Tremec T56 Parts Diagram Overview

In the realm of automotive engineering, the intricate assembly of a vehicle’s gearbox plays a crucial role in its overall performance. Each individual element contributes to the smooth operation and reliability of the system, ensuring optimal power transfer from the engine to the wheels. A comprehensive exploration of these components not only enhances one’s knowledge but also aids in effective maintenance and upgrades.

Mechanics and enthusiasts alike benefit from visual representations that detail the various elements within the transmission. By examining these schematics, one can gain insights into the function and interrelation of each part, which is essential for troubleshooting and restoration projects. This understanding allows for a more informed approach to modifications and repairs, ultimately leading to enhanced driving experiences.

As we delve into the specifics, we will uncover the critical components that define the gearbox’s functionality. Each section will provide clarity on how these elements work together, contributing to the efficiency and performance of the vehicle. Embracing this knowledge empowers both novice and seasoned practitioners in the automotive field.

Tremec T56 Overview

This section provides an insightful look into a renowned transmission system known for its robust performance and adaptability in various high-performance applications. Designed to deliver exceptional gear shifting capabilities, it has become a preferred choice among automotive enthusiasts and engineers alike.

Key Features

The highlighted mechanism is equipped with an advanced engineering design, ensuring both strength and reliability. Its unique gear ratios allow for improved acceleration and efficiency, making it suitable for a wide range of vehicles, from muscle cars to modern sports machines.

Applications

Widely utilized in performance-oriented models, this transmission offers compatibility with numerous engine types. Its versatility makes it an ultimate choice for custom builds and restorations, appealing to those who seek enhanced driving experiences.

Key Features of the T56 Transmission

This section explores the distinctive characteristics of a renowned manual gearbox that has gained a reputation for its robust performance and adaptability in various automotive applications. Understanding these features can enhance appreciation for its engineering and functionality.

Performance Advantages

- High torque capacity enables it to handle powerful engines.

- Precise gear shifting improves driver control and responsiveness.

- Optimized gear ratios for better acceleration and speed management.

Design and Durability

- Modular design facilitates easier maintenance and upgrades.

- Robust construction ensures longevity under demanding conditions.

- Lightweight materials contribute to overall efficiency without sacrificing strength.

Components of the T56 Assembly

The assembly in question consists of several critical elements that work in unison to facilitate smooth transmission of power. Each component plays a vital role in ensuring efficiency and reliability, contributing to the overall functionality of the system.

Transmission Case: This robust outer shell houses all internal components, providing protection and structural integrity.

Gear Set: Comprising various ratios, this set enables the adjustment of torque and speed, allowing for optimal performance across different driving conditions.

Shifter Mechanism: This component facilitates driver control, translating gear selection into precise movement within the assembly.

Clutch Assembly: Essential for engaging and disengaging the engine from the transmission, this unit ensures smooth transitions and prevents wear.

Bearings and Seals: These elements reduce friction and maintain fluid integrity, enhancing durability and operational efficiency.

Understanding the individual roles of these components helps in grasping the assembly’s overall functionality and reliability.

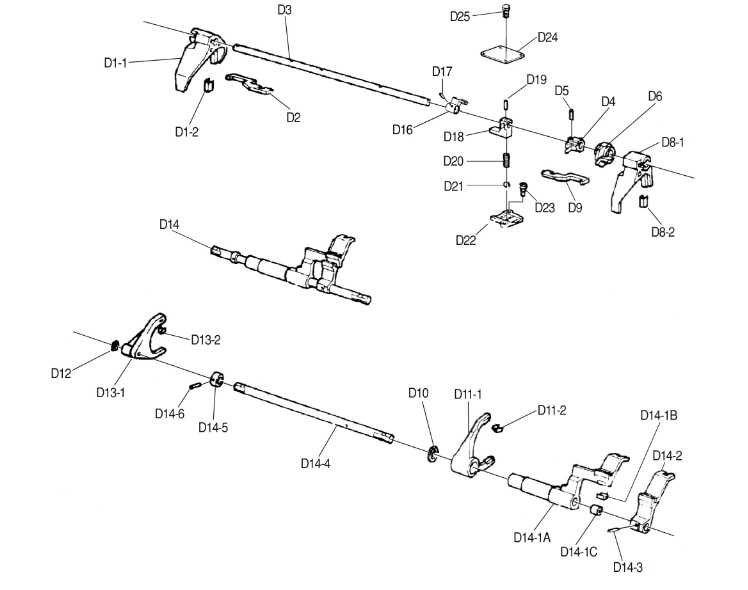

Understanding the Parts Diagram

Grasping the layout of mechanical components is essential for anyone looking to enhance performance or conduct repairs. A well-structured illustration serves as a valuable guide, allowing enthusiasts and technicians to identify each element and its function within the system. Familiarity with these visual representations simplifies the process of troubleshooting and upgrading various assemblies.

Each segment illustrated in the layout plays a crucial role, contributing to the overall efficiency and functionality of the mechanism. Recognizing how these components interconnect provides deeper insight into potential areas for improvement or replacement. This understanding can lead to better maintenance practices and informed decision-making during modifications.

Utilizing such a schematic empowers users to visualize the assembly process, facilitating a smoother workflow during installation or disassembly. By breaking down the system into its individual elements, one can easily assess wear and tear, ensuring that each part is operating optimally. This approach not only extends the lifespan of the assembly but also enhances its performance capabilities.

Common Issues with T56 Parts

Various components of manual transmissions can encounter several problems over time. Understanding these issues can help enthusiasts maintain their vehicles more effectively.

- Wear and Tear: Over time, friction can lead to degradation of certain elements, affecting performance.

- Fluid Leaks: Gaskets and seals may deteriorate, causing essential lubricants to escape.

- Shifting Difficulties: Misalignment or internal wear can result in challenging gear changes.

Regular inspections can mitigate these common issues and enhance the overall lifespan of the transmission system.

Replacement Options for T56 Components

When it comes to enhancing performance or addressing wear and tear in high-performance gearboxes, selecting the right replacement components is crucial. A variety of aftermarket solutions are available to ensure optimal functionality, durability, and efficiency. This section explores the various alternatives for upgrading or replacing essential elements of your transmission system.

Aftermarket Alternatives

Numerous manufacturers offer upgraded components designed to enhance performance. These replacements often feature improved materials and engineering, resulting in greater reliability and better handling of increased power outputs. For instance, consider high-strength input shafts, enhanced synchronizers, and performance-oriented gears that promise smoother shifting and extended lifespan.

OEM Replacement Parts

For those preferring factory specifications, original equipment manufacturer options are readily available. These components maintain the integrity of the gearbox as designed by the original engineers. While OEM parts may be more costly, they provide peace of mind regarding compatibility and performance consistency. Depending on the specific needs, both aftermarket and OEM choices can significantly impact your vehicle’s performance.

Conclusion: Selecting the right components for replacement is essential for maintaining performance and reliability. Whether opting for upgraded aftermarket solutions or sticking with OEM parts, understanding the available options ensures informed decision-making for your gearbox needs.

How to Read the Parts Diagram

Understanding a schematic representation of components is crucial for effective assembly and maintenance. This section will guide you through the essential elements to ensure you can interpret the layout with confidence.

To start, familiarize yourself with the following key aspects:

- Labels: Each element is marked with a unique identifier, allowing you to locate and reference specific components easily.

- Connections: Arrows or lines indicate how different pieces interact or connect with one another.

- Legend: A legend may provide explanations for symbols and notations used within the illustration.

By grasping these foundational elements, you’ll be well-equipped to explore the intricate relationships and functions of each component.

Performance Upgrades for the T56

Enhancing the capabilities of a high-performance transmission involves several strategic modifications that can significantly improve overall efficiency and power delivery. These upgrades focus on increasing strength, reducing weight, and optimizing shifting speed, ultimately transforming the driving experience.

One effective enhancement is the installation of upgraded gear sets, which can handle higher torque loads and provide a more aggressive gear ratio. This adjustment not only boosts acceleration but also enhances overall performance during competitive driving.

Another valuable upgrade is the implementation of a short-throw shifter, which allows for quicker gear changes, reducing the time spent shifting and improving responsiveness. This modification is particularly beneficial for track enthusiasts looking for an edge in precision.

Additionally, reinforcing the internal components with high-strength materials can ensure durability under demanding conditions. This prevents premature wear and maintains reliability, allowing drivers to push their vehicles to the limit without concerns.

Finally, exploring the integration of electronic controls can offer advanced tuning options, enabling more precise adjustments tailored to specific driving styles or conditions. This ultimate upgrade leads to a more personalized and engaging experience behind the wheel.

Maintenance Tips for T56 Owners

Proper care is essential for ensuring optimal performance and longevity of your transmission system. Regular maintenance can prevent costly repairs and enhance driving experience.

- Check fluid levels regularly and change the lubricant according to the manufacturer’s recommendations.

- Inspect seals and gaskets for wear or leaks to maintain pressure and fluid integrity.

- Keep an eye on shifting performance; address any grinding or difficulty in gear engagement promptly.

- Ensure proper alignment and installation of components to avoid premature wear.

By following these guidelines, owners can delve into the ultimate upkeep of their systems, ensuring reliability and efficiency for years to come.

Installation Guide for T56 Parts

This section provides a comprehensive overview of the essential steps involved in the installation process of a specific transmission system. Proper guidance ensures not only a smooth setup but also optimal performance and longevity of the components involved.

Preparation Steps

Before beginning the installation, it’s crucial to gather all necessary tools and components. Follow these preliminary steps:

- Review the installation manual for specific requirements.

- Ensure the workspace is clean and organized.

- Gather essential tools such as wrenches, screwdrivers, and torque specifications.

Installation Process

Follow these steps to successfully install the transmission system:

- Positioning: Align the transmission with the engine using a jack for support.

- Fastening: Secure the unit using the specified bolts, ensuring they are tightened to the recommended torque.

- Connecting: Attach the necessary linkages, ensuring all connections are tight and secure.

- Fluid Filling: Fill the system with the appropriate lubricant as outlined in the manual.

- Testing: Conduct a thorough check of all connections and perform a test run to ensure proper functionality.

Following these guidelines will facilitate a successful installation and contribute to the overall efficiency of the vehicle’s performance.

Tools Required for T56 Repairs

When undertaking repairs on a specific type of transmission, having the right equipment is essential for efficiency and accuracy. A well-prepared workspace with the necessary tools can significantly streamline the repair process, ensuring that every task is completed effectively and safely.

Essential Tools

- Socket set (metric and standard)

- Torque wrench

- Ratchet and extension bars

- Flathead and Phillips screwdrivers

- Pliers and adjustable wrenches

Specialized Equipment

- Transmission jack

- Gear puller

- Seal installer tool

- Magnetic pickup tool

- Alignment tool for shafts

Ensuring that these tools are available will enhance the repair experience, allowing for a more organized and efficient workflow. Proper maintenance and assembly are critical for the longevity of the transmission system.

Comparing T56 with Other Transmissions

When evaluating different manual gear systems, it’s essential to consider their performance characteristics, durability, and driving experience. Each transmission type has its unique attributes, influencing not only acceleration but also the overall feel of the vehicle.

Performance Metrics

One significant aspect of these systems is their ability to handle torque and provide smooth shifts. Some options are known for superior performance at high power outputs, while others may excel in efficiency and ease of use. The comparison often highlights how gear ratios impact acceleration and top speed.

Durability and Applications

Durability is another crucial factor. Certain systems are designed for high-stress environments, making them ideal for racing or heavy-duty applications. In contrast, others may prioritize comfort and longevity for everyday driving. Evaluating these factors helps in making an informed choice based on specific needs.

FAQs About T56 Components

This section addresses common inquiries regarding the various elements of a specific transmission system. Understanding these components can enhance performance and maintenance knowledge for enthusiasts and professionals alike.

- What are the key components of this transmission?

- Gear set

- Syncros

- Bearings

- Case

- Shifter mechanism

- How can I identify wear in the parts?

- Look for abnormal noises during operation.

- Check for fluid leaks around seals.

- Inspect for excessive play in the shifter.

- Are there upgrades available for performance?

- Higher-strength gear sets

- Aftermarket shifters

- Improved lubrication systems

- What maintenance is recommended?

- Regular fluid changes

- Inspection of mounting points

- Replacement of worn components as needed

- Can I swap parts with other models?

- Some components may be interchangeable.

- Verify compatibility before attempting swaps.

- Consult manufacturer specifications for detailed information.