Understanding the Trail King Lowboy Parts Diagram

The intricate assembly of transport equipment plays a pivotal role in ensuring efficiency and reliability in the movement of heavy loads. This specialized machinery, designed for robust performance, consists of various elements that work in harmony to facilitate the transport process. A comprehensive understanding of these components is essential for operators and technicians alike, enabling them to maintain optimal functionality.

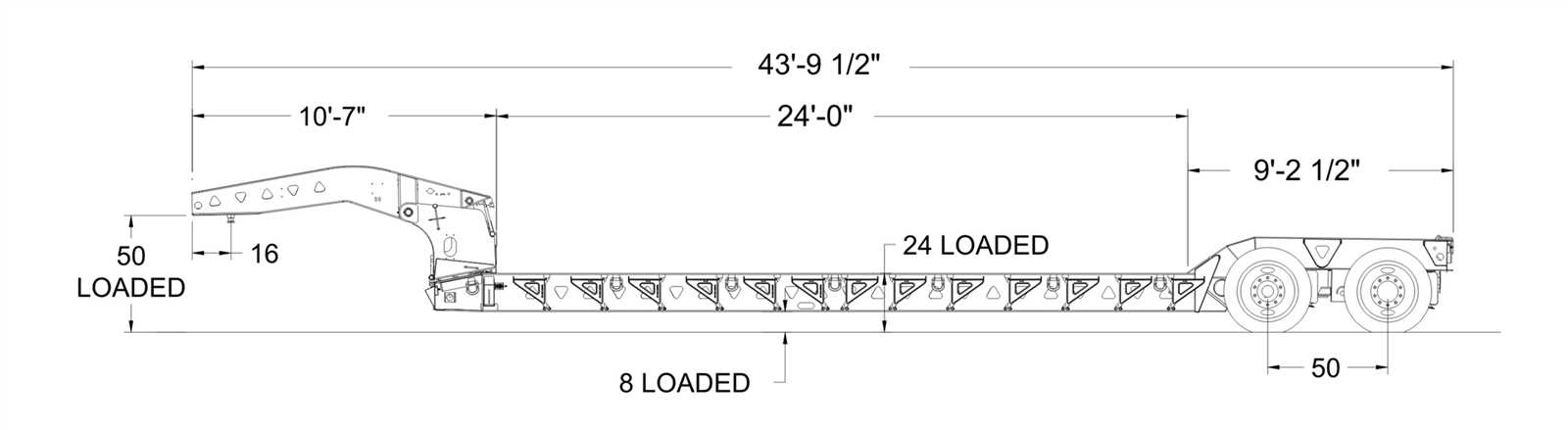

In the world of heavy machinery, visual aids become invaluable. They provide clear insights into the arrangement and interaction of each part, making it easier to diagnose issues and plan maintenance. By analyzing these illustrations, one can gain a deeper appreciation for the engineering that underpins such formidable transport solutions.

Moreover, familiarity with the individual elements not only enhances operational efficiency but also contributes to safety standards. Recognizing how each component integrates into the larger system allows for proactive measures in maintenance, reducing the risk of breakdowns and ensuring uninterrupted service. This knowledge ultimately translates into improved performance and longevity of the equipment.

Understanding Trail King Lowboy Trailers

Heavy-duty transport solutions are essential for industries requiring the movement of oversized equipment. These specialized vehicles are designed to provide stability and support for large loads, ensuring safety and efficiency on the road. The design and functionality of these trailers are crucial for operators who need reliable transportation for their valuable cargo.

Key Features and Benefits

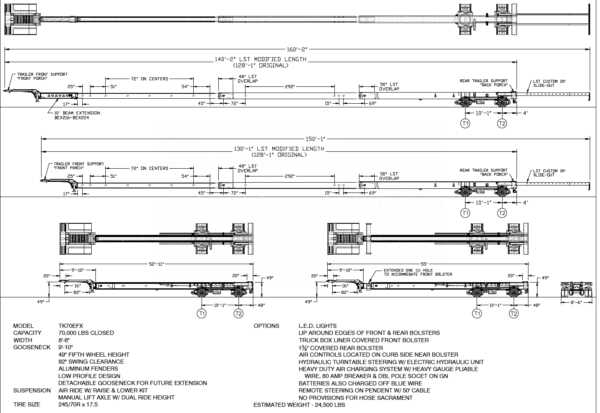

These transport solutions come equipped with several key characteristics that enhance their usability and performance. From their robust construction to adjustable height features, each aspect is tailored to facilitate the movement of substantial machinery and materials. Operators benefit from improved load distribution and increased versatility, making them a preferred choice in various sectors.

Maintenance and Care

Regular upkeep is vital for ensuring the longevity and performance of these trailers. Understanding the components and their functions allows operators to perform effective maintenance, minimizing downtime and maximizing productivity. Following a systematic maintenance schedule can significantly extend the lifespan of these transport vehicles.

| Component | Function |

|---|---|

| Frame | Supports the overall structure and weight distribution. |

| Axles | Facilitate movement and load bearing during transit. |

| Wheels | Provide traction and stability on various surfaces. |

| Ramp | Allows easy loading and unloading of heavy equipment. |

Key Components of Lowboy Trailers

Understanding the essential elements of flatbed transport solutions is crucial for efficient loading and hauling. These specialized trailers are designed to accommodate heavy and oversized loads, featuring a unique structure that facilitates stability and accessibility. Various components work together to ensure safety, performance, and ease of use.

The primary structure typically includes a robust frame that supports significant weight, while a low profile allows for lower clearance, making loading and unloading simpler. Additionally, adjustable ramps or platforms are essential for accommodating different vehicle heights and types, ensuring versatility across various hauling needs.

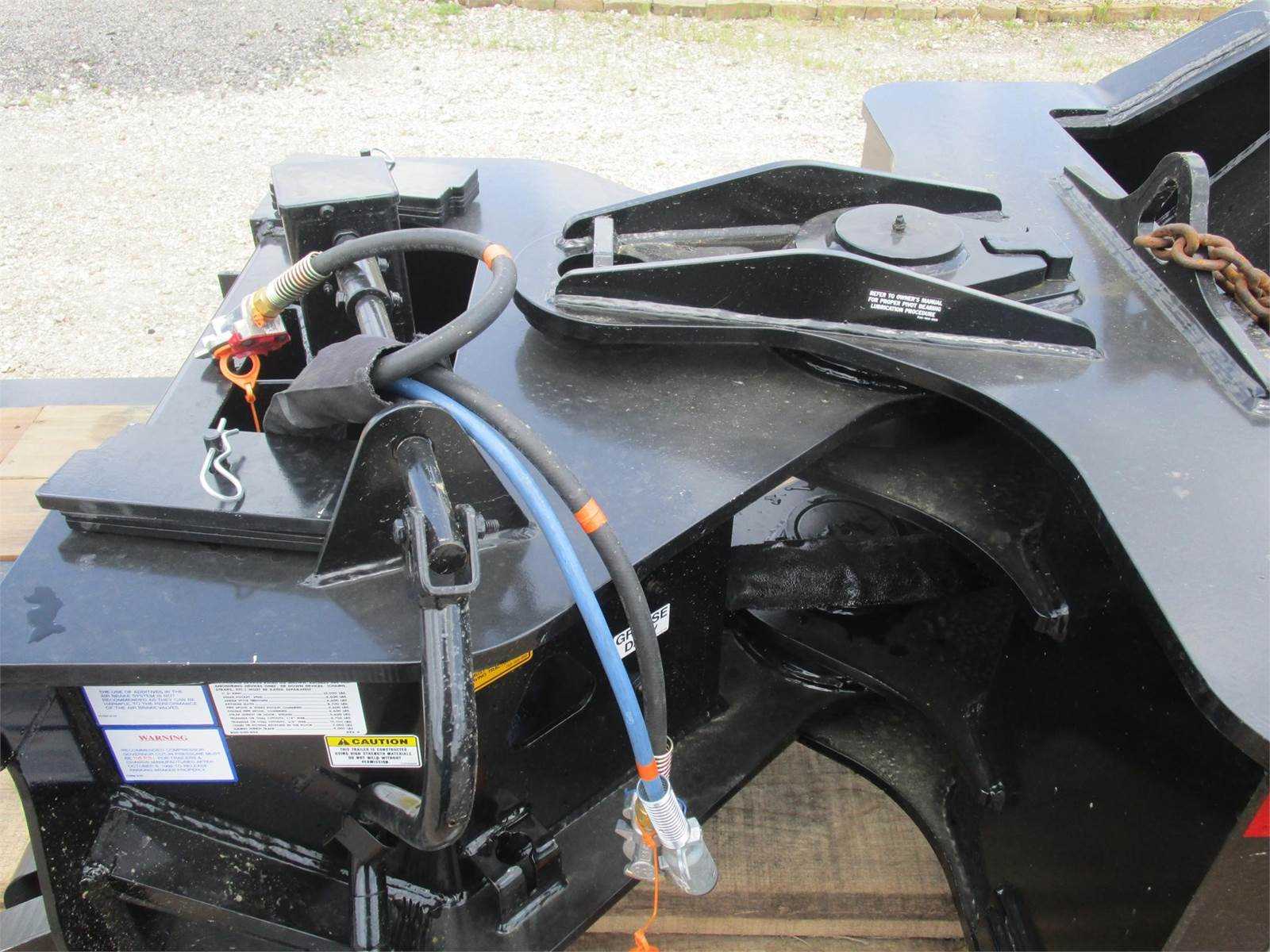

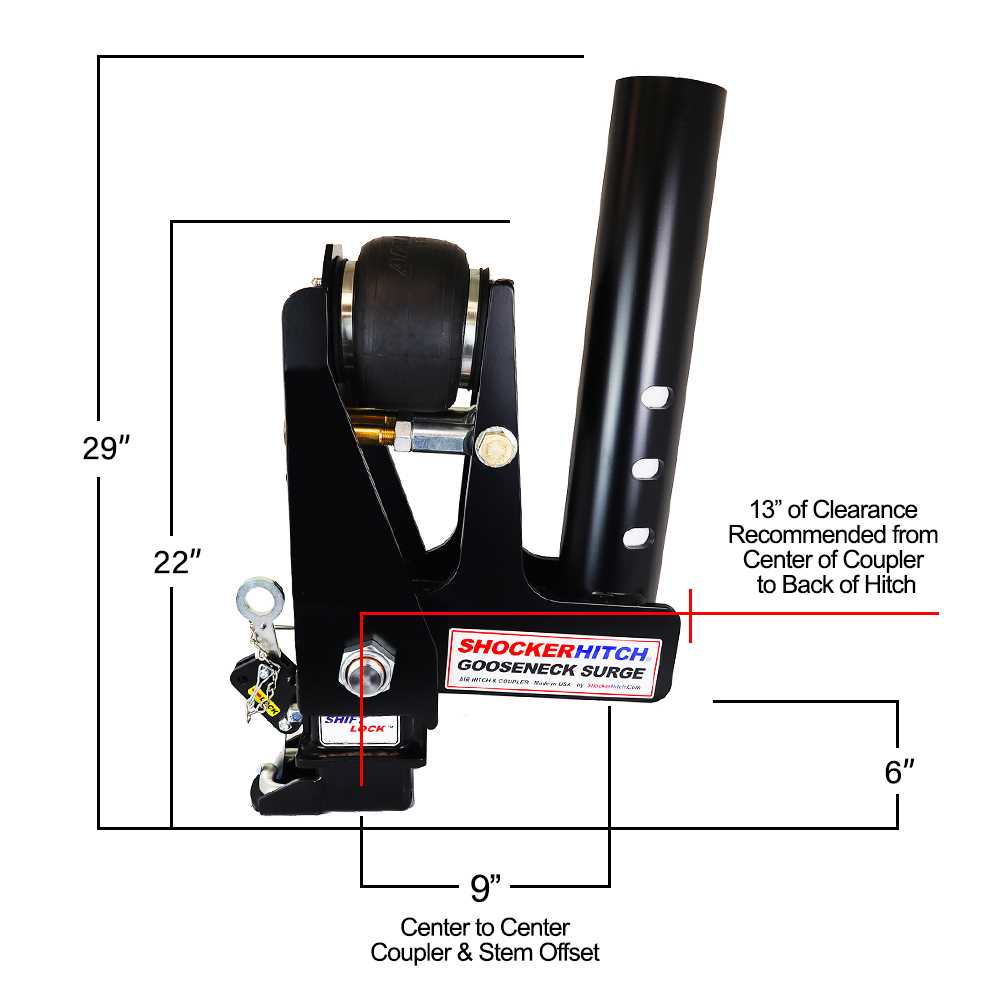

Suspension systems play a vital role in providing a smooth ride, enhancing stability during transport. Wheels and axles are engineered to handle substantial loads, contributing to overall durability and safety. Couplers and hitching mechanisms ensure secure connections to towing vehicles, allowing for seamless transport operations.

Finally, safety features such as lighting, reflectors, and brake systems are critical for compliance with transportation regulations and for ensuring visibility on the road. Together, these elements form the backbone of effective and reliable flatbed trailers, making them indispensable in the logistics industry.

Importance of Proper Maintenance

Regular upkeep of heavy machinery is essential for ensuring optimal performance and longevity. Neglecting maintenance can lead to unexpected failures, increased downtime, and higher operational costs. By adhering to a systematic maintenance schedule, operators can enhance safety, improve efficiency, and prolong the lifespan of their equipment.

Moreover, effective maintenance practices contribute to better fuel efficiency and reduce the likelihood of costly repairs. It is important to monitor various components and systems regularly to identify potential issues before they escalate.

| Benefit | Description |

|---|---|

| Enhanced Safety | Regular checks minimize the risk of accidents caused by equipment failure. |

| Cost Savings | Preventive measures reduce the likelihood of expensive repairs and replacements. |

| Increased Efficiency | Well-maintained machines operate at peak performance, ensuring productivity. |

| Extended Lifespan | Consistent care can significantly increase the operational life of equipment. |

In summary, committing to regular maintenance is not just an option but a necessity for anyone looking to optimize their machinery’s performance and reliability. Properly maintained equipment not only meets operational demands but also supports a safer working environment.

Common Issues with Lowboy Parts

Transport equipment often faces a variety of challenges that can impact its functionality and safety. Understanding these issues is crucial for maintaining efficiency and ensuring longevity. Below are some frequent complications encountered with this type of transport vehicle.

- Wear and Tear: Continuous use can lead to significant degradation of components, affecting overall performance.

- Improper Maintenance: Neglecting regular checks can result in overlooked problems that escalate over time.

- Load Distribution: Unevenly distributed loads can cause undue stress on specific parts, leading to potential failures.

- Corrosion: Exposure to elements may result in rust and deterioration, especially in metal components.

- Brake Issues: Problems with braking systems are common and can compromise safety if not addressed promptly.

Being aware of these challenges allows operators to implement preventive measures, thereby enhancing performance and safety in transport operations.

How to Read Parts Diagrams

Understanding technical illustrations is essential for effective maintenance and repair. These visual representations provide crucial insights into the components of machinery, helping users identify and locate specific elements quickly. Familiarity with these diagrams can greatly enhance troubleshooting and assembly tasks.

Key Elements to Identify

- Labels: Often, parts are labeled with numbers or letters, corresponding to a legend or list.

- Symbols: Recognize common symbols that indicate different components, such as fasteners or electrical connections.

- Views: Diagrams may present multiple angles, showing how parts fit together from different perspectives.

Steps for Effective Reading

- Start by reviewing the legend to understand the notation used.

- Identify the main assembly and its relationship to other parts.

- Trace connections between components, noting any special instructions.

- Cross-reference with the accompanying documentation for additional details.

By mastering these skills, users can navigate technical illustrations with confidence, ensuring more efficient repairs and maintenance tasks.

Identifying Replacement Parts

Understanding the components of a heavy-duty transport vehicle is crucial for ensuring optimal performance and longevity. When it comes to maintenance and repairs, recognizing the various elements that may require replacement is essential for seamless operation.

Common Components to Monitor

- Suspension elements

- Deck surfaces

- Wheels and tires

- Hydraulic systems

- Lighting fixtures

Steps for Identifying Components

- Conduct a thorough visual inspection to spot any wear or damage.

- Refer to the vehicle’s manual for detailed descriptions of each element.

- Utilize online resources or forums to find information on specific issues.

- Consult with a professional mechanic if uncertain about any components.

Being proactive in recognizing and addressing component needs not only improves safety but also enhances the overall efficiency of the equipment.

Benefits of OEM vs. Aftermarket Parts

When considering replacements for equipment components, two primary options emerge: original manufacturer offerings and alternatives produced by third-party suppliers. Each choice comes with its own set of advantages that can significantly impact performance, longevity, and overall satisfaction. Understanding these benefits is crucial for making informed decisions that align with operational needs.

Original manufacturer components are engineered specifically for the machinery, ensuring compatibility and optimal functionality. These items often come with warranties and are tested under strict standards, providing peace of mind regarding reliability and safety. Users can expect a perfect fit, which can reduce the likelihood of malfunctions and enhance the equipment’s performance over time.

On the other hand, alternatives from independent producers can offer cost savings and increased availability. Many of these products are designed to meet or exceed industry standards, allowing users to maintain their equipment without excessive expenditure. Furthermore, the variety offered by aftermarket suppliers can lead to innovative solutions that may not be available through the original manufacturer.

Ultimately, the choice between original and alternative components depends on individual priorities, such as budget constraints, desired quality, and specific performance requirements. Evaluating these factors can help users select the most suitable option for their operational needs.

Tools Needed for Repairs

Effective maintenance and repair of equipment require a selection of essential instruments. Having the right tools at hand not only simplifies the process but also ensures safety and efficiency during the work. Below are some fundamental implements you should consider for your repair tasks.

Basic Tools

- Wrenches: Various sizes for loosening and tightening bolts.

- Screwdrivers: Both flathead and Phillips for different screw types.

- Pliers: For gripping, twisting, and cutting wires.

- Hammers: Useful for tapping components into place.

Specialized Instruments

- Torque Wrench: To apply a specific torque to fasteners.

- Jack: For lifting heavy sections safely.

- Multimeter: To check electrical connections and troubleshoot issues.

- Cutting Tools: For removing damaged or outdated components.

Equipping yourself with these tools will help streamline your repair projects and contribute to successful outcomes.

Safety Precautions During Repairs

Ensuring safety during maintenance tasks is paramount. Proper precautions help to prevent accidents and injuries, creating a secure environment for workers and equipment alike. Adhering to established guidelines fosters an atmosphere of caution and awareness, essential for successful operations.

Here are some vital safety measures to consider:

- Always wear appropriate personal protective equipment (PPE), including gloves, goggles, and hard hats.

- Ensure the work area is well-ventilated to prevent the accumulation of harmful fumes.

- Keep the workspace organized and free of clutter to minimize tripping hazards.

- Use proper lifting techniques or mechanical aids when handling heavy components.

- Disconnect power sources and use lockout/tagout procedures to prevent accidental activation of machinery.

By following these essential precautions, individuals can significantly reduce the risk of injuries and create a safer repair environment.

Tips for Efficient Trailer Upkeep

Maintaining your hauling vehicle in optimal condition is essential for safety and longevity. Regular care not only prevents unexpected breakdowns but also enhances overall performance. Here are some practical suggestions to keep your transport unit in peak shape.

Regular Inspections

Conducting frequent assessments helps identify potential issues before they escalate. Focus on the following areas:

- Tires: Check for proper inflation and tread wear.

- Brakes: Ensure they function correctly and replace worn components.

- Lights: Test all signals and markers for proper operation.

- Frame: Look for signs of rust or damage.

Routine Maintenance Tasks

Establish a schedule for maintenance to keep everything running smoothly. Key tasks include:

- Lubricating moving parts to reduce friction.

- Cleaning surfaces to prevent corrosion.

- Checking electrical connections for security and wear.

- Inspecting and replacing fluids as necessary.

By following these tips, you can ensure that your hauling unit remains reliable and safe for years to come.

Resources for Parts and Service Manuals

Accessing reliable resources for maintenance and repair documentation is crucial for ensuring optimal performance and longevity of heavy equipment. These materials provide essential information on assembly, components, and troubleshooting, enabling users to effectively manage their machinery.

Online Resources

The internet offers a wealth of information for users seeking service documentation. Websites dedicated to heavy equipment often host downloadable manuals and schematics. Forums and community groups also serve as valuable platforms for sharing insights and experiences, allowing users to connect with others in the industry.

Manufacturer Support

Reputable manufacturers typically provide comprehensive resources directly through their official websites. Here, you can find detailed service guides, instructional videos, and customer support contacts. Utilizing these official channels ensures that the information is accurate and tailored to specific models, making it an indispensable asset for any operator.