Understanding the Wacker WP1550AW Parts Diagram for Efficient Maintenance

When dealing with complex machinery, grasping the intricacies of individual components is essential for efficient maintenance and repair. A well-structured visual representation serves as a crucial tool for operators and technicians alike, aiding in the identification and understanding of various parts and their functions. This knowledge not only streamlines the troubleshooting process but also enhances overall operational efficiency.

In this section, we will explore the visual outlines that illustrate how different elements interconnect within a specific model. These visuals not only highlight the physical arrangement but also emphasize the relationships between various sections of the equipment. By breaking down these layouts, users can gain a clearer understanding of how each part contributes to the machinery’s performance.

Furthermore, having access to a detailed overview allows for better planning during repairs and upgrades. With a comprehensive reference at hand, users can ensure that they select the right replacements and carry out adjustments with confidence. This ultimately leads to longer-lasting equipment and reduced downtime, making it an invaluable resource for anyone involved in the operation or upkeep of such machinery.

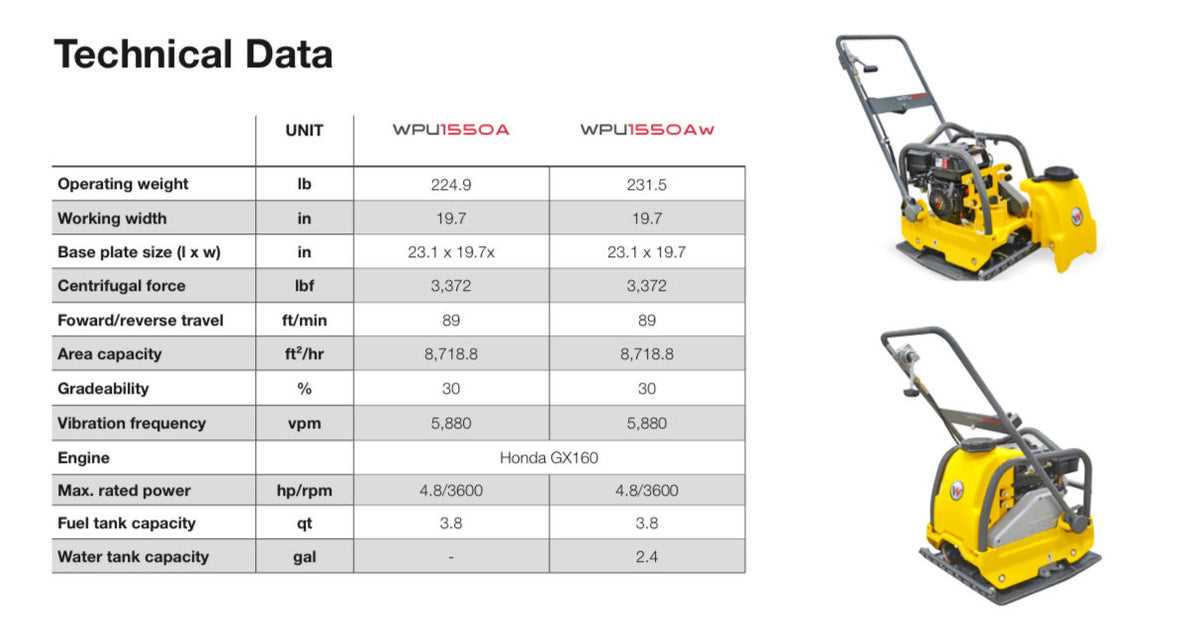

Overview of Wacker WP1550AW

This section provides an in-depth look at a specific model designed for efficient operation in various tasks. Known for its reliability and performance, this machine has become a popular choice among professionals in the construction and landscaping industries.

The equipment boasts several key features that enhance its functionality and user experience:

- Powerful Engine: Equipped with a robust motor that ensures effective performance across diverse applications.

- Durability: Constructed with high-quality materials to withstand harsh working conditions and ensure longevity.

- Easy Maneuverability: Designed for ease of transport and handling, making it user-friendly even in tight spaces.

- Maintenance Accessibility: Engineered for straightforward upkeep, allowing users to perform regular checks and repairs with minimal effort.

In addition to these features, this model offers a variety of configurations, making it adaptable to specific needs. Users can choose from different settings that cater to various tasks, whether it’s for compacting soil, gravel, or asphalt.

Overall, this machine stands out for its combination of efficiency, strength, and versatility, making it an essential tool for anyone looking to achieve high-quality results in their projects.

Key Features of the Model

This exceptional machine stands out in its category due to a combination of innovative design and robust performance. It is engineered to meet the diverse needs of professionals in various industries, ensuring reliability and efficiency in every task.

Durability: Crafted from high-quality materials, this unit is built to withstand challenging environments. Its sturdy construction ensures longevity, minimizing the need for frequent repairs and maintenance.

Versatility: This model excels in a wide range of applications, from construction to landscaping. Its adaptable features allow users to tackle different projects with ease, enhancing overall productivity.

Ease of Use: Designed with user-friendly controls, it simplifies operation for both seasoned professionals and newcomers. The intuitive interface reduces the learning curve, enabling quicker task completion.

Power Efficiency: Equipped with advanced technology, this unit optimizes energy consumption without compromising on performance. Users benefit from reduced operational costs while achieving outstanding results.

Compact Design: Its streamlined shape allows for easy transportation and maneuverability in tight spaces. This feature is particularly advantageous on job sites with limited access.

Importance of Parts Diagrams

Visual representations of components play a crucial role in maintenance and repair processes. They serve as a guide, offering clarity on the arrangement and functionality of various elements within a machine. Understanding these illustrations can significantly enhance efficiency and accuracy during service tasks.

Benefits of Visual Guides

- Enhanced Understanding: Clear visuals aid in comprehending the structure and relationships between different components.

- Streamlined Repairs: Technicians can quickly identify the necessary parts needed for a repair, reducing downtime.

- Preventing Mistakes: Reference images help avoid errors in assembly or disassembly, ensuring correct installation.

- Training Tool: These illustrations serve as effective teaching aids for new technicians, improving their learning experience.

Applications in Maintenance

- Identifying Issues: Visual aids allow for easier diagnosis of problems by showcasing potential failure points.

- Ordering Components: Accurate identification ensures that the correct replacements are sourced, minimizing delays.

- Improving Safety: Understanding the layout of components can lead to safer handling and servicing practices.

In summary, visual representations of components are indispensable tools in the maintenance and repair industry, facilitating understanding, accuracy, and efficiency in every task.

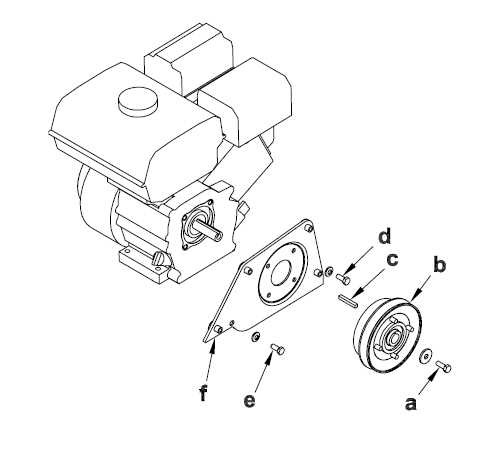

Identifying Components in Diagrams

Understanding the layout of machinery or equipment through visual representations is crucial for effective maintenance and repair. These illustrations serve as guides, providing a clear overview of how various elements fit together and interact within the system. Recognizing each part’s role helps in diagnosing issues and ensuring proper functionality.

Key Elements to Look For

When examining such visual aids, focus on key features that can simplify the identification process. Labels and color coding often highlight specific components, making them easier to locate. Additionally, numbers or letters typically correspond to a legend or key, providing further context about each part’s function.

Understanding Relationships Between Parts

Another essential aspect is grasping the relationships between various components. Look for lines or arrows indicating connections or flows, which illustrate how each piece interacts with others. This interconnectedness is vital for troubleshooting and implementing effective repairs.

Common Replacement Parts

Over time, various components of outdoor equipment may require updates to maintain optimal performance. Identifying the most frequently needed substitutes can assist in keeping the machine in working condition, ensuring efficiency and reliability.

Items like engine belts and air filters often need to be replaced due to wear and tear, contributing to smooth operation. Regularly checking these elements can prevent unexpected breakdowns and extend the life of the equipment.

Another frequently exchanged item includes rubber mounts, which help reduce vibrations and protect other components from damage. Keeping these in good condition is crucial for minimizing stress on the machine’s structure.

Drive mechanisms such as pulleys and bearings are also subject to routine maintenance. These elements ensure the power transfer system functions smoothly, providing stability during use. Replacing these components as needed is essential for maintaining consistent performance.

Maintenance Tips for WP1550AW

Proper care is essential for ensuring the longevity and efficiency of any compact compactor. Consistent upkeep not only enhances performance but also helps avoid unexpected breakdowns. Following a few practical steps can significantly extend the working life of your equipment, making sure it operates smoothly on a regular basis.

Check Fluid Levels Regularly: Inspecting oil and hydraulic fluid levels is crucial before each use. Maintaining the correct levels helps to prevent overheating and ensures all moving parts remain lubricated, reducing wear and tear.

Clean Air Filters Frequently: Dust and debris can quickly accumulate in the air intake system. Cleaning or replacing air filters ensures that the engine receives proper airflow, which is essential for efficient operation and prevents engine strain.

Inspect the Belt for Wear: The drive belt plays a vital role in power transmission. Regularly check for signs of cracks or fraying and replace it if necessary. A well-maintained belt ensures that the machine continues to deliver consistent power without interruptions.

Keep the Base Plate Clean: Dirt and soil can build up under the base, affecting compaction quality. After each use, clean the plate thoroughly to maintain optimal contact with surfaces and ensure even compaction.

Monitor Fasteners: Vibrations from operation can

Where to Find Parts Diagrams

Locating visual guides for assembly or repair can greatly simplify the process of maintaining or fixing various equipment. These resources provide a clear view of how components fit together, offering a reference for identifying and sourcing replacements or ensuring accurate reassembly.

Online Resources and Manufacturer Websites

Official manufacturer websites often host comprehensive resources, including exploded views and breakdowns of various models. These platforms allow users to access up-to-date information and verify compatibility with different versions. Additionally, many offer downloadable files for easy offline reference.

Community Forums and Specialist Websites

Enthusiast forums and websites dedicated to specific machinery types frequently include collections of visual references shared by other users. These platforms provide valuable insights, including user-uploaded guides and tips for accessing hard-to-find details. Such communities can be especially useful for finding older or discontinued models.

Understanding Part Numbers

Identifying specific components often involves using numerical codes that contain essential details about the item. These sequences serve as a key to unlock information such as specifications, compatibility, and manufacturing details.

Decoding the Structure: Each code is typically structured to represent certain characteristics. For instance, the initial digits may indicate the series, while others might specify dimensions or material composition. This system helps in pinpointing the exact type among similar items.

Why It Matters: Recognizing these codes ensures that replacements match the original component’s requirements, reducing errors during selection. It also aids in finding suitable alternatives when direct substitutes are unavailable, ensuring consistent performance.

When dealing with repairs or upgrades, understanding these sequences allows for smoother communication with suppliers or technical support, streamlining the process and avoiding potential delays.

Using Diagrams for Repair

Visual guides can greatly simplify the process of restoring machinery to its optimal condition. These representations help in understanding the arrangement of components and connections, providing clarity for maintenance tasks.

- Identifying Components: Diagrams allow users to pinpoint specific elements within the system, making it easier to locate parts that need attention.

- Step-by-Step Assembly: With a clear illustration, the reassembly process becomes more intuitive, minimizing the chance of errors during repair.

- Troubleshooting Assistance: When malfunctions occur, visual guides offer insights into potential problem areas, facilitating quicker diagnosis.

Overall, relying on these illustrations during repairs ensures a more efficient workflow, reducing time spent and improving the accuracy of each step taken.

Comparing Parts with Other Models

Understanding the distinctions between similar equipment models can offer valuable insights when evaluating compatibility and durability. Each model is built with specific attributes, but many elements may share a close resemblance to those found in other variations.

Structural Components: Some variations might utilize identical frames or supports, which can simplify the search for replacements. These commonalities are often found in the outer structure, such as brackets and housings, making certain parts interchangeable across various units.

Internal Mechanisms: Moving to the internal setup, differences often emerge. While engines or hydraulic systems may follow similar layouts, the arrangement and exact specifications can vary. This means that although one model’s mechanism might fit another, performance differences could arise due to variations in torque, flow rates, or power output.

By analyzing these similarities and distinctions, it becomes easier to identify which elements can be interchanged or modified. This comparison allows for informed decisions, especially when considering replacements or upgrades for long-term use.

Cost Considerations for Replacement Parts

When maintaining equipment, it’s important to account for the expenses involved in acquiring new components. Understanding the financial aspects can help users make informed choices, ensuring a balance between quality and affordability.

- Budget Planning: Allocating funds for different items can prevent unexpected financial strain. By estimating potential expenses in advance, users can avoid overspending.

- Quality vs. Price: Cheaper alternatives might seem appealing, but they could compromise on durability. Investing in higher-grade components may provide better long-term value and reduce the need for frequent replacements.

- Availability of Alternatives: Sometimes, finding generic or third-party options can be a cost-saving solution. However, it’s crucial to ensure compatibility and performance standards before making a purchase.

- Shipping and Handling Fees: The cost of delivery can add up, especially for heavier items or international orders. Comparing rates from different suppliers can lead to savings.

- Bulk Purchase Discounts: For commonly needed components, buying in larger quantities can lead to discounts. This approach can be particularly useful for businesses

Benefits of Genuine Parts

Using original components ensures optimal performance and longevity of your equipment. These components are specifically designed to fit and function seamlessly with the machinery, providing a reliable and efficient solution. Choosing authentic options can be crucial for maintaining the overall quality and avoiding potential issues that might arise from incompatible substitutes.

Enhanced Durability

Original components are manufactured to meet the highest standards, which significantly contributes to their longevity. This quality means less frequent replacements, reducing both downtime and maintenance costs. The durable nature of these components also helps the equipment handle demanding tasks with ease, ensuring a longer operational life.

Cost-Effectiveness in the Long Run

While authentic components may come with a higher upfront cost, they often prove to be more economical over time. Their superior build quality minimizes the risk of unexpected breakdowns, which can save on repair expenses. Investing in such components ensures smoother operation, reducing the need for frequent servicing and unplanned expenses.