Understanding the Vermeer 605m Parts Diagram for Efficient Maintenance

In the world of industrial equipment, a clear grasp of the individual elements that make up a machine is essential for efficient operation and maintenance. This section delves into the intricacies of one such robust piece of machinery, highlighting the significance of each component and their interrelationships. Proper knowledge of these elements not only enhances functionality but also extends the lifespan of the equipment.

Every complex system comprises various essential units that work in harmony to ensure optimal performance. By examining these units, users can identify potential issues before they escalate into significant problems. The detailed exploration of each segment empowers operators and technicians alike, fostering a deeper understanding of the mechanisms at play.

Furthermore, a comprehensive breakdown of these components facilitates effective troubleshooting and repairs. Familiarity with the layout and functions of each part equips users with the tools they need to address challenges promptly and effectively. In this discourse, we will navigate through the vital aspects of these components, offering insights into their roles and best practices for maintenance.

Understanding Vermeer 605m Components

When examining the intricacies of any machinery, it’s essential to grasp the individual elements that contribute to its overall functionality. Each component plays a significant role in ensuring optimal performance and efficiency. A thorough understanding of these elements not only aids in maintenance but also enhances operational knowledge.

The following table outlines key components, their functions, and typical specifications, providing a clearer picture of how they work together to facilitate seamless operation.

| Component | Function | Specifications |

|---|---|---|

| Engine | Powers the entire system, providing necessary force for operation. | Max HP: 60, Fuel Type: Diesel |

| Transmission | Transfers power from the engine to the wheels, enabling movement. | Type: Hydrostatic |

| Chassis | Provides structural support and houses various components. | Material: Steel, Weight Capacity: 3000 lbs |

| Hydraulic System | Facilitates various functions such as steering and lifting. | Pressure: 2000 psi |

| Control Panel | Central hub for operator controls and monitoring. | Features: LCD Display, Emergency Stop |

Familiarizing oneself with these components fosters a deeper appreciation for the equipment and its capabilities. Proper knowledge not only enhances user experience but also promotes safety and reliability in operation.

Overview of the 605m Model

The model in discussion is renowned for its robust design and exceptional functionality. It serves a crucial role in various applications, providing reliable performance for operators in the field. With a focus on efficiency and user-friendliness, this equipment has become a preferred choice among professionals.

Key Features

This machinery boasts a range of innovative features that enhance its usability. The compact structure allows for easy maneuverability, while the powerful engine ensures optimal performance in challenging conditions. Additionally, the intuitive controls make it accessible for users of all experience levels, promoting productivity on the job site.

Applications and Versatility

Its versatility is one of its standout qualities, making it suitable for multiple tasks across different industries. From landscaping to construction, this equipment adapts seamlessly to various environments. Its capability to handle demanding workloads without compromising on efficiency sets it apart in the market.

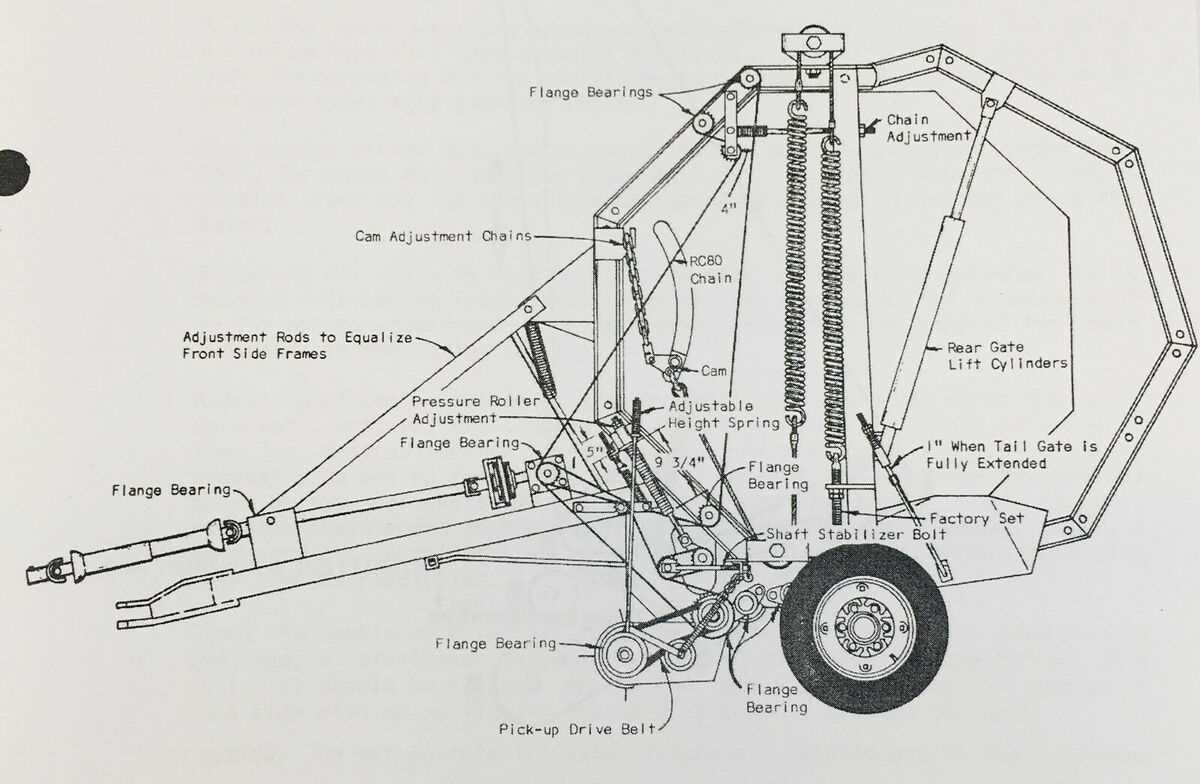

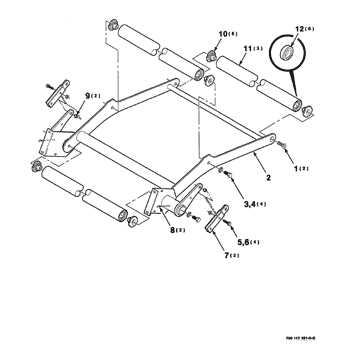

Importance of Parts Diagrams

Understanding the intricacies of machinery and equipment is crucial for effective maintenance and repair. Visual representations of components serve as essential tools for technicians and operators, allowing them to identify, locate, and replace elements efficiently.

- Enhanced Clarity: Visual aids break down complex systems into manageable parts, making it easier to grasp their functions and interconnections.

- Streamlined Repairs: Quick reference to visuals can significantly reduce downtime by enabling faster identification of necessary components.

- Improved Communication: Clear illustrations facilitate better dialogue among team members, ensuring everyone is on the same page regarding repairs and maintenance.

Utilizing these visual resources not only increases efficiency but also contributes to safety by minimizing the risk of errors during servicing.

- Accurate identification of parts prevents misuse and potential damage.

- Proper understanding leads to more effective troubleshooting.

- Educational value for new technicians enhances overall team competency.

In summary, the use of visual guides is integral for maintaining the functionality and longevity of equipment, fostering a proactive approach to maintenance practices.

Key Features of Vermeer 605m

This section highlights the essential characteristics of a specific piece of equipment designed for efficiency and productivity in various applications. Understanding these features can provide valuable insights into its functionality and operational advantages.

Powerful Performance: Engineered for optimal output, this machine boasts a robust engine that ensures high efficiency and reliability during operation. Its design allows for quick and effective processing, making it suitable for demanding tasks.

Durable Construction: Built with high-quality materials, this model offers exceptional durability and longevity. The rugged framework withstands harsh conditions, providing peace of mind for users in challenging environments.

User-Friendly Controls: Featuring an intuitive control panel, operators can easily navigate functions and settings. This user-centric design enhances ease of use, reducing the learning curve for new users.

Compact Size: The equipment’s compact dimensions enable it to access tight spaces where larger machines might struggle. This feature increases versatility and expands the range of potential applications.

Enhanced Safety Features: Equipped with multiple safety mechanisms, this model prioritizes operator safety. These features help minimize risks and promote a secure working environment.

Efficient Maintenance: Designed for easy access to critical components, routine maintenance is streamlined, ensuring that the equipment remains in top working condition with minimal downtime.

Commonly Replaced Parts Explained

In the realm of machinery maintenance, certain components tend to experience wear and tear more frequently than others. Understanding which elements are commonly replaced can significantly enhance the efficiency and longevity of equipment. This section delves into the most frequently serviced items, highlighting their roles and the importance of timely replacements.

Hydraulic Components

One of the critical systems in machinery is the hydraulic setup, which relies on various elements to function optimally. Hydraulic hoses and filters are often among the first to show signs of deterioration due to constant pressure and fluid exposure. Regular inspections and replacements of these components ensure that the system operates smoothly, preventing costly breakdowns.

Drive Belts and Chains

Another essential category involves drive belts and chains, which are vital for transmitting power throughout the machine. Over time, these parts can stretch or wear out, leading to decreased performance and potential damage to other components. Monitoring their condition and replacing them as needed is crucial for maintaining overall efficiency and avoiding unexpected downtimes.

Maintenance Tips for Longevity

Proper upkeep is essential for ensuring the extended life of your equipment. Regular attention not only enhances performance but also prevents costly repairs and downtime. Here are some key strategies to maintain optimal functionality and durability.

- Regular Inspections: Conduct routine checks to identify any signs of wear or damage. Early detection can save time and money.

- Cleanliness: Keep all components free from dirt and debris. A clean machine operates more efficiently and has a reduced risk of malfunctions.

- Lubrication: Apply appropriate lubricants as recommended by the manufacturer. Proper lubrication minimizes friction and wear on moving parts.

- Filter Replacement: Regularly replace air and fluid filters to maintain optimal performance and protect internal systems from contaminants.

- Fluid Checks: Monitor fluid levels consistently. Ensure that hydraulic, oil, and coolant levels are within recommended ranges to prevent overheating and system failure.

By adhering to these practices, you can significantly enhance the reliability and lifespan of your machinery, ensuring that it continues to perform effectively for years to come.

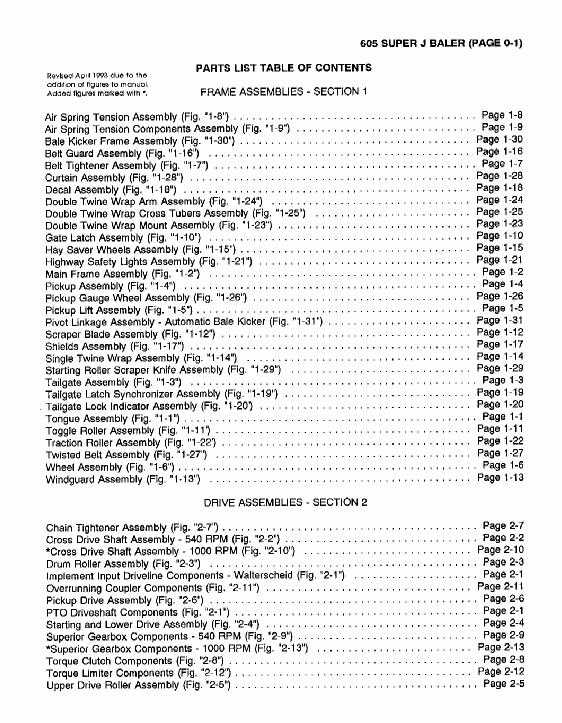

Where to Find Official Diagrams

Locating authentic technical schematics for machinery can significantly enhance your understanding of the equipment’s assembly and functionality. These resources provide invaluable insights for maintenance, repairs, and upgrades, ensuring that you work with accurate information. Here are some reliable sources to help you access these essential guides.

Manufacturer’s Website

The most trustworthy source for official schematics is the manufacturer’s website. Most companies provide downloadable resources, including user manuals and detailed technical drawings, in the support or resources section. Make sure to search for your specific model to find the most relevant information.

Authorized Dealers and Service Centers

Authorized dealers and service centers are excellent places to seek out official documentation. These establishments often have direct access to the latest technical materials and can provide you with printed or digital copies. Additionally, they may offer personalized support to help you interpret the information effectively.

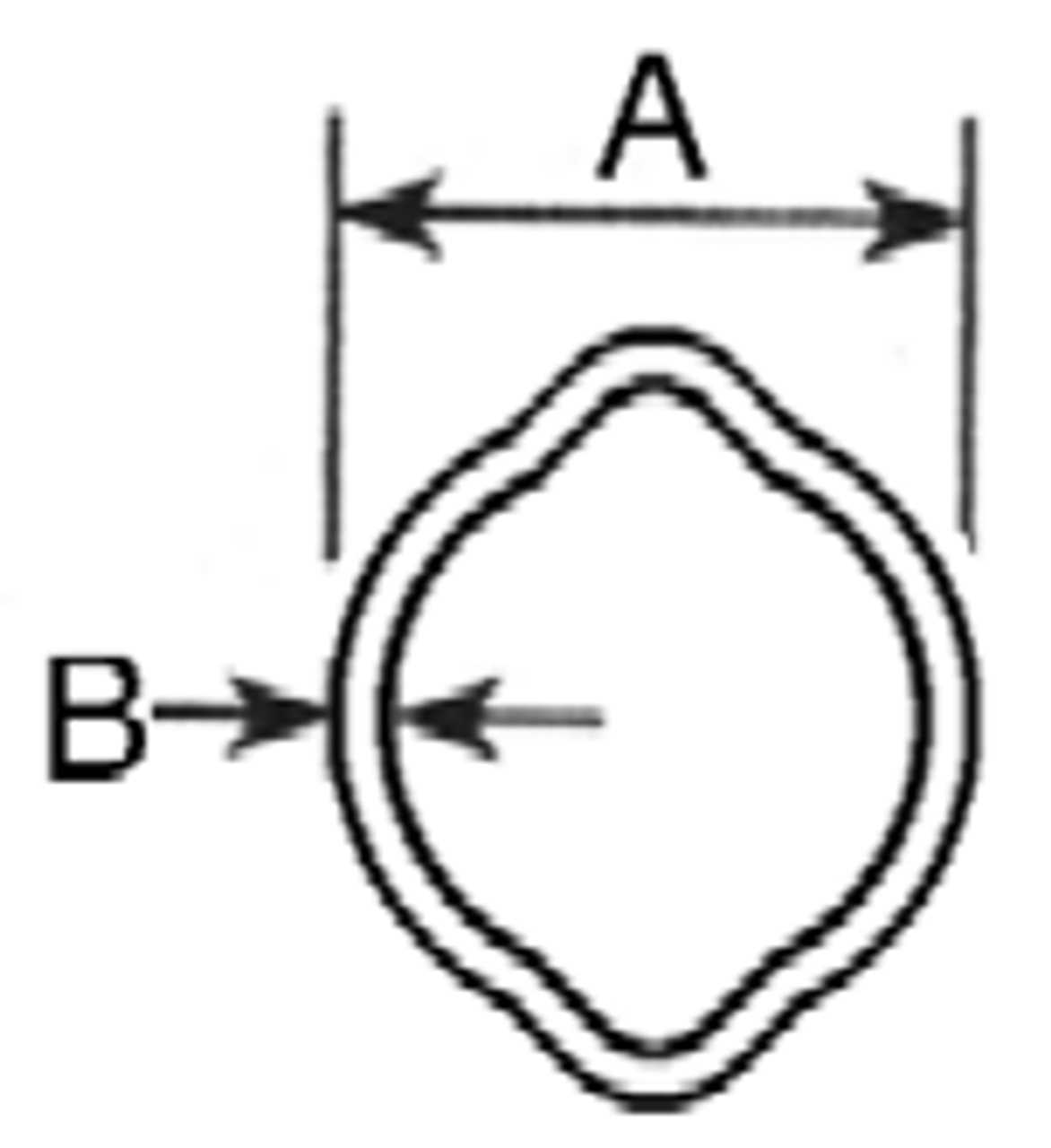

How to Read Parts Diagrams

Understanding technical illustrations is essential for effective maintenance and repairs. These visual guides provide crucial information about the components of machinery, helping users identify and locate each piece efficiently. Familiarizing yourself with these visuals can significantly enhance your troubleshooting skills.

Here are key steps to effectively interpret these illustrations:

- Identify the Legend: Most diagrams include a legend that explains symbols and color codes used throughout the illustration.

- Focus on the Layout: Pay attention to how components are arranged. This layout often reflects their physical placement in the actual equipment.

- Note the Labels: Look for any annotations or labels that provide additional context or details about specific parts.

- Reference the Manual: Consult the accompanying manual for detailed explanations that can aid in understanding complex sections.

By following these steps, you can navigate technical illustrations with confidence, making it easier to perform maintenance tasks and repairs accurately.

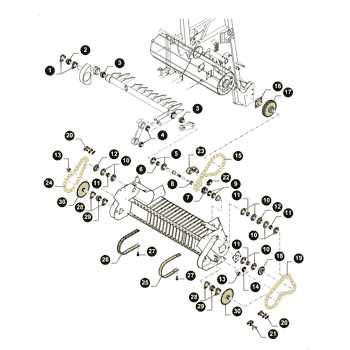

Identifying Specific Components

Understanding the various elements within machinery is crucial for efficient operation and maintenance. By recognizing the specific parts and their functions, users can troubleshoot issues more effectively and ensure optimal performance. Each component plays a distinct role, and familiarity with these elements enhances both usability and safety.

To accurately identify individual pieces, one should start by consulting relevant resources that outline the structure and function of the equipment. These references typically provide clear descriptions, allowing operators to pinpoint the exact location and purpose of each part. Familiarity with common terminology related to these components further aids in effective communication and understanding among technicians and operators alike.

Moreover, hands-on experience can significantly contribute to recognizing components. Engaging with the machinery directly enables individuals to develop an intuitive sense of how parts interact, leading to a deeper comprehension of the overall system. This practical knowledge complements theoretical resources, creating a well-rounded understanding of the equipment’s architecture.

In summary, mastering the identification of specific elements not only supports troubleshooting efforts but also fosters a more profound appreciation of the machinery’s design and functionality.

Tools Needed for Repairs

When undertaking maintenance or fixing machinery, having the right equipment is crucial for efficiency and effectiveness. Proper tools not only expedite the process but also ensure that repairs are conducted safely and correctly, reducing the risk of future issues.

Essential Hand Tools

To start, a basic set of hand tools is indispensable. This includes wrenches, screwdrivers, and pliers. These instruments allow for the loosening and tightening of various components, enabling straightforward adjustments and replacements. A good quality socket set can also be extremely beneficial for accessing hard-to-reach areas.

Specialized Equipment

In addition to standard hand tools, certain specialized equipment may be required. A multimeter is essential for diagnosing electrical issues, while a hydraulic jack is crucial for lifting heavy parts safely. Furthermore, having a reliable toolbox to keep everything organized can save valuable time and prevent the loss of essential items during repairs.

Frequently Asked Questions

This section aims to address common inquiries related to equipment components and their functionalities. Here, we provide answers to some of the most frequently posed questions to assist users in navigating their concerns effectively.

-

What is the best way to identify the components of my machine?

You can refer to the user manual, which typically includes detailed information about each part. Additionally, online resources or forums can be helpful for visual identification.

-

How can I determine if a component needs replacement?

Signs that a part may need replacement include unusual noises, decreased performance, or visible wear and tear. Regular maintenance checks can help in early detection.

-

Where can I find replacement parts?

Replacement components can be sourced from authorized dealers, online marketplaces, or specialized retailers. Ensure that the parts are compatible with your specific model.

-

Are there any maintenance tips for prolonging the life of my equipment?

Routine maintenance is crucial. This includes cleaning, lubrication, and regular inspections to catch potential issues before they escalate.

-

What should I do if I encounter a problem during operation?

First, consult the troubleshooting section of your manual. If the issue persists, consider reaching out to customer support or a professional technician for assistance.

Comparative Analysis with Other Models

This section explores the distinctions and similarities between a specific model and its competitors within the same category. By examining various features, functionalities, and design choices, we aim to provide a comprehensive understanding of how this model stands out or aligns with others in the market.

Performance and Efficiency

When comparing the efficiency levels, it becomes evident that this model exhibits superior performance metrics in several key areas. For instance, it often outperforms its peers in terms of operational speed and power consumption. This can lead to significant cost savings for users over time, enhancing its value proposition. Additionally, the engineering behind this model ensures that it operates seamlessly even under challenging conditions, a trait that may not be as pronounced in other designs.

User Experience and Maintenance

The user interface and ease of maintenance play crucial roles in the overall satisfaction of equipment owners. This particular model tends to feature a more intuitive control system, making it accessible for operators with varying levels of expertise. Furthermore, maintenance routines are simplified, reducing downtime and operational disruptions. In contrast, some alternative models require more frequent servicing, which can lead to increased operational costs and decreased productivity.

In summary, while this model presents numerous advantages over its counterparts, the choice ultimately depends on specific user needs and preferences. Careful consideration of the comparative aspects can guide potential buyers toward the best fit for their requirements.

Resources for Further Learning

Expanding your knowledge in machinery maintenance and repair can significantly enhance your skills and efficiency. Various resources are available to help deepen your understanding and practical abilities in this field.

- Books:

- “Heavy Equipment Maintenance Manual” – A comprehensive guide covering various aspects of equipment upkeep.

- “Fundamentals of Machinery Repair” – Focuses on essential repair techniques and troubleshooting methods.

- Online Courses:

- Coursera – Offers a range of courses on equipment management and maintenance practices.

- edX – Provides specialized training modules from industry experts.

- Forums and Communities:

- Reddit – Join communities focused on heavy machinery for discussions and tips.

- Equipment World – A forum where professionals share insights and experiences.

- Videos and Tutorials:

- YouTube – Many channels provide hands-on tutorials and maintenance tips.

- Vimeo – Look for educational content from experienced technicians and mechanics.

Utilizing these resources can help you stay updated with the latest techniques and best practices, ultimately enhancing your competence in machinery management.