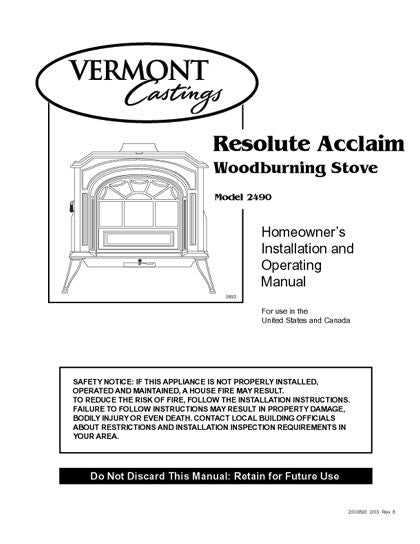

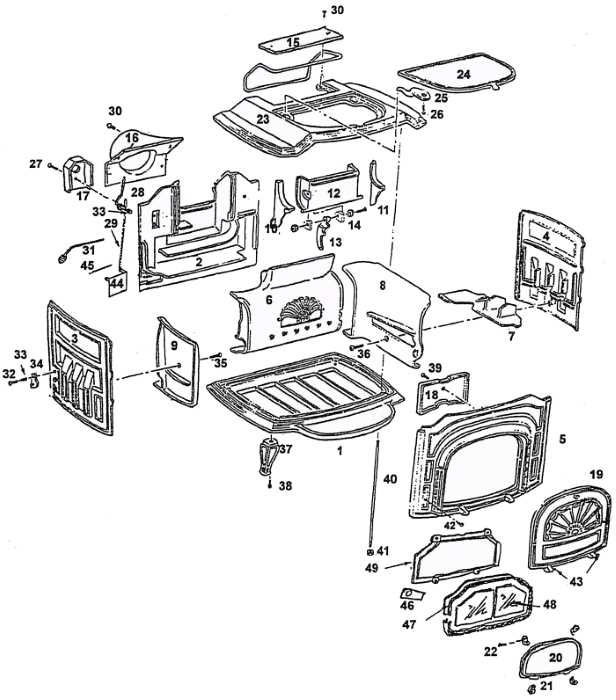

Vermont Castings Resolute III Replacement Parts Overview

In this section, we will dive into the intricate setup of elements that ensure the smooth performance of your heating system. Understanding how various sections connect and operate together is crucial for maintenance and optimization. By exploring the different components, you can ensure that the system functions effectively and remains in good condition for an extended period.

Key focus areas include the proper alignment and interaction of internal sections, which play a vital role in the overall performance. Regular inspection of these parts allows for preventive measures, reducing the likelihood of issues and improving efficiency. We will also highlight strategic connections between the elements, enabling better comprehension of how each piece supports the whole system.

This guide will offer valuable insights into the structure and features, helping you identify areas that require attention and maintenance, ultimately leading to optimal system functionality.

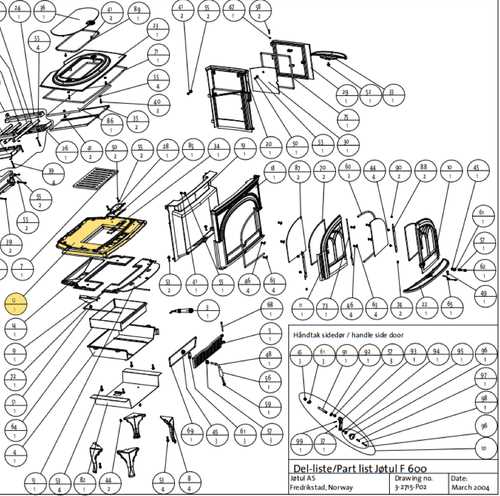

Overview of Vermont Castings Resolute III Components

This section provides a detailed review of the main structural elements and functional parts of the popular heating appliance. The information focuses on the essential mechanisms that ensure optimal performance, longevity, and safety. Understanding the core features will help in identifying key components for maintenance or upgrades.

Main Sections and Features

- Primary body structure designed for heat retention

- Combustion system ensuring efficient fuel use

- Adjustable airflow mechanisms for temperature control

Key Functional Components

- Firebox for burning materials

- Heat shields to protect surrounding areas

- Ventilation systems for safe air circulation

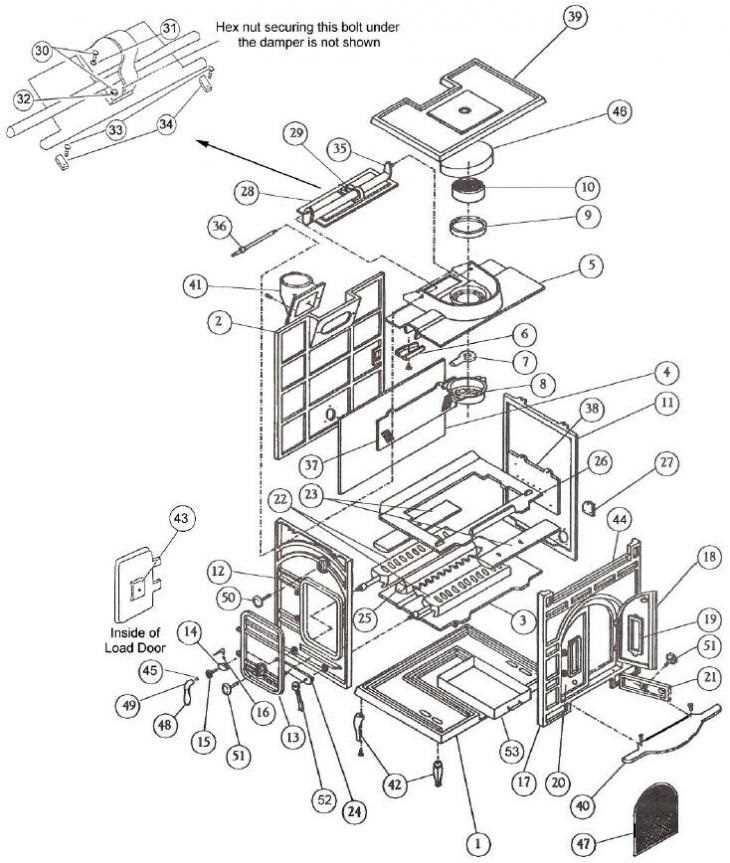

Main Structural Elements of the Stove

The stove is comprised of several key components that ensure both its functionality and durability. Each part is designed to withstand high temperatures and maintain efficiency during prolonged use. In this section, we will explore the essential elements that contribute to its robust performance.

Outer Frame and Body

The external casing of the stove serves as the foundation that supports all other elements. This framework is usually made from high-grade materials that provide insulation and protection against extreme heat. It also ensures the longevity of the unit by preventing wear and tear.

- Heat-resistant metal exterior

- Reinforced corners and edges

- Designed for optimal heat distribution

Internal Chambers

Inside the stove, several compartments are dedicated to different stages of the combustion process. These include areas for fuel burning and air circulation, both of which are critical for efficient energy use. Proper alignment of these chambers ensures maximum heat output with minimal fuel consumption.

- Primary combustion chamber

- Secondary air intake system

- Ash collection tray

Internal Parts Breakdown and Functionality

Understanding the structure and the purpose of various components within this heating unit is essential for optimal performance and maintenance. Each element plays a crucial role in ensuring that the device operates efficiently and safely. In this section, we will explore the key internal mechanisms, their placement, and how they contribute to the overall functionality.

Key Structural Elements

The central elements include multiple interconnected sections that work together to channel heat and maintain airflow. These areas are designed to optimize the distribution of warmth and regulate temperature effectively, ensuring consistent output throughout the operation.

Heat Regulation Mechanisms

Specific mechanisms within the unit are responsible for controlling heat intensity and fuel consumption. These features allow for precise adjustment, improving energy efficiency while ensuring the unit remains safe and reliable during prolonged use. Proper understanding of these systems can help extend the lifespan of the device and reduce wear over time.

Replacement Procedures for Key Components

Ensuring the longevity and efficiency of your appliance often involves replacing essential elements. Regular maintenance and timely part replacement can prevent major issues and ensure smooth operation.

Below are the steps for replacing important elements of your heating system:

- Remove the old components: Begin by disconnecting the unit from any power or fuel sources. Allow the device to cool down completely before proceeding with any disassembly.

- Access the internal parts: Depending on the element you are replacing, locate the appropriate access point. This could be a panel or cover that can be unscrewed or lifted off.

- Detach the worn part: Use appropriate tools to safely remove the element you plan to replace. Be cautious to avoid damaging any surrounding structures or connectors.

- Install the new part: Carefully position the new component in place, ensuring that it is securely fastened and correctly aligned. Follow any specific guidelines for the element to avoid installation errors.

- Reassemble and test: Once the new part is installed, reattach

Cast Iron Sections and Their Importance

Cast iron has been a fundamental material in the construction of heating devices for centuries. Its durability and heat retention properties make it an ideal choice for many products. Understanding the different sections of a cast iron unit can help in maintaining its performance and longevity. Each section plays a crucial role in ensuring efficient heat distribution and overall operation.

Durability of Cast Iron

One of the key advantages of cast iron is its robustness. The various components are designed to withstand high temperatures and physical stress. This makes cast iron parts essential for ensuring long-term reliability in heating systems. Regular maintenance of these sections is crucial to keep them functioning at their best.

Heat Distribution

The design of cast iron sections significantly impacts heat distribution. With proper arrangement and upkeep, these elements can maximize heat retention, ensuring even warmth throughout a space. This efficiency is what makes cast iron such a valuable material in both traditional and modern heating technologies.

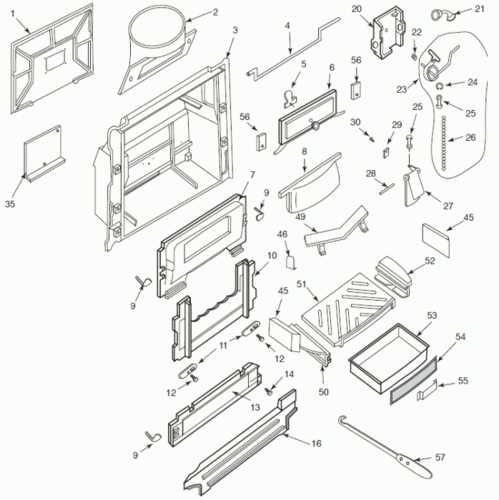

Firebox Assembly and Key Features

The firebox serves as the core of any heating unit, designed to maximize efficiency while ensuring safety and durability. Understanding its structure and significant attributes can greatly enhance your experience and performance of the appliance.

Key Components

- Inner Liner: Provides insulation, maintaining optimal temperatures.

- Grate: Supports fuel and allows for ash drainage, facilitating clean operation.

- Door Seals: Ensure an airtight closure, preventing heat loss and enhancing combustion efficiency.

- Air Intake: Controls airflow for efficient burning, impacting heat output.

Benefits of a Well-Designed Firebox

- Enhanced Efficiency: Optimized design promotes better fuel consumption.

- Safety Features: Built-in mechanisms reduce risks associated with high temperatures.

- Durability: Made from robust materials that withstand extreme conditions.

- Easy Maintenance: Designed for straightforward access to essential components.

Door Mechanism and Sealing Parts

The functionality and efficiency of any heating appliance greatly depend on its door mechanism and sealing components. These elements are essential for maintaining optimal temperature control and ensuring that heat is contained within the unit. A well-designed door system not only enhances usability but also contributes to the overall performance of the device.

Key Components of the Door System

Central to the operation is the door latch, which secures the entrance and ensures a tight fit when closed. Additionally, hinges play a critical role in providing smooth movement while allowing easy access. A robust locking mechanism further enhances safety and efficiency by preventing accidental openings during operation.

Importance of Sealing Elements

Sealing components, such as gaskets, are vital for preventing air leaks, which can significantly impact performance. A high-quality gasket forms a tight seal when the door is closed, minimizing heat loss and maximizing energy efficiency. Regular maintenance of these sealing elements is crucial for ensuring long-lasting functionality and optimal heat retention.

Maintenance of Air Flow Controls

Proper upkeep of air circulation mechanisms is essential for optimal performance and efficiency. Ensuring that these components function smoothly can significantly enhance the overall heating experience, contributing to a comfortable indoor environment.

Regular inspection is crucial in identifying any blockages or malfunctions that may hinder airflow. Checking the components for debris, dust, or soot buildup can prevent operational issues and maintain consistent airflow.

Adjustment of control mechanisms should be carried out periodically to ensure they respond accurately. This includes calibrating any dampers or vents to facilitate the desired air distribution within the space. Ensuring that these controls operate smoothly can greatly improve efficiency.

Lastly, sealing any gaps in the air control system is vital to prevent leaks. This not only enhances performance but also reduces energy consumption, leading to cost savings in the long run.

Essential Parts for Heat Efficiency

To maximize thermal performance in heating systems, understanding the core components that contribute to heat retention and distribution is crucial. Each element plays a significant role in ensuring optimal functionality and energy conservation.

The combustion chamber is vital for maintaining high temperatures during fuel burning, allowing for efficient heat generation. Additionally, the flue system is designed to effectively channel exhaust gases while preventing heat loss. Insulation materials surrounding the heating unit are equally important, as they help maintain warmth within the system and reduce energy consumption.

Moreover, the air control mechanisms regulate airflow, enabling precise adjustments to combustion levels, which directly impacts heat output. Finally, the construction materials used in the heating appliance significantly influence its ability to radiate warmth effectively, ensuring longevity and sustained performance.

Installation of Ash Handling Systems

Efficient management of ash disposal is crucial in any heating system utilizing solid fuels. The proper installation of handling mechanisms not only streamlines waste removal but also enhances the overall performance of the system. This section outlines essential considerations for implementing an effective ash handling system.

Before commencing installation, it is important to evaluate the following components:

- System Design: Assess the layout and configuration to ensure compatibility with existing infrastructure.

- Material Selection: Choose durable materials that can withstand high temperatures and corrosive elements.

- Accessibility: Ensure easy access for maintenance and regular cleaning to prolong system life.

The installation process typically involves several key steps:

- Preparation: Clear the installation area and ensure all tools and materials are on hand.

- Assembly: Follow the provided guidelines to assemble the various components accurately.

- Connection: Securely connect the handling system to the primary unit, ensuring all joints are tight and leak-proof.

- Testing: Conduct thorough testing of the system to verify its operational efficiency and safety.

Proper installation of ash handling systems can significantly impact the efficiency of waste management and overall system performance. Regular maintenance and timely upgrades are also essential for long-term effectiveness.

Common Issues with Component Wear

In any mechanical system, the gradual deterioration of various elements is a frequent occurrence. Understanding these challenges can help in prolonging the lifespan of the equipment and maintaining its efficiency. This section focuses on the typical problems associated with the wear and tear of components that are crucial for optimal performance.

One prevalent issue involves gasket degradation, which can lead to air leaks and affect the overall efficiency. Regular inspection and replacement of these seals are vital to prevent further complications.

Another concern is the erosion of internal surfaces, often caused by prolonged exposure to high temperatures and corrosive substances. This wear can compromise the functionality and safety of the device. Implementing a routine maintenance schedule can significantly mitigate this risk.

Additionally, wear on moving parts such as bearings and hinges can result in increased friction, leading to potential malfunctions. Lubrication is key to minimizing this friction and ensuring smooth operation. Identifying early signs of wear can save time and resources in the long run.

Addressing these common issues promptly is essential for sustaining performance and reliability. Proactive maintenance and timely replacements are fundamental strategies for overcoming challenges related to component wear.

Repair Guide for Moving Elements

Maintaining the functionality of mobile components is crucial for ensuring the optimal performance of heating appliances. This section provides an overview of common issues encountered with these mechanisms and offers practical solutions for effective repairs. Understanding the various elements involved will aid in prolonging the life of your equipment.

Common Issues and Solutions

One of the frequent challenges faced with moving parts is wear and tear, often leading to misalignment or stiffness. Regularly inspecting these components can help identify problems early. If you notice any unusual noises or difficulties in operation, it may be necessary to lubricate the joints and pivot points to restore smooth movement. Applying a high-quality lubricant can significantly enhance the performance of these elements.

Maintenance Tips

To ensure the longevity of moving elements, incorporate routine checks into your maintenance schedule. Look for any signs of corrosion or damage that could impede functionality. Additionally, cleaning the parts regularly will prevent the buildup of dust and debris, which can cause blockages or hinder movement. By following these simple maintenance practices, you can avoid major repairs and ensure your system operates efficiently.

Compatible Accessories and Upgrades

Enhancing your heating appliance with suitable add-ons can significantly improve its efficiency and functionality. These enhancements not only increase the overall performance but also provide additional features that cater to specific user needs.

Essential Accessories

Investing in essential accessories can elevate the user experience. Consider options such as heat shields that protect surrounding areas from excessive heat, or ash pans that facilitate easy cleaning and maintenance. These tools ensure that the unit operates smoothly and safely.

Performance Upgrades

For those looking to boost efficiency, performance upgrades are a great choice. Upgrading to a high-efficiency blower can enhance heat distribution throughout your space, while advanced thermostats allow for precise temperature control, ensuring optimal comfort. These upgrades are designed to maximize the appliance’s capabilities.