Understanding the Trane Air Conditioner Parts Diagram for Efficient Repairs

Every efficient cooling system comprises a myriad of components, each playing a crucial role in maintaining optimal indoor temperatures. Understanding these elements can enhance your maintenance efforts and improve overall performance.

Identifying the individual elements within a system allows homeowners to better comprehend how each interacts with the others. This knowledge can ultimately lead to more informed decisions regarding repairs and upgrades.

In this exploration, we will delve into the essential components that contribute to the functionality of a cooling system. From the mechanical parts to electrical systems, recognizing their arrangement can empower users to achieve greater efficiency and longevity.

Understanding Trane Air Conditioner Components

Gaining insight into the various elements of a cooling system is essential for effective maintenance and troubleshooting. Each component plays a crucial role in the overall functionality, working in harmony to ensure optimal performance. Familiarity with these individual pieces can enhance understanding and facilitate better care of the entire system.

Compressor: This central unit serves as the heart of the system, compressing refrigerant and circulating it throughout the setup. Its efficiency directly affects the cooling capacity.

Evaporator Coil: Located indoors, this coil absorbs heat from the surrounding environment, allowing the refrigerant to evaporate and cool the air. A clean and functioning coil is vital for effective heat exchange.

Condenser Coil: Situated outdoors, this component releases the heat absorbed by the refrigerant. Proper airflow around this coil is essential for efficient operation.

Expansion Valve: This device regulates the flow of refrigerant into the evaporator, ensuring that the right amount is available for optimal heat absorption.

Fan: Integral to the system, the fan circulates air over the coils, promoting heat exchange and maintaining comfortable indoor temperatures.

Filters: These components trap dust and debris, preventing them from entering the system. Regular maintenance and replacement of filters are essential for air quality and system efficiency.

Understanding these elements not only aids in effective usage but also empowers users to identify potential issues and perform necessary maintenance, ultimately extending the life of the system.

Key Parts of Trane AC Units

Understanding the essential components of cooling systems is crucial for efficient operation and maintenance. Each element plays a significant role in ensuring optimal performance, contributing to the overall functionality and reliability of the unit. By familiarizing oneself with these vital sections, users can better appreciate how they work together to deliver comfort and efficiency.

The compressor is often regarded as the heart of the system, responsible for circulating refrigerant and maintaining pressure. The evaporator coil facilitates the absorption of heat from the environment, while the condenser coil releases it outside. Additionally, the expansion valve regulates refrigerant flow, ensuring the right amount enters the evaporator. Finally, the fan assembly aids in airflow, distributing cool air throughout the space effectively.

Functionality of Each Component

This section explores the essential roles played by various elements within a cooling system, highlighting how each contributes to the overall efficiency and performance. Understanding these functions allows for better maintenance and optimization.

Compressor

The compressor acts as the heart of the system, pressurizing refrigerant gas and facilitating its flow throughout the unit. By raising the temperature and pressure, it prepares the refrigerant for heat exchange.

Evaporator Coil

The evaporator coil is crucial for absorbing heat from the surrounding environment. As the refrigerant flows through, it evaporates, transforming from liquid to gas, thereby cooling the air that circulates through the space.

Common Issues with AC Parts

In the realm of cooling systems, various components may encounter frequent challenges that can impact overall performance. Understanding these common problems is essential for effective maintenance and timely repairs.

One prevalent issue involves refrigerant leaks, which can significantly diminish efficiency and lead to increased energy costs. Identifying and sealing these leaks promptly is crucial to restore optimal function.

Another common concern is the accumulation of dirt and debris in the filters and coils. This buildup can restrict airflow, causing the unit to work harder and potentially leading to overheating or failure. Regular cleaning and replacement of these components can help prevent such issues.

Electrical failures, including faulty wiring or malfunctioning thermostats, can also disrupt operation. These problems often require professional inspection and repair to ensure safe and effective functioning of the system.

Lastly, mechanical wear and tear, such as issues with the compressor or fan motor, can result in noise or inefficiency. Routine checks and servicing can extend the lifespan of these critical components and enhance reliability.

Maintenance Tips for Longevity

Proper upkeep of your cooling system can significantly enhance its lifespan and efficiency. Regular attention to key components ensures optimal performance, reducing the likelihood of costly repairs or replacements.

Regular Inspections

Schedule routine check-ups to identify potential issues early. Inspecting elements like filters and coils can prevent malfunctions and maintain airflow.

Keep Surroundings Clean

Maintain a clutter-free area around your unit. This practice helps avoid debris accumulation, which can obstruct airflow and lead to overheating.

| Maintenance Task | Frequency |

|---|---|

| Replace Filters | Every 1-3 months |

| Clean Coils | Annually |

| Check Refrigerant Levels | Annually |

| Inspect Electrical Components | Twice a year |

How to Identify Faulty Parts

Recognizing malfunctioning components in a cooling system is crucial for maintaining optimal performance. Understanding common signs can help you address issues promptly and avoid further damage.

- Unusual Noises: Listen for grinding, rattling, or hissing sounds.

- Reduced Efficiency: Notice if the unit struggles to maintain the desired temperature.

- Increased Energy Bills: A sudden spike may indicate inefficiencies.

Once you observe these indicators, follow these steps to pinpoint the problematic components:

- Check the thermostat settings and functionality.

- Inspect electrical connections for any signs of wear or corrosion.

- Examine filters for dirt accumulation; clean or replace as needed.

- Look for refrigerant leaks around the coils and connections.

By methodically assessing these areas, you can effectively identify which components require attention or replacement.

Replacement Options for Components

When it comes to maintaining efficient performance, understanding the various alternatives for component replacement is essential. Selecting the right options can significantly enhance the longevity and reliability of your system. This section explores different types of replacements, ensuring that you can make informed decisions tailored to your specific needs.

Original Equipment Manufacturer (OEM) Parts

Choosing OEM components is often regarded as the best practice. These pieces are designed to meet the exact specifications of the original unit, ensuring compatibility and optimal functionality. While they may come at a higher price point, the benefits include enhanced reliability and peace of mind, knowing that the parts will work seamlessly with your existing setup.

Aftermarket Alternatives

Aftermarket options can provide a more cost-effective solution without sacrificing quality. Many manufacturers produce components that are compatible with original systems but at a lower price. However, it’s crucial to research and select reputable brands to avoid potential issues. Always check customer reviews and warranty information to ensure that you’re making a sound investment.

Importance of OEM Parts

Using original equipment manufacturer components ensures optimal performance and longevity of your system. These elements are designed to meet strict specifications, providing reliability and efficiency that generic alternatives may lack.

Investing in authentic components can prevent future malfunctions, saving time and costs associated with repairs. Additionally, they often come with warranties that offer further peace of mind, emphasizing their superior quality.

When it comes to maintenance, utilizing original components helps maintain the integrity of the entire system. This alignment with the manufacturer’s standards is crucial for achieving the ultimate efficiency and effectiveness in operation.

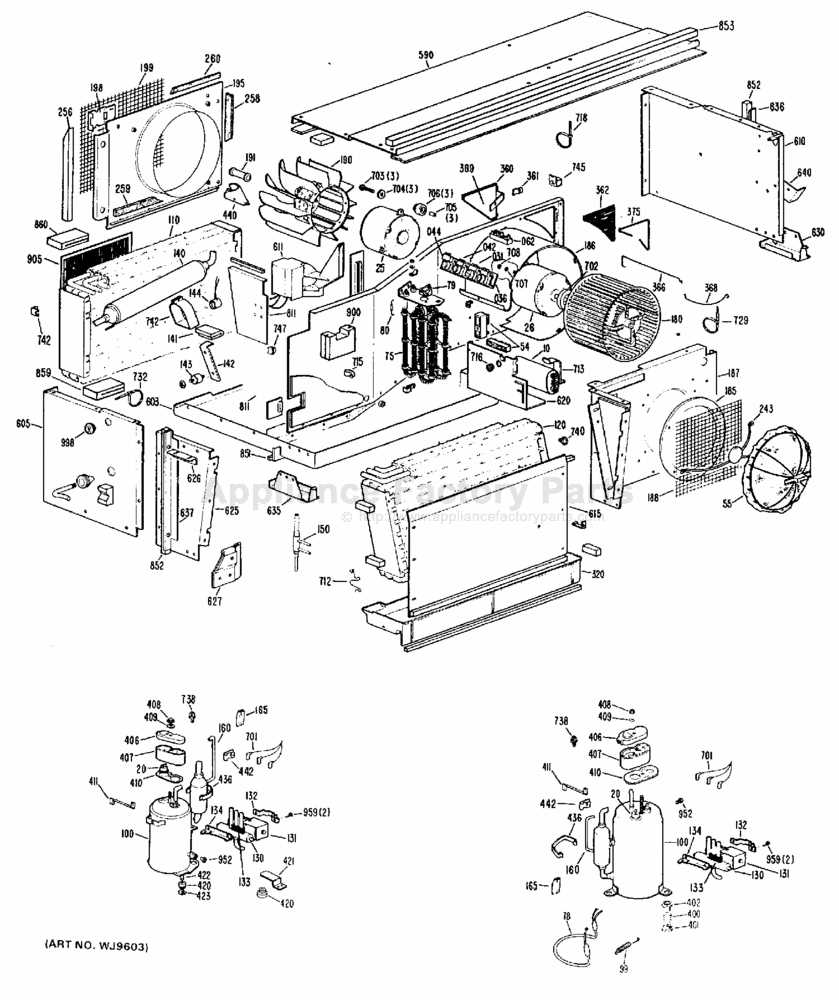

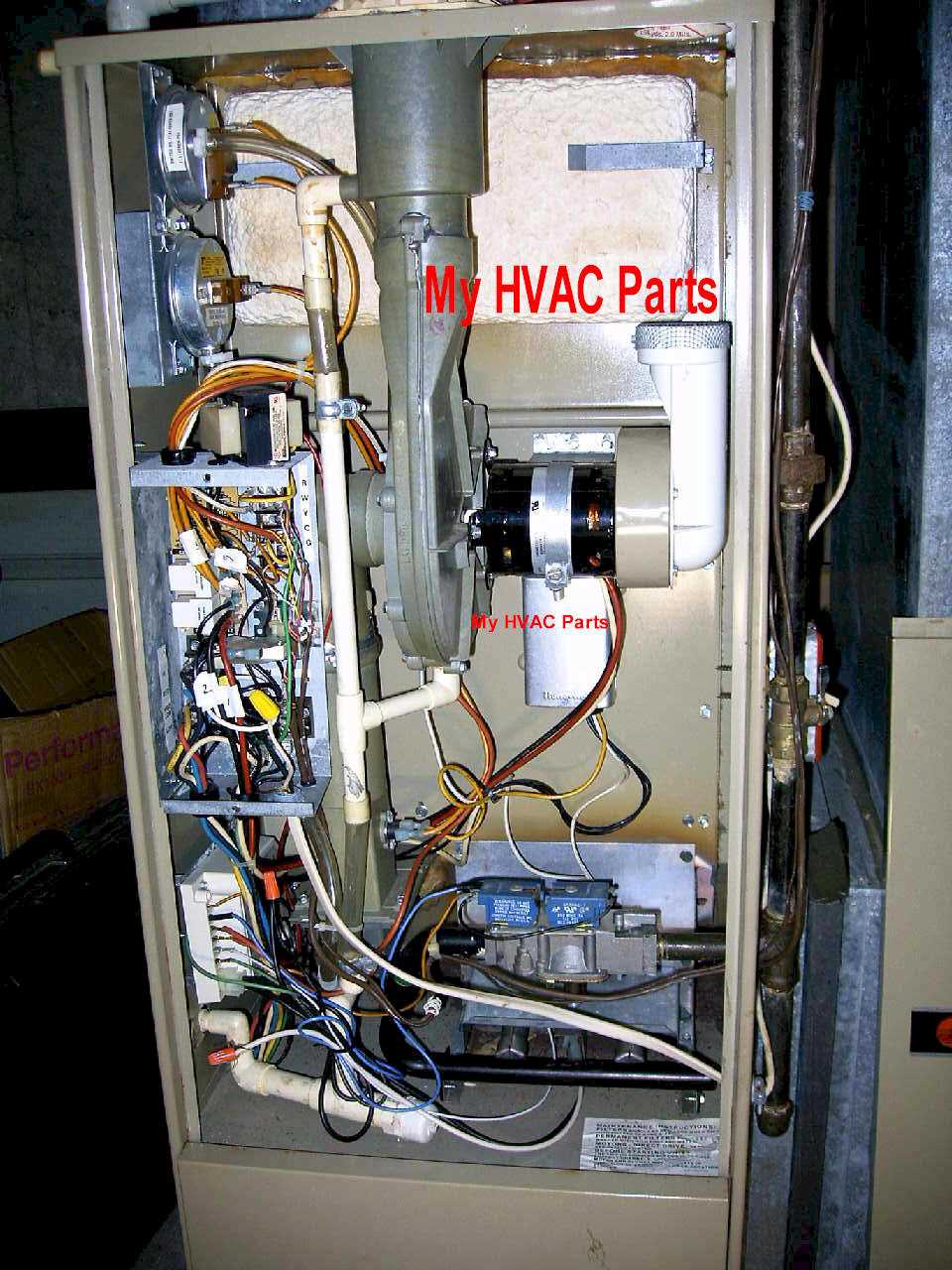

Visual Representation of AC Parts

Understanding the components of cooling systems is essential for effective maintenance and repair. A visual illustration helps to clarify the intricate relationships and functions of each element within the system. This approach enhances comprehension, allowing users to identify and troubleshoot issues more efficiently.

Each element plays a specific role, contributing to the overall functionality of the unit. From the compressor to the fan, visual aids provide insights into how these components interact. This understanding can lead to better performance and longevity of the system.

Step-by-Step Repair Guide

This guide offers a comprehensive approach to troubleshoot and resolve common issues with your cooling system. By following these structured steps, you can effectively identify problems and implement solutions.

- Begin by gathering the necessary tools, including screwdrivers, wrenches, and a multimeter.

- Ensure safety by disconnecting the power supply before starting any work.

- Inspect the unit for visible signs of damage or wear.

- Check the electrical connections for any loose or corroded wires.

- Test the thermostat settings and functionality.

- Examine the drainage system for blockages and clean as needed.

- Replace any faulty components identified during the inspection.

- Reconnect the power supply and run the system to verify repairs.

By following this systematic approach, you can ensure optimal performance and longevity of your cooling system.

Tools Needed for Maintenance

Regular upkeep of your cooling system is essential for optimal performance and longevity. Utilizing the right instruments ensures that every component functions effectively, minimizing the risk of unexpected failures and costly repairs. This section outlines the essential tools required for routine servicing and maintenance tasks.

Basic Tools

Having a selection of fundamental instruments is crucial. A screwdriver set will allow for easy access to various fasteners, while a wrench set is necessary for tightening or loosening connections. Additionally, a multimeter is invaluable for diagnosing electrical issues, providing insight into voltage, current, and resistance.

Specialized Instruments

For more advanced maintenance, certain specialized tools can greatly enhance efficiency. A manifold gauge set is essential for monitoring refrigerant levels and pressures, ensuring optimal functionality. Furthermore, an inspection camera can help identify blockages or damage within hard-to-reach areas, aiding in comprehensive evaluation.

Equipping yourself with these tools not only facilitates smoother maintenance procedures but also fosters a proactive approach to system care, ultimately extending the life of your unit.

Energy Efficiency and Component Impact

In modern climate management systems, the efficiency of energy consumption is paramount. Every element within the system plays a critical role in optimizing performance, contributing to both the sustainability of resources and the reduction of operational costs. Understanding how each component interacts can lead to significant improvements in overall efficiency.

Key Components Affecting Efficiency

Several crucial elements directly influence energy consumption. The compressor, for example, is essential for circulating refrigerant and maintaining desired temperatures. Its design and functionality can greatly affect energy usage. Additionally, the fan and coil systems are integral in heat exchange processes, where their efficiency can lead to noticeable changes in power consumption. Regular maintenance of these components ensures optimal performance.

Importance of Regular Maintenance

Routine inspections and upkeep not only extend the lifespan of the system but also enhance its energy efficiency. Cleaning coils and checking for leaks can prevent unnecessary energy waste, while timely replacements of worn-out components can help maintain optimal performance levels. Investing in preventive measures ultimately yields substantial savings and promotes a more eco-friendly operation.

Upgrading Parts for Performance Boost

Enhancing the efficiency and effectiveness of your climate control system can lead to significant improvements in comfort and energy savings. By focusing on specific components, you can elevate overall functionality and ensure optimal operation throughout its lifespan.

Identifying Key Components: Begin by assessing the main elements that contribute to performance. This includes examining the compressor, fan, and other vital mechanisms. Upgrading these parts can result in a noticeable enhancement in cooling capabilities.

Choosing Quality Replacements: When selecting new components, prioritize high-quality options that are compatible with your existing setup. Investing in superior materials and technology can lead to better energy efficiency and reliability.

Regular Maintenance: Alongside upgrades, establishing a routine maintenance schedule is crucial. This not only prolongs the lifespan of new parts but also ensures that the system operates at peak performance, minimizing the risk of unexpected breakdowns.

Ultimately, focusing on strategic enhancements can transform the functionality of your system, leading to improved performance and reduced operational costs.