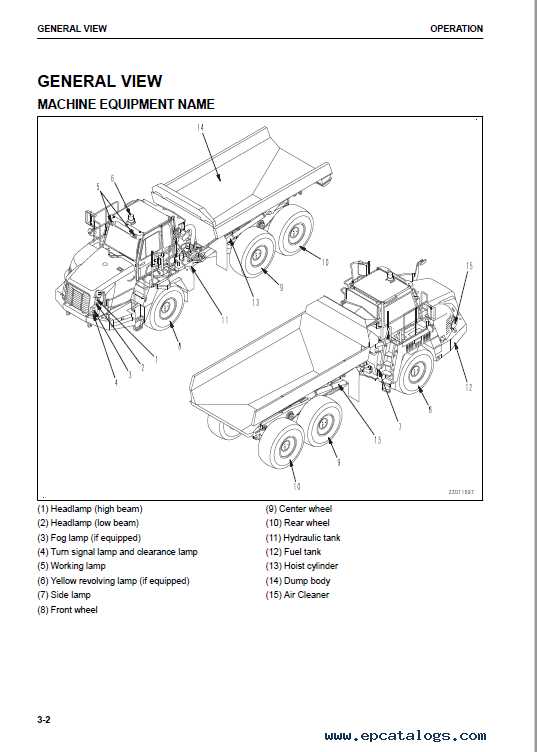

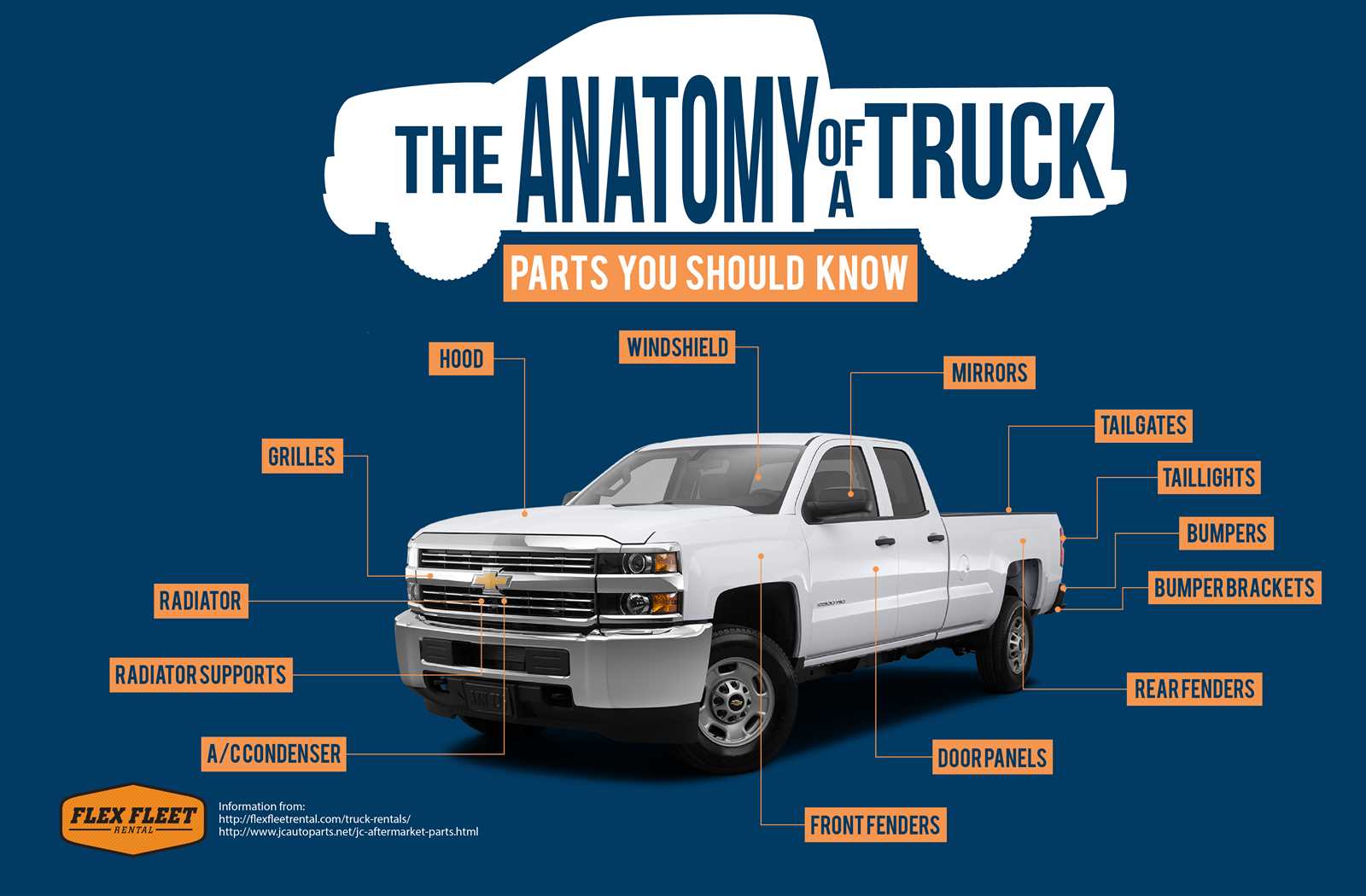

Essential Truck Parts Illustrated with Diagrams

The intricate machinery that powers heavy-duty vehicles is composed of numerous crucial elements, each playing a specific role in overall functionality. Mastery of these essential components is vital for anyone involved in maintenance or repair, ensuring optimal performance and safety.

In this section, we aim to explore the various segments of these robust vehicles, providing clarity on their functions and interrelations. An informed understanding will empower operators and mechanics alike, enhancing their ability to address issues efficiently.

To facilitate this journey, a visual representation will accompany our detailed exploration, making it easier to grasp the intricate relationships among these components. By delving into the specifics, readers will gain a comprehensive overview, ultimately leading to better maintenance practices.

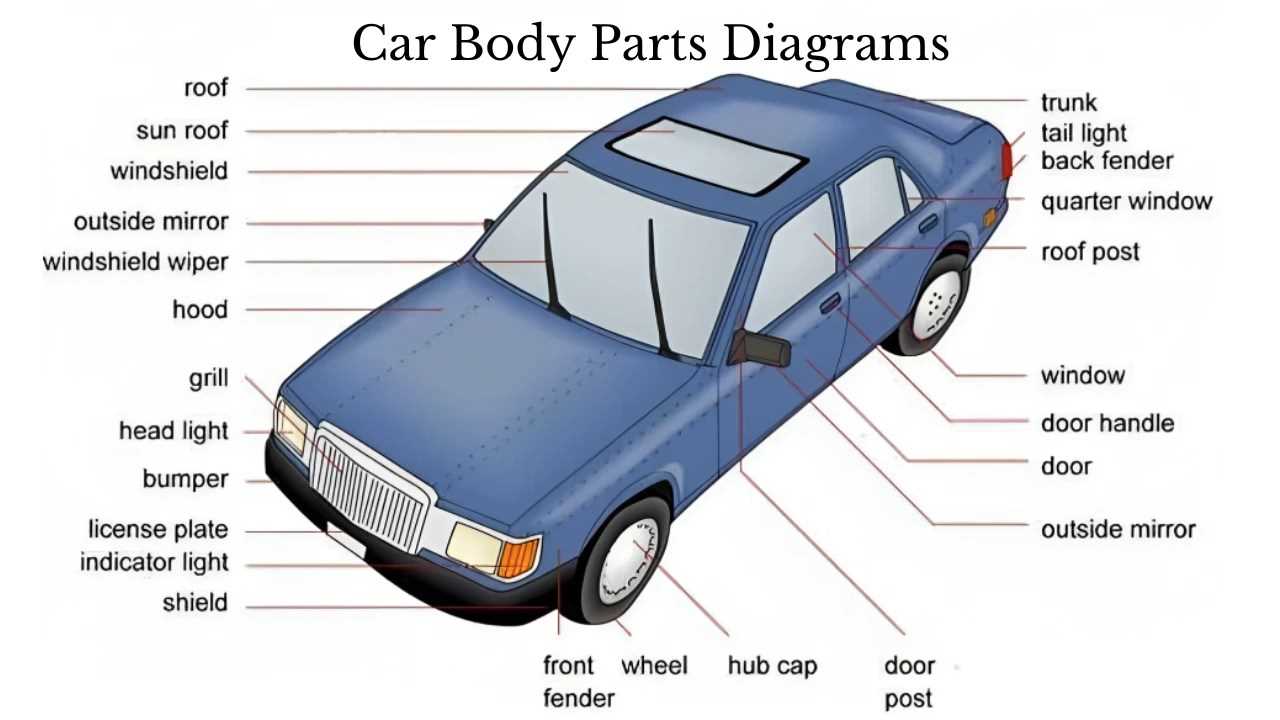

Essential Truck Components Overview

This section aims to provide a comprehensive insight into the fundamental elements that make up a heavy vehicle. Understanding these components is crucial for maintaining performance and safety on the road.

Chassis serves as the foundation, supporting all other systems and providing structural integrity.

Engine, the heart of the vehicle, converts fuel into mechanical power, driving performance and efficiency.

Transmission plays a key role in controlling the power output, allowing for smooth acceleration and deceleration.

Braking System ensures safe stopping capabilities, utilizing various technologies to maximize effectiveness.

Suspension maintains stability and comfort, absorbing shocks from the road surface and improving handling.

Electrical System powers essential functions, from lighting to onboard diagnostics, ensuring operational reliability.

Fuel System stores and delivers the necessary energy source, optimizing performance and efficiency.

Each of these components is vital to the overall functionality, highlighting the importance of regular maintenance and understanding of their roles.

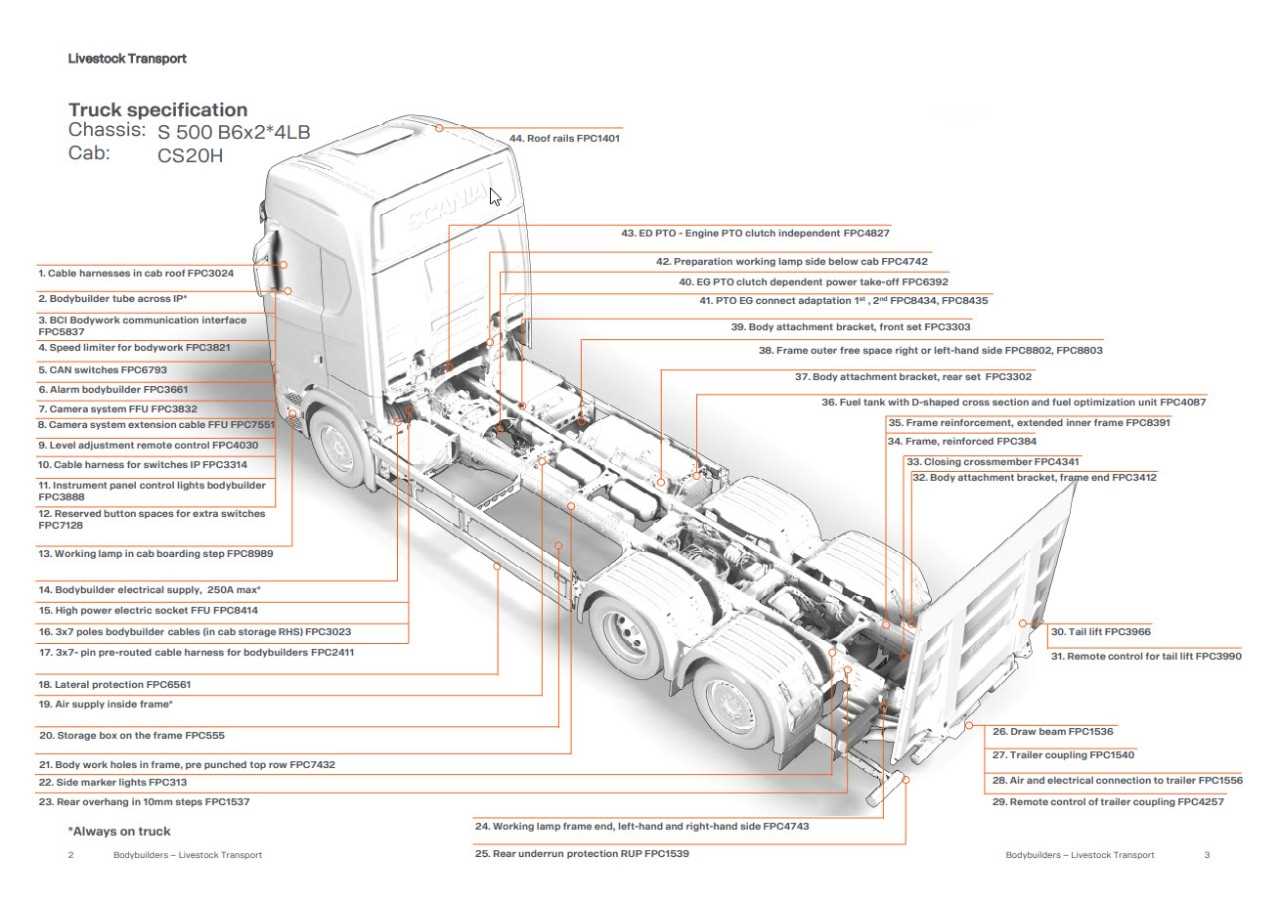

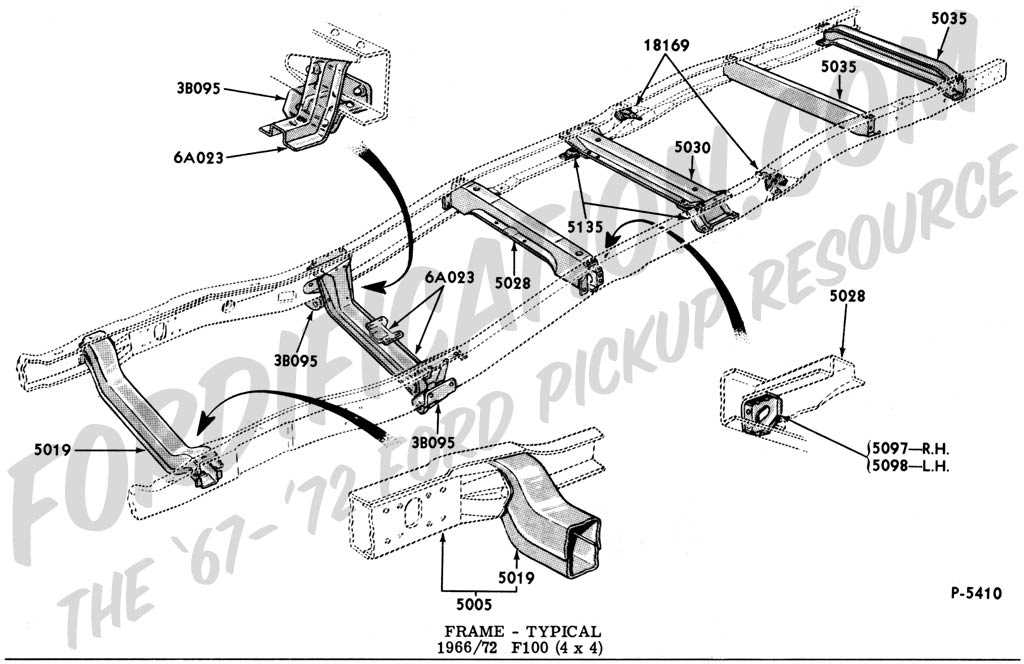

Understanding the Truck Chassis Layout

The foundation of any heavy-duty vehicle plays a crucial role in its overall performance and functionality. This structure supports various components, ensuring stability and strength while accommodating diverse loads. A clear comprehension of its configuration aids in maintenance and enhances operational efficiency.

Key Components of the Structure

Central to the foundation are several essential elements. These include the frame, axles, suspension, and wheels. The frame acts as the backbone, providing support and resilience against heavy weights. Axles facilitate movement, transferring power from the engine to the wheels. Meanwhile, the suspension system absorbs shocks and ensures a smooth ride, significantly influencing handling and safety.

Importance of Layout Design

Thoughtful arrangement of these components is vital for performance. An efficient design maximizes load capacity while minimizing wear and tear. Additionally, the positioning of elements can affect the vehicle’s maneuverability and stability, making it essential for operators to understand this layout. Proper knowledge leads to informed decisions regarding upgrades and repairs, ultimately prolonging the vehicle’s lifespan.

Key Engine Parts and Functions

Understanding the essential components of an engine is crucial for grasping how it operates effectively. Each element plays a vital role in ensuring optimal performance, contributing to the overall efficiency and functionality of the vehicle. By exploring these critical elements, one can appreciate their interconnectedness and importance in the engine’s lifecycle.

Cylinder Block

The cylinder block serves as the main structure of the engine, housing the cylinders where fuel combustion occurs. It supports various components, including the pistons, and provides pathways for coolant and oil circulation, which are essential for maintaining temperature and lubrication.

Cylinder Head

The cylinder head covers the top of the cylinders, playing a key role in the combustion process. It contains intake and exhaust valves, which regulate airflow, and houses the spark plugs, ensuring the ignition of the fuel-air mixture. Proper functioning of the cylinder head is crucial for achieving optimal engine performance.

Transmission System Explained

The transmission system serves as a crucial mechanism that enables power transfer from the engine to the wheels, facilitating movement and control of the vehicle. This intricate assembly consists of various components that work in harmony to optimize performance and efficiency.

Key Components

Functionality

Braking System Elements and Types

The braking mechanism is crucial for ensuring safety and control during operation. It comprises various components that work together to halt motion effectively, providing the driver with a reliable means to manage speed and stop as necessary.

Key Components

Understanding the main components of the braking system allows for better insight into its functionality. Each element plays a vital role in the overall effectiveness of the system.

| Component | Description |

|---|---|

| Brake Pads | Friction material that presses against the rotor to slow down the vehicle. |

| Brake Rotors | Disc that the brake pads clamp down on to create friction. |

| Calipers | Holds the brake pads and applies pressure to them when brakes are engaged. |

| Master Cylinder | Generates hydraulic pressure needed to activate the braking system. |

Types of Braking Systems

There are several types of braking systems, each designed for specific applications and performance characteristics. Understanding these types helps in choosing the right system for different scenarios.

| Type | Features |

|---|---|

| Disc Brakes | Provide excellent heat dissipation and consistent performance. |

| Drum Brakes | Typically more cost-effective, offering good stopping power for lighter applications. |

| Anti-lock Braking System (ABS) | Prevents wheel lock-up during hard braking, enhancing control. |

Electrical Components in Modern Trucks

The advancement of technology has significantly transformed the way vehicles operate, making electrical systems an integral aspect of their functionality. These systems facilitate a wide range of operations, from basic ignition processes to sophisticated entertainment features. Understanding the various elements within these networks is essential for both enthusiasts and professionals in the automotive industry.

Power Supply Units serve as the heart of the electrical setup, ensuring a stable flow of energy throughout the vehicle. They are critical for powering essential features and maintaining efficiency.

Control Modules act as the brain, processing information from various sensors and managing functions such as engine performance, safety features, and comfort settings. Their role is pivotal in enhancing the overall driving experience.

Lighting Systems include headlights, taillights, and interior illumination, which are crucial for visibility and safety. Modern designs often incorporate LED technology, improving energy efficiency and longevity.

Battery Systems are vital for starting the engine and powering all electrical components when the engine is off. Advanced batteries ensure reliability and support the growing demand for electronic accessories.

Sensors are integral for monitoring conditions within the vehicle, providing data that influences performance and safety. From temperature gauges to collision detection systems, they enhance the overall functionality.

Understanding these components not only aids in maintenance but also highlights the intricate relationship between technology and vehicle performance, emphasizing the importance of electrical systems in today’s automotive landscape.

Suspension System Basics and Importance

The suspension system plays a crucial role in the overall functionality and comfort of a vehicle. It serves as the connection between the chassis and the road, ensuring a smooth ride while absorbing shocks and vibrations. A well-designed suspension enhances stability, steering response, and safety, contributing to an enjoyable driving experience.

Understanding the components of this system is essential for recognizing its significance. It comprises various elements that work together to maintain proper alignment and control, allowing the vehicle to adapt to changing road conditions. This adaptability not only improves handling but also extends the lifespan of other mechanical systems.

Ultimately, investing in a quality suspension system leads to improved performance and increased driver confidence. Regular maintenance and awareness of potential issues can prevent more significant problems, ensuring that the vehicle remains reliable and efficient over time.

Fuel System: Components and Operation

The fuel system plays a crucial role in ensuring efficient engine performance by managing the delivery of fuel. It comprises several key elements that work together to facilitate the combustion process, optimize power output, and maintain overall functionality.

Key Components

The primary components include the fuel tank, pump, filter, injectors, and rail. Each part serves a distinct purpose, from storing the fuel to ensuring it reaches the engine in the correct manner. The fuel tank stores the liquid, while the pump propels it through the system. Filters are essential for removing impurities, and injectors deliver precise amounts into the combustion chamber.

Operational Process

Operation begins when the fuel is drawn from the tank by the pump, which creates pressure. This pressurized fuel then travels through the filter, eliminating contaminants before reaching the injectors. These injectors atomize the fuel and spray it into the engine cylinders, allowing for efficient combustion. This intricate process ultimately maximizes performance and minimizes emissions.

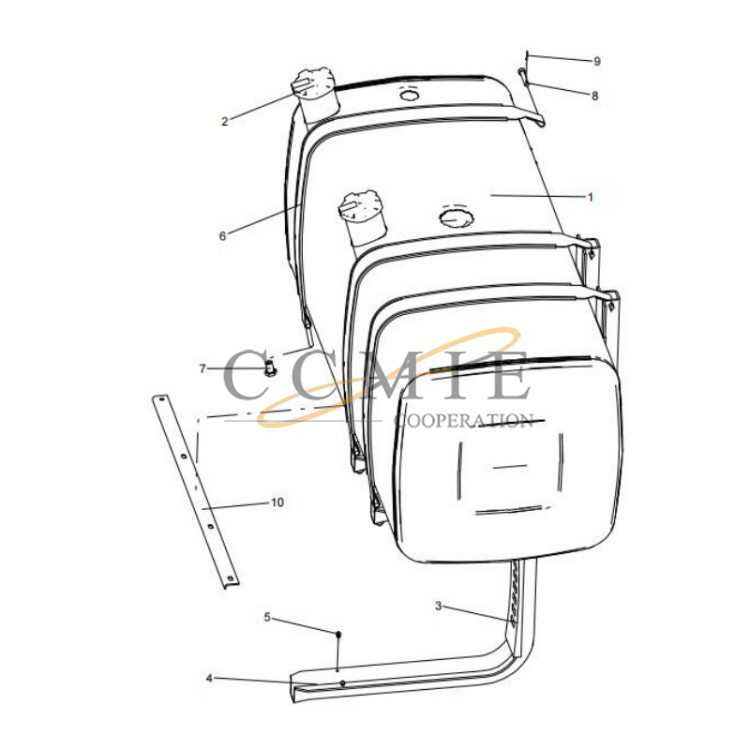

Cooling System Parts and Their Roles

The efficiency of any vehicle’s engine heavily relies on a well-functioning cooling mechanism. This intricate system ensures optimal operating temperatures, preventing overheating and enhancing performance. Understanding its components is crucial for maintaining engine health and longevity.

Key Components

Several essential elements contribute to the functionality of the cooling system. These include the radiator, which dissipates heat, the water pump that circulates coolant, and the thermostat that regulates temperature. Each plays a vital role in ensuring the engine remains within a safe temperature range.

Importance of Maintenance

Regular checks and maintenance of these components can prevent severe engine damage. For instance, a malfunctioning water pump can lead to inadequate coolant flow, while a faulty thermostat may cause temperature fluctuations. Keeping these elements in optimal condition is the ultimate way to ensure the engine operates smoothly.

Steering Mechanism and Its Components

The steering system plays a crucial role in guiding and controlling a vehicle’s direction, ensuring safe navigation on various terrains. Its design involves a blend of precision engineering and robust materials, aimed at providing optimal responsiveness and stability.

Key elements of the steering mechanism include the steering wheel, which serves as the primary control interface, and the steering column, connecting the wheel to the rest of the system. The rack and pinion setup is commonly utilized, converting rotational motion into linear movement, allowing for effective wheel alignment.

Other vital components are the tie rods, which link the steering gear to the wheels, and the steering knuckles, enabling pivoting actions. Together, these elements ensure that a vehicle responds accurately to the driver’s inputs, enhancing overall maneuverability.

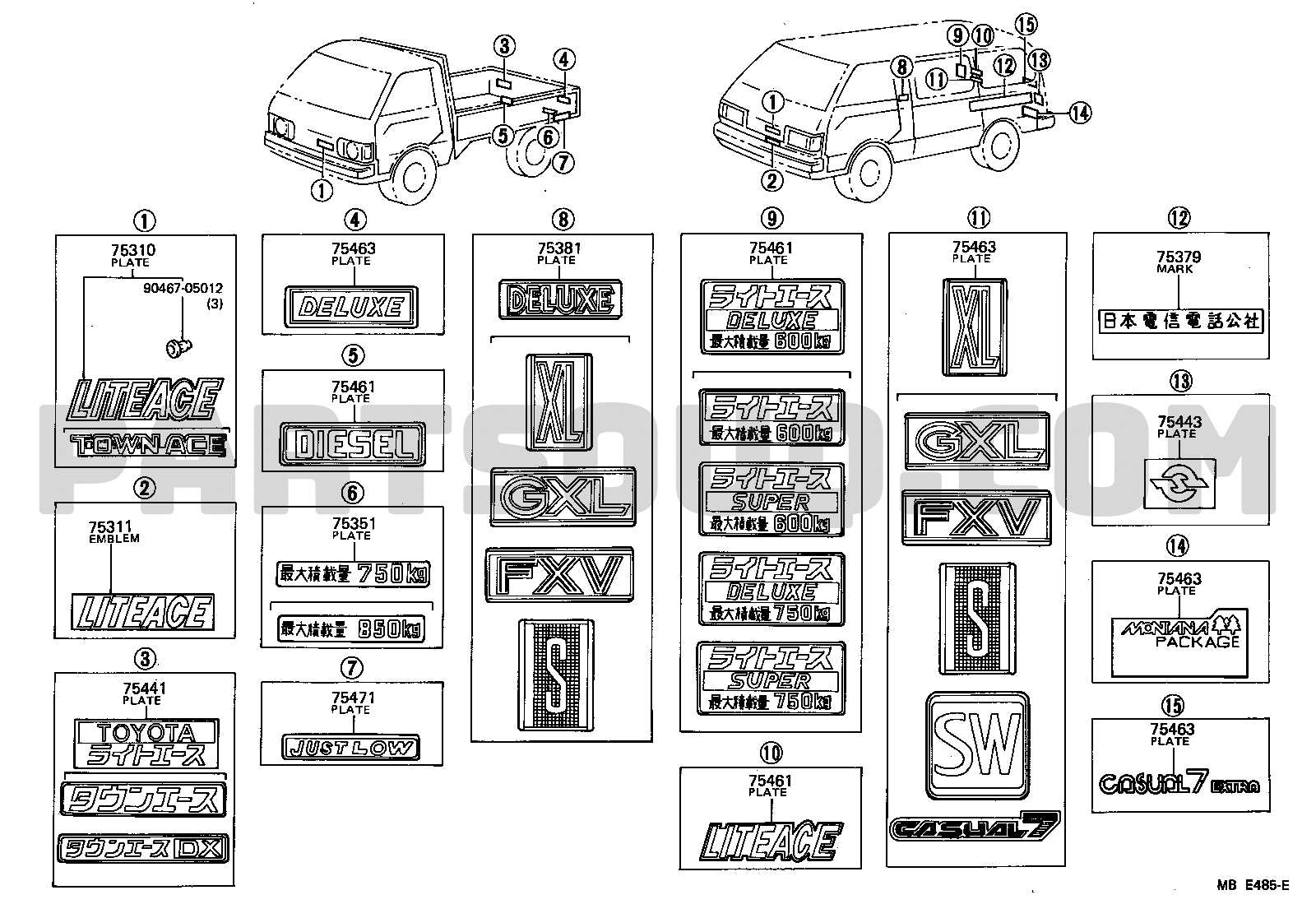

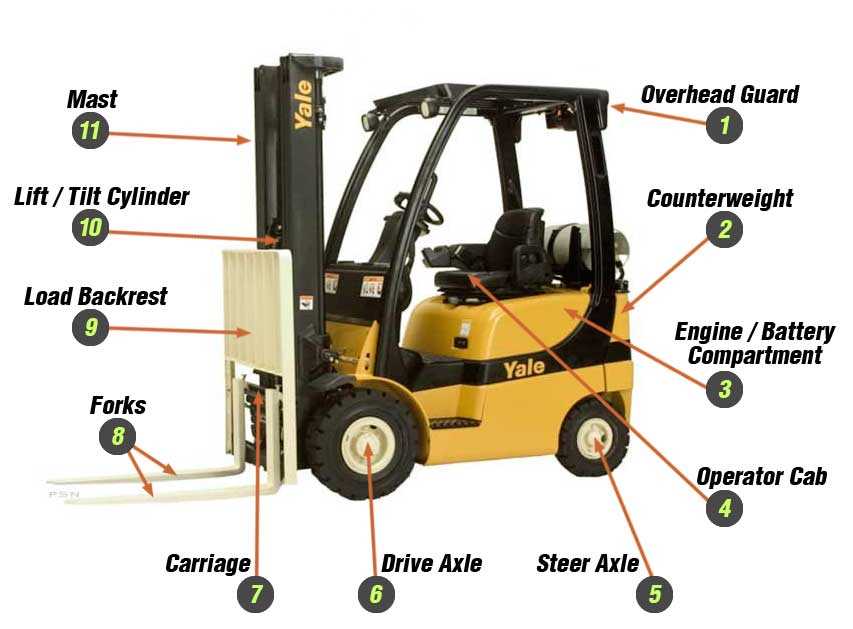

Truck Body Types and Structure

This section explores the various configurations and frameworks that define the vehicles used for transportation and logistics. Each design serves specific purposes, influencing functionality and efficiency in diverse applications.

- Flatbed: Open platform ideal for carrying oversized loads.

- Box: Enclosed structure providing protection against elements.

- Refrigerated: Climate-controlled unit for perishable goods.

- Dump: Designed for unloading materials easily.

- Tow: Equipped for transporting other vehicles or equipment.

Understanding these configurations helps to optimize their use in various industries and enhances operational efficiency.

Common Wear Parts in Trucks

In the realm of heavy-duty vehicles, certain components inevitably undergo significant stress and degradation over time. Understanding these elements is crucial for maintaining optimal performance and ensuring safety on the road. Regular inspection and timely replacement can enhance longevity and functionality, preventing costly breakdowns and enhancing overall reliability.

One of the most frequently replaced items is the brake pad. This element is essential for safe stopping, and wear can lead to reduced efficiency and longer stopping distances. Another critical component is the tire, which directly affects traction and stability. Over time, tread depth diminishes, necessitating attention to avoid hazardous situations.

Additionally, the fuel filter plays a vital role in maintaining engine performance by preventing contaminants from entering the fuel system. Neglecting to change this component can lead to engine inefficiencies and increased emissions. The wiper blades are also essential for visibility, and their degradation can impair driving safety during adverse weather conditions.

Finally, the battery is another key element that may require regular monitoring and replacement. As it ages, its ability to hold a charge diminishes, impacting overall vehicle reliability. Recognizing these common wear elements allows for proactive maintenance, ultimately leading to improved safety and efficiency on the road.

Maintenance Tips for Truck Parts

Regular upkeep is essential for ensuring optimal performance and longevity of your vehicle’s components. By implementing effective care strategies, you can minimize wear and tear, ultimately enhancing reliability and efficiency.

Routine Inspections

Conducting frequent checks allows for early detection of potential issues. Look for signs of wear, such as cracks or leaks, and address them promptly to avoid more significant problems down the line.

Proper Lubrication

Ensuring adequate lubrication is vital for smooth operation. Regularly apply the recommended lubricants to moving elements to reduce friction and extend their lifespan.