Understanding the Wacker BS600 Parts Diagram for Effective Maintenance

The intricate design of construction equipment requires a thorough understanding of its individual elements. Each component plays a vital role in ensuring optimal performance and longevity, making knowledge of these parts essential for maintenance and repair.

Visual representation of these elements not only aids in identifying each part but also enhances the ability to troubleshoot and replace them effectively. By breaking down the machinery into its core components, operators can better appreciate the engineering behind these powerful tools.

In this section, we will delve into the essential components of a specific machine model, providing an overview that equips users with the ultimate understanding necessary for efficient operation and upkeep. Emphasizing clarity and accessibility, the information presented here serves as a valuable resource for both novice and experienced users alike.

Understanding Wacker BS600 Components

This section aims to provide an insightful overview of the various elements that contribute to the functionality of a specific construction tool. Each component plays a vital role in ensuring optimal performance and efficiency during operation.

| Component | Description |

|---|---|

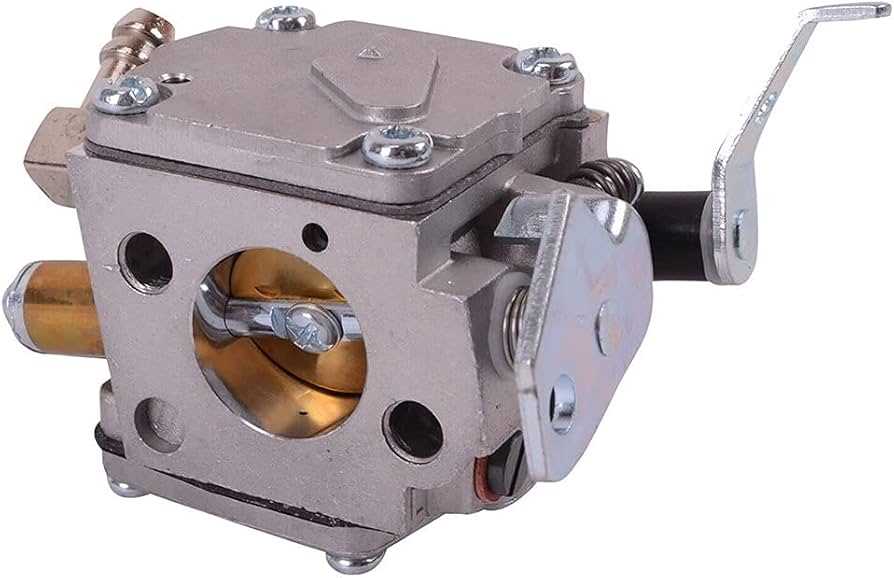

| Engine | Delivers the necessary power for operation and drives the entire mechanism. |

| Fuel System | Supplies the engine with the required fuel for combustion. |

| Control Panel | Allows the user to operate and monitor the tool’s functions easily. |

| Vibration System | Minimizes user fatigue by absorbing excess vibrations during use. |

| Chassis | Provides structural support and stability while facilitating mobility. |

Importance of Parts Diagrams

Visual representations of components play a crucial role in understanding the intricate workings of machinery. These illustrations serve as essential tools for technicians, providing clarity on how various elements interact within a system. By breaking down complex assemblies into easily digestible segments, they facilitate efficient maintenance and repair processes.

Enhanced Understanding

Having a clear visual reference allows users to grasp the overall structure and functionality of a device. This comprehension is vital for diagnosing issues effectively. When each element is labeled and organized, it becomes simpler to pinpoint problems and determine the necessary corrective actions.

Streamlined Maintenance

With accurate visual guides, technicians can conduct maintenance tasks more efficiently. They can identify wear and tear, locate replacement items quickly, and follow the correct procedures for disassembly and reassembly. This not only saves time but also reduces the risk of errors during repairs, ultimately prolonging the lifespan of the equipment.

In conclusion, utilizing clear illustrations of components is indispensable for effective management and care of machinery. They foster a deeper understanding and enable streamlined operations, ensuring optimal performance and longevity.

Key Features of Wacker BS600

This model is designed with a range of innovative characteristics that enhance its performance and usability. Built to withstand demanding conditions, it ensures reliability and efficiency across various applications. Users can expect a combination of robust engineering and advanced technology that meets the needs of professionals in the field.

Durability and Build Quality

The construction of this machine utilizes high-quality materials that provide exceptional durability. Its rugged design enables it to operate effectively in challenging environments, minimizing downtime and maintenance needs. This focus on longevity ensures that it remains a valuable asset over time.

User-Friendly Operation

Featuring an intuitive interface and ergonomic design, this model simplifies operation for users of all skill levels. Easy-to-access controls and a comfortable grip allow for extended use without fatigue. This thoughtful design approach not only enhances user experience but also promotes safety during operation.

Common Issues with BS600 Parts

When dealing with heavy machinery components, certain challenges frequently arise that can hinder performance and reliability. Understanding these common concerns is essential for effective maintenance and optimal operation.

| Issue | Description | Possible Solutions |

|---|---|---|

| Wear and Tear | Over time, components may degrade due to constant use, leading to inefficiencies. | Regular inspections and timely replacements can mitigate this issue. |

| Contamination | Debris or dirt can infiltrate parts, causing blockages and performance drops. | Implementing proper cleaning routines and using protective covers can help. |

| Improper Installation | Incorrect assembly can lead to malfunctions or damage to the machinery. | Ensuring adherence to manufacturer guidelines during setup is crucial. |

| Lubrication Issues | Insufficient or incorrect lubrication can lead to friction and overheating. | Regularly check lubricant levels and use recommended types for each component. |

| Electrical Failures | Wiring and connections may fail, leading to operational disruptions. | Routine electrical checks and prompt repairs can prevent breakdowns. |

Identifying Wacker BS600 Models

Understanding the various iterations of this equipment is crucial for maintenance and repair. Each variant possesses unique features that cater to different applications, making it essential for users to recognize their specific model.

Common Characteristics

Most units share a set of identifiable traits, such as size, engine type, and design elements. Familiarizing oneself with these characteristics allows for easier differentiation between models.

Model Numbers and Specifications

Checking the model number is a definitive method for identification. Typically found on the machine’s frame, this number can lead to detailed specifications and compatibility information. Knowing the exact model ensures access to the appropriate resources for effective servicing.

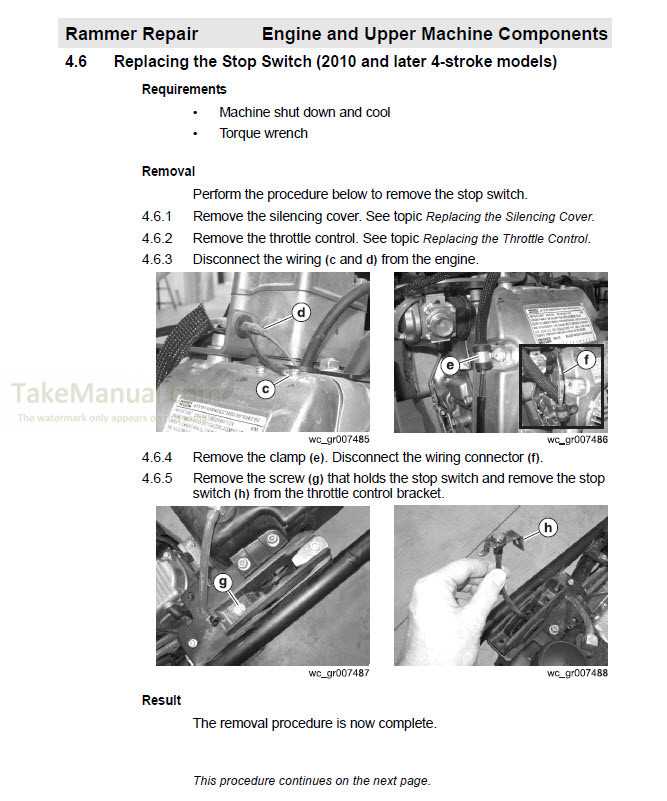

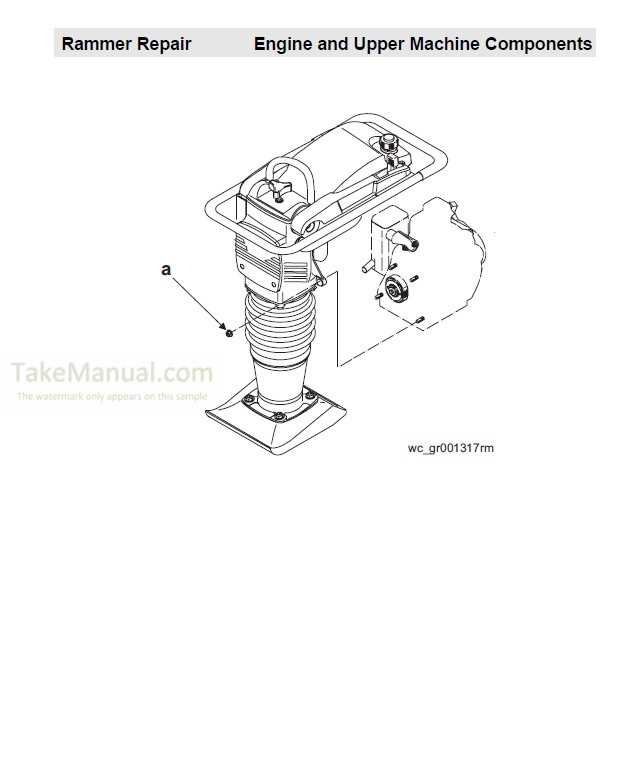

How to Read Parts Diagrams

Understanding visual representations of components is crucial for efficient maintenance and repair. These illustrations serve as a guide to help users identify individual pieces, their arrangement, and how they interact within a larger assembly. Familiarity with these visuals can significantly enhance the repair process, making it more intuitive and less time-consuming.

Interpreting Symbols and Labels

Most schematics include various symbols and annotations that convey essential information. Labels often indicate the names or numbers of the items, while symbols may represent specific functions or connections. Taking the time to familiarize yourself with these elements will aid in comprehending the overall structure.

Understanding the Layout

The organization of components within the illustration is equally important. Typically, parts are arranged logically, often following the order of assembly or operation. Pay attention to the relationships between items, as this will provide insight into how they work together. Observing these patterns can be invaluable for troubleshooting issues effectively.

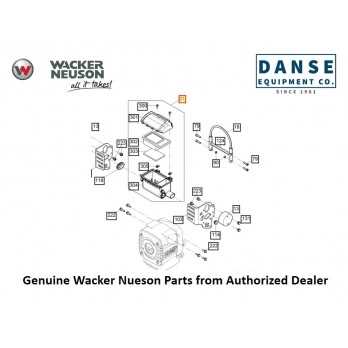

Replacement Parts for Wacker BS600

Maintaining machinery in optimal condition often requires replacing worn or damaged components. Understanding the essential elements of your equipment can enhance performance and extend its lifespan. This section explores key substitutions that ensure reliable functionality.

Key Components

Critical elements include drive belts, filters, and seals. Each of these plays a significant role in ensuring efficient operation. Regular inspection and timely replacement can prevent costly downtime and enhance productivity.

Finding Quality Replacements

When sourcing substitutions, prioritize reputable suppliers to guarantee quality. High-grade materials contribute to durability and reliability, ensuring your equipment continues to perform at its best. Always consult manufacturer recommendations for the ideal choices.

Maintenance Tips for Longevity

Regular upkeep is essential for ensuring the extended lifespan and optimal performance of your equipment. By following a few simple practices, you can significantly enhance durability and reliability, reducing the likelihood of unexpected failures.

1. Regular Inspections: Conduct thorough checks on all components. Look for signs of wear and tear, such as cracks, rust, or unusual noises. Early detection can prevent more severe issues down the line.

2. Cleanliness: Keep the machinery clean from debris and dirt. Accumulation of materials can lead to overheating and other operational problems. Use appropriate cleaning methods to ensure all surfaces are clear.

3. Lubrication: Apply the right lubricants to moving parts as specified by the manufacturer. Proper lubrication reduces friction and wear, extending the life of critical components.

4. Proper Storage: When not in use, store the equipment in a dry, sheltered environment. Protecting it from the elements will minimize rust and degradation of materials.

5. Scheduled Maintenance: Follow a routine maintenance schedule, including filter changes and part replacements. Adhering to the recommended timeline ensures that all systems function optimally.

6. Operator Training: Ensure that all users are well-trained on the correct operation and handling of the equipment. Understanding the machinery’s limits can prevent misuse and potential damage.

By implementing these maintenance strategies, you can achieve better performance and longevity from your machinery, ultimately leading to cost savings and increased productivity.

Where to Buy Wacker Parts

Finding reliable components for construction machinery can be a challenging task, but there are several avenues to explore. Whether you’re looking for original equipment or high-quality alternatives, knowing where to search is crucial for efficient repairs and maintenance.

Online retailers often provide a vast selection, allowing you to compare prices and availability easily. Websites dedicated to construction tools frequently have detailed listings, ensuring you find the exact item you need. Additionally, local suppliers and specialized shops can offer personalized assistance and immediate access to essential items.

Don’t overlook second-hand options, as refurbished items can be a cost-effective solution. Auctions and online marketplaces also host a variety of components, often at competitive prices. Always check reviews and ratings to ensure you’re purchasing from reputable sources.

Comparison with Similar Models

This section explores how various equipment types stack up against one another, highlighting key features, performance metrics, and unique characteristics. Understanding these distinctions can aid in making informed decisions for specific applications.

Key Features Overview

When evaluating different models, several criteria come into play, including power output, operational efficiency, and ease of maintenance. Below is a comparative analysis that outlines these attributes across selected machines.

| Model | Power Output (HP) | Weight (lbs) | Fuel Efficiency (MPG) |

|---|---|---|---|

| Model A | 20 | 250 | 25 |

| Model B | 22 | 270 | 30 |

| Model C | 19 | 230 | 27 |

Performance Insights

Performance metrics vary significantly between models. Factors such as speed, maneuverability, and operational versatility play crucial roles in their effectiveness across different tasks. A deeper understanding of these aspects can lead to selecting the ultimate machine for your specific needs.

Repairing Wacker BS600 Components

Maintaining the integrity of machinery is essential for optimal performance and longevity. Regular inspection and timely repairs can prevent minor issues from escalating into major failures, ensuring that the equipment operates smoothly.

To effectively address repairs, consider the following steps:

- Identify the malfunctioning component through thorough diagnostics.

- Gather necessary tools and replacement parts for the repair process.

- Follow the manufacturer’s guidelines for disassembly and assembly.

Key components often requiring attention include:

- Engine parts, which may need tuning or replacement.

- Hydraulic systems, essential for optimal operation.

- Electrical components, crucial for functionality.

By adhering to these practices, you can ensure that your equipment remains reliable and efficient throughout its use.

Safety Precautions During Maintenance

Ensuring safety while performing maintenance is crucial to prevent accidents and injuries. Proper precautions not only protect the individual conducting the service but also safeguard the equipment being handled. Following established guidelines can lead to a more efficient and risk-free maintenance process.

Personal Protective Equipment

Always wear appropriate personal protective equipment (PPE) such as gloves, goggles, and helmets. This gear acts as a barrier against potential hazards, including sharp edges and harmful substances. It is essential to ensure that all PPE is well-maintained and suitable for the tasks being performed.

Work Environment Considerations

Maintain a clean and organized work area to minimize risks. Remove any unnecessary tools or materials that could create tripping hazards. Additionally, ensure adequate ventilation if working with fumes or chemicals. Being mindful of the surroundings contributes significantly to a safe working atmosphere.

Customer Reviews and Feedback

This section focuses on the insights and opinions shared by users regarding their experiences with the equipment. Understanding customer perspectives can provide valuable information for potential buyers and help improve future models.

Here are some common themes noted by users:

- Overall performance and efficiency

- Durability and longevity of the machinery

- Ease of maintenance and accessibility of components

- Customer service and support experiences

Users often highlight the following aspects:

- Reliable operation under various conditions

- Cost-effectiveness in terms of maintenance

- Positive impact on productivity

- Areas for improvement, such as user manuals

Feedback from customers is instrumental in identifying strengths and weaknesses, ultimately guiding improvements and enhancements in future products.