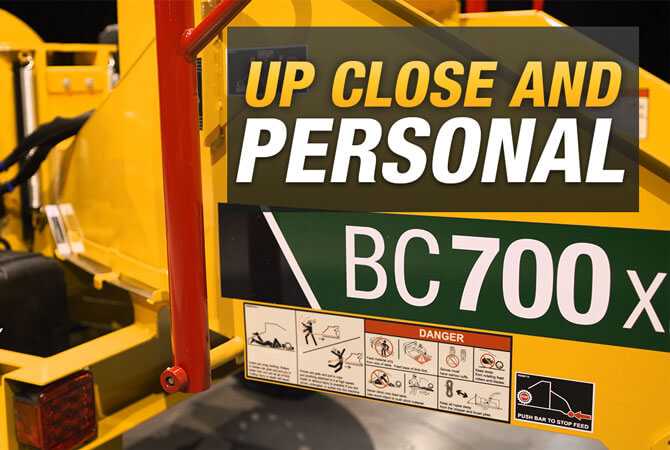

Understanding the Vermeer BC700XL Parts Diagram for Efficient Maintenance

In the realm of machinery, a clear understanding of various components is crucial for efficient operation and maintenance. Each piece plays a vital role, contributing to the overall functionality of the equipment. Recognizing the intricate relationships between these elements allows operators and technicians to troubleshoot effectively and ensure peak performance.

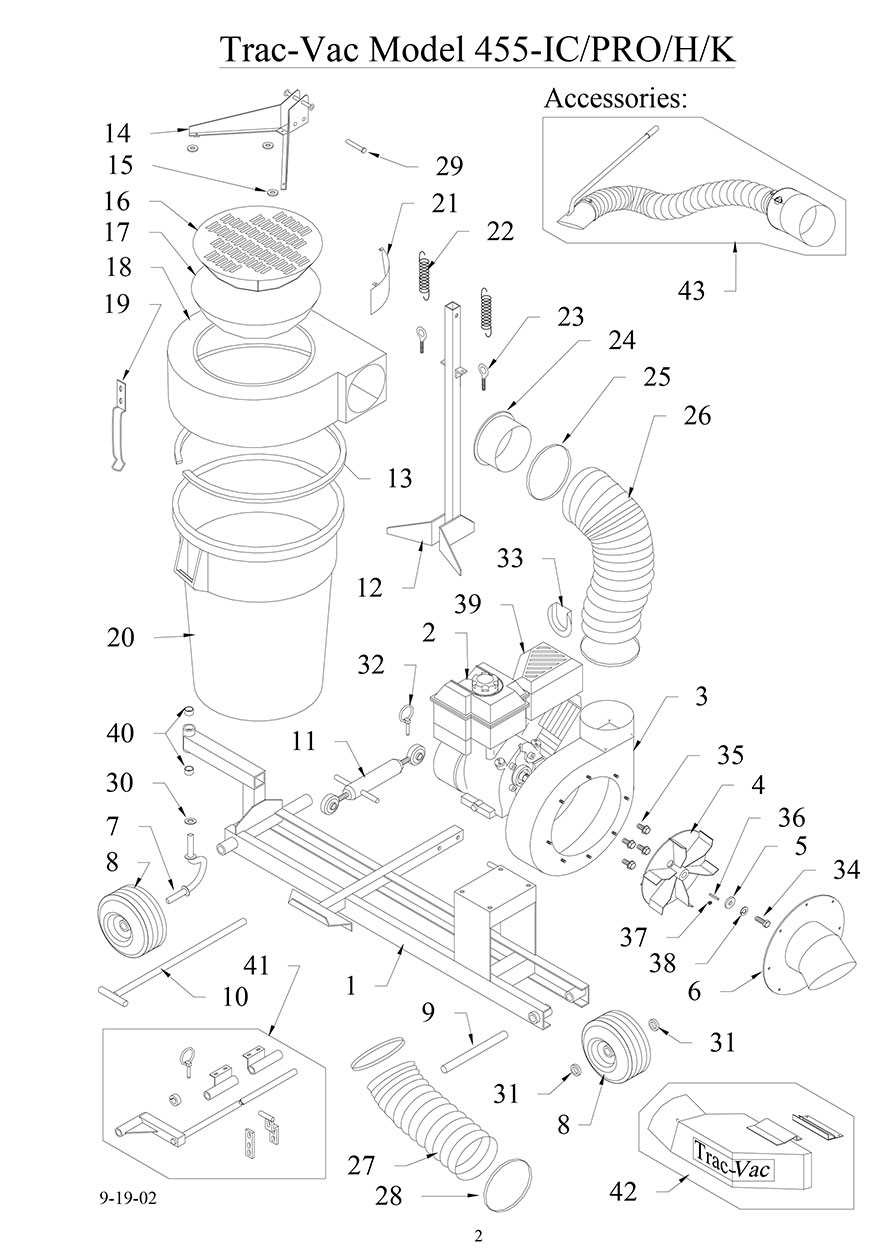

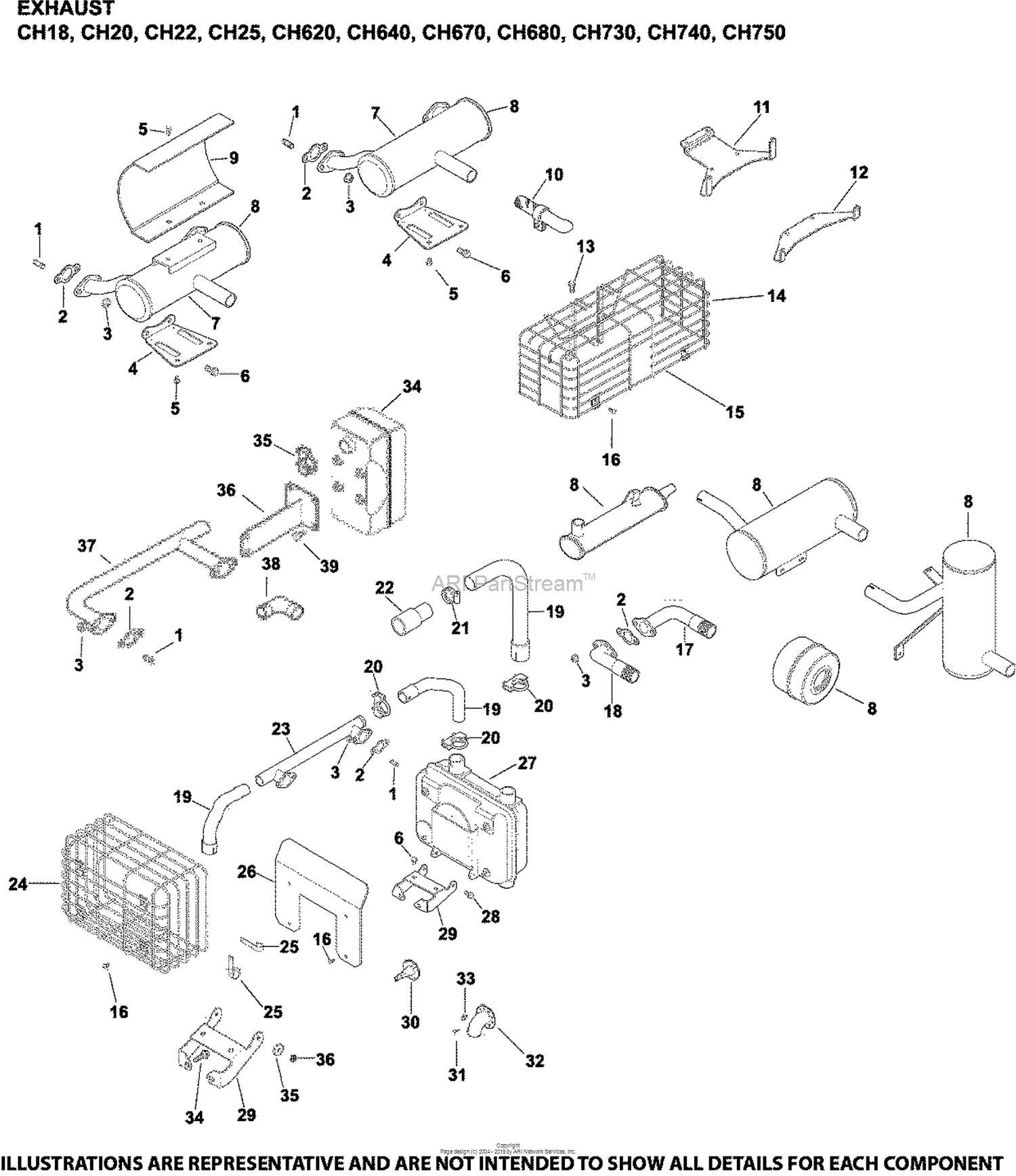

Visual representation of these components provides invaluable insight into their arrangement and interconnections. By examining detailed illustrations, one can grasp how each segment fits into the larger system. This knowledge not only aids in repairs but also enhances preventive measures, reducing the likelihood of unforeseen breakdowns.

Furthermore, having a thorough grasp of the components fosters a proactive approach to machinery care. Understanding the specific roles and potential wear patterns of individual parts empowers users to undertake timely maintenance, ultimately extending the lifespan of the equipment and improving its efficiency.

Understanding Vermeer BC700XL Components

To effectively operate and maintain a particular piece of machinery, it’s essential to grasp the various elements that make up its structure. Each component plays a significant role in the overall functionality, ensuring that the equipment performs optimally in diverse conditions. A comprehensive understanding of these parts can enhance troubleshooting, repair, and maintenance efforts.

Key Elements of the Machine

Among the crucial elements are the engine, which serves as the powerhouse, and the cutting mechanism that directly impacts performance. Other integral features include the hydraulic system, responsible for the operation of various attachments, and the frame that supports the entire assembly. Familiarity with these components allows operators to pinpoint issues and implement timely solutions.

Maintenance and Care

Regular upkeep is vital for longevity. Routine inspections of the engine, lubrication of moving parts, and monitoring of hydraulic fluid levels are essential practices. Understanding how each section functions contributes to effective maintenance, minimizing downtime and extending the lifespan of the equipment.

Importance of Parts Diagrams

Understanding the components of machinery is crucial for efficient maintenance and repair. Visual representations help users quickly identify individual elements, ensuring that any necessary replacements or adjustments can be made swiftly. This clarity reduces downtime and enhances overall functionality.

Enhanced Troubleshooting

Having a visual guide enables technicians to pinpoint issues more effectively. By referencing these illustrations, they can trace problems back to their sources, ultimately facilitating quicker resolutions and preventing future complications.

Streamlined Repairs

Clear visual aids simplify the repair process by providing a reference for correct assembly and disassembly. This not only speeds up the work but also minimizes the risk of errors, ensuring that all parts fit together seamlessly once maintenance is completed.

Key Features of BC700XL Model

The model in question is distinguished by its innovative design and advanced functionality, tailored for efficiency and ease of use. Users will appreciate the thoughtful integration of features that enhance performance and reliability, making it a valuable asset in various applications.

Exceptional Performance

With a powerful engine and optimized mechanics, this unit delivers superior output and productivity. Its robust construction ensures durability, allowing it to handle demanding tasks effortlessly.

User-Friendly Design

The intuitive interface and accessible controls simplify operation, catering to both novices and experienced operators. Enhanced safety measures further contribute to a worry-free experience, allowing users to focus on their work.

Common Issues with Vermeer Chippers

When operating wood chippers, users may encounter several frequent challenges that can impact performance and efficiency. Understanding these issues can aid in timely maintenance and troubleshooting.

- Engine Problems: Difficulties starting or unusual noises can indicate mechanical issues.

- Feeding Issues: Blockages or improper feed can hinder material processing.

- Knives Dullness: Worn blades lead to inefficient cutting and increased wear on the machine.

- Overheating: Insufficient cooling or airflow can cause overheating, affecting performance.

- Vibration: Excessive vibrations might signal misalignment or loose components.

Addressing these problems promptly can enhance the lifespan and functionality of the equipment.

How to Read Parts Diagrams

Understanding visual representations of components is crucial for effective maintenance and repair. These illustrations provide a clear view of how various elements fit together, making it easier to identify necessary replacements and repairs.

Here are some key steps to help you interpret these visuals:

- Familiarize Yourself with Symbols: Different shapes and lines represent various elements. Take time to learn what each symbol signifies.

- Identify Key Components: Focus on the main pieces highlighted in the illustration. This helps in grasping the overall layout.

- Pay Attention to Labels: Written annotations are often included. These can provide essential information about each element’s function.

- Follow the Flow: Many visuals depict a logical sequence. Understanding the order of assembly or disassembly can simplify the process.

- Consult the Legend: If a key is provided, refer to it for clarification on symbols and terminology.

By mastering these techniques, you can effectively navigate and utilize these crucial visual tools for your projects.

Essential Replacement Parts to Consider

When maintaining heavy machinery, identifying critical components for replacement is vital to ensure optimal performance and longevity. Regular assessment can help prevent costly downtime and extend the lifespan of your equipment.

| Component | Description | Importance |

|---|---|---|

| Hydraulic Filters | These remove contaminants from hydraulic fluid. | Essential for system efficiency and protection. |

| Belts | Drive belts transfer power within the machinery. | Critical for smooth operation and reliability. |

| Seals | Prevent fluid leaks and protect internal mechanisms. | Vital for maintaining pressure and functionality. |

| Blades | Used for cutting and digging tasks. | Key for achieving desired results and efficiency. |

Tools Needed for Maintenance

Proper upkeep of machinery is essential to ensure optimal performance and longevity. Having the right instruments on hand can significantly simplify routine tasks, allowing for efficient inspections and repairs. This section outlines the essential tools necessary for effective maintenance, ensuring that every aspect of the equipment can be addressed without complications.

| Tool | Purpose |

|---|---|

| Wrench Set | For tightening and loosening bolts and nuts. |

| Screwdriver Set | To secure or remove screws from various components. |

| Socket Set | For efficient handling of fasteners in tight spaces. |

| Torque Wrench | To apply specific torque settings when fastening. |

| Multimeter | For diagnosing electrical issues and ensuring proper function. |

| Pliers | For gripping, twisting, and cutting wire or other materials. |

| Cleaning Supplies | To keep surfaces and components free of debris and contaminants. |

| Safety Gear | To protect the technician during maintenance tasks. |

Equipped with these essential tools, maintaining machinery can be a straightforward process, reducing downtime and ensuring that equipment remains in peak condition.

Steps for Proper Assembly

Achieving optimal performance in your equipment relies heavily on meticulous assembly. Following a systematic approach ensures each component is correctly positioned, enhancing durability and efficiency. This guide outlines essential steps to facilitate a smooth and effective assembly process.

1. Gather Necessary Tools and Components: Before starting, ensure you have all required tools and components at hand. This includes wrenches, screwdrivers, and any specialized equipment needed for assembly. Having everything organized will streamline the process.

2. Review Instructions Thoroughly: Carefully examine the provided instructions or manuals. Familiarize yourself with each step and the corresponding components involved. Understanding the sequence will prevent mistakes during assembly.

3. Prepare the Workspace: A clean and well-lit workspace is crucial. Ensure you have enough space to maneuver and place all parts securely. A tidy area minimizes the risk of losing components and enhances safety.

4. Follow Step-by-Step Instructions: Adhere to the sequence outlined in the manual. Start with the base assembly and progressively add components. Double-check each connection before moving on to the next step.

5. Tighten Connections Securely: Once all components are in place, ensure all connections are tightened properly. Use the appropriate tools to avoid damaging parts. Loose fittings can lead to operational issues and increased wear over time.

6. Conduct Final Inspections: After assembly, perform a thorough inspection. Check for any misalignments or loose connections. This final review is crucial to ensure everything is functioning as intended before operational use.

7. Test the Assembly: Before putting the equipment into full service, conduct a test run. Monitor its performance and listen for any unusual sounds. This step confirms that all components work harmoniously together.

Locating OEM Parts for Your Chipper

Finding authentic components for your chipper can significantly enhance its performance and longevity. Using original equipment can ensure compatibility and maintain the efficiency of your machine.

- Start by identifying the model and serial number of your equipment.

- Check the manufacturer’s official website for a list of authorized dealers.

- Consult your user manual for recommended suppliers and specifications.

Consider the following sources for authentic components:

- Local dealerships that specialize in heavy machinery.

- Reputable online retailers known for quality and reliability.

- Forums and communities dedicated to machinery maintenance and repair.

By taking these steps, you can ensure that your equipment runs smoothly and efficiently with the right components. Ultimately, investing in genuine items will pay off in the long run.

DIY Repairs: What You Need to Know

Engaging in self-repair projects can be both fulfilling and cost-effective. Understanding the fundamentals of maintaining and fixing your equipment empowers you to tackle minor issues without relying on professionals. This section provides essential insights to help you navigate your repair journey.

Tools and Materials

Before starting any repair, it’s crucial to gather the right tools and materials. A well-equipped workspace can make a significant difference in the success of your project. Below is a list of commonly needed items:

| Tool/Material | Purpose |

|---|---|

| Screwdriver Set | For removing and securing screws |

| Wrench | For tightening or loosening nuts and bolts |

| Multimeter | For checking electrical components |

| Pliers | For gripping and manipulating small objects |

| Replacement Parts | To replace damaged components |

Safety Precautions

Safety should always be a priority during any repair task. Wearing appropriate gear and ensuring your workspace is organized can prevent accidents. Always disconnect power sources before beginning work on electrical devices to avoid hazards.

Customer Support Resources

Accessing reliable support is crucial for maintaining equipment efficiency and longevity. This section provides valuable information on where to find assistance, resources, and expert advice tailored to your needs.

Online Help Center

The online help center offers a comprehensive database of resources, including manuals, troubleshooting guides, and instructional videos. Users can easily search for specific topics to quickly find the information they need, ensuring a smoother experience with their machinery.

Customer Service Contacts

For personalized assistance, reach out to dedicated customer service representatives. Whether through phone or email, these professionals are equipped to address inquiries and provide solutions. Prompt support ensures that you can get back to work with minimal downtime.

Best Practices for Long-Term Care

Providing effective long-term support requires a thoughtful approach that prioritizes the well-being and dignity of individuals. This section outlines key strategies that can enhance the quality of care, ensuring that individuals receive the attention they need while fostering a positive environment.

Key Strategies for Effective Care

- Establish Comprehensive Care Plans

- Encourage Active Participation of Individuals

- Foster Open Communication Among Caregivers

- Regularly Review and Update Care Protocols

Promoting a Supportive Environment

- Create a Comfortable and Safe Living Space

- Incorporate Social Activities to Enhance Engagement

- Provide Access to Mental Health Resources

- Encourage Family Involvement in Care Decisions

Implementing these practices can significantly improve the experience of those receiving care, leading to better health outcomes and greater satisfaction.