Exploring the Tomos A35 Parts Diagram for Ultimate Understanding

The intricate design of vintage mopeds showcases a harmonious blend of mechanical ingenuity and artistry. Each component plays a crucial role in the overall functionality, contributing to the vehicle’s performance and reliability. Exploring the arrangement of these elements can enhance one’s appreciation for the engineering behind such classics.

Familiarity with the various segments of the machine allows enthusiasts to better maintain and restore their beloved rides. By breaking down the construction into its essential units, one can effectively tackle repairs or upgrades. This detailed exploration serves as a roadmap for those looking to delve deeper into the mechanical heart of these two-wheeled treasures.

In this section, we will examine the critical aspects of the assembly, focusing on how each element interacts with the others. Understanding these relationships not only aids in restoration efforts but also provides insight into the ultimate design philosophies that govern moped engineering.

Understanding Tomos A35 Components

Gaining insight into the various elements of a classic two-wheeled vehicle is essential for enthusiasts and mechanics alike. Each component plays a crucial role in the overall functionality and performance, making it vital to understand their individual characteristics and interrelationships. This section will delve into the key features of these essential elements, providing a comprehensive overview for better maintenance and repair practices.

Key Functional Elements

Every vehicle comprises several core functional parts that work in harmony to ensure optimal performance. Understanding these components helps in diagnosing issues and implementing effective solutions. The main categories include the engine, transmission, suspension, and braking systems.

| Component | Description |

|---|---|

| Engine | The powerhouse that converts fuel into motion, essential for acceleration and overall speed. |

| Transmission | Transfers power from the engine to the wheels, crucial for managing speed and torque. |

| Suspension | Ensures stability and comfort by absorbing shocks and maintaining tire contact with the ground. |

| Braking System | Critical for safety, it allows for controlled deceleration and stopping. |

Maintenance Tips

Regular upkeep of these components is vital for longevity and reliable performance. Routine checks and timely replacements of worn parts can prevent more significant issues down the road. Familiarity with the functions and potential problems associated with each element empowers owners to take proactive steps in vehicle care.

Key Features of Tomos A35

This section explores the standout characteristics of a classic moped that has captivated enthusiasts over the years. Its design, performance, and reliability make it a noteworthy choice for riders seeking a blend of vintage charm and functionality.

Design and Build Quality

The moped boasts a sleek, compact frame that enhances maneuverability while maintaining a robust structure. Attention to detail in its craftsmanship ensures durability, allowing it to withstand the rigors of everyday use.

Performance and Efficiency

Equipped with a powerful engine, it delivers a satisfying riding experience characterized by smooth acceleration and impressive fuel economy. This combination not only makes it enjoyable to ride but also economical for daily commuting.

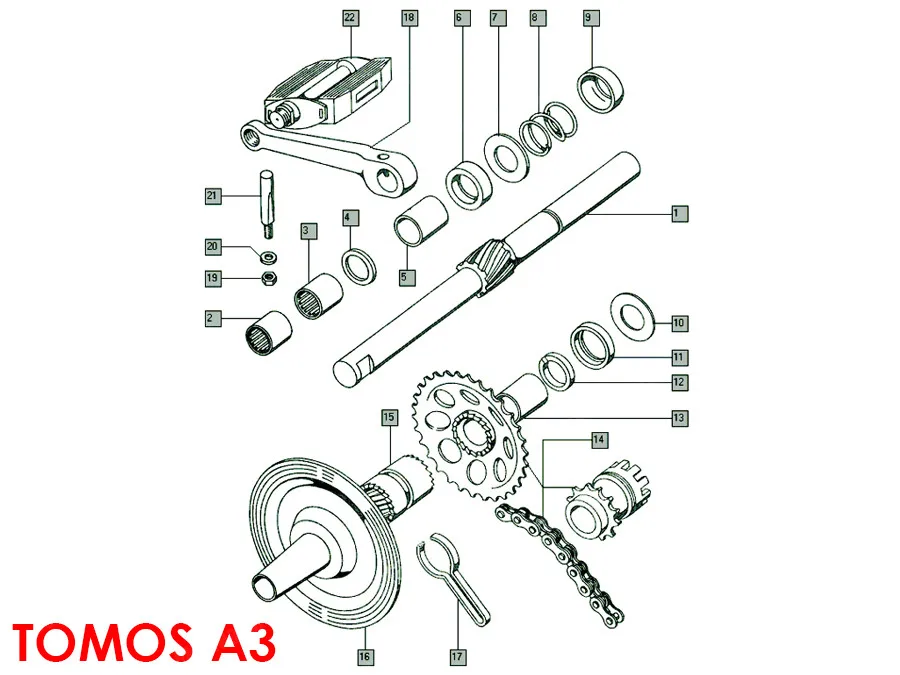

Parts Identification Guide

This section aims to assist users in recognizing and understanding the various components of their vehicle, ensuring they can identify each element with ease. Accurate identification is crucial for maintenance and repairs, enhancing the overall performance and longevity of the machine.

Key Components

- Engine Assembly

- Transmission System

- Suspension Parts

- Electrical System

- Fuel System

Identification Tips

- Refer to the manufacturer’s manual for specific details.

- Use online resources for visual references.

- Consult with a professional if unsure about any component.

Common Issues and Solutions

This section explores frequent challenges encountered with specific mechanical devices and offers practical solutions to address them. Understanding these common problems can enhance the longevity and functionality of your equipment.

Performance Issues

Devices may exhibit reduced efficiency over time. Regular maintenance is essential. Check for blockages or wear in key components. Cleaning or replacing filters can often restore optimal performance.

Electrical Failures

Another prevalent concern involves electrical malfunctions. Ensure all connections are secure and free of corrosion. Inspect wiring for damage and replace any faulty parts to prevent further complications.

Where to Find Replacement Parts

Finding the right components for your vehicle can be a straightforward process if you know where to look. There are several reliable sources that cater to enthusiasts and those in need of repairs. Here are some options to consider when searching for suitable items:

- Online Retailers: Numerous websites specialize in motorcycle and scooter accessories. They often have extensive inventories and may provide useful customer reviews.

- Local Dealerships: Authorized dealers can be a dependable source for genuine components. Visiting them may also offer insights into the latest products and upgrades.

- Aftermarket Suppliers: Companies that focus on aftermarket solutions frequently offer compatible alternatives that may be more affordable than original parts.

- Salvage Yards: Visiting a salvage yard can yield unexpected finds. Many facilities dismantle vehicles and sell individual components at reduced prices.

- Online Marketplaces: Platforms like eBay or Craigslist can connect you with private sellers who have items for sale, often at negotiable prices.

Each of these sources presents its own advantages and disadvantages. Researching thoroughly and comparing prices will help you make informed choices. Always consider the quality and warranty options when acquiring new components.

Maintenance Tips for Longevity

Ensuring the durability and optimal performance of your vehicle requires consistent care and attention. By following a few essential guidelines, you can significantly extend its lifespan and enhance its reliability on the road.

Regular Inspections: Conduct routine checks to identify any potential issues before they escalate. Pay special attention to fluid levels, tire condition, and overall functionality. Early detection can save time and resources.

Routine Cleaning: Keeping the exterior and interior clean not only improves aesthetics but also prevents rust and deterioration. Use appropriate cleaning agents that are gentle on surfaces to maintain their quality.

Fluid Maintenance: Regularly change oils, lubricants, and other fluids as recommended by the manufacturer. Fresh fluids help reduce friction and wear, ensuring smooth operation and enhancing overall performance.

Tire Care: Monitor tire pressure and tread wear regularly. Properly inflated tires improve fuel efficiency and provide better handling, while adequate tread depth ensures safety.

Storage Conditions: When not in use, store your vehicle in a dry, sheltered environment. Protecting it from extreme weather conditions minimizes damage and deterioration.

Professional Servicing: Schedule periodic professional inspections. Experienced technicians can identify and rectify issues that may not be apparent to the average user, ensuring long-term reliability.

By incorporating these maintenance practices into your routine, you will not only enhance the performance of your vehicle but also enjoy a safer and more efficient riding experience.

Upgrades for Improved Performance

Enhancing the efficiency and capability of a vehicle often involves strategic modifications. These upgrades can lead to significant improvements in speed, handling, and overall responsiveness, transforming a standard model into a more dynamic machine. Focusing on key components can provide noticeable results, elevating the riding experience and ensuring better performance on the road.

Engine Modifications

One of the most impactful areas for enhancement is the engine. Upgrading to a high-performance air filter can improve airflow, resulting in better combustion and increased power output. Additionally, a high-performance exhaust system can reduce back pressure and enhance engine efficiency. Together, these changes can lead to a noticeable boost in acceleration and top speed.

Suspension and Handling

Improving suspension components can dramatically affect handling and stability. Installing aftermarket shocks and struts will provide better control over rough terrain, enhancing the overall ride quality. Furthermore, upgrading to performance tires can significantly increase grip and traction, ensuring safer and more agile maneuvering during various driving conditions.

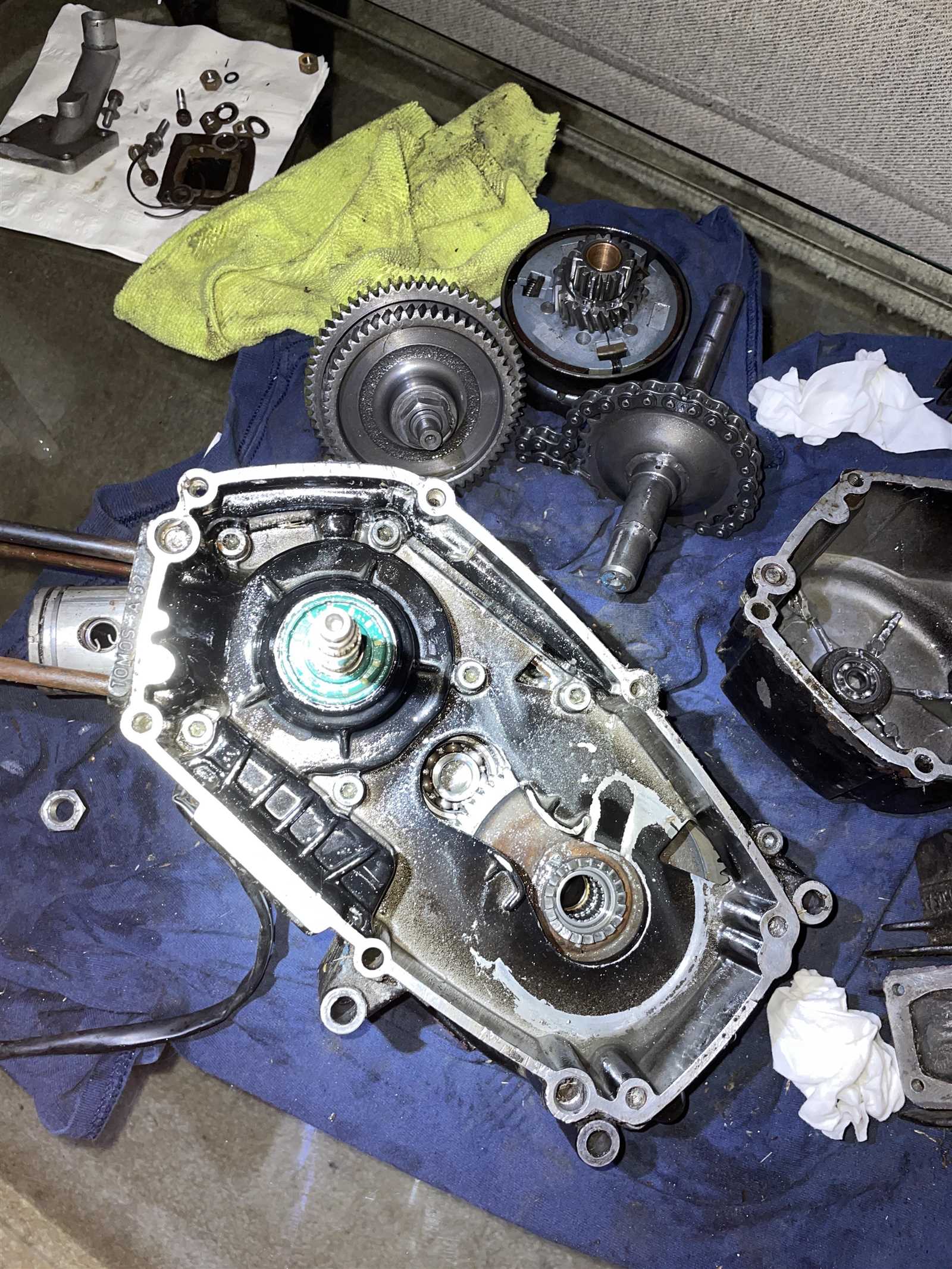

Disassembly Process Explained

The process of dismantling mechanical equipment requires careful attention and methodical execution. Understanding the sequence of steps is crucial for ensuring that each component can be removed without damage and reassembled correctly. This guide outlines the essential stages involved in safely taking apart an assembly.

Preparation Steps

Before beginning the disassembly, gather the necessary tools and create a clean workspace. Ensure that all fasteners, screws, and clips are accounted for, as losing any small parts can complicate reassembly. Documenting the arrangement of components through photographs or notes can also be beneficial for future reference.

Disassembly Techniques

Start by removing external covers and protective casings to expose internal elements. Work systematically, taking care to avoid applying excessive force. Utilize the appropriate tools for specific fasteners to prevent stripping or damaging the threads. As each piece is removed, organize them in a logical manner, which will simplify the reassembly process.

Wiring Diagram Overview

This section provides a comprehensive examination of the electrical layout that governs the operation of the vehicle’s systems. Understanding the intricacies of the wiring setup is essential for troubleshooting, modifications, and ensuring optimal functionality of the various components. By exploring this visual representation, users can gain insights into the connections that facilitate power distribution and signal transmission throughout the system.

Key Components and Their Functions

The schematic illustrates various elements, including the ignition system, lighting circuits, and battery connections. Each component plays a crucial role in the overall performance and reliability of the vehicle. Familiarity with these parts allows for better maintenance practices and informed decision-making when it comes to repairs or upgrades.

Common Issues and Troubleshooting Tips

Misconnections, shorts, and wear can lead to numerous challenges. Identifying these issues typically involves cross-referencing with the schematic to locate the source of the problem. Regular inspection of the wiring can prevent potential failures and ensure a seamless operation of all electrical features.

Tools Needed for Repairs

Effective maintenance and restoration require a specific set of instruments to ensure precision and efficiency. Having the right gear not only simplifies the process but also enhances the quality of the work performed. Each tool serves a unique purpose, contributing to a seamless repair experience.

Basic hand tools such as wrenches, screwdrivers, and pliers are essential for disassembly and assembly tasks. Additionally, specialized instruments like torque wrenches and feeler gauges may be necessary for more intricate adjustments. Properly organized workspaces and storage solutions further facilitate efficient workflow.

Finally, safety equipment, including gloves and goggles, is crucial to protect oneself during repairs. Investing in high-quality tools and prioritizing safety will ultimately lead to more successful and satisfying outcomes in any repair endeavor.

Frequently Asked Questions

This section addresses common inquiries regarding the assembly and components of a popular model, aiming to provide clarity and assistance to users seeking information.

General Inquiries

- What are the main components of this model?

- How can I locate specific parts for maintenance?

- Are there any common issues I should be aware of?

Technical Assistance

- How do I troubleshoot performance problems?

- What tools are necessary for repairs?

- Where can I find reliable service manuals?