding these choices will help you make an informed decision.

First, consider the design and compatibility with your existing setup. Different mechanisms vary in size and operation, so it’s essential to choose one that fits seamlessly within your current configuration. Additionally, think about the flushing power; some systems offer stronger performance, which can lead to better waste removal and reduced clogs.

Next, evaluate the material quality. High-grade components tend to last longer and perform better over time, reducing the need for frequent replacements. Look for options that offer a balance between durability and cost-effectiveness, ensuring you get the best value.

Lastly, ease of installation and maintenance should not be overlooked. Some models are designed for quick setup and require minimal upkeep, which can save you time and effort in the long run. Assess user reviews and recommendations to find a solution that meets your specific needs while ensuring reliability and efficiency.

Impact on Water Efficiency

Understanding the mechanisms that control water flow can significantly influence overall conservation efforts. By optimizing these systems, users can reduce unnecessary consumption while maintaining effective operation.

Importance of Proper Functioning

When these systems operate efficiently, they minimize wastage. A well-tuned mechanism ensures that only the necessary amount of liquid is utilized, contributing to sustainability goals and lowering utility bills.

Innovative Solutions

Advancements in design and technology have led to more effective solutions. Smart systems can adapt to usage patterns, allowing for a dynamic approach to water management, thus achieving the ultimate balance between functionality and efficiency.